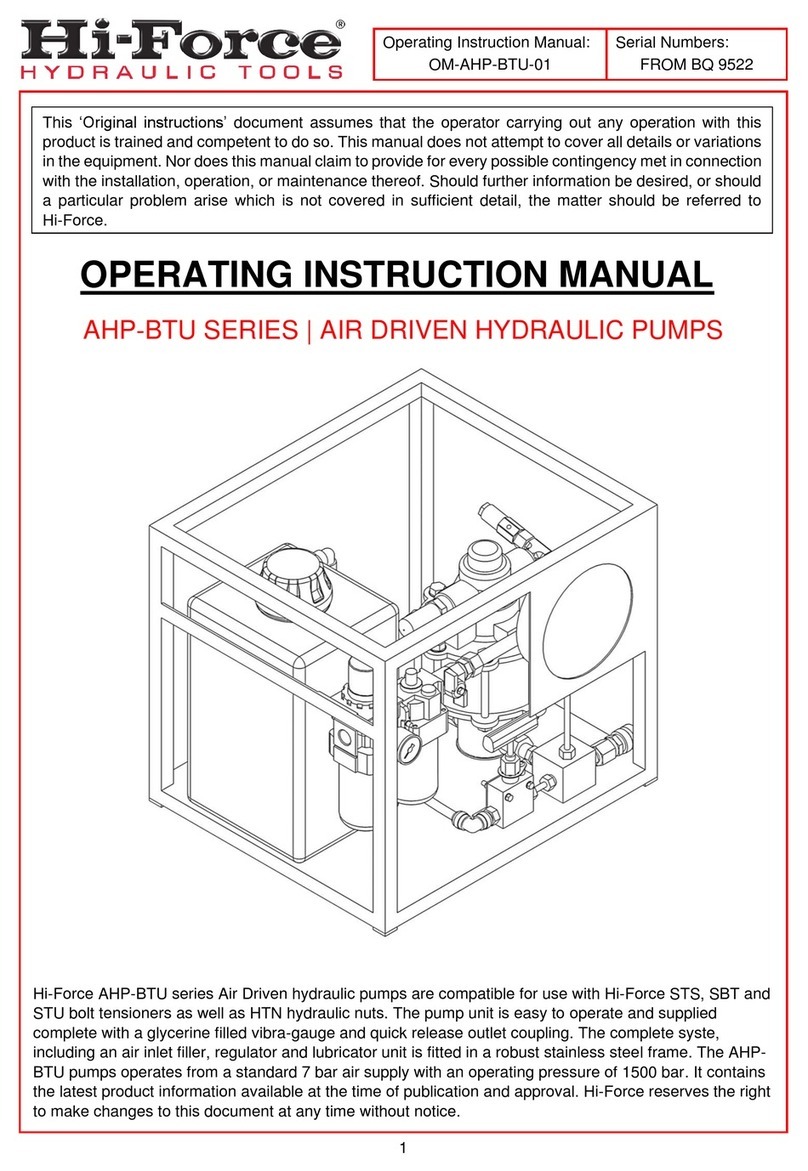

INSTRUCTION MANUAL –AIR DRIVEN HYDRAULIC PUMPS:

Model Series: AHP1120, AHP1120R, AHP1121, AHP1121R, AHP1122, AHP1122R, AHP1141, AHP1142,

HAP21011, HAP21012, HAP21014, HAP21016, HAP21021, HAP21022, HAP21024, HAP21026, HAP21031,

HAP21032, HAP21034, HAP21036, HAP21041, HAP21042, HAP21044, HAP21046,

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

11.0 Preparing the Pump for first use:

1. Immediately after unpacking, examine

the pump for signs of transit damage

and if found contact the shipping

company.

2. Establish the oil level in the oil reservoir

using the level gauge on the end of

the tank. Depending on the shipping

method used, the reservoir may either

be supplied full or empty. If the

reservoir is empty it must be correctly

filled before use. Remove the

temporary transit plate which is fitted in

the position of the filler breather cap

(3) by undoing the 3 screws. Fit the filler

breather cap (packed separately)

using the 3 screws which held the

transit plate.

3. To fill the reservoir: Remove the filler

cap (3) and fill the tank with clean

HFO46 oil to the upper level indicator

(2).

4. Connect the air supply to the Motor air

inlet (11). Max inlet pressure 7 bar. It is

recommended that a filter and

lubricator are incorporated in the air

supply.

5. Ensure your air supply circuit includes a

ball or sliding valve close at hand,

which can be used to control the air

supply.

6. Remove hexagon headed plugs and

make hydraulic connections to service

ports (8).These ports have a 3/8” NPT

female thread and the corresponding

male connections should be wrapped

with PTFE tape or other suitable

sealant.

7. Ensure the lever of the hydraulic

directional control valve (7) is in the

neutral position. This is fully

anticlockwise for models with 2 way

valve (HAP21021, HAP21022, HAP21024,

HAP21026) and the central position for

models with 3 or 4 way valves

(HAP21031, HAP21032, HAP20134,

HAP20136, HAP21041, HAP21042,

HAP21044, HAP21046) Where valves

are remotely mounted, ensure these

are adjusted such that pressure will not

build up during the starting operation.

11.1 Operation of the Pump:

Hi-Force does not necessarily know what

equipment this pump will power. Read and

understand the appropriate operating

instructions relating to the equipment in use.

1. With all hydraulic connections

made and air motor running,

operate the directional control

valve (7) if fitted to control the

cylinders or tools in use.

2. For pumps with 2 way valves:

Turning the lever full clockwise will

supply oil to the service port and

advance the cylinder. Turning the

lever anticlockwise will retract the

cylinder.

3. For pumps with 3 way valves: Mid

position is the load hold position.

Moving the lever so that it is above

the service port (anti-clockwise)

will supply oil to the port and

advance the cylinder. Moving the

lever away from the service port

will connect the service port to

tank and retract the cylinder.

4. For pumps with 4 way valves: Mid

position is the load hold position.

Moving the lever so that it is above

either service port will supply oil to

that port and connect the

opposite port to tank.

5. The pump is fitted with an

adjustable pressure relief valve (6)

to restrict the out-put pressure to

any desired value up to the

maximum working pressure of the

pump. To increase the relief valve

setting turn the control knob

clockwise. To decrease the relief

valve setting turn the control knob

anticlockwise. Leaving the pump

running for extended periods with

the relief valve operating will

cause the oil to overheat.

6. Ensure that the oil level does not

fall below the minimum level as

shown by the lower indicator (2)

12.0 Maintenance:

In order to ensure the longest service life and

best performance from your pump, regularly

carry out the following routine maintenance.

Inspect the pump for damage after

each use

If a gauge is fitted to the pump ensure

it is regularly checked to ensure it is

within its calibration limits.

Regularly check the oil level in the

pump reservoir by means of the oil

level gauge ( item 2 in the diagrams)

Never run the pump with the oil level in

the reservoir below its bottom limit.