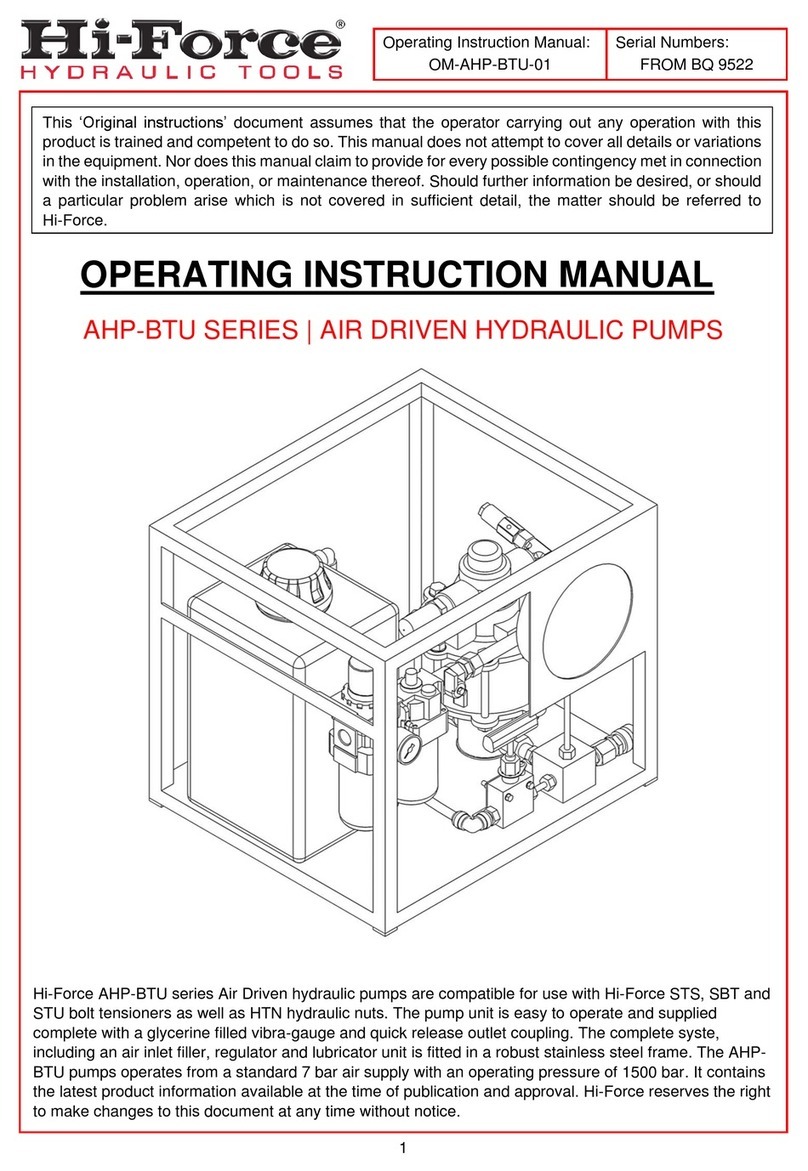

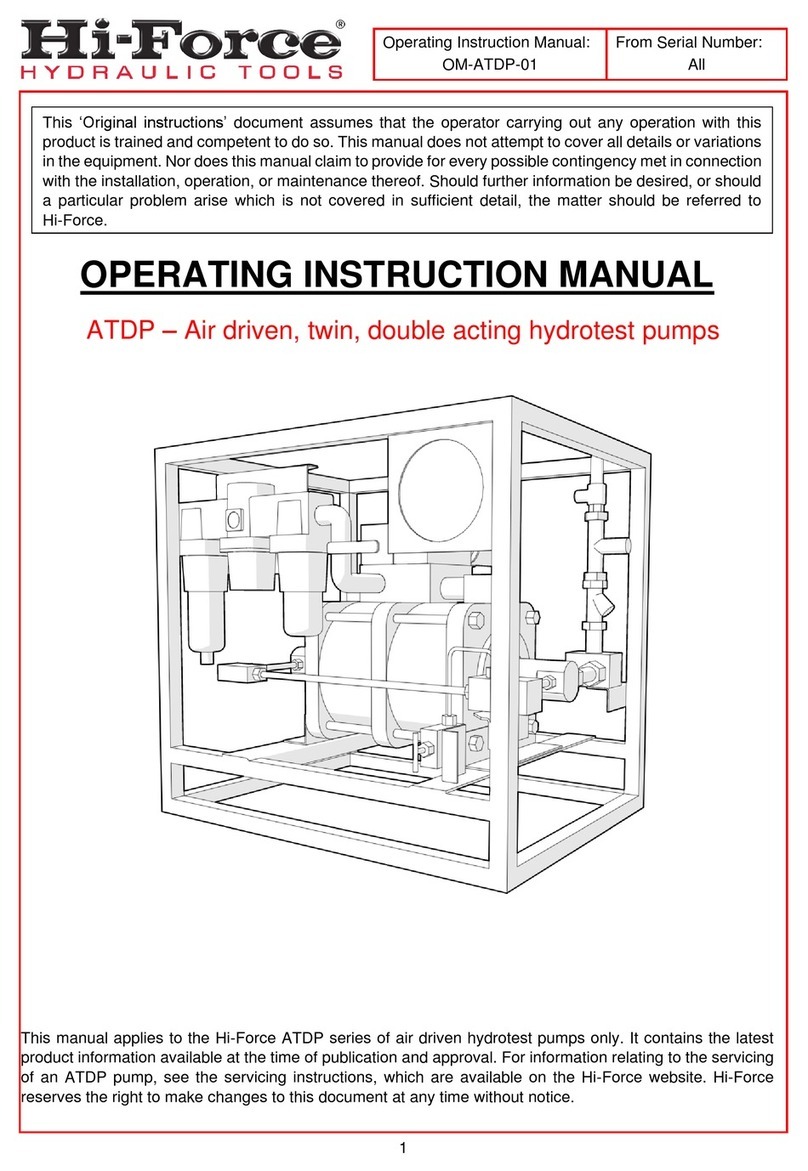

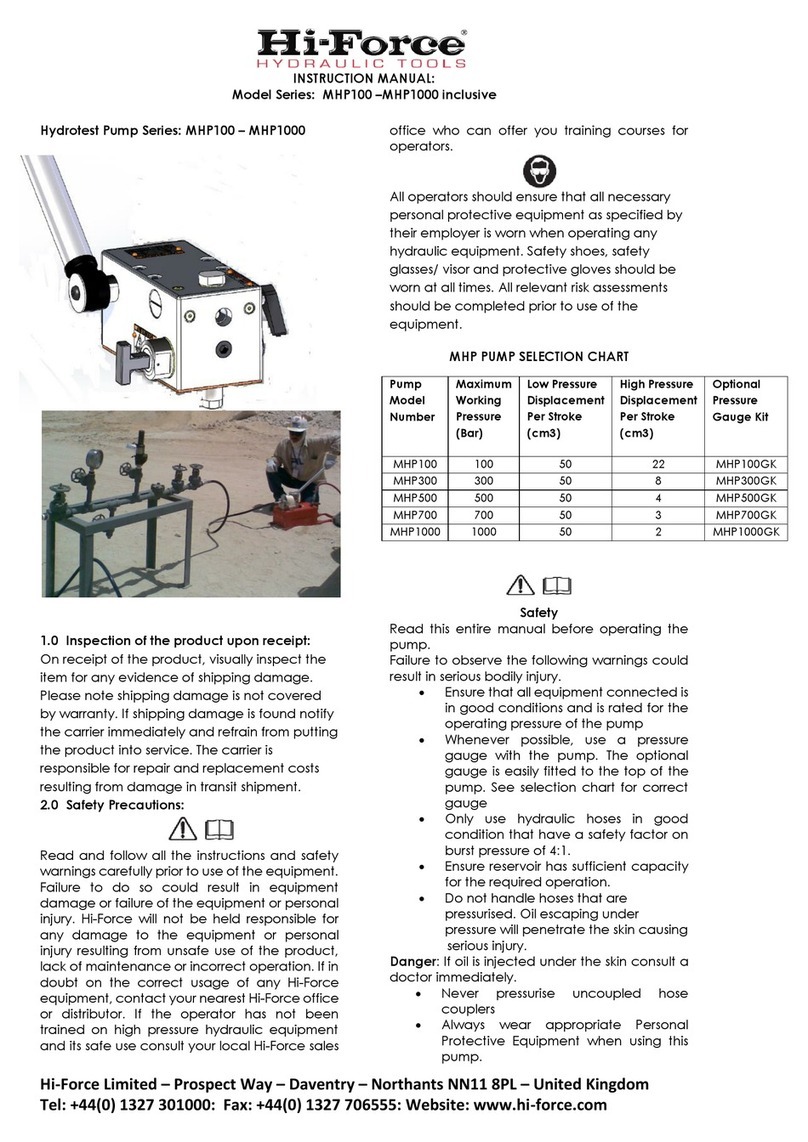

INSTRUCTION MANUAL –AIR DRIVEN HYDROTEST PUMPS:

Model Series: AHP10.AHP26, AHP36, AHP58, AHP107, AHP187, AHP275, AHP425,

AHP2-036, AHP2-060, AHP2-097, AHP2-144, AHP2-237, AHP3-040, AHP3-060, AHP3-100, ATDP63 ATDP125,

ATDP216,

Hi-Force Limited –Prospect Way –Daventry –Northants NN11 8PL –United Kingdom

Tel: +44(0) 1327 301000: Fax: +44(0) 1327 706555: Website: www.hi-force.com

The hydraulic pressure to be generated by the

air driven pump is dependent upon the air

pressure applied i.e.

Pump ratio 216/1: 1psig air drive pressure

applied can generate 216psig hydraulic

pressure.

PREPARATION FOR USE.

It is recommended to use good quality clean &

dry air (without moisture content) to drive the air

driven pump unit. As the air pressure drops at the

pump exhaust ports, the air will cool and any

water droplets in the air can freeze prematurely

due to temperature variation. For this reason we

include and recommend the use of ‘Killfrost’ at

all times to be placed in the installed pump oil

lubrication bottle. The lubricator bottle drop

feed rate is advised at 1 drop per 20 pump

strokes.

If for any reason the lubricator is not used, the air

motor should be disassembled, inspected and

repacked with suitable compound grease every

1 million strokes. Silicone type grease is prone to

stiffening when not in use, at a minimum the

grease should be changed after a 6month idle

period and every 12 months in a scheduled

routine service interval at a minimum.

Connect the hydraulic pressure outlet port to

the equipment to be pressurised via a flexible

hose assembly or via a rigid pipe-work system.

Ensure that all attached hose, pipe-work and

fittings are rated suitably to match, at a

minimum, or exceed the maximum working

pressure rating of the pump unit.

Direct the provided drain hose into a suitable

container or drain.

Connect a 1” bore air supply hose to the power

pack air inlet port. Use appropriately pressure

rated air hose and fittings for this purpose, these

components must be rated at a higher working

pressure than the maximum supply air pressure

that can be applied to the power pack. (1/2”

bore air supply tubing is the smallest size that will

allow the pump to operate).

Ensure that the air on/off valve on the pump is in

the closed before switching on the air supply.

(Note: To achieve the potential maximum

working pressure and output flow capability,

ensure an air supply of 7 bar (100psi) is available

with a flow rate of 212 SCFM (6M³/min). The use

of a smaller bore air hose or a smaller SCFM

volume supply is acceptable but will diminish the

maximum potential flow-rate from the pump.

Make connections to the fluid inlet port using

suitably rated hose, pipe-work and fittings and a

fluid isolation valve. The fluid inlet hose and

fittings bore is recommended to be not less than

1” bore.

(Once the pump has raised hydraulic pressure

DO NOT close the fluid inlet isolation valve).

Ensure the water supply is sufficient and only at

7 bar maximum pressure. It is advisable to ensure

clean water (fluid) is used as this prevents any

possible chance of debris contaminating the

pump check valves (Y type strainer filter built in

pump unit water line).

If fluid is being supplied from a tank ensure the

tank is sited close to the fluid inlet port on the

power pack or sited above the level of the fluid

inlet port (positive head/displacement pump).

Reducing the fluid supply inlet hose/pipe bore or

supplying water from a tank at a lower level

than the pump inlet port may cause pump

cavitation’s and potential damage, so should

always be avoided. DO NOT run the pump dry,

as this will damage the hydraulic components.

PRINCIPLE STEPS OF OPERATION

1) Check that the pump on/off air valve is

closed, and that the hydraulic pressure release

valve is in the open position.

2) Adjust the pump air pressure-regulating valve

anticlockwise until it is fully wound out. Switch

on the air supply to the pump by external

means.

3) Plug the hydraulic outlet connection.

4) Turn on the water supply to the pump. As long

as the water supply is above approximately

0.7bar (10 psi) the water will flow through the

pump and through the drain hose attached to

the pressure release valve, bleeding the system.

If not (flowing water) turn the pump air pressure-

regulating valve slowly clockwise until 15-20 psi is

shown on the air pressure regulators own air

pressure gauge, the pump will operate pumping

the inlet water supply to drain.

5) Turn the pump air on/off valve to the off

position and close the hydraulic pressure release

valve once any air bubbles, seen in the nylon

drain hose, have disappeared and the system is

bled properly.

6) To use the pump:

Open the pump air on/off valve.