Hi-P T Series Parts list manual

3A6823A

EN

Instructions-Parts

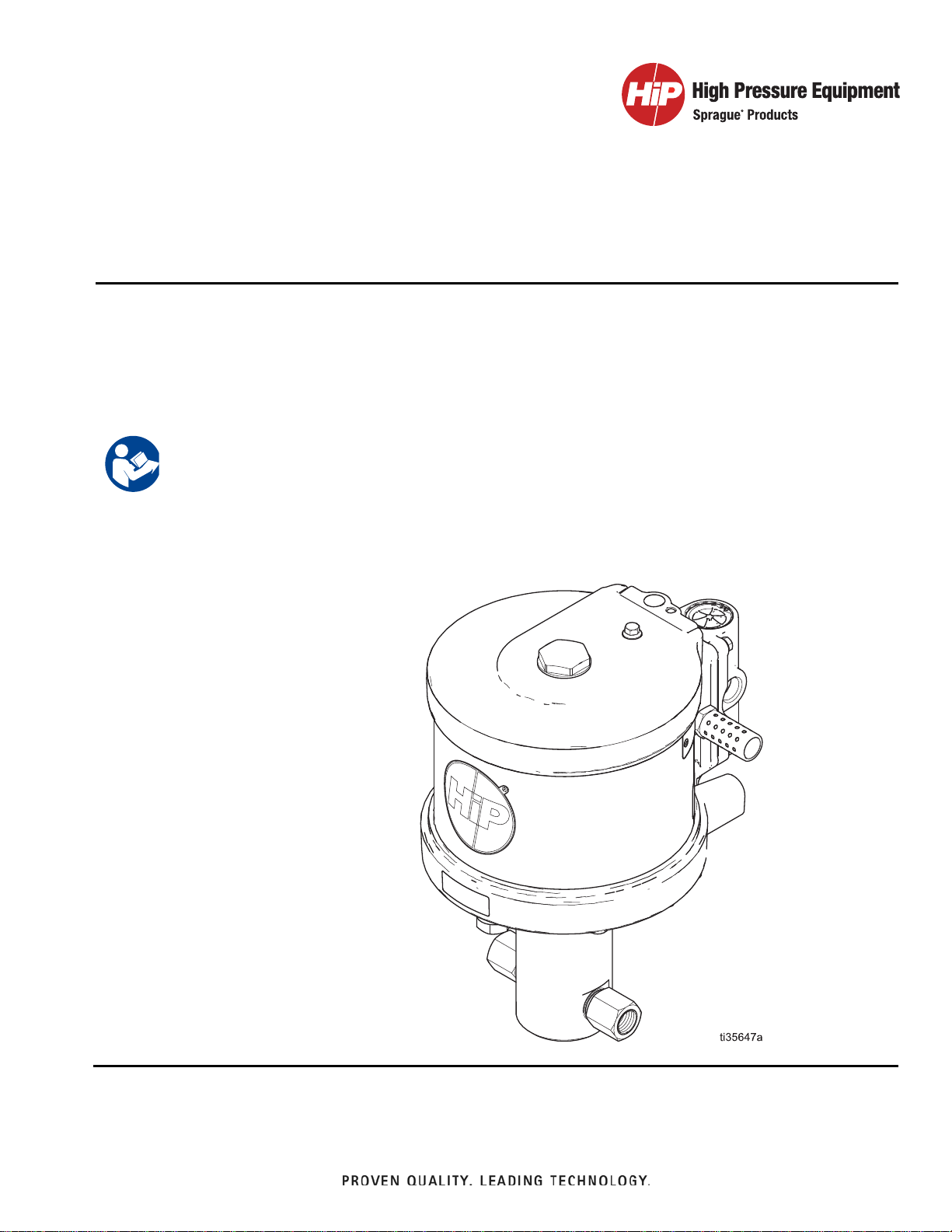

T-Series Intensifier

Pump

Pneumatic pump for generating high pressure for hydrostatic tests and

hydraulically-operated systems. For professional use only.

See page 3 for model information, including maximum working pressures.

Important Safety Instructions

Read all warnings and instructions in this manual

before using the equipment. Save all instructions.

Approvals

23A6823A

Contents

Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6.0 Inch Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

7.5 Inch Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Required Accessories . . . . . . . . . . . . . . . . . . . . . 7

Flush Before Using Equipment . . . . . . . . . . . . . . 7

Typical Installation . . . . . . . . . . . . . . . . . . . . . . . 8

Mount the Pump and Connect Fluid Supply . . . . 9

Connect Pneumatic Supply . . . . . . . . . . . . . . . . . 9

Connect Fluid Outlet . . . . . . . . . . . . . . . . . . . . . . 9

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . 10

Flush the Equipment . . . . . . . . . . . . . . . . . . . . . 10

Prime the Pump . . . . . . . . . . . . . . . . . . . . . . . . 11

Build Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Preventive Maintenance Schedule . . . . . . . . . . 12

Tighten Threaded Connections . . . . . . . . . . . . . 12

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Repair - Pump Lower . . . . . . . . . . . . . . . . . . . . . . . 14

Disconnect the Pump Lower . . . . . . . . . . . . . . . 14

Pump Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Reconnect the Pump Lower . . . . . . . . . . . . . . . 16

Repair - Pneumatic Motor . . . . . . . . . . . . . . . . . . . 17

Pneumatic Valve . . . . . . . . . . . . . . . . . . . . . . . . 17

Replace Pilot Valves . . . . . . . . . . . . . . . . . . . . . 19

Repair Pneumatic Motor . . . . . . . . . . . . . . . . . . 20

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

T-Series Intensifier Pump . . . . . . . . . . . . . . . . . 23

Pump Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Pneumatic Motor . . . . . . . . . . . . . . . . . . . . . . . . 26

Pneumatic Valve . . . . . . . . . . . . . . . . . . . . . . . . 28

Kits and Accessories . . . . . . . . . . . . . . . . . . . . . . . 30

Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

T-Series Pump Dimensions . . . . . . . . . . . . . . . . 33

Pneumatic Mounting Hole Diagrams . . . . . . . . . 34

Technical Specifications . . . . . . . . . . . . . . . . . . . . 35

Graco High Pressure Equipment Company

Standard Warranty . . . . . . . . . . . . . . . . . . . . . 36

Approvals

II 2 G Ex h IIA T6 Gb

NOTE: “h”: Type of protection

applied is Constructional

Safety “c”.

Models

3A6823A 3

Models

6.0 Inch Motor

* Optimal seal life is achieved at less than 80 cycles per minute.

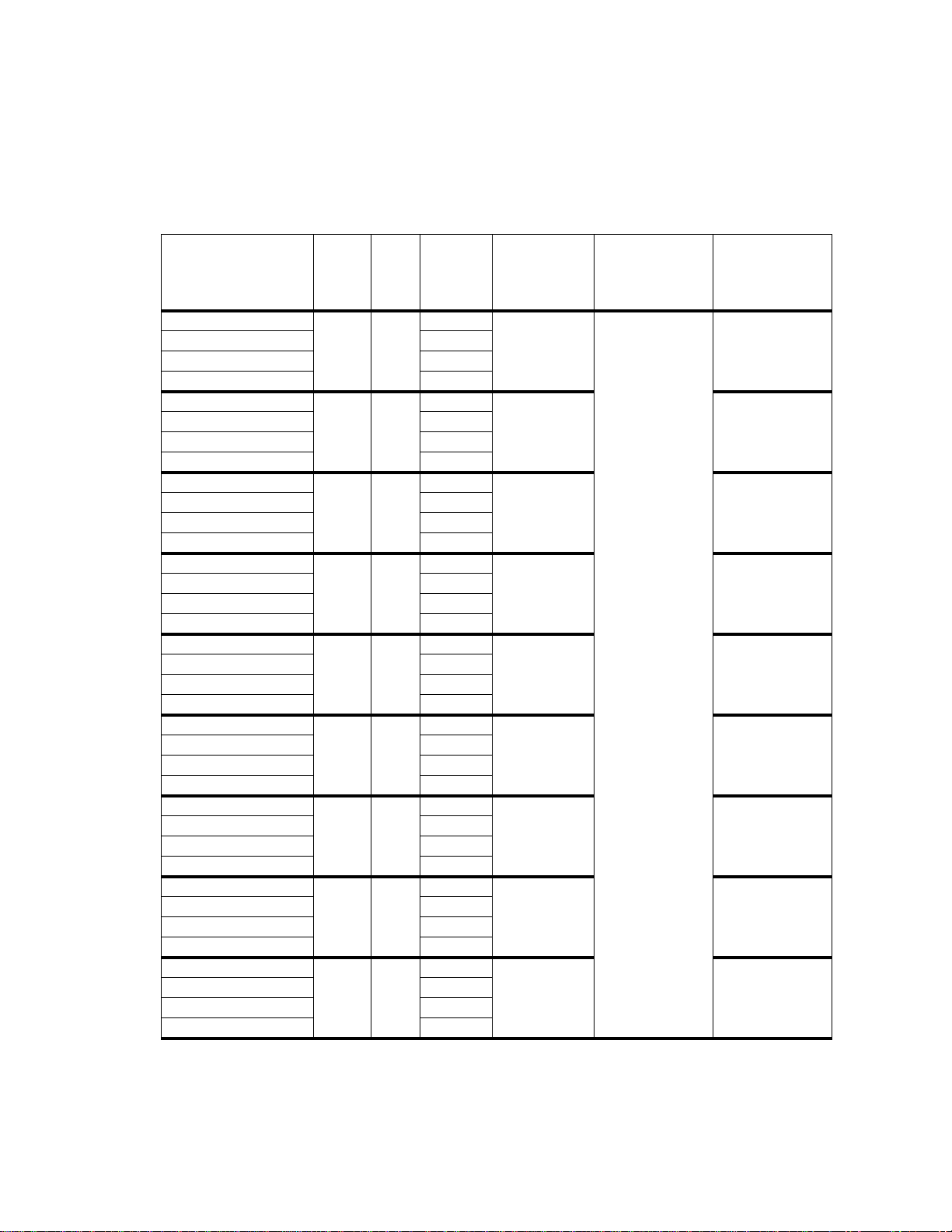

Part No. Model Ratio Seal

Material

Maximum

Working

Pressure

psi (MPa, bar)

Maximum

Pneumatic Inlet

Pressure

psi (MPa, bar)

Displacement /

Stroke*

in3(ml)

T6058-576-NBR-00

T6058 576:1

NBR 58,000

(399.8, 3998)

100 (0.69, 6.9)

0.12 (2.0)

T6058-576-FKM-00 FKM

T6058-576-FFKM-00 FFKM

T6058-576-EPR-00 EPR

T6036-365-NBR-00

T6036 365:1

NBR 36,500

(251.6, 2516) 0.19 (3.2)

T6036-365-FKM-00 FKM

T6036-365-FFKM-00 FFKM

T6036-365-EPR-00 EPR

T6025-254-NBR-00

T6025 254:1

NBR 25,250

(174.0, 1740) 0.28 (4.5)

T6025-254-FKM-00 FKM

T6025-254-FFKM-00 FFKM

T6025-254-EPR-00 EPR

T6016-163-NBR-00

T6016 163:1

NBR 16,250

(112.0, 1120) 0.43 (7.1)

T6016-163-FKM-00 FKM

T6016-163-FFKM-00 FFKM

T6016-163-EPR-00 EPR

T6012-125-NBR-00

T6012 125:1

NBR 12,500

(86.2, 862) 0.56 (9.2)

T6012-125-FKM-00 FKM

T6012-125-FFKM-00 FFKM

T6012-125-EPR-00 EPR

T6010-101-NBR-00

T6010 101:1

NBR 10,000

(68.9, 689) 0.70 (11.5)

T6010-101-FKM-00 FKM

T6010-101-FFKM-00 FFKM

T6010-101-EPR-00 EPR

T6006-064-NBR-00

T6006 64:1

NBR 6300

(43.4, 434) 1.11 (18.1)

T6006-064-FKM-00 FKM

T6006-064-FFKM-00 FFKM

T6006-064-EPR-00 EPR

T6005-047-NBR-00

T6005 47:1

NBR 4800

(33.1, 331) 1.49 (24.4

T6005-047-FKM-00 FKM

T6005-047-FFKM-00 FFKM

T6005-047-EPR-00 EPR

T6003-032-NBR-00

T6003 32:1

NBR 3200

(22.1, 221) 2.20 (36.0)

T6003-032-FKM-00 FKM

T6003-032-FFKM-00 FFKM

T6003-032-EPR-00 EPR

Models

43A6823A

7.5 Inch Motor

* Optimal seal life is achieved at less than 80 cycles per minute.

Part No. Model Ratio Seal

Material

Maximum

Working

Pressure

psi (MPa, bar)

Maximum

Pneumatic Inlet

Pressure

psi (MPa, bar)

Displacement /

Stroke*

in3(ml)

T7568-900-NBR-00

T7568 900:1

NBR 68,000

(468.8, 4688) 75 (0.52, 5.2) 0.12 (2.0)

T7568-900-FKM-00 FKM

T7568-900-FFKM-00 FFKM

T7568-900-EPR-00 EPR

T7557-571-NBR-00

T7557 571:1

NBR 57,100

(393.6, 3936)

100 (0.69, 6.9)

0.19 (3.2)

T7557-571-FKM-00 FKM

T7557-571-FFKM-00 FFKM

T7557-571-EPR-00 EPR

T7539-397-NBR-00

T7539 397:1

NBR 39,500

(272.3, 2723) 0.28 (4.5)

T7539-397-FKM-00 FKM

T7539-397-FFKM-00 FFKM

T7539-397-EPR-00 EPR

T7525-255-NBR-00

T7525 255:1

NBR 25,500

(175.8, 1758) 0.43 (7.1)

T7525-255-FKM-00 FKM

T7525-255-FFKM-00 FFKM

T7525-255-EPR-00 EPR

T7519-195-NBR-00

T7519 195:1

NBR 19,500

(134.4, 1344) 0.56 (9.2)

T7519-195-FKM-00 FKM

T7519-195-FFKM-00 FFKM

T7519-195-EPR-00 EPR

T7516-158-NBR-00

T7516 158:1

NBR 15,750

(108.5, 1085) 0.70 (11.5)

T7516-158-FKM-00 FKM

T7516-158-FFKM-00 FFKM

T7516-158-EPR-00 EPR

T7510-100-NBR-00

T7510 100:1

NBR 10,000

(68.9, 689) 1.11 (18.1)

T7510-100-FKM-00 FKM

T7510-100-FFKM-00 FFKM

T7510-100-EPR-00 EPR

T7507-074-NBR-00

T7507 74:1

NBR 7400

(51.0, 510) 1.49 (24.4

T7507-074-FKM-00 FKM

T7507-074-FFKM-00 FFKM

T7507-074-EPR-00 EPR

T7505-050-NBR-00

T7505 50:1

NBR 5000

(34.4, 344) 2.20 (36.0)

T7505-050-FKM-00 FKM

T7505-050-FFKM-00 FFKM

T7505-050-EPR-00 EPR

Warnings

3A6823A 5

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclama-

tion point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area be aware that flammable fumes can ignite or

explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Ground all equipment in the work area.

• Keep work area free of debris, including rags and spilled or open containers of solvent.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Use only grounded hoses.

•Stopoperationimmediatelyifstaticsparkingoccurs oryou feel ashock.Do not use equipmentuntil

you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

SKIN INJECTION HAZARD

High-pressure fluid from dispensing device, hose leaks, or ruptured components will pierce skin. This

may look like just a cut, but it is a serious injury that can result in amputation. Get immediate surgical

treatment.

• Do not put your hand over the fluid outlet.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read Safety Data Sheet (SDS) to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

Warnings

63A6823A

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system com-

ponent. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request Safety Data Sheet (SDS) from distributor or retailer.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Checkequipmentregularly.Repairorreplacewornordamagedparts immediately with genuineman-

ufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations ormodifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. Protective equipment includes but is not

limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer.

Installation

3A6823A 7

Installation

Grounding

Pump: ground through electrically conductive pneu-

matic and fluid lines.

Pneumatic and fluid lines: use only electrically con-

ductive lines.

Air compressor: follow manufacturer’s recommenda-

tions.

Fluid supply container: follow local code.

Required Accessories

Install the following required accessories in the order

shown in FIG. 1, using adapters as necessary.

NOTE: If you supply your own accessories, be sure they

are adequately sized and pressure rated for your sys-

tem.

Pneumatic Line

•Bleed-type master pneumatic valve (C): required

in your system to relieve air trapped between it and

the pneumatic motor when the valve is closed.

• Be sure the valve is easily accessible from the

pump and located downstream from the pneu-

matic regulator.

•Pump pneumatic regulator (D): to control pump

speed and outlet pressure. Locate it close to the

pump.

•Pneumatic line filter (B): removes harmful dirt and

moisture from compressed air supply.

Fluid Line

•Fluid filter/strainer (F): with a 60 mesh (250

micron) stainless steel element to filter particles

from the fluid before it reaches the pump.

•Supply fluid shutoff valve (N): shuts off supply

fluid flow.

•Shutoff/bleed valve (G): shuts off pump fluid flow

to hydraulic system.

•Fluid pressure relief valve (H): use to release

pressure in outlet lines by redirecting fluid to the

fluid supply container.

Flush Before Using Equipment

The equipment was tested with lightweight oil, which is

left in the fluid passages to protect parts. To avoid con-

taminating your fluid with oil, flush the equipment with a

compatible solvent before using the equipment. See

Flush the Equipment, page 10.

To reduce the risk of injury from ejected ice, do not

operate the motor without a plumbed exhaust line or

muffler installed.

Installation must comply with all local codes and regu-

lations.

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes to

ignite or explode. Grounding provides an escape wire

for the electric current.

Installation

83A6823A

Typical Installation

FIG. 1 is an example of an installation with an Intensifier

pump. Your installation may differ from what is shown

here. (See Required Accessories, page 7.) The Inten-

sifier pump (E) is the only component in FIG. 1 supplied

by HiP. All other components are available from HiP to

be ordered separately.

Key:

A Main pneumatic supply line

B Pneumatic line filter

C Bleed-type master pneumatic valve

D Pump pneumatic regulator

E Intensifier pump

F Fluid filter/strainer (at the fluid supply container)

G Shutoff/bleed valve (outlet only)

H Fluid pressure relief valve

J Fluid inlet line

K Inlet port

LOutletport

M Fluid outlet line to hydraulic system

N Supply fluid shutoff valve

FIG. 1: Typical Installation

A

B

D

C

E

H

J

G

F

KL

M

Fluid Supply

Container

N

Installation

3A6823A 9

Mount the Pump and Connect

Fluid Supply

NOTE: A strainer (F) or fluid filter is required before the

pump inlet. This will keep debris from the fluid supply

container from reaching the pump and check valve

seals. For maximum performance, the inlet port (K)

should be mounted below the fluid supply container.

1. Mount the pump (E) and connect the fluid inlet

line (J).

Connect Pneumatic Supply

1. Install the pressure regulator (D) and gauge to con-

trol the inlet pressure. See Models on page 3 for

your model’s maximum pneumatic pressure.

2. Install a pneumatic line filter (B) to keep debris from

affecting pump performance and to increase pump

life.

3. Connect the outlet of the master valve (C) to the 1/2

in. female NPT port on the Intensifier pump (E).

Connect Fluid Outlet

1. Connect a fluid line from the outlet port (L) to the

hydraulic system.

2. Install a fluid pressure relief valve (H) on the outlet

side of the pump.

Operation

10 3A6823A

Operation

Pressure Relief Procedure

Perform the Pressure Relief Procedure when-

ever you see this symbol.

NOTE: Always discharge fluid into an approved con-

tainer or location.

1. Close the bleed-type master pneumatic valve (C).

2. Use the fluid pressure relief valve (H) to release

pressure in system by redirecting the fluid to the

fluid supply container.

3. Set the pressure regulator (D) to 0 PSI/MPa/bar.

Flush the Equipment

• Flush with a fluid that is compatible with the fluid

being dispensed and the equipment wetted parts.

1. Perform the Pressure Relief Procedure.

2. Connect inlet to the supply source of the flushing

fluid.

3. Connect outlet to a waste reservoir.

4. Run the pump until the dispensed fluid is predomi-

nately flushing fluid.

5. Perform the Pressure Relief Procedure.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury from

pressurized fluid, such as skin injection and splashing

fluid, follow the Pressure Relief Procedure when

you stop dispensing and before cleaning, checking, or

servicing the equipment.

To avoid fire andexplosion, always ground equipment

and waste container. To avoid static sparking and

injury from splashing, always flush at the lowest pos-

sible pressure.

Operation

3A6823A 11

Prime the Pump

1. Perform the Pressure Relief Procedure on

page 10.

2. Attach the hydraulic system to the fluid outlet line

(M) and verify all connections and fluid lines are

tight.

a. Close the shutoff/bleed valve (G) and open the

fluid pressure relief valve (H).

b. Set the pressure regulator (D) to

0 PSI/MPa/bar.

NOTE: The pressure regulator (D) and bleed-type mas-

ter pneumatic valve (C) both affect the pump cycle rate.

After the inlet pressure is set, the bleed-type master

pneumatic valve (C) can serve as a speed control.

3. Turn on the air at the bleed-type master pneumatic

valve (C). Slowly increase the pressure using the

pressure regulator (D) to slowly cycle (less than 80

cycles per minute) the Intensifier pump (E).

4. Keep the pump cycle rate at less than 80 cycles per

minute. The pump is primed when discharge from

the pump has transitioned from air, to bubbly fluid,

to pure fluid.

Build Pressure

1. Close the fluid pressure relief valve (H) and open

the fluid outlet valve (G) that is connected to the

hydraulic system. Bleed the hydraulic system of all

air per the manufacturer’s recommended practice.

2. Turn off the air at the pneumatic valve (C) and set

the pressure regulator (D) to 0 PSI/MPa/bar. Seal

the hydraulic system per the manufacturer’s recom-

mended practice. You are now ready to build pres-

sure.

3. Turn on the air at the bleed-type master pneumatic

valve (C) and slowly increase pressure with the

pressure regulator (D) until the desired pressure is

produced in the hydraulic system.

NOTE: Hydraulic pressure increases proportionally to

inlet pressure up to the maximum working pressure of

the pump.

4. After pressurization of the hydraulic system is com-

plete, perform the Pressure Relief Procedure on

page 10.

NOTICE

Pump runaway may occur if the pressure regulator is

opened too far for pressure settings, causing damage

to the packing seals.

Maintenance

12 3A6823A

Maintenance

Preventive Maintenance

Schedule

The operating conditions of your particular pump deter-

mines how often maintenance is required. Establish a

preventive maintenance schedule by recording when

and what kind of maintenance is needed, and then

determine a regular schedule for checking your pump.

Tighten Threaded Connections

Check that all threaded connections are tight before

each use and at routine intervals.

Storage

If the pump is going to be stored for long periods, flush

the pump with a light-weight oil or rust inhibitor before

storage to protect pump components. Store the pump

with protective fluid inside whenever possible.

Troubleshooting

3A6823A 13

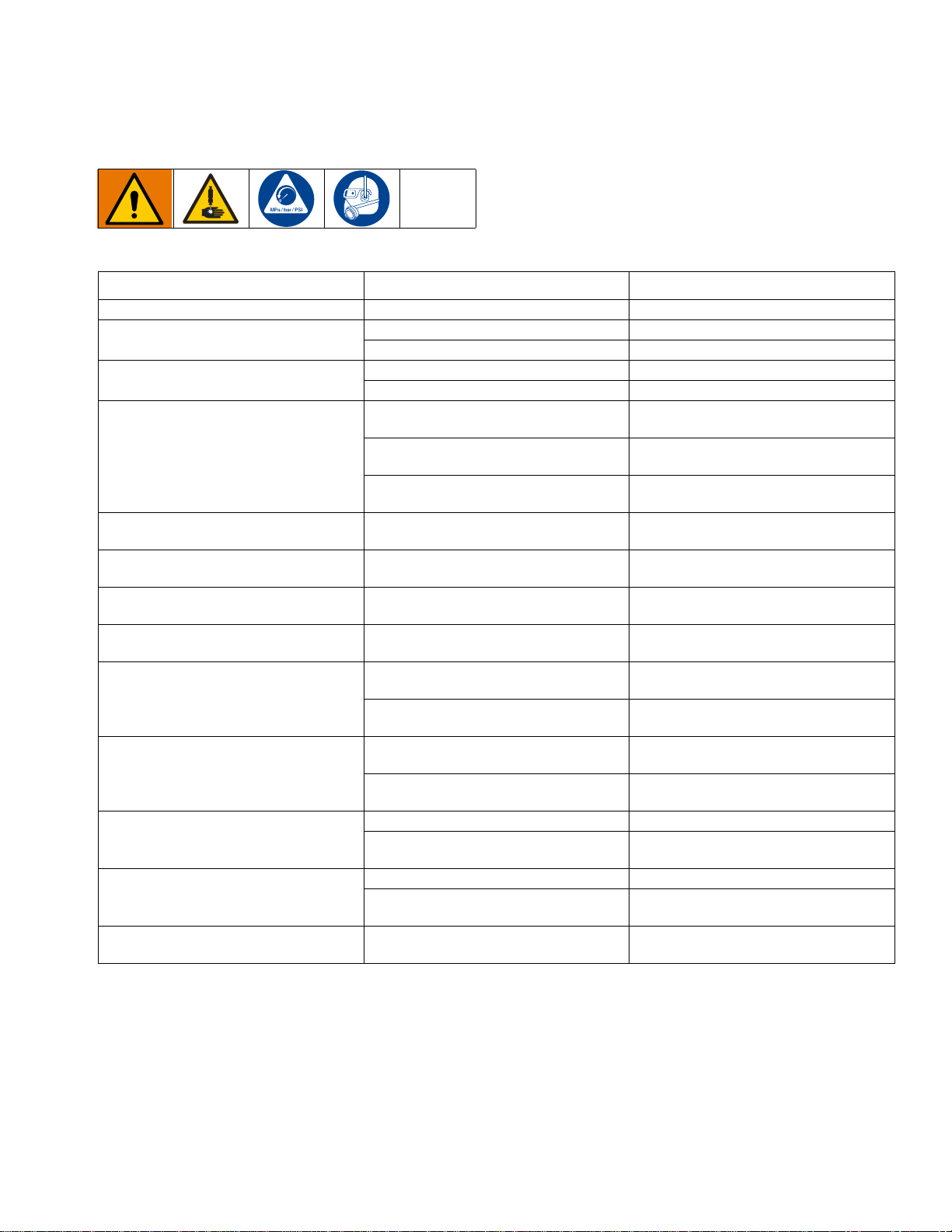

Troubleshooting 1. Perform Pressure Relief Procedure, page 10,

before checking or repairing pump.

2. Check all possible problems and causes before dis-

assembling pump.

Problem Cause Solution

Air bubbles in fluid. Fluid inlet line is loose. Tighten.

Fluid leaking. Loose fittings. Tighten fittings.

Worn seals. Replace packing.

Pump stroking, but no fluid moving. Air in pump. Prime pump. See page 11.

Worn or damaged check valve seals. Rebuild check valves.

Pneumatic motor will not run. Damaged pneumatic valve (217). Replace or service pneumatic valve (217).

See page 17.

Damaged pilot valve (219). Replace pilot valves (219).

See page 19.

Fluid valve (K) shut. Open fluid valve (K).

See page 8.

Air continuously exhausting around

pneumatic motor plunger. Damaged u-cups (203 and 233). Replace plunger u-cups (203 and 233).

See page 20.

Air continuously exhausting from muffler. Damaged pneumatic valve plate (305) or

cup (312). Replace or service pneumatic valve (217).

See page 17.

Pneumatic motor “bounces” at top of

stroke. Damaged bottom pilot valve (219). Replace bottom pilot valve (219). See

page 19.

Pneumatic motor “bounces” at bottom of

stroke. Damaged top pilot valve (219). Replace top pilot valve (219).

See page 19.

Icing inside motor. Pneumatic motor operating at high pres-

sure or high cycle rate. Reduce pressure, cycle rate, or duty cycle

of motor.

Excessive moisture in pneumatic supply

line. Reduce dew point of compressed air in

moisture coalescing filter.

Pump fails to operate. Restricted line or inadequate air supply;

closed or clogged valves. Clear line or increase air supply. Check

that the valves are open.

Obstructed fluid line; fluid line ID is too

small. Open, clear*; use line with larger ID.

Pump operates, but output is low. Worn packings in pump. Replace packings. See page 15.

Held open or worn check valves or pack-

ings. Clear valve; replace packings.

See page 15.

Erratic or accelerated pump speed. Exhausted fluid supply. Refill and prime.

Held open or worn check valves or

packings. Clear valve, replace packings.

See page 15.

Fluid being pumped is visible on the pack-

ing nut. Worn packings. Replace packings. See page 15.

Repair - Pump Lower

14 3A6823A

Repair - Pump Lower

• Always use Genuine Graco Parts and Accessories,

available from your Graco distributor.

Disconnect the Pump Lower

1. Stop the pump.

2. Perform the Pressure Relief Procedure, page 10.

3. Disconnect the fluid lines.

4. Remove the screws (5) and remove the pump

lower (3). It is not necessary to loosen or remove

either the lower bracket (111) or the locking ring

(110) from the pump lower (3).

5. Slide the pump lower (3) off of the pump, with the

lower bracket (111) and locking ring (110) still

attached to the pump lower.

Before servicing or repairing your pump, verify that

pressure is relieved according to the Pressure Relief

Procedure, page 10, and that all fluid and pneumatic

lines are properly shut off. Threads are very sharp. Use a rag to protect hands

when turning or carrying the pump.

FIG. 2

111

5

3

110

Repair - Pump Lower

3A6823A 15

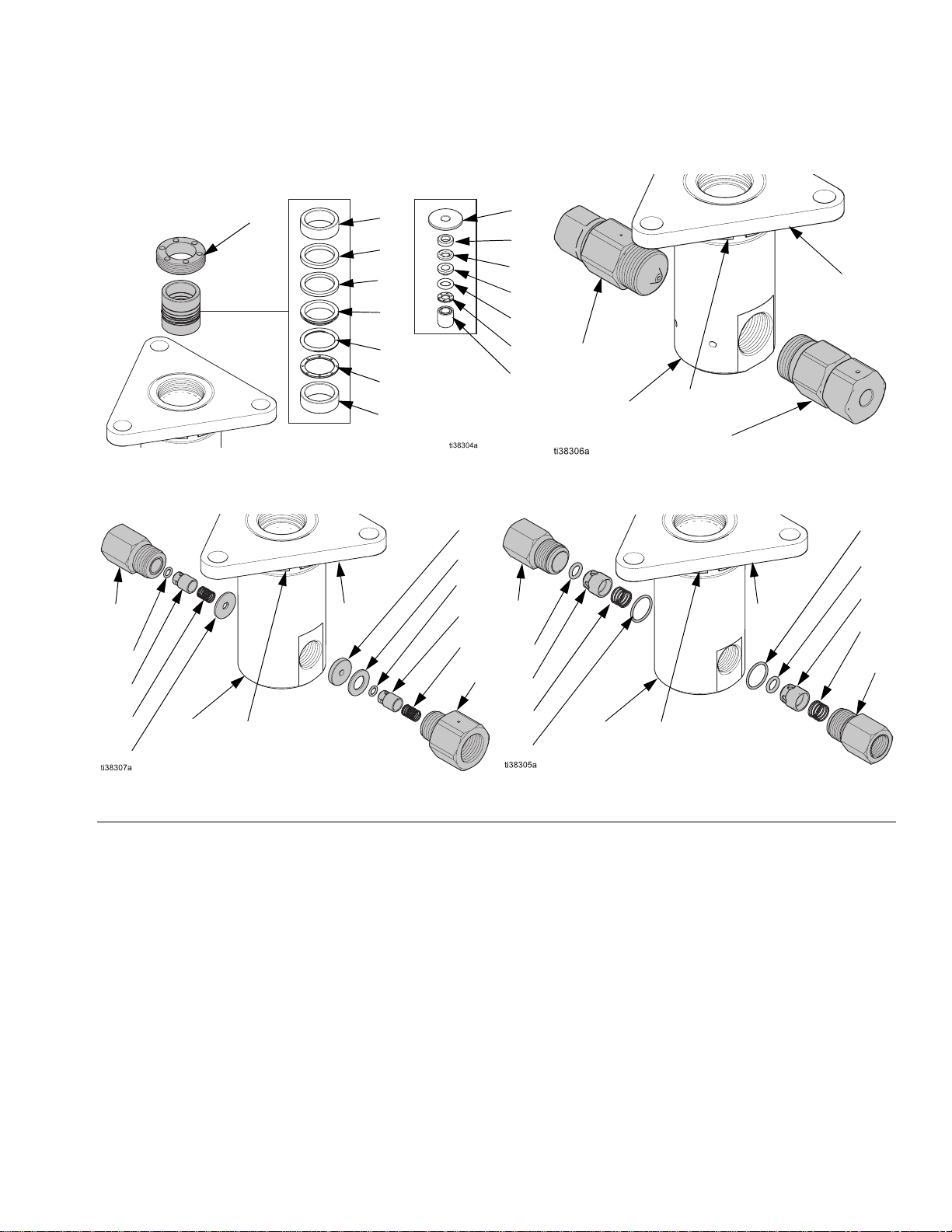

Pump Repair

1. Remove the packing nut (109) from the top of the

fluid cylinder (101). Do not remove either the lower

bracket (111) or locking ring (110).

2. Remove the seal stack. Inspect seals and rings for

damage and wear, and replace as necessary

3. Remove the inlet and outlet check housings (117

and 118; low- and medium-pressure pumps) or inlet

and outlet checks (122 and 123; high-pressure

pumps).

4. Medium-pressure pumps only. Remove the

o-rings (115), compression springs (116), and check

poppets (114).

5. Low-pressure pumps only. Remove the o-rings

(113 and 115), compression springs (116), and

check poppets (114). Inspect for damage and wear,

and replace as necessary.

NOTE: Assuming the orientation shown in FIG. 3, and

with the point of lower bracket (111) pointing to the front

of the pump when installed, the inlet port will be to the

left and the outlet port to the right.

6. Low- and medium-pressure pumps only. Install

the small o-ring (115) onto the check poppet (114),

then install the poppet (115) and compression

spring (116) into the inlet check housing (117), as

shown.

FIG. 3

Seal Stacks High Pressure Checks

Low Pressure Checks

Low/Medium Pressure High Pressure

102

107

106

105

104

103

102

108

107

106

105

104

103

102

109

122

123

111

110

117

115

114

116

113

113

115

114

116

118

110

111

101

101

Medium Pressure Checks

110

111

117

115

116

121

114

119

120

114

116

115

118

101

Repair - Pump Lower

16 3A6823A

7. Low-pressure pumps only. Install the large

o-ring (113) into the inlet port of the fluid

cylinder (101), then install the inlet check

housing (117).

8. Medium-pressure pumps only. Install the spacer

(121) into the inlet port of the fluid cylinder (101),

then install the inlet check housing (117).

9. Low- and medium-pressure pumps only. Install

the small o-ring (115) onto the check poppet (114),

then install the poppet (114) and compression

spring (116) into the outlet check housing (118), as

shown.

10. Low-pressure pumps only. Install the large

o-ring (113) into the outlet port of the fluid

cylinder (101), then install the outlet check housing

(118).

11. Medium-pressure pumps only. Install the spacers

(119 and 121) into the outlet port of the fluid cylinder

(101), then install the outlet check housing (118).

12. Stack and install the seal stack, as shown. Use

grease during installation.

13. Install the packing nut (109) with a medium strength

thread locking compound, and torque to 5-10 ft-lbs

(7-14 n•m). The packing nut (109) should be flush

with the surface of the fluid cylinder (101).

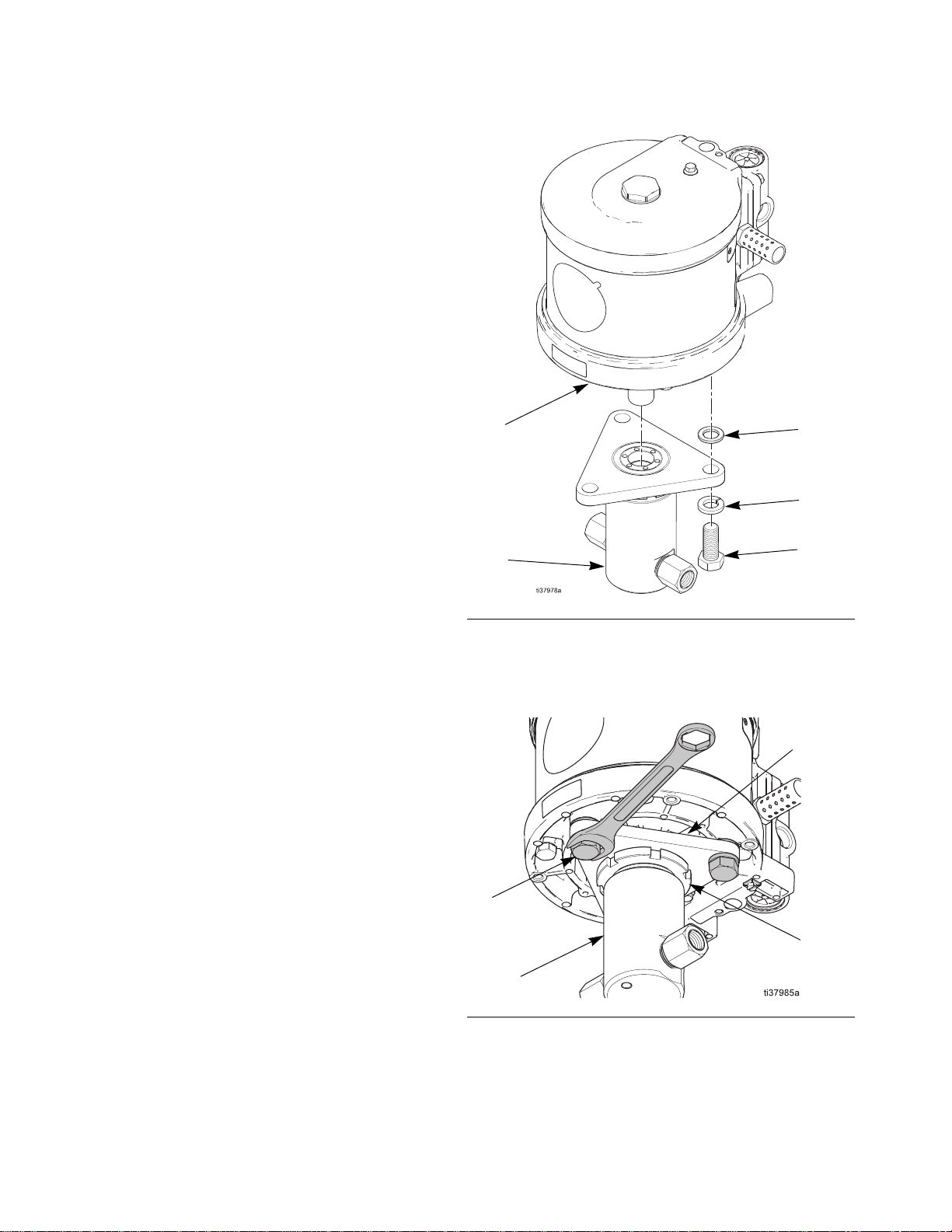

Reconnect the Pump Lower

1. Align the pump lower (3) so that the inlet port is to

the left when facing the front of the pump (1).

2. Install the screws (5), lock washers (4), and spacers

(2), as shown in FIG. 4, and align with the holes in

the bottom of the pump (1), as shown in FIG. 5.

3. Torque the screws (5) to 50-60 ft-lbs (68-81 N•m).

FIG. 4

FIG. 5

1

35

4

2

111

5

3

110

Repair - Pneumatic Motor

3A6823A 17

Repair - Pneumatic Motor

Pneumatic Valve

Replace Complete Pneumatic Valve

1. Stop the pump and perform the Pressure Relief

Procedure, page 10.

2. Disconnect the pneumatic line to the motor.

3. See the figure on page 26. Use a 10 mm socket

wrench to remove four screws (218). Remove the

pneumatic valve (217) and gasket (216*).

4. To repair the pneumatic valve, go to Disassemble

the Pneumatic Valve, page 17. To install a replace-

ment pneumatic valve (217), continue with step 5.

5. Align the new pneumatic valve gasket (216*) on

the manifold, then attach the pneumatic valve (217).

Torque screws (218) to 95-105 in-lb (11-12 N•m).

6. Reconnect the pneumatic line to the motor.

Replace Seals or Rebuild Pneumatic Valve

Inspect and replace seals and worn parts while disas-

sembling and reassembling the pneumatic valve on the

following pages.

Use FIG. 6 and the following table to identify the kits

needed for replacements:

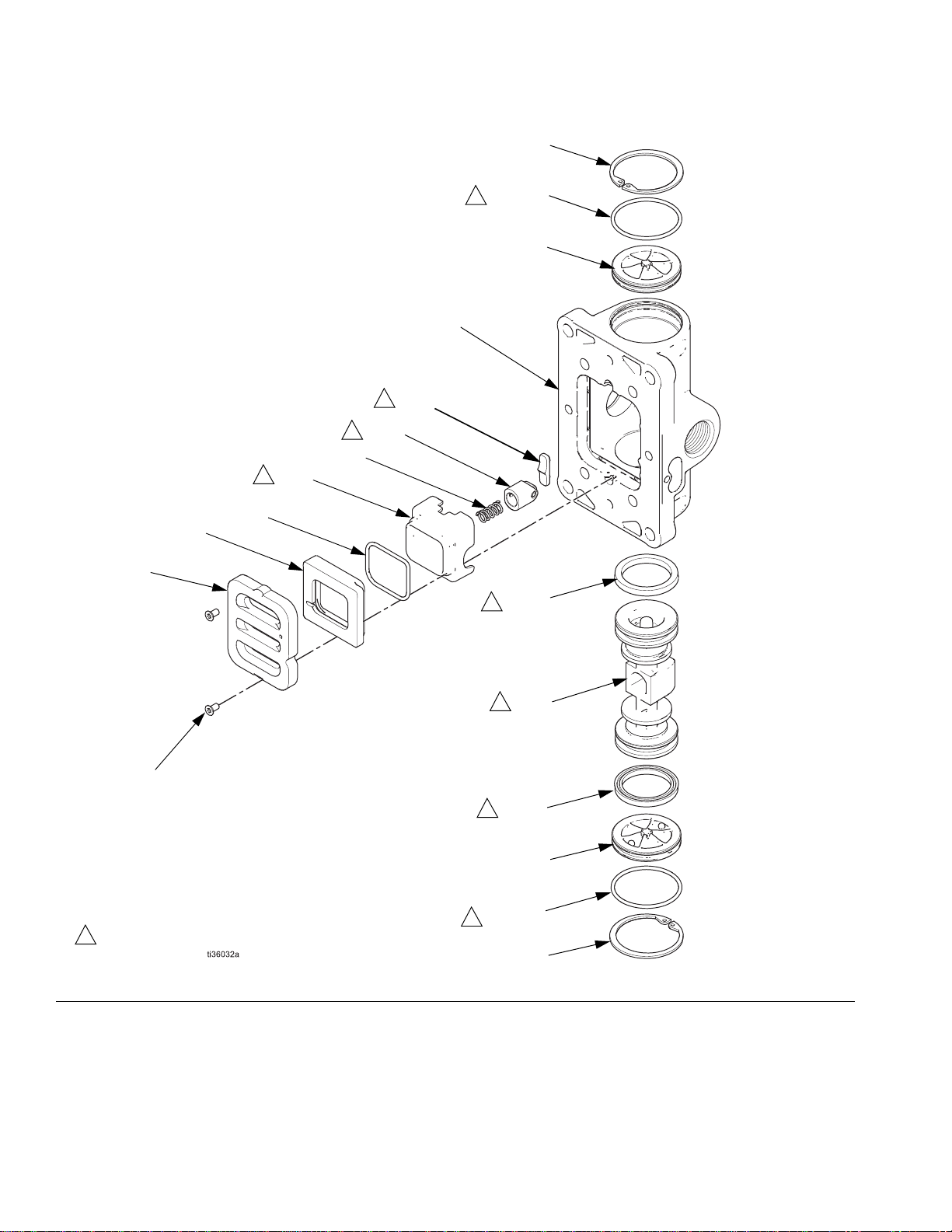

Disassemble the Pneumatic Valve

1. Perform steps 1-3 under Replace Complete Pneu-

matic Valve, page 17.

2. See FIG. 6. Use a T10 star screwdriver to remove

two screws (309†). Remove the valve plate

(305), cup (312), and spring (311).

3. See FIG. 6. Remove the snap ring (310) from

each end. Use the piston (302) to push the end

caps (307) out of the ends. Remove end cap

o-rings (306†).

4. Remove the piston (302). Remove the u-cup seals

(308†) from each end, and the detent assembly

(303) and detent cam (304) from the center.

Symbol Kit Description

† Pneumatic Valve Seal Kits. See page 29.

Pneumatic Valve Repair Kits. See page 29.

Pneumatic Valve End Cap Kits. See

page 29.

Repair - Pneumatic Motor

18 3A6823A

FIG. 6

310

307

307

†309

305

312 311

303

302

†308

†

308

301

304

310 ti16213a

†321

†321

313

314

1

1

1

1

1

1

1

1

1

Apply lubricant.

Repair - Pneumatic Motor

3A6823A 19

Reassemble the Pneumatic Valve

1. See FIG. 6. Lubricate detent cam (304) and install

into housing (301).

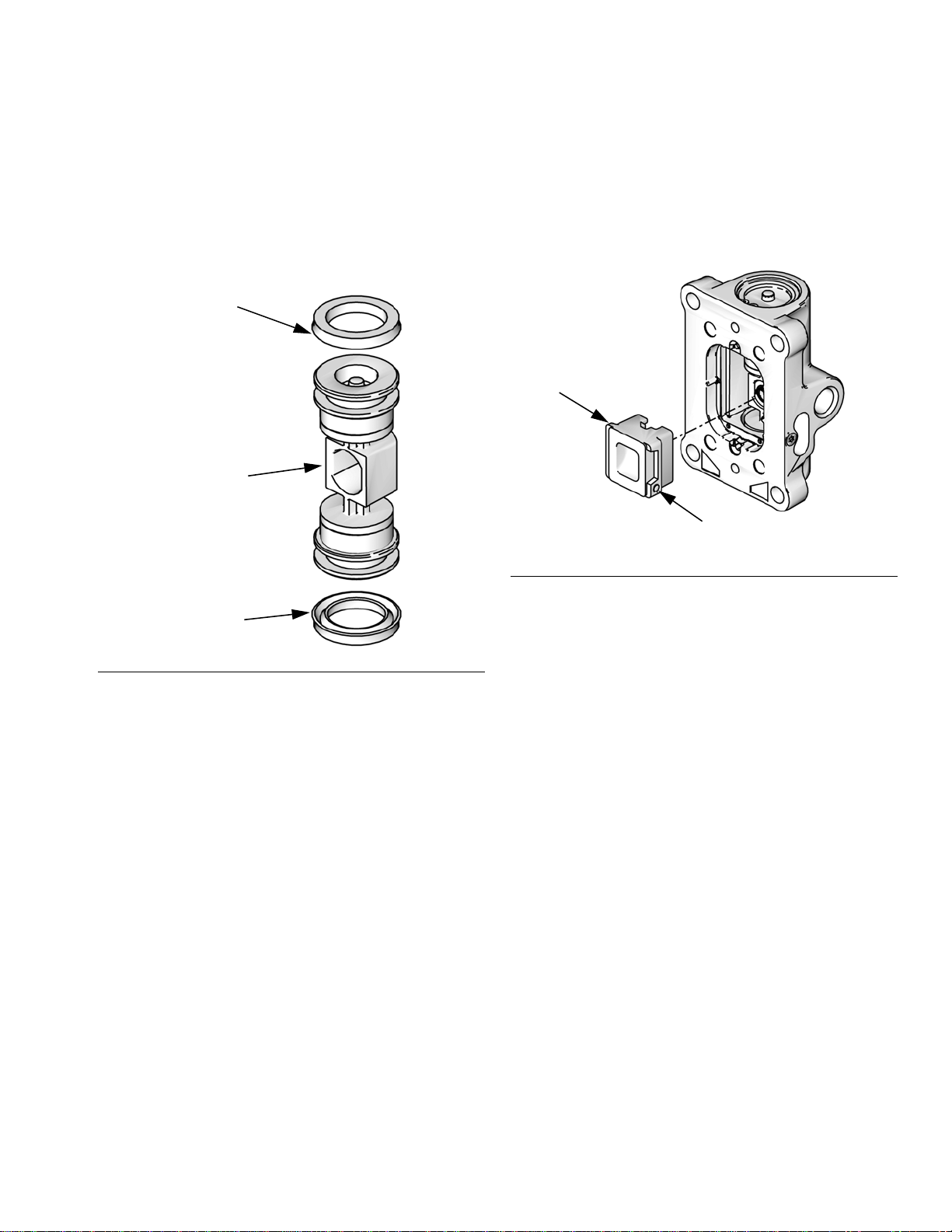

2. See FIG. 7. Lubricate the u-cups (308†) and install

on the piston (302) with lips facing toward the cen-

ter of the piston.

3. See FIG. 6. Lubricate both ends of the piston (302)

and install it in the housing (301).

4. Lubricate and install the detent assembly (303)

into the piston (302).

5. Lubricate new o-rings (306†) and install on the

end caps (307). Install the end caps into the hous-

ing (301).

6. Install a snap ring (310) on each end to hold end

caps in place.

7. Install the spring (311). Lubricate and install the

pneumatic valve cup (312), see FIG. 8. Align the

small round magnet with the pneumatic inlet.

8. Install the valve plate (305). Tighten the screws

(309†) to hold it in place.

9. Perform steps 5 and 6 under Replace Complete

Pneumatic Valve, page 17.

Replace Pilot Valves

1. Stop the pump and perform the Pressure Relief

Procedure, page 10.

2. Disconnect the pneumatic line to the motor.

3. Use a 10 mm socket wrench to remove the old pilot

valves (219) from the top (213) and bottom (201)

covers. See the figure on page 26.

4. Lubricate and install the new pilot valves (219).

Torque to 95-105 in-lb (11-12 N•m).

5. Reconnect the pneumatic line to the motor.

FIG. 7

Lips face down

Lips face up

†308

†308

302

ti12754a

FIG. 8

312

ti16283a

Magnet

Repair - Pneumatic Motor

20 3A6823A

Repair Pneumatic Motor

NOTE: Pneumatic Motor Seal Kits are available. See

Pneumatic Motor Parts List, page 27, for the correct

kit for your motor. For best results, use all parts in the

kit.

Disassemble the Pneumatic Motor

1. Disconnect the Pump Lower, page 14.

2. Use a 10 mm socket wrench to remove the four

screws (218), and remove the pneumatic valve

(217) and gasket (216). See the figure on page 26.

3. Remove the four screws (218), and remove the

manifold (215) and two gaskets (214).

4. Use a 10 mm socket wrench to remove the pilot

valves (219), and the top and bottom covers (213

and 201).

5. Use a 17 mm socket wrench to the tie bolts (210).

The number of bolts depends on your configuration.

6. Remove the top cover (213) and the o-ring (209).

7. Remove the shield (212) from around the

cylinder (211), and remove the cylinder.

8. Slide the piston assembly straight up off the bottom

cover (201).

NOTE: There is no need to take apart the piston assem-

bly. If any part is worn or damaged, the individual pis-

tons and plungers are available as kits and should be

replaced.

9. Remove the o-ring (208) from around the piston

(205).

10. Remove the retaining ring (204), u-cup seals (203

and 233), and the o-ring (209) from the bottom

cover (201).

Reassemble the Pneumatic Motor

NOTE: For easier reassembly, start with the top

cover (213) turned over on the workbench and assem-

ble the pneumatic motor upside-down.

1. Lubricate and install the o-ring (209) on the top

cover (213). See the figure on page 26.

2. Install the upper bumper (229) on the top cover.

3. Lubricate the inside of the cylinder (211). Lower the

cylinder onto the top cover (213).

4. Lubricate and install the o-ring (208) around the pis-

ton (205).

5. Slide the piston assembly down onto the

cylinder (211). Be sure the o-ring (208) stays in

place.

6. Install the shield (212) around the cylinder (211) and

in the groove on the top cover (213).

7. High-pressure pumps only. Lubricate and install

the u-cups (203 and 233) into the seal

housing (240).

8. The arrange the seal stack as shown in FIG. 9. (low-

and high-pressure pumps have different seal stack

arrangements), then lubricate and install into the

bottom cover (201).

9. Install the spacer (202) and retaining ring (204).

Configuration

T6000

T7500

ti12749a

ti12750a

This manual suits for next models

92

Table of contents