Hi-Tec HFP-30 User manual

Instruction Manual

Introduction

Contents

Programming

Congratulations on the purchase of the HFP-30. The HFP-30 is

designed to program all Hitec Digital Programmable Servos (D Series,

5xxx/7xxx, and Brushless) as well as test any brand servo.

Layout

Powering On

Main Screens

1. Main Programming Screen

2. Main Servo Test Screen

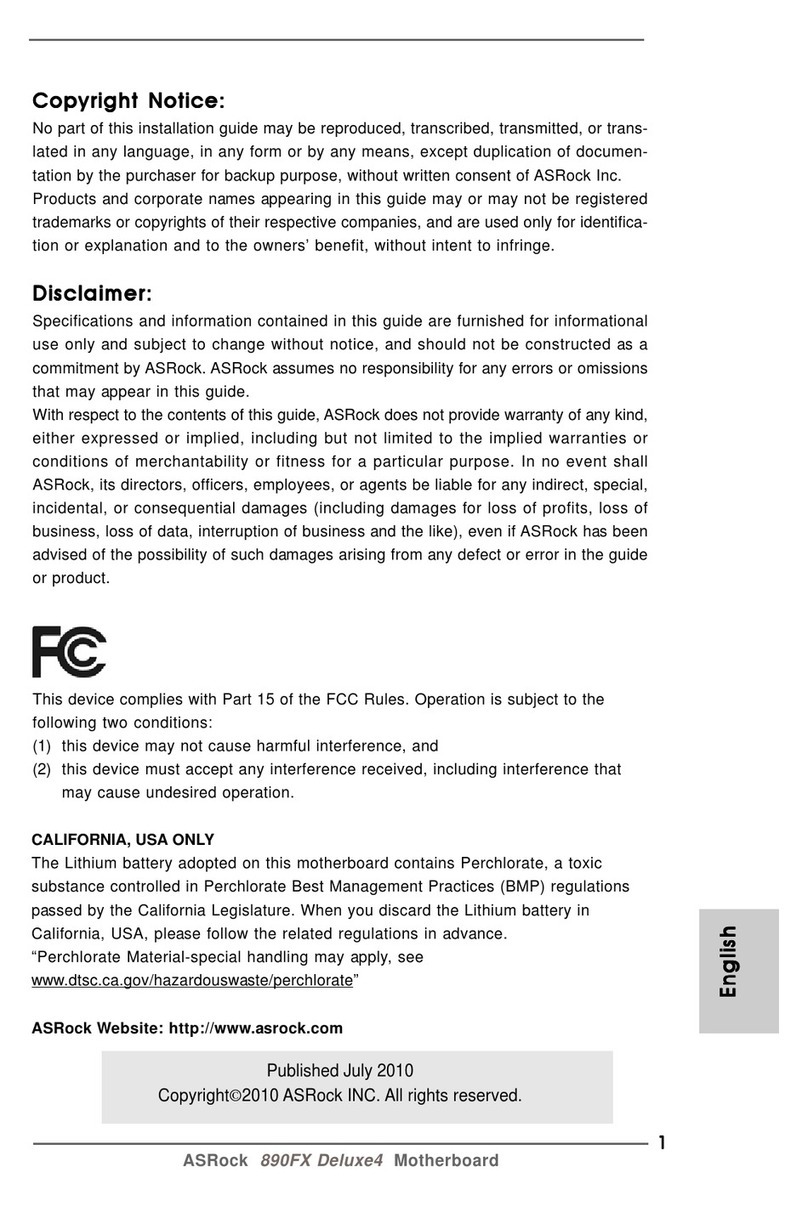

Test Mode

1. Manual Test

2. Auto Test

3. Auto Deadband Testing

4. Settings

D Series Program Mode

1) Set EPA/Neutral

2) Servo Sync

3) Set Rotation (CW_CCW)

4) Set Deadband (DB_Width)

5) Set Speed

6) Set ID (ID_Read)

7) Set Failsafe

8) Set Soft Start

9) Factory Reset (Factory Default Set)

5/7 Series Program Mode (For 5xxx*/7xxx Servos)

1) Set EPA/Neutral

2) Servo Sync

3) Set Rotation (CW_CCW)

4) Set Deadband (DB_Width)

5) Set Speed

6) Set Failsafe

7) Set Resolution

8) Set Overload Protection (OLP)

9) Factory Reset (Factory Default Set)

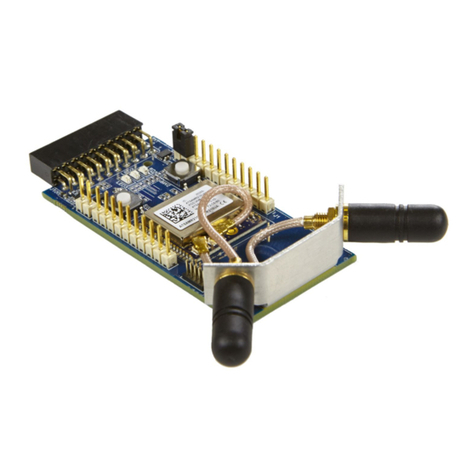

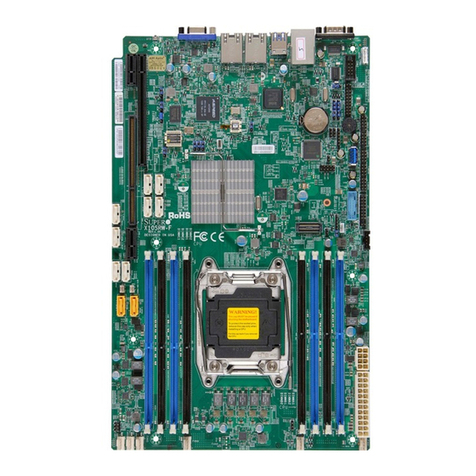

1. Adjust Dial

2. Back Button

3. Analog Dial for Pulse Adjustment

4. USB Port

5. Test/Program Select Switch

6. Battery/Receiver Port

7. Servo Sync Port

8. Servo Port

9. LCD

B Series Program Mode (BLDC Servos)

1) Set EPA/Neutral

2) Servo Sync

3) Set Rotation (CW_CCW)

4) Set Deadband (DB_Width)

5) Set Speed

6) Set Failsafe

7) Set Soft Start

8) Factory Reset (Factory Default Set)

The HFP-30 is powered by a user provided 4.8VDC to 7.4VDC battery

pack plugged into the Batt/RX slot. Optionally, a receiver with the

correct adapter can power the unit.

Note: Make sure the battery voltage corresponds to the servos

being used. Do not use a 7.4V battery with a servo designed for

6V and under, or damage may occur to the servo.

Depending on the position of the Test/Program select switch, the

following screens will appear when powered on. Once powered on,

it is possible to toggle between the screens using the Test/Program

switch.

Main Programming Screen

Use the Adjust Dial to switch between the three dierent series of

servos. Once the correct one is highlighted, press the Adjust Dial to

enter.

1

5

3

6

4

2

9

7

8

Layout

Contents

Powering On

Main Screens

Dial Button

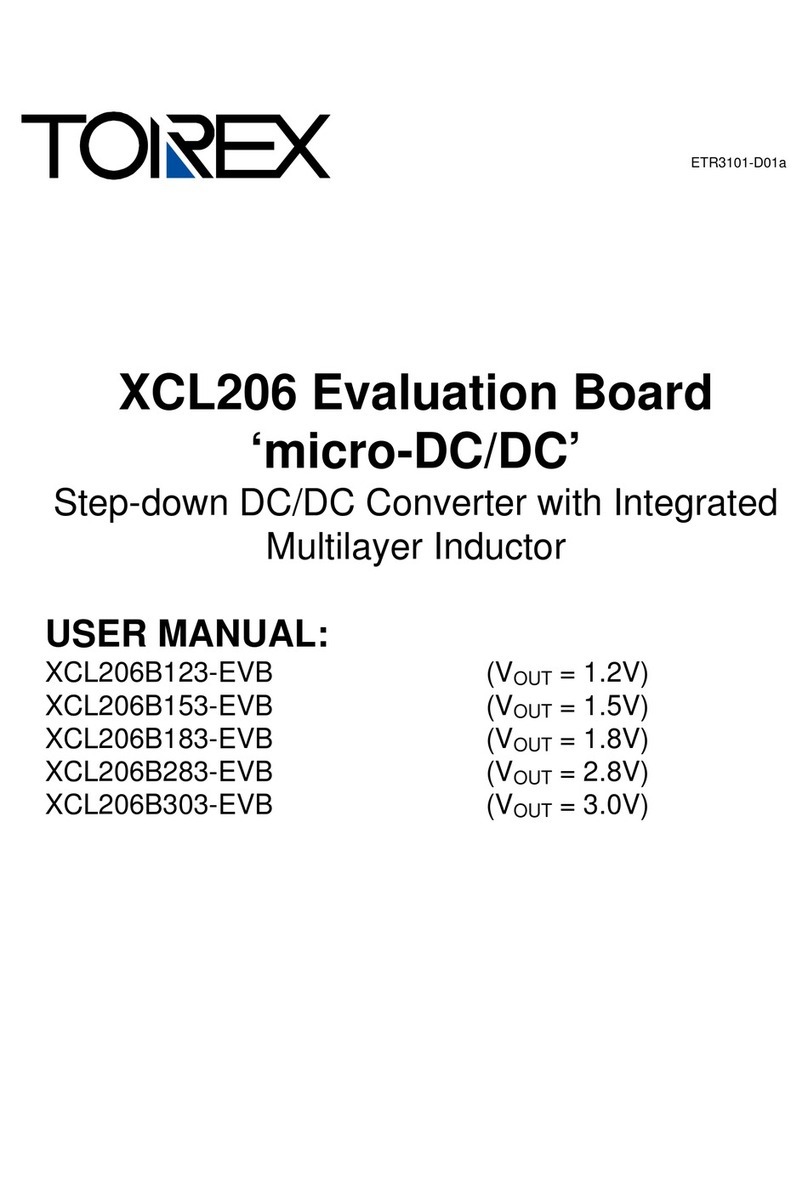

AUTO-Extreme

With this highlighted, press the Adjust Dial. This will select the Test

Mode and show a ‘Pause’ indicator in the lower right of the screen.

Pressing the Adjust Dial again will select ‘Play’ and the servo will

start moving. The servo speed is adjusted by turning the Adjust Dial.

Press the Adjust Dial to ‘Pause’ or the BACK button to switch to a

dierent Auto Test Mode.

AUTO-Sweep

With this highlighted, press the Adjust Dial. This will select the Test

Mode and show a ‘Pause’ indicator in the lower right of the screen.

Pressing the Adjust Dial again will select ‘Play’ and the servo will

start moving. The cycle speed is adjusted by turning the Adjust Dial.

Press the Adjust Dial to ‘Pause’ or the BACK button to switch to a

dierent Auto Test Mode.

AUTO-Step

With this highlighted, press the Adjust Dial. This will select the Test

Mode and show a ‘Pause’ indicator in the lower right of the screen.

Pressing the Adjust Dial again will select ‘Play’ and the servo will

start moving. The Step increments are adjusted by turning the Adjust

Dial.

Press the Adjust Dial to ‘Pause’ or the BACK button to switch to a

dierent Auto Test Mode.

AUTO-DB (Deadband)

Use the Adjust Dial to highlight AUTO-DB and press it to enter the

menu. The Auto Test will check the servos Deadband. When in the

menu, press the Adjust Dial to begin the Test. A ‘Play’ symbol will be

displayed in the lower right screen. Turning the Adjust Dial will adjust

the microsecond range. The jitter range is 0.25 microseconds to

100.0 microseconds.

Press the BACK button to exit.

Dial Button

Dial Button

In this mode, all manufacturer’s servos can be tested for operation.

To begin testing servos, plug a servo into the servo slot on the

programmer and install the correct battery type in the battery slot.

Move the select switch to the TEST position.

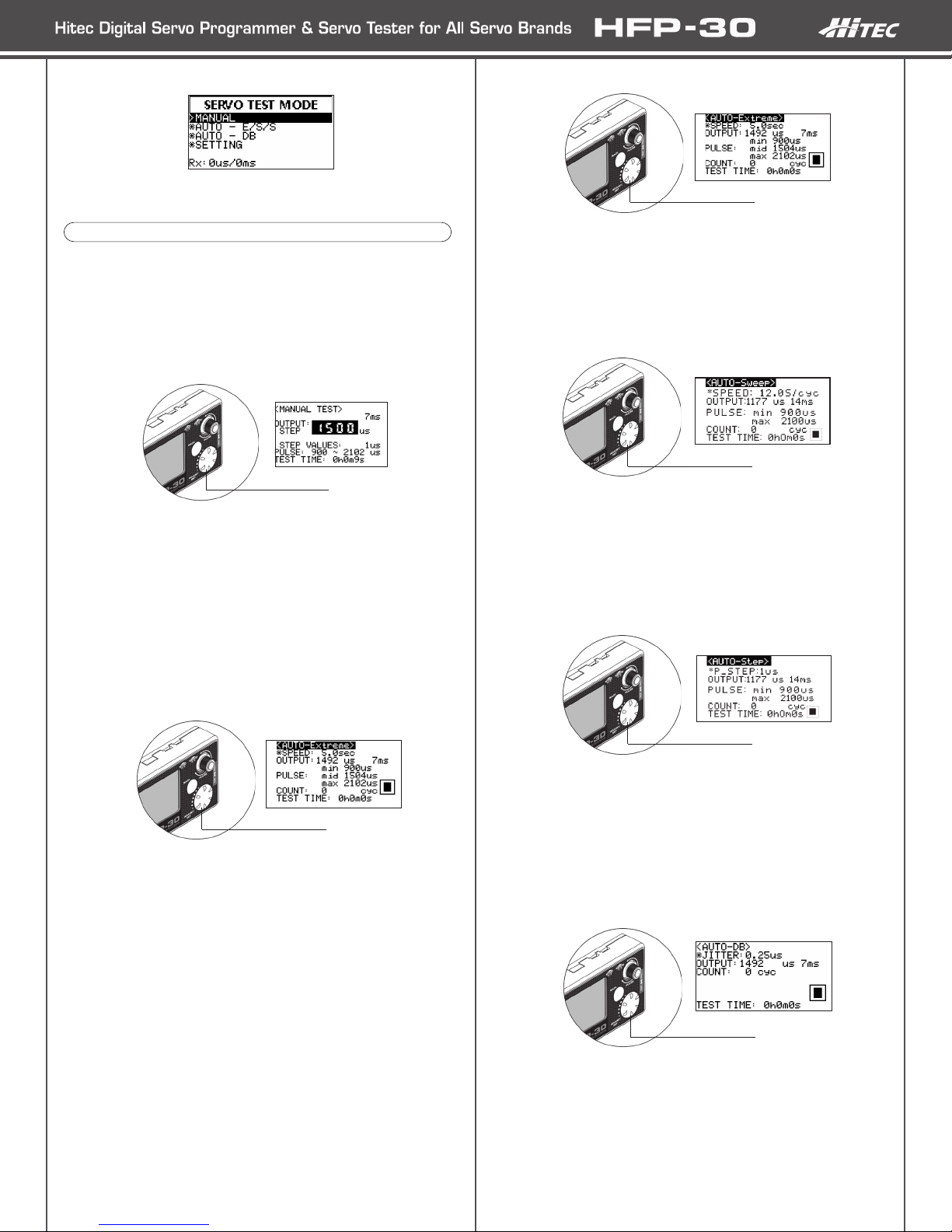

1. Manual test

Using the Adjust Dial, highlight Manual, and press then Adjust

Dial to enter.

At this point it is possible to move the servo using the Pulse Dial.

As the dial is turned the OUTPUT box will show the current position

of the servo in microseconds.

Pressing the Adjust Dial will switch to STEP mode allowing much

ner control. Use the Adjust Dial to adjust the microseconds. Press

again to exit.

Press the BACK button to exit the menu.

1. AUTO – E/S/S Test (Extreme, Sweep, Step)

Use the Adjust Dial to highlight AUTO – E/S/S and press it to

enter the menu.

In the Auto Test menu, it is possible to switch between Extreme,

Sweep, and Step modes by turning the Adjust Dial. Each mode will

display a cycle count and how much time has passed during the

test. Before a mode is selected, the Pulse Dial will move the servo

manually.

Here’s a brief explanation of the dierent modes:

Extreme – Moves the servo through minimum, middle (neutral),

and maximum endpoints. Speed of the total movement can be

adjusted. If the movement is set faster than the servo is rated,

then the servo will not be able to move to each end point before

changing direction. The speed ranges from 0.1 second to 5.0

second.

Sweep – Moves the servo through minimum and maximum

endpoints at an adjustable speed. The speed of the Sweep is

adjustable between 2.4 seconds/cycle to 120 seconds/cycle.

Step – Moves the servo through the minimum and maximum

positions at an adjustable Pulse Step. The Step range is 0.25

microseconds to 100.0 microseconds.

Dial Button

Test Mode

Dial Button

Dial Button

Main Servo Test Screen

Use the Adjust Dial to select the desired test function. Once the

function is highlighted, press the Adjust Dial to enter.

The Settings menu is where specic test parameters can be set for

all servo test modes. Use the Adjust Dial to highlight SETTING and

press it to enter the menu.

To make adjustments to the various settings, use the Adjust Dial to

highlight it and then press the dial to enter editing mode. To change

the value, use the Adjust Dial. Either press it again to conrm and

exit or press the BACK button to exit without saving.

The dierent features that can be edited are:

GYRO MODE (ON/OFF): This is for use with specically designed

tail rotor servos. These servos generally use a dierent neutral and

endpoints than other servos. Turning this feature on will automatically

reset the pulse widths and frame rate for testing. Do not use this

setting unless the servo being tested states it is a high frame rate tail

rotor servo.

PULSE_w (Pulse Range): For setting the Pulse Width Test

parameters for a servo. The adjustments are made to middle

(neutral), minimum and maximum endpoints. To edit a point, highlight

it using the Adjust Dial and then press the dial to begin editing.

The range for each is:

Mid: 1100 – 1900 microseconds

Min: 100 – 1500 microseconds

Max: 1500 – 2520 microseconds

Note: Adjust these settings with caution. If the pulse is too wide,

the servo may stall which will cause damage.

PULSE_p (Frame Rate): The Frame Rate is how fast the signal

is sent to the servo. The lower the number the faster the signal is

sent. The range is from 3 milliseconds to 30 milliseconds. Caution is

required as analog servos cannot handle frame rates faster than 14

milliseconds. Doing so will cause damage.

STEP VALUES: The increments moved when testing. The range is

from 0.25 microseconds

to 1 microsecond.

TEST: The speed and number of cycles to test at when using AUTO

E/S/S mode.

The ranges are:

Speed: 0.1 second to 5.0 seconds.

Count: 0 - 50000 cycles.

LCD Contrast: Change the LCD screen contrast for better

personalized viewing.

SET Default: Revert all settings to their defaults.

To program the dierent series of Hitec digital servos, plug the servo

into the SERVO port of the programmer and the battery or receiver

into the BATT/RX port. Once connected, move the selector switch

to the PROG position. On the SERIES SELECTION screen, use the

Adjust Dial to select the appropriate series of the servo connected.

Press the dial to enter the menu. Each setting is selected with the

Adjust Dial. Once highlighted, press the dial to edit.

Note: It is highly recommended that the servo being programmed

is not connected to any linkage.

1. EPA Neutral Settings

Press the Adjust Dial to enter the menu. If the Pulse Dial is o center,

the program will ask that the dial is center so the indicator is at 12

o’clock. Once adjusted, the Neutral Settings screen will appear. Use

the Adjust Dial to elect either to change the Neutral position or to

skip and move on to the endpoints.

To change the Neutral position, highlight NEUTRAL, and press the

Adjust Dial to enter the edit mode. To make an adjustment, use the

Pulse Dial. To save the setting to the servo, press the Adjust Dial,

otherwise, press the BACK button to exit without making a change.

Note: Changing the neutral position to an extreme will affect the

throw of the servo’s endpoints. Try to never vary the position too

far from nominal. Also, if the neutral position is programmed, then

the endpoints must be programmed.

The endpoints can be programmed without setting the neutral

position. To do this, highlight ‘Skip to Neutral Set’ and press the

Adjust Dial.

To set the Left or Right position of the throw, highlight the direction

and press the Adjust Dial to edit. Once in editing, use the Pulse Dial

to make changes. Press the Adjust Dial to conrm or the BACK

button to exit without saving.

After making changes to the servo’s EPA settings, use the BACK

button to return to the main screen. This will save the settings to the

servo. Once back at the main screen, the recently saved changes will

show below the EPA Neutral Settings.

Note: The Hitec Digital Servos are programmed to match a .9 to

2.1 millisecond pulse width with 1.5 millisecond pulse as neutral.

When plugged into a receiver, the programmed positions might

vary slightly due to manufacturing differences from radio to radio.

EPA percentages and subtrim might have to be used for nal

adjustment.

2. Servo Sync

To match two brushless servos together, use the Servo Sync option

when programming endpoints. The rst step is to program and

save the rst servo at the desired positions. Exit the programming

mode and then place the programmed servo into the SYNC slot of

the HFP-30. Place the next servo into the servo slot and enter the

programming mode. Enter the EPA and Neutral Setting menu and

begin programming the servo. As the servo’s endpoints are adjusted,

you will see the servo in the SYNC slot move to its preprogrammed

endpoints allowing easy matching of the new servo and those

positions.

3. Rotation (CW_CCW)

Highlight CW_CCW on the main screen and press the Adjust Dial to

enter the menu. Under the Now Values will be the current rotation

direction. Below will be the value to set. Use the Adjust Dial to

change from CW to CCW. Once at the desired rotation, press the

Adjust Dial to save the value to the Now Values. Press the BACK

button to exit to the main menu.

Settings D Series Program Mode

Programming

4. Deadband (DB_Width):

Highlight DB_Width on the main screen and press the Adjust Dial to

enter the menu.

Note: Hitec Digital Servos from the factory are set to the tightest

Deadband possible by default. Even if the Deadband can be set

lower with the programmer, it will have no effect on the servo.

Once in the menu, the current Deadband is displayed under Now

Values. Use the Adjust Dial to change the value under the ‘Set

Values’. When the desired Deadband is reached, press the Adjust

Dial to save the value to ‘Now Values’. Use the BACK button to exit

to the main menu. Values for the Deadband are 1-10.

5. Speed:

At times, it is required to slow a servo down for a desired application.

Highlight Speed in the main menu and press the Adjust Dial. Once

in the menu, the current speed is displayed under ‘Now Values’. Use

the Adjust Dial to change the value under the ‘Set Values’. Once the

desired speed is reached, press the Adjust Dial to save the value to

Now Values. Use the BACK button to exit to the main menu. Values

for speed are 10 – 100%.

6. ID (ID_Read):

With D Series servos, you have the ability to assign an individual ID

number. On the main menu, the current ID is displayed. To change it,

highlight ID_Read and press the Adjust Dial to enter the menu. In the

menu, adjust the ID number and press the Adjust Dial to assign it.

Use the BACK button to exit to the main menu.

7. Failsafe:

Sometimes it is desired to have the servo go to a preset position

with loss of signal. To program and turn on the feature enter the

menu. To enter the menu, use the Adjust Dial to scroll to page 2

of the main menu and press the dial once highlighted. Follow the

on-screen instructions and center the Pulse Dial. Current Failsafe

settings are listed under ‘Now Values’. Use the Pulse Dial to set the

Failsafe position. Once set, use the Adjust Dial to turn Failsafe on or

o. Press the Adjust Dial to the save setting to the servo. The new

setting will be displayed in the ‘Now Values’. Use the Back button to

exit the menu.

8. Soft Start:

1. EPA Neutral Settings

Press the Adjust Dial to enter the menu. If the Pulse Dial is o center,

the program will ask that the dial be moved so the indicator is at 12

o’clock. Once adjusted, the Neutral Settings screen will appear. Use

the Adjust Dial to elect either to change the Neutral position orto skip

and move on to the endpoints.

To change the Neutral position, highlight NEUTRAL, press the Adjust

Dial to enter edit mode. To make an adjustment, use the Pulse Dial. To

save the setting to the servo, press the Adjust Dial, otherwise, press

the BACK button to exit without making a change.

Note: Please note that changing the Neutral position to an extreme

will affect the throw of the servo’s endpoints. Try to never vary

the position to far from nominal. Also, if the Neutral position is

programed, then the endpoints must be programmed.

The endpoints can be changed without setting the Neutral position. To

do this, highlight ‘Skip to Neutral Set’ and press the Adjust Dial. To set

the Left or Right position of the throw, highlight the direction and press

the Adjust Dial to edit. Once in editing, use the Pulse Dial to make

changes. Press the Adjust Dial to conrm or the BACK button to exit

without saving.

2. Servo Sync

To match two servos together, use the Servo Sync option when

programming Neutral and Endpoints. The rst step is to program and

save the rst servo at the desired positions. Exit the programming

mode and then place the programmed servo into the SYNC slot of

the HFP-30. Place the next servo into the Servo slot and enter the

programming mode. Enter the EPA and Neutral Setting menu and

begin programming the servo. As the servos neutral and endpoints

are adjusted, you will see the servo in the SYNC slot move to its

preprogrammed center and endpoints allowing easy matching of the

new servo and those positions.

5xxx/7xxx Series Program Mode

The Soft Start feature, depending on the setting, allows the servo

to either quickly or slowly move to the received signal when rst

turned on. Once it reaches the correct position, normal operation of

the servo resumes. By default, this feature is enabled on D Series

servos. To enter the menu, use the Adjust Dial to scroll to page 2

of the main menu and press the dial once highlighted. Current Soft

Start settings are list under ‘Now Values’. To change the values, turn

the Adjust Dial to the desired percentage and press the dial to set it.

The new setting will be displayed in the ‘Now Values’. Use the Back

button to exit the menu.

9. Factory Default (Factory Default Set):

Sometimes it is best to restore the servo back to Factory Default

settings. To enter the menu, use the Adjust Dial to scroll to page 2 of

the main menu and press the dial once highlighted. Follow the on-

screen prompts to reset the servo. Once each prompt is completed,

the corresponding box will say ok. After the last one, the servo will

be reset to factory defaults.

degrees. If turned o, total programmable throw is 180 degrees. To

adjust the resolution, highlight the High_Resolution menu and press the

Adjust Dial to enter. The current status is displayed under ‘Now Status’.

To change the status, use the Adjust Dial to change the highlighted on

or o and press the dial to save. Use the Back button to exit the menu.

8. Overload Protection:

Hitec 7xxx Series Digital Servos can be programmed with Overload

Protection. By default, this setting is set to o. To adjust the Overload

Protection, highlight ‘OLP Set’ and press the Adjust Dial. The current

status is displayed under ‘Now Status’. Use the Adjust Dial to change

to the desired value and press the dial to save. The OLP range is o –

50%, in 10% increments.

9. Factory Default (Factory Default Set):

Sometimes it is best to restore the servo back to Factory Default

settings. To enter the menu, use the Adjust Dial to scroll to page 2 of

the main menu and press the dial once highlighted. Follow the on-

screen prompts to reset the servo. Once each prompt is completed,

the corresponding box will say ok. After the last one, the servo will be

reset to factory defaults.

1. EPA Neutral Settings

Press the Adjust Dial to enter the menu. If the Pulse Dial is o center,

the program will ask that the dial be moved so the indicator is at 12

o’clock. Once adjusted, the Neutral Settings screen will appear. Use

the Adjust Dial to elect either to change the neutral position or to

skip and move on to the endpoints. To change the neutral position,

highlight NEUTRAL, press the Adjust Dial to enter edit mode. To make

an adjustment, use the PULSE dial. To save the setting to the servo,

press the Adjust Dial, otherwise, press the BACK button to exit without

making a change.

Note: Changing the neutral position to an extreme will affect the

throw of the servo’s endpoints. Try to never vary the position too far

from nominal. Also, if the neutral position is programmed, then the

endpoints must be programmed.

The endpoints can be changed without setting the neutral position. To

do this, highlight ‘Skip to Neutral Set’ and press the Adjust Dial.

To set the left position, highlight LEFT and press the Adjust Dial. To

activate, turn the Pulse Dial all the way to the left (counterclockwise).

Once activated, turn the Pulse Dial to the right (clockwise) to set the

desired throw in the left position. Press the Adjust Dial to save the

setting or press the BACK button to exit without saving.

To set the right position, highlight RIGHT and press the Adjust Dial. To

activate, turn the Pulse Dial all the way to the right (clockwise). Once

activated, turn the Pulse Dial to the left (counterclockwise) to set the

desired throw in the right position. Press the Adjust Dial to save the

setting or press the BACK button to exit without saving.

Brushless (BLDC) Series Program Mode

3. Rotation (CW_CCW)

Highlight CW_CCW on the main screen and press the Adjust Dial to

enter the menu. Under the Now Values will be the current rotation

direction. Below will be the value to set. Use the Adjust Dial to change

from CW to CCW. Once at the desired rotation, press the Adjust Dial

to save the value to the Now Values. Press the BACK button to exit to

the main menu.

4. Deadband (DB_Width):

Highlight DB_Width on the main screen and press the Adjust Dial to

enter the menu.

Note: Hitec Digital Servos from the factory are set to the tightest

Deadband possible by default. Even if the Deadband can be set

lower with the programmer, it will have no effect on the servo.

Once in the menu, the current Deadband is displayed under Now

Values. Use the Adjust Dial to change the value under the Set Values.

Once the desired Deadband is reached, press the Adjust Dial to save

the value to Now Values. Use the BACK button to exit to the main

menu. Values for the Deadband are 1-16.

5. Speed:

Highlight Speed in the main menu and press the Adjust Dial. Once it

the menu, the current Speed is displayed under Now Values. Use the

Adjust Dial to change the value under the Set Values. Once the desired

speed is reached, press the Adjust Dial to save the value to Now

Values. Use the BACK button to exit to the main menu. Values for the

speed are 1 – 64, with 1 being the slowest and 64 the fastest.

6. Failsafe

Sometimes it is desired to have the servo go to a preset position when

it loses signal. To enter the menu, use the Adjust Dial to scroll to page

2 of the main menu and press the dial once highlighted. Follow the on-

screen instructions and center the Pulse Dial. Current Failsafe settings

are listed under ‘Now Values’. Use the Pulse Dial to set the Failsafe

position. Once set, use the Adjust Dial to turn Failsafe on or o. Press

the Adjust Dial to save the setting to the servo. The new setting will be

displayed in the ‘Now Values’. Use the Back button to exit the menu.

7. High Resolution:

Hitec 7xxx Series Digital Servos have a high resolution circuit that

can be turned on or o. When on, total programmable throw is 120

2. Servo Sync

To match two servos together, use the Servo Sync option when

programming Neutral and Endpoints. The rst step is to program and

save the rst servo at the desired positions. Exit the programming

mode and then place the programmed servo into the SYNC slot of

the HFP-30. Place the next servo into the Servo slot and enter the

programming mode. Enter the EPA and Neutral Setting menu and

begin programming the servo. As the servo’s neutral and endpoints

are adjusted, you will see the servo in the SYNC slot move to its

preprogrammed center and endpoints allowing easy matching of the

new servo and those positions.

3. Rotation (CW_CCW):

Highlight CW_CCW on the main screen and press the Adjust Dial to

enter the menu. Under the Now Values will be the current rotation

direction. Below will be the value to set. Use the Adjust Dial to change

from CW to CCW. Once at the desired rotation, press the Adjust Dial to

save the value to the Now Values. Press the BACK button to exit to the

main menu.

4. Deadband (DB_Width):

Highlight DB_Width on the main screen and press the Adjust Dial to

enter the menu.

Note: Hitec Digital Servos from the factory are set to the tightest

Deadband possible by default. Even if the Deadband can be set

lower with the programmer, it will have no effect on the servo.

Once in the menu, the current Deadband is displayed under Now

Values. Use the Adjust Dial to change the value under the Set Values.

Once the desired Deadband is reached, press the Adjust Dial to save

the value to Now Values. Use the BACK button to exit to the main

menu. Values for the Deadband are 1-20.

5. Speed:

Highlight Speed in the main menu and press the Adjust Dial. Once

in the menu, the current speed is displayed under Now Values. Use

the Adjust Dial to change the value under the Set Values. Once the

desired speed is reached, press the Adjust Dial to save the value to

Now Values. Use the BACK button to exit to the main menu. Values for

speed are 10 – 100%.

6. Failsafe:

Sometimes it is desired to have the servo go to a preset position when

it loses signal.

To enter the menu, use the Adjust Dial to scroll to page 2 of the main

menu and press the dial once highlighted. Follow the on-screen

instructions and center the Pulse Dial. Current Failsafe settings are

listed under ‘Now Values’. Use the Pulse Dial to set the Failsafe

position. Once set, use the Adjust Dial to turn Failsafe on or o.

Press the Adjust Dial to save setting to servo. The new setting will be

displayed in the ‘Now Values’. Use the Back button to exit the menu.

7. Soft Start:

The Soft Start feature, depending on the setting, allows the servo to

either quickly or slowly move to the received signal when rst turned

on. Once it reaches the correct position, normal operation of the servo

resumes. By default, this feature is enabled on D Series servos. To

enter the menu, use the Adjust Dial to scroll to page 2 of the main

menu and press the dial once highlighted. Current Soft Start settings

are listed under ‘Now Values’. To change the values, turn the Adjust

Dial to the desired percentage and press the dial to set it. The new

setting will be displayed in the ‘Now Values’. Use the Back button to

exit the menu.

8. Factory Default (Factory Default Set):

Sometimes it is best to restore the servo back to Factory Default

settings. To enter the menu, use the Adjust Dial to scroll to page 2 of

the main menu and press the dial once highlighted. Follow the on-

screen prompts to reset the servo. Once each prompt is completed,

the corresponding box will say OK. After the last one, the servo will be

reset to factory defaults.

NOTES:

Hitec RCD USA, Inc. | 12115 Paine St., Poway CA, 92064

Contact Information

Table of contents

Other Hi-Tec Motherboard manuals