Hi-Tech Diamond Slant Cabber Glass/Crystal User manual

INSTRUCTION MANUAL

Slant Cabber

GLASS/CRYSTAL MODEL

EST. 1984

HI TECH

EST. 19 84

HI TECH

2

SAFETY INSTRUCTIONS

IMPORTANT! READ FIRST

For your own safety be sure to read, understand and follow all warnings, safety rules and

instructions in this instruction manual before using this machine. Failure to do so can

result in serious personal injury. This instruction manual is intended for the following

machine models: 20-011, 20-013, 20-004 and 20-005.

Save these instructions

SETUP

• Intended for indoor use only.

• Avoid dangerous environments. Do not use

this machine near gasoline or other flammable

liquids.

• Make sure machine is securely placed on a

sturdy, level surface with ample working area

and away from open electrical outlets.

• Check for damaged parts. Before use of this

machine, always check for any damaged parts

to determine that it will operate properly and

perform its intended function. Check for proper

alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any

other conditions that may aect its operation. A

part that is damaged must be properly replaced

through the manufacturer of this machine to

avoid risk of injury.

• Use only identical Slant Cabber parts for

replacement parts. Use of any other parts not

originally intended for the Slant Cabber create a

hazard or cause product damage.

• Use only recommended accessories. The use

of improper accessories on this machine may

cause risk of injury.

• Know your power tool. Read this instruction

manual carefully. Learn the correct applications

and limitations as well as specific warnings and

hazards related to this machine.

USAGE

• Always wear proper apparel. Do not wear any

loose clothing, gloves, neckties or jewelry that

can get caught in the machine’s moving parts.

Long hair must be secured with a rubber band or

hair tie.

3

SAFETY INSTRUCTIONS

• Always wear proper eye protection to protect

you from any debris that may fly out while

grinding. We recommend wearing safety goggles

or safety glasses with side shields. Everyday

glasses are not safety glasses. If anyone is around

the machine while it is in use, they must wear

safety glasses.

• Keep work area well lit and clean. Make sure

your work area is not cluttered.

• Do not operate unattended. Adult supervision

is required at all times. Never leave the machine

running unattended.

• Do not operate this machine while under the

influence of drugs, alcohol or any medication.

• Never run discs dry. Make sure there is

adequate water used while grinding so that

rock dust is not formed. This dust contains

chemicals that can be hazardous to your lungs

if inhaled and is known to cause cancer, birth

defects or other reproductive harm. To reduce

your exposure to these chemicals, work in a well

ventilated area and wear a face or dust mask if

the grinding operation is dusty.

• Use only water as a coolant.

• Never grind more than one workpiece at a

time.

• Some rocks contain poisonous elements.

Avoid grinding rocks that contain uranium,

mercury, lead, arsenic, etc. Make sure you know

the material you are grinding.

• Do not allow water to run down the sha

and into the motor. This will cause the motor to

instantly burn out. This machine is designed in such

a way that this does not occur with normal use.

• Do not force the tool or attachment to do a job

it is not designed to do.

• Discs continue to spin aer turn o,

eventually slowing to a stop.

• Avoid awkward operations and hand

positions. Make sure you have good balance

while working on this machine. A sudden slip

could cause your hand to move into the disc.

MAINTENANCE

• Always disconnect from power before

servicing. Disconnect machine from power

source before making any adjustments and when

not in use.

• Do not abuse the power cord. Never carry

the machine by the cord or yank it to disconnect

from receptacle. Keep cord away from heat, oil

and sharp edges.

• Do not open the blue machine housing. There

are no user serviceable parts inside.

• Clean and dry machine aer use.

4

TABLE OF CONTENTS

SAFETY INSTRUCTIONS 2

WARRANTY INFORMATION 5

MACHINE DETAILS 6

OPERATING INSTRUCTIONS 7

GRINDING AND POLISHING 8

MAINTENANCE 10

PRO-FLOW WATER COOLING SYSTEM 11

ACCESSORIES 12

FAQS 14

TROUBLESHOOTING 15

REGISTER YOUR PRODUCT

Register your Hi-Tech Diamond Slant Cabber at

hitechdiamond.com/register to help facilitate

any warranty related requests. You can also

register your Slant Cabber by completing and

mailing us the enclosed registration form.

Complimentary mailing envelope is included for

your convenience.

5

ONE-YEAR LIMITED WARRANTY

What does this warranty cover?

This warranty covers all parts of your Hi-Tech

Diamond motorized equipment. This includes the

4" Trim saw, 5" Trim saw, 6" Trim saw, 10" Slab

saw, All-U-Need and Slant Cabber.

What does this warranty not cover?

This warranty does not cover problems resulting

from abuse, misuse, intentional damage,

incorrect usage, failure to adequately take care

of the machine or improperly following the

instructions. This warranty also excludes all Hi-

Tech Diamond accessories. Per industry standard,

consumable items such as saw blades, diamond

abrasives and polishing accessories will not

receive our one-year warranty service.

Who is covered under this warranty?

This warranty covers the original purchaser of the

equipment and is non-transferable.

What is the warranty period?

This warranty service is in force for one full year

from the date of your purchase. Please retain

the original invoice of your machine for proof

of warranty or register your product.

Reentel International Inc. stands behind the quality of its Hi-Tech Diamond machines.

That’s why they’re warranted to be free from defect for one full year from the

date of purchase. Registering your product helps facilitate warranty requests.

Whom should I contact if I need a

warranty service?

Contact Hi-Tech Diamond directly by phone

at 1 (630) 596-9909 or by email at sales@

hitechdiamond.com and we will assist you

through our warranty service. You must prove

that you are under warranty by providing us

with the original invoice of your machine or

by registering your product in order to receive

our warranty service.

6

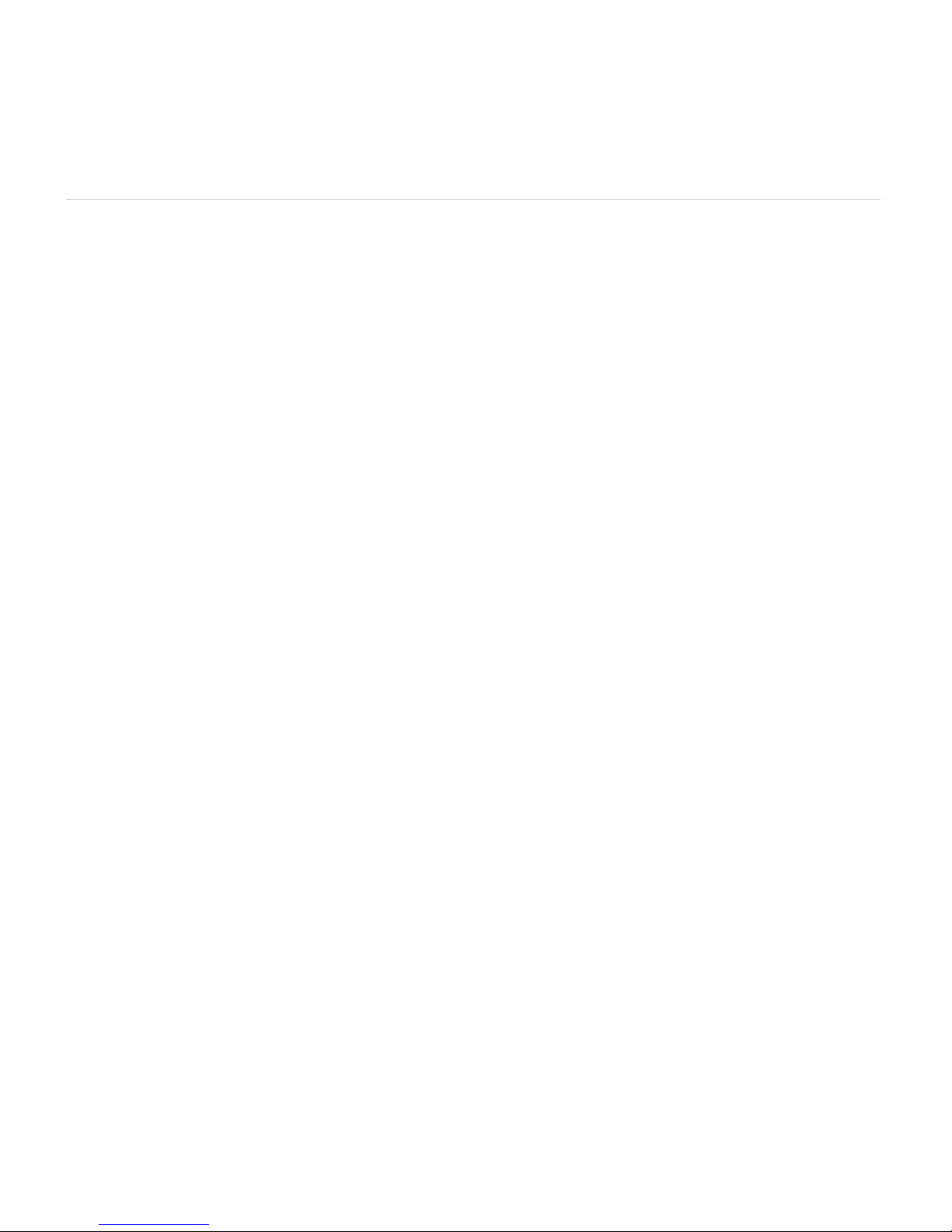

MACHINE DETAILS

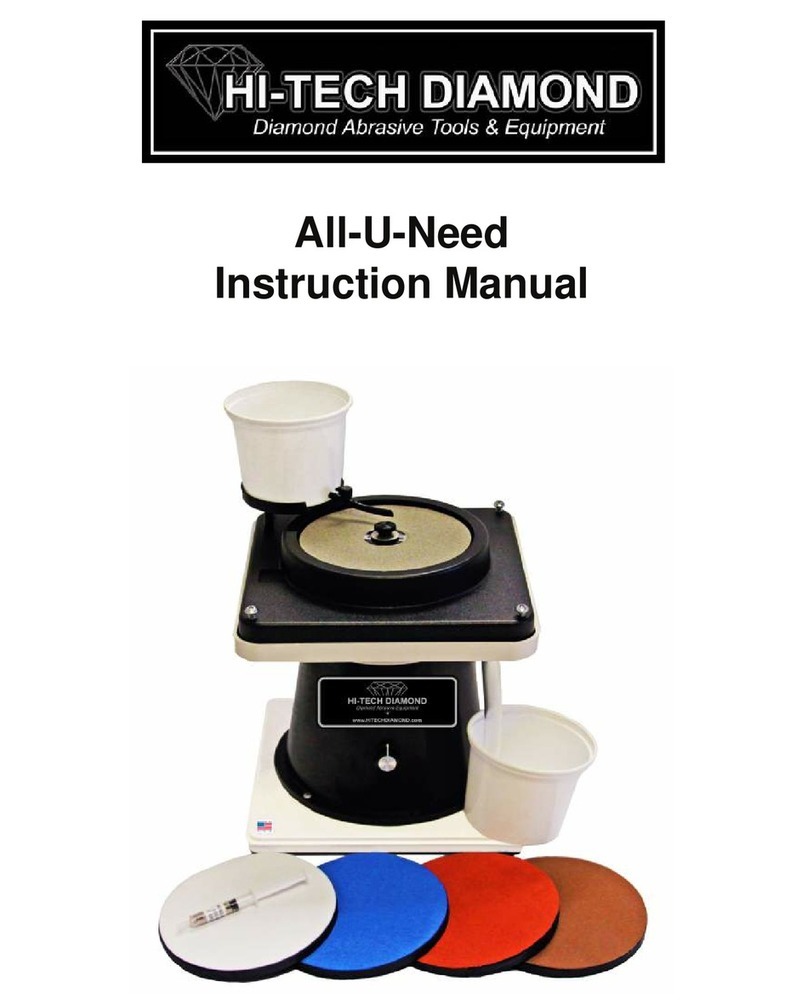

This image shows parts and accessories included with your Slant Cabber machine

SPEED CHART

The motor installed in the Slant

Cabber is variable speed, delivering

speeds of 800 rpm - 3,400 rpm. Use

this speed chart as a guide so you

can work at the speed you desire.

These values are approximate. Actual

speeds may vary.

3,400 rpm 800 rpm

1,800 rpm

2,300 rpm

1,200 rpm2,900 rpm

1

2

3

4

6

5

8

1. On/o power control knob

2. Modular water tube with

water control valve

3. Silver arbor with black

knob and washer

4. Slant Cabber base unit

(1/4 hp variable speed motor)

5. Black spray shield

6. Clear drain tube (included

with instruction manual)

7. 3/32" Allen wrench

(included with instruction

manual)

8. 360# diamond disc with

acrylic backing plate

9. 600# diamond disc

10. 1,200# diamond disc

11. 3,000# diamond disc

12. Tech-11 polishing pad

with 14,000# diamond paste

syringe

13. Acrylic backing plate - to

be used with Tech-11 pad

14. Disc bushing - inserts

into backing plate arbor hole

7

910 11 12

14

13

7

OPERATING INSTRUCTIONS

1Carefully unpack the Slant Cabber from

the box and remove all loose foam and

accessories. Set the packaging aside should

you need it in the future. Check to make sure

all parts are present on both the machine and

in the accessory kit. If you find any missing or

damaged parts, call us immediately at 1 (630)

596-9909 or email us at sales@hitechdiamond.

com. Place the Slant Cabber on a table or surface

that is flat in a well lit location. Make sure the

machine sits level.

2

Set up the water system by inserting the clear

drain tube into the fitting located on the right

side of the machine. Place the other end of the

tube into a bucket (not included). Fill the top water

reservoir with clean water. Adjust the flexible

modular water tube to the center of the disc (Fig.

A). This allows the water to spread evenly across

the surface of the discs while they spin. Never

re-use water. Note: To install the optional Pro-Flow

water cooling system, see page 11.

3

Included in the Slant Cabber accessory kit

are four nickel-electroplated diamond discs,

one Tech-10 polishing pad, one 2-gram diamond

paste syringe and one acrylic backing plate. To

determine what disc you need to start with, see

page 8. To properly install your discs, place the

backing plate onto the arbor (Fig. B). The backing

plate has a 1/2" arbor hole which fits snug onto

the lip of the arbor. Next, place the diamond disc

on top of the backing plate, making sure the 1/2"

arbor hole in the disc and the 1/2" arbor hole in

the backing plate are centered. Secure the disc

and backing plate with the ¼"-20 thread knurled

knob and washers (Fig. B). Make sure the disc has

even contact with the backing plate surface. Note:

Always use a backing plate for diamond discs or

polishing pads on the Slant Cabber.

4

Put on safety goggles (not included) and

turn the power switch on. Use the black

water control valve located on the centered

water tube to control the water flow on and o.

You only need a few constant drops of water to

lubricate the discs. Do not use wipers or sponges,

as they may become contaminated with larger

diamond particles. IMPORTANT NOTE: If water

isn’t coming out of the water tube aer

twisting the water control valve on, refer to

Troubleshooting on page 15.

5

The arbor may be adjusted up and down

using the included Allen wrench to keep the

discs below the black spray shield. See page 10

for arbor adjustment instructions.

Fig. A

Centered

water tube

Top water reservoir

Knurled knob

& washers Arbor

Fig. B

8

GRINDING AND POLISHING

STEP 1: ROUGHING

The 360# diamond disc is the coarsest disc that

comes with this Slant Cabber. If you have less than

a millimeter to remove, we suggest skipping this

step and begin at step 2. The 360# disc is required

if you need to remove a large amount of material

from your work piece, or to remove glass le from

the punty. Install the 360# disc according to the

instructions on page 7. Remove material until you

obtain the general shape, size or depth of your

finished piece.

STEP 2: SHAPING

The 600# diamond disc will either create your

first intial shape, or if you started at step 1,

remove the deeper scratches le by the 360# disc

and attain the final shape. Install the 600# disc

according to the instructions on page 7. Remove

material until you have a look simliar to a surface

having been roughly sandblasted.

STEP 3: SMOOTHING

The 1,200# diamond disc will remove scratches

le behind from step 2. Install the 1,200# disc

according to the instructions on page 7. Proceed

to grind until you have a finely frosted surface. A

properly shaped surface is perfectly smooth and

satiny in appearance. Rinsed and dried, you should

not see any scales (aka dimples, facets, flats, etc,)

or scratches. Hold it up to a bright light and look

for deep lines. Scales are most easily observed by

watching the piece dry. Because the “scales” will

have deeper puddles of water, they will evaporate

more slowly. Wet your piece and watch for this

phenomenon. If you see any scratches or scales,

you may not have smoothed long enough. If aer

additional smoothing you

360# diamond disc

600# diamond disc

1,200# diamond disc

9

GRINDING AND POLISHING

still see scratches or scales, they are too deep to

remove. You must return to step 1 (360# disc) and

start this process over. If aer this step, your piece

has a finely frosted finish, then you are ready to

move onto step 4.

STEP 4: PRE-POLISHING

The 3,000# diamond disc removes the satin-like

finish from the previous step. Install the 3,000#

disc according to the instructions on page 7. Your

goal aer this step is a very smooth, hazy surface.

There should be no visible scratches or scales at

this point. If you can still see scratches, you need

to go back to step 1. This disc preps your piece for

the final polish.

STEP 5: POLISHING

The Tech-10 polishing pad is used to put the final

polish on your material. You will need to charge

the Tech-10 polishing pad with the 14,000#

diamond paste before use. To do this, take the

diamond paste syringe, remove the cap and

squeeze the syringe plunger in a series of small

dots onto the surface of the Tech-10 pad (Fig.

C). Use your fingers to rub these small dots into

the pad. Once charged, you will only need to

apply additional diamond paste to the pad when

you notice that the pad is no longer polishing.

Using the Tech-10 polishing pad with water is

not required because the diamond compound

mixture contains its own carriers. However, if you

are working with brittle, heat sensitive material,

such as opal, be careful not to let your work

piece overheat. To avoid overheating, use a very

small amount of clean water to keep your work

piece cool or simply lower the RPM to reduce

heat buildup. Note: Use only one type of polishing

compound per Tech-10 polishing pad. Do not mix.

3,000# diamond disc

Fig. C

Tech-10 polishing pad with

14,000# diamond paste syringe

10

MAINTENANCE

OILING & ARBOR ADJUSTMENTS

The only part you need to oil on the Slant Cabber

machine is the inside of the 2" silver arbor. This is

required because the motor sha and arbor are

made of dierent materials. Over time, they can

seize together, making it impossible to remove

the arbor. Every two months or so, remove the

arbor by inserting the included Allen wrench into

the set screw, turning counter-clockwise. Turn the

arbor upside down. Apply a few drops of motor

oil, way oil, lithium or water pump grease into the

area where the arbor fits onto the sha. Make

sure there is no excess oil so that oil doesn’t drip

down the motor sha and get into the motor.

This will cause an instant motor burn-out. When

putting the arbor back onto the sha, make sure

the screw is positioned against the flat side of the

motor sha. If the screw is positioned against the

rounded side of the sha, it will make a squeak-

ing noise and create friction, causing the motor

sha to get hot. Once the arbor is positioned

properly, check the set screw for tightness on the

arbor using the Allen wrench. Do not over tighten

the set screw. The arbor may be adjusted up and

down as necessary to keep the spinning disc

below the black spray shield.

CLEANING

The Slant Cabber is designed to be easily

cleaned. Aer each use, flush out the bottom

water reservoir with clean water so the rock

sediment gets washed down the drain tube. Any

used water must not be disposed down a sink, as

it can harden like cement, closing o the drain.

Allow the machine to dry completely then store it

in a safe place, away from children.

Note: When you are finished using the diamond

discs, rinse and spin completely dry. Store them in

a clean, dry plastic bag until next use. Maximum

weight of any discs/laps should not exceed 1.5lbs

on your Slant Cabber machine.

FUSE DETAILS

The fuse is installed in the back of the Slant Cab-

ber machine. It is a 250V, 2AMP slo-blo cartridge

fuse. If you need a replacement, this fuse can be

found at your local hardware store. See below for

how to change the fuse.

Set

screw

Push in with a flat head screwdriver, then turn to the le

(counter-clockwise)

Arbor

11

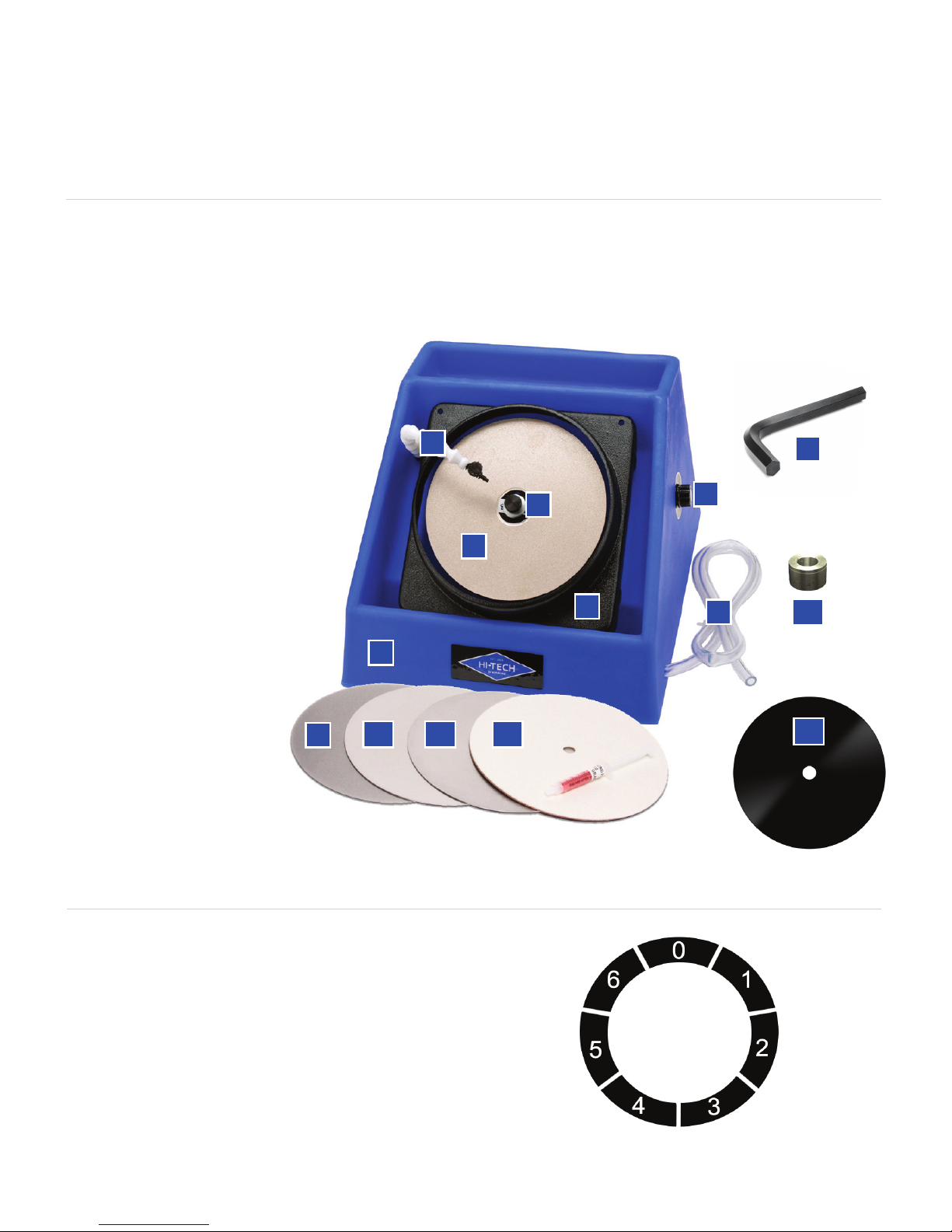

PRO-FLOW WATER SYSTEM

The Pro-Flow oers two innovative ways to increase the water reservoir capacity on the

Slant Cabber. If you’re looking for an eicient cooling system, then the Pro-Flow is for you.

Upgrade to the Pro-Flow water system today at hitechdiamond.com.

PRO-FLOW PRESSURE TANK

The Pro-Flow’s one-gallon pressure tank provides

hours of drips with the occasional priming.

Instead of filling the top water reservoir, fill the

pressure tank with clean water. Insert the black

tube connected to the pressure tank into the

tube located on the top water reservoir. Once

connection is secure, use the Slant Cabber as

normal and manually pump when needed.

PRO-FLOW WATER PUMP

The Pro-Flow’s submersible water pump provides

even more hours of drips than the pressure tank.

Instead of filling the top water reservoir, fill a

five-gallon bucket with clean water and place

the water pump in the bucket. Insert the Pro-

Flow tube connected to the water pump into the

tube located on the top water reservoir. Once

connection is secure, plug the water pump into

an electrical outlet and use the Slant Cabber as

normal. Water pumps available in 110V and 220V.

12

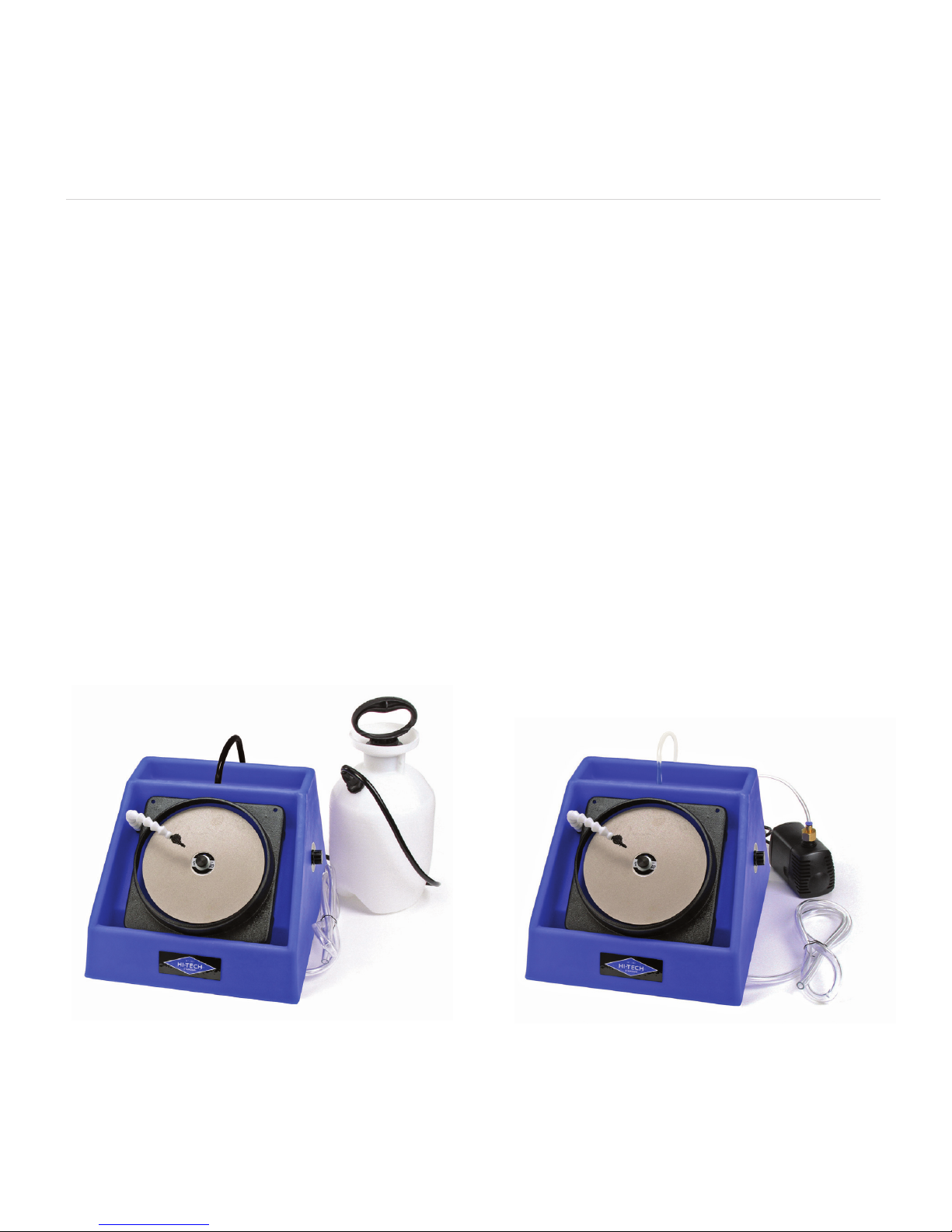

ACCESSORIES

Backing plates

Our 6" and 8" acrylic backing plates provide a

flat surface to back diamond discs, diamond

smoothing discs and polishing pads. They are

3/8" thick and have 1/2" arbor holes.

Tech-11 polishing pads

Our 6" and 8" Tech-11 polishing pads serve as a

general polishing pad to polish stone and glass.

Use with cerium oxide, tin oxide or diamond

compound.

Final polish pads

Our 6" and 8" final polishing pads are specially

designed to put a mirror polish on stone and

glass. They are pre-charged with cerium oxide so

you don’t need to mess with slurry or diamond

paste .

Electroplated diamond discs

Our 6" and 8" diamond discs are used for precise

rough and fine grinding on glass and stone.

They are nickel electroplated, using top grade

diamond powder. Discs are 1mm thick top plates.

Select from the following grits: 60#, 80#, 100#,

180#, 260#, 360#, 600#, 1,200# and 3,000#.

For more Hi-Tech Diamond products and accessories, visit hitechdiamond.com.

13

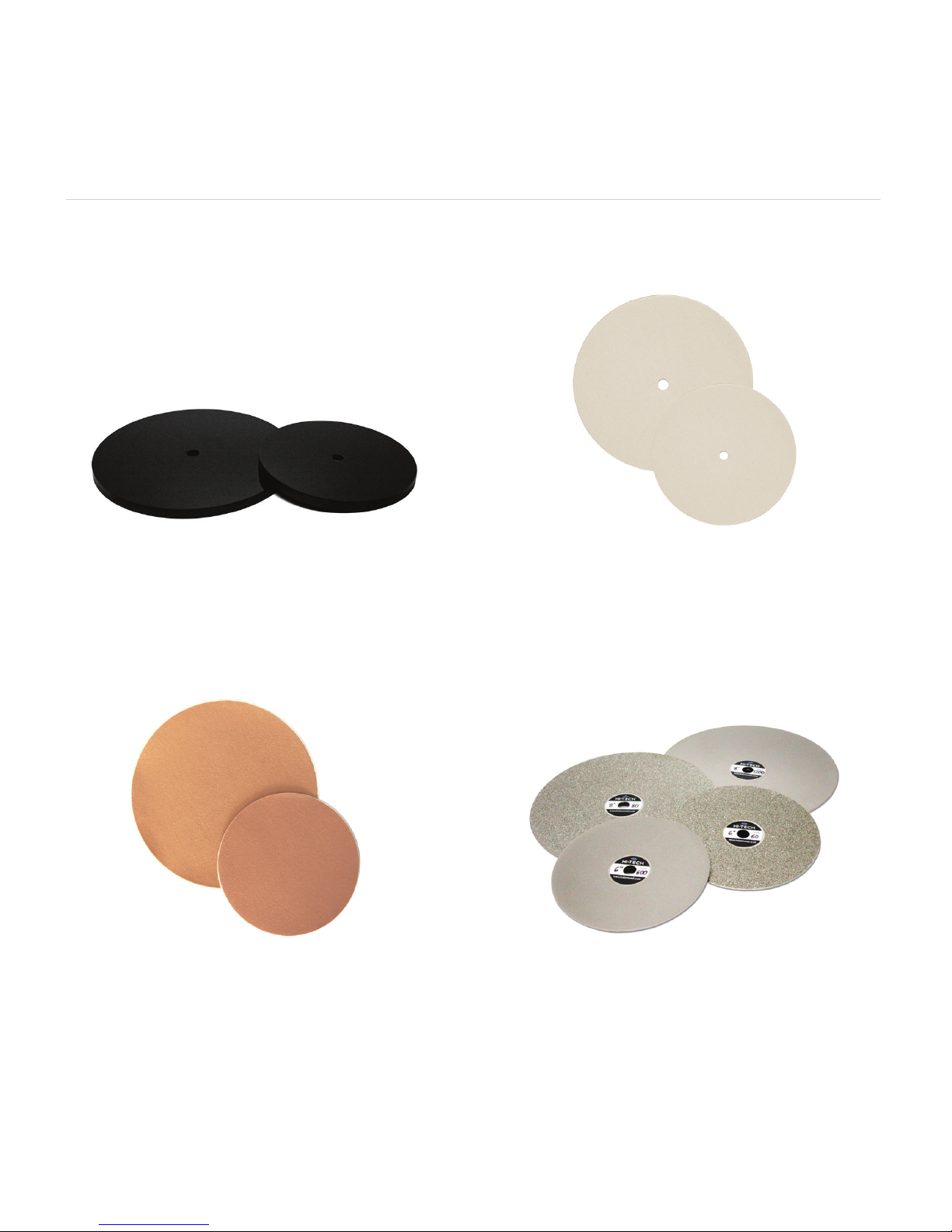

Glass/crystal disc kit

Our glass/crystal disc kit is the same accessory

kit included with this All-U-Need. It’s great for

replacing all of your discs at once. Kits include

the following: 360# disc, 600# disc, 1,200# disc,

3,000# disc, Tech-11 polishing pad, 14,000#

diamond paste and two backing plates.

Sponge pads

Our 6" and 8" sponge pads are used under

diamond smoothing discs and polishing pads to

provide a cushion that helps facilitate doming

into cabochons and removes flat spots. They are

1/8" thick and ideal for making cabochons.

Electroplated diamond laps

Our 6" and 8" diamond laps use high quality

diamond discs for precise rough and fine

grinding. This disc is then professionally bound

to an acrylic backing plate, making it ready to

use. Select from the following grits: 60#, 80#,

100#, 180#, 260#, 360#, 600#, 1,200# and 3,000#.

Diamond smoothing discs

Our 6" and 8" diamond smoothing discs are

used for smoothing, refining and polishing

gemstones, glass, synthetic material and metal.

Discs are available in the following grits: 220#,

325#, 600#, 1,200# and 3,000#.

ACCESSORIES

For more Hi-Tech Diamond products and accessories, visit hitechdiamond.com.

14

FAQS

What lubricants should I use with the

Slant Cabber?

Only use clean water with the Slant Cabber. If

desired, you may add a water soluble coolant to

the water.

Can I reuse water for diamond

grinding?

You can, but we don’t recommend this. When you

reuse water, you risk getting contamination on

your diamond discs which increases the chances

of unwanted scratches on your work pieces. For

best results, use clean water every time you use

the Slant Cabber.

How do I clean the bottom water

reservoir?

To prevent the drain tube from clogging with rock

sediment, flush the bottom water reservoir aer

each use. Take a small bucket of clean water and

pour the water into the reservoir so the leover

rock sediment gets flushed down the drain tube.

Once you see all of the sediment gone and the

reservoir is clean, your Slant Cabber will be ready

for the next use.

Do you sell electrical spare parts for

my Slant Cabber? Whom do I contact

if I need a repair or replacement for my

Slant Cabber?

Due to the technical nature of our machines,

we do not oer electrical spare parts for you to

install yourself such as motors, speed controllers,

rectifiers, etc. Instead, we oer a repair

service that is done in-house by our qualified

technicians. For more information about our

repair service, visit hitechdiamond.com/repairs.

15

TROUBLESHOOTING

My machine is vibrating...

The motor that is installed in the Slant Cabber

is variable speed, meaning you can adjust the

speed in-between the range of 800 rpm - 3,400

rpm. When the Slant Cabber runs at lower

speeds, you may experience a vibration. We

recommend running the Slant Cabber at higher

speeds to prevent this vibration. If you are still

experiencing a vibration aer running the Slant

Cabber at high rpms, check to see if your discs

are properly centered. If the diamond lap disc,

diamond smoothing discs or polishing pads are

not accurately centered with the 1/2" arbor hole

in the backing plate, this will cause a vibration.

Remember to always use your machine on a flat,

sturdy workbench or surface.

Water isn’t coming out of my water

tube.

This means an air bubble formed in the inner

tubing, causing a blockage in the water system.

Try one of two things:

1) Move the water tube clockwise in large circles.

2) Blow air through the top water reservoir fitting

using compressed air or a straw.

What should I do if the drain tube

keeps clogging with sediment?

If the drain tube keeps clogging with leover rock

sediment, simply flush out the sediment with lots

of clean water until the sediment gets flushed

down the drain tube. If a large piece of sediment

is clogged and stuck in the drain tube, use an air

spray gun to blow it out.

My Slant Cabber makes a high speed,

“whirring” sound. Is this normal?

Yes, this is a normal sound the Slant Cabber

makes. The “whirring” sound is produced by a

thin, white disc (also known as a slinger) that is

installed under the arbor and around the motor

sha. This disc prevents water from getting into

your motor.

My motor is beginning to rust, why is

this?

The only possible way the motor can rust is

if there is water getting into the motor. Water

should never get into the motor with the correct

water set up so if you are seeing rust, make sure

your water set up doesn’t allow water to drip into

the motor.

I can’t remove the arbor from the

motor shaft.

If you can’t remove the arbor from the motor

sha using the Allen wrench, it is most likely

because the arbor and motor sha seized

together. This is a result from not oiling the inside

of the arbor according to the oiling instructions

on page 10. If it impossible to remove, please

contact Hi-Tech Diamond at 1 (630) 596-9909 and

one of our specialized technicians will help you

over the phone for correct removal.

MANUFACTURED BY

Reentel International Inc.

808 Burr Oak Drive

Westmont, IL 60559

U.S.A.

PHONE

1 (630) 596-9909

EMAIL

WEBSITE

hitechdiamond.com

FACEBOOK

facebook.com/hitechdiamond

TWITTER

twitter.com/hitechdiamond

EST. 1984

HI TECH

Rev 07/31/18

EST. 19 84

HI TECH

This manual suits for next models

1

Table of contents

Other Hi-Tech Diamond Sander manuals

Popular Sander manuals by other brands

Kunzle & Tasin

Kunzle & Tasin NEW GOLIA PLUS User & maintenance manual

Hitachi

Hitachi S 18SB instruction manual

Surtek

Surtek LE612 User manual and warranty

Thomashilfen

Thomashilfen EASyS Advantage Assembly instructions-Accessory

Jepson

Jepson 3405 instruction manual

Parkside

Parkside 364419 2010 Translation of the original instructions