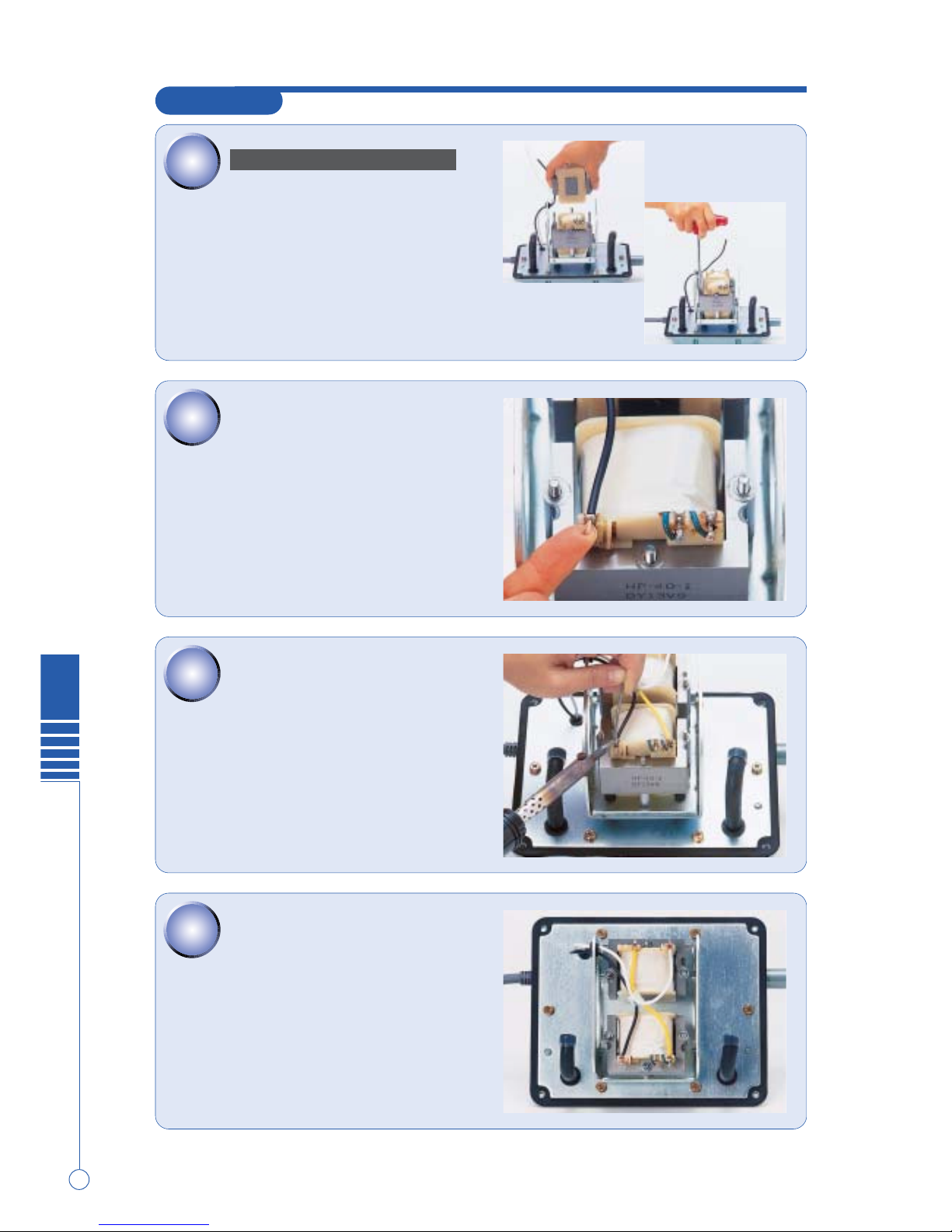

Introduction

We thank you very much purchasing our TECHNO TAKATSUKI

HIBLOW air pumps. The introduction of the first HIBLOW pump

was over twenty years ago. More than 3 million HIBLOW pumps

have now been produced and found widespread applications. This

guide book is explained comprehensible as everyone can repair

easily. Can be useful when repairing by all means. Also, please

utilize our maintenance tools for replacement.

What is ISO 9001?

In 1987, the International Organization for Standardization (ISO)

established its ISO 9000 standards. These internationally approved

standards provide specifications not for products but for quality-

assurance systems. ISO 9000 consists of three separate standards:

ISO 9001, 9002, and 9003. Of these, ISO 9001 is the most rigorous,

encompassing points ranging from design control to after-sales

service. To qualify for an ISO 9001 certificate, applicants must first

pass in-company, customer, and third-party audits. After receiving

ISO 9001 certification, regular checks are then conducted to ensure

that the company maintains the required standards. In addition,

management policies on product quality are documented and checked

against actual practice throughout the entire organization. In essence,

the ISO 9001 standard certifies that a company has not only

established an outstanding quality-control record, but has also proven

capable of sustaining this record.

The Product Liability Law

Japan's Product Liability Law was introduced in July 1995 in

response to the increasing difficulty consumers were having in

evaluating the quality of high-technology products and in claiming

damages associated with product defects. With the Product Liability

Law making it easier for customers to claim damages, manufacturers

must now assign a higher priority to quality control.At Techno

Takatsuki Co., Ltd., our response to the above developments was to

create a program that ensured our products were in compliance with

the Product Liability Law. At the same time, we implemented a full

range of safety measures. As a result of these efforts, we received

ISO9001 certification in December 1995, a testament to the high

quality of our product design and manufacturing systems. Despite

this initial success, we remain determined to further improve our

quality-control system, and look forward to the support of our

customers as Techno Takatsuki continues to evolve in years to come.