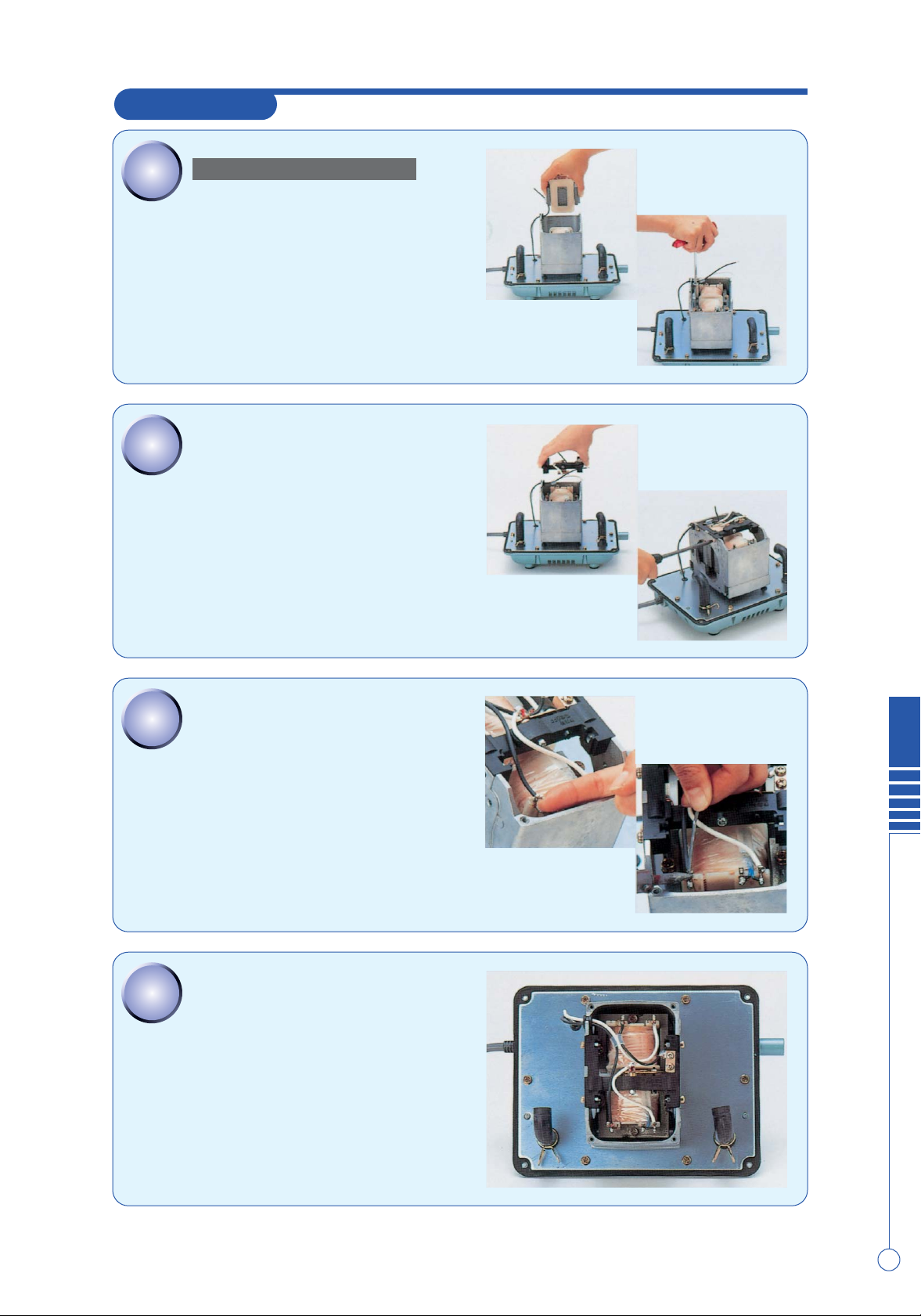

HIBLOW HP Series User manual

Other manuals for HP Series

3

This manual suits for next models

2

Table of contents

Other HIBLOW Pond Pump manuals

Popular Pond Pump manuals by other brands

TeichTip

TeichTip SUNSUN Adjustable SuperECO CET-8000 Operation manual

Mebner

Mebner system-X 750 operating instructions

Oase

Oase AquaMax Eco Premium 4000 Commisioning Guide

SunSun

SunSun SuperECO CET-15000 Operation manual

ubbink

ubbink PowerClear 5000 UVC Operating instruction

Hozelock Cyprio

Hozelock Cyprio Cascade 1500 Installation and operating instructions

Profi-pumpe

Profi-pumpe Solar Aqua-Vital 9-UV-C operating instructions

ubbink

ubbink AcquaArte Trente quick start guide

Danner

Danner Pondmaster 1250 Care and operating instructions

Hozelock Cyprio

Hozelock Cyprio Aquaforce Series Installation and operating instructions

Profi-pumpe

Profi-pumpe OASIS 501R-1 operating instructions

Pontec

Pontec PondoSolar Lily Island operating instructions