HIBLOW HP Series User manual

1

HP-150/200

HP

HP Series

STRUCTURE AND PART NAMES

HP-150

/

200

Air pump Start of production

Discontinuance of production

HP-150

HP-200

2001/9

2001/9

─

─

HP-150/200

漓 FilterCover

滷 SemiCoverPacking

澆 Filter

潺 FittingBoss

潸 UpperHousing

澁

SoundAbsorber(Lap)

澀 CasingA

潯

ValveChamberPacking

潛 CasingB

濳 Valve

潭 DiaphragmRing

澂 Diaphragm

潼 DiaphragmBase

潘 ActuatingRod

澎 SPSwitch

澑

Safetypin+Lockingcollar

濂 FrameStay

潦 Electromagnet

澳 FrameCover

澣 L-Tube

澡 HoseBand

澤

VibrationControlRubber

澹 CenterPlate

濆 Gasket

澪

SoundAbsorber(Filter)

濟 LowerHousing

濕 PowerCord

2

HP

ReplacingtheChamberBlock

HP-

150

/

200

REPLACING THE CHAMBER BLOCK

CAUTION!

●

Besuretounplugthepumpunit.

●

Replacethediaphragmsandthevalveswithnewonesatleastonceayeartooneand

ahalfyearregularlyinordertomaintaintheirinitialperformance.

●

For chamber block replacement, be sure to change both chamber blocks at the same

time.

●

The rod employs powerful permanent magnets. Therefore, be sure to remove your

watchandanyotherprecisionmachinesbeforeoperationastheymaybeaffectedby

thestrongmagneticforce.

●

Donotputtheactuatingrodclosetoamagneticcard,magneticdiskorothermagnetic

mediaasthedatamaybedestroyed.

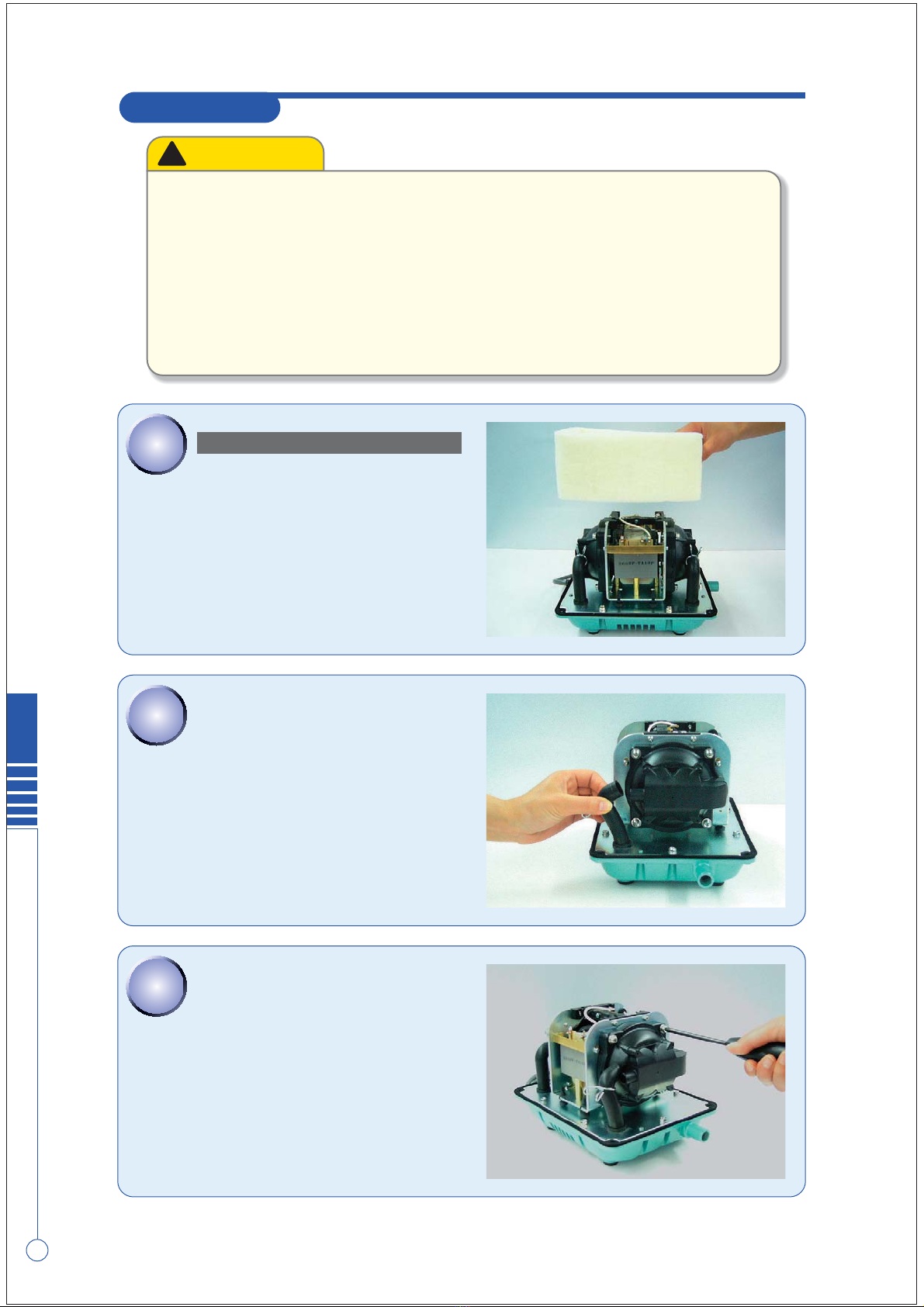

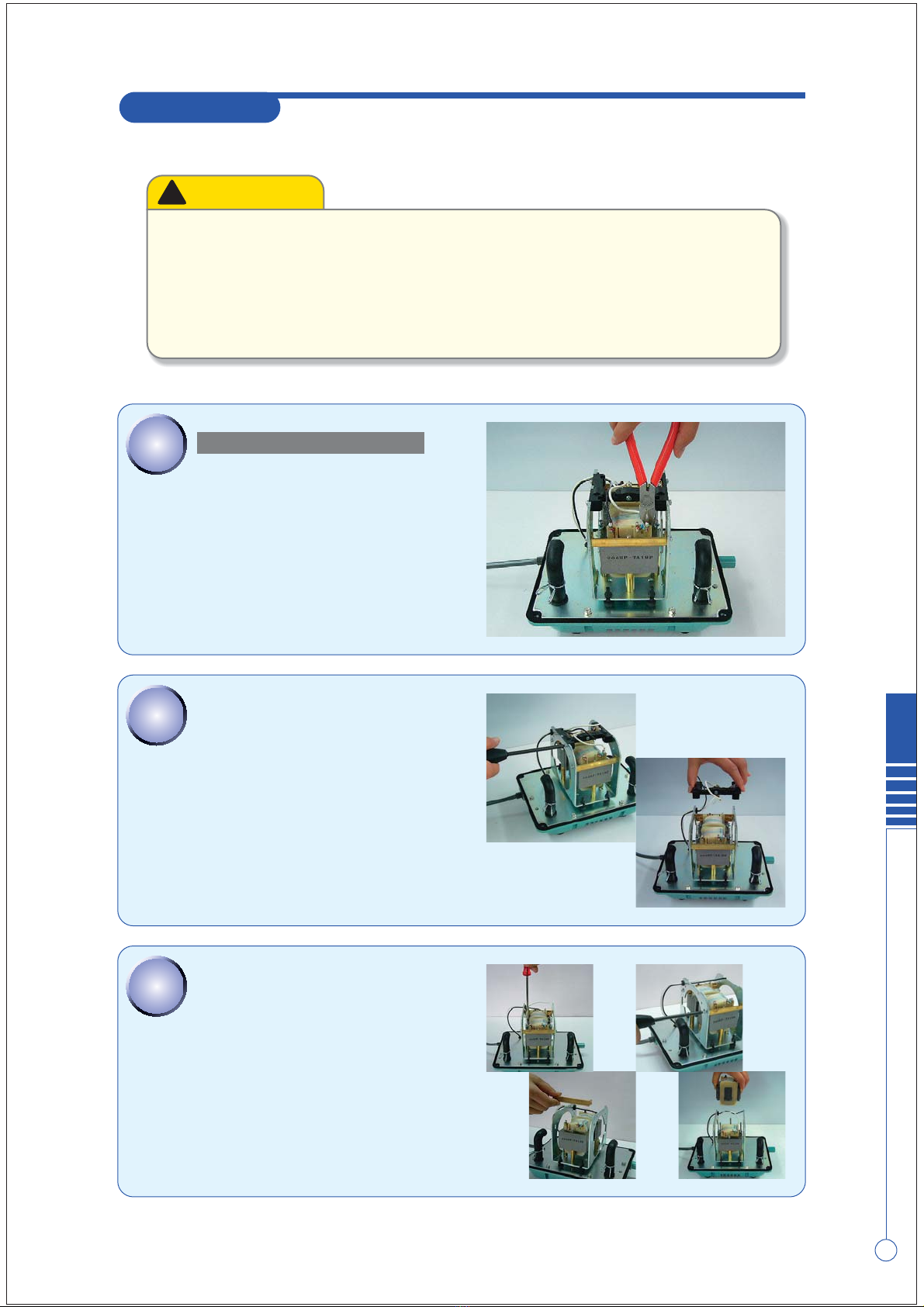

STEP

1

STEP

1

REMOVAL OF THE CHAMBER BLOCKS

Toremovetheupperhousing.

(Referto

REMOVINGUPPERHOUSING

)

Removethesoundabsorber.

STEP

2

STEP

2

PullouttheL-tubefromthecasingblock.

STEP

3

STEP

3

Remove the 4 screws holding the chamber block

andthecasingblock.

(4screwsoneachside)

3

ReplacingtheChamberBlock

HP

HP-

150

/

200

REPLACING THE CHAMBER BLOCK

STEP

4

STEP

4

STEP

5

STEP

5

STEP

6

STEP

6

In case of replacing the whole diaphragm

mountingblock,movestraighttoSTEP 11.

Removethediaphragmringfromthediaphragm,

and then, detach the diaphragm from the

diaphragmbase.

REPLACING THE DIAPHRAGM

Remove 2 U-lock nuts from one side holding the

diaphragmmountingblocktotherod.

●

Usethenutdrivertoloosen(ortighten)theU-locknut.

STEP

7

STEP

7

Fit a new diaphragm and diaphragm ring in the

diaphragmbase.

●

Besurenottoleaveagapbetweenthem.

Remove one of the diaphragm mounting blocks

from the actuating rod and pull out the other

diaphragm mounting block with the rod. After

that,separatethediaphragmmountingblockand

therod.

●

Whenpullingouttherod,besurenottocatchtherod

projectionontheleveroftheSPswitch.

●

If the pump stops automatically, the safety pin must be broken to prevent any

furtherdamagetothepump.Besureallbrokenpiecesareremovedfromtheunit.

(SeeStep14)

4

HP

ReplacingtheChamberBlock

HP-

150

/

200

REPLACING THE CHAMBER BLOCK

STEP

8

STEP

8

REPLACING THE VALVE

STEP

9

STEP

9

Inserteachnewvalveintothecenterholdofvalve

seat,andsecurethembypullingwithradiopliers.

●

When reinstalling the valves, make sure the exhaust

andintakesidesarecorrectlyfitted.

STEP

10

STEP

10

Cut away end of respective valves pulling parts

(justinfrontofthickparts)byscissorsornippers.

HoldthevalvechamberpackingbetweencasingA

andcasingB.

Then,fixthemwith5screws.

STEP

11

STEP

11

Fittheactuatingrodbyaligningitwiththegroove

andtightenU-locknutandflatwasherbythenut

driver.

●

UsenewU-locknutandwasher,otherwise,U-locknut

mayworklooseandcausemalfunction.

FITTING CHAMBER BLOCKS

In case of replacing the whole diaphragm casing

block,movestraighttoSTEP 11.

separate casing A and casing B, by removing 5

innerscrews.

RemovethevalvesfromcasingB.

●

If it is difficult to separate them, insert the tip of a

flatbladescrewdriverintotheclearance.

●

Pulloutthevalvesastheycanberemovedeasily.

●

Checkifthevalvechamberpackingisbroken.

CasingB

Valve

Chamber

Packing

CasingB

Valve

Chamber

Packing

CasingA

5

ReplacingtheChamberBlock

HP

HP-

150

/

200

REPLACING THE CHAMBER BLOCK

STEP

12

STEP

12

STEP

13

STEP

13

STEP

14

STEP

14

Checkthatthebrokenpinisremovedfromunit.

●

Ifthebrokenpinisleftinsidetheunit,itcangetcaught

in between electromagnets and actuating rod, which

cancausebreakdown.

REPLACEMENT OF SAFETY PIN

Inserttheactuatingrodintothemachinebody.Be

suretofitthepositioningbossonthediaphragm

baseintotheconcavepartoftheframestay.

Secure the diaphragm mounting block on the

other side and tighten washers and U-lock nuts

withthenutdriver.

Make sure that gap between the actuating rod

andtheelectromagnetsiseven.

Mountthecasingblockwithscrews(4screwson

eachside).

And insert L-tube into the nozzle of casing A.

Then,fixitwithhoseclip.

Completetheothercasingblockinthesameway.

STEP

15

STEP

15

Insert a new safety pin through the hole on the

terminalside.

(Please Insert safety pin through the spring

electrode,L-shapedleverinsuchorder.)

6

HP

ReplacingtheChamberBlock

HP-

150

/

200

REPLACING THE CHAMBER BLOCK

STEP

16

STEP

16

Installthelockingcollarfromtheothersideofthe

terminalandinsertituntilitclicks.

STEP

17

STEP

17

Thiscompletes the replacement ofthe safety pin

procedure.

Make sure the gap between L-shaped lever and

taboftheactuatingrodiseven.

●

Becarefulnottotouchtheterminalwhenthepoweris

on,testingtheoperatingconditionsasthiswillresultin

anelectricshock.

●

Unplugthepumpimmediatelyafterthecheck.

STEP

19

STEP

19

STEP

18

STEP

18

Installthesoundabsorber.

Placetheupperhousingbackonbody.

●

Be extremely careful not to catch the sound absorber

ontheupperhousing.

Fastenitwiththebolts.

Then, place the filter and filter cover on the

upper housing. (Refer to

FILTER CLEANING AND

REPLACEMENT

)

HP-

150

/

200

REPLACING THE ELECTROMAGNET

STEP

1

STEP

1

REMOVAL OF ELECTROMAGNET

Cutthewirefromtheterminalsonelectromagnets

withnippers.

●

Itisrecommendedthatyoumakeanoteofthewiring.

STEP

2

STEP

2

Loosenthescrew,fixingSPswitchandremoveit.

(There are hexagonal nuts at SP switch side. Be

surenottolosethemastheyfallinsidetheunit.)

STEP

3

STEP

3

Removethehexagonalnutsbythenutdriver.

(8mmwrench)

Loosen the screw holding the frame stay, and

removeit.

Pullouttheelectromagnetfromthepumpbody.

CAUTION!

●

Besuretounplugthepumpunit.

●

Whenperformingreplacementwork,thepumpbody may still be hot and you could

getburned.Sopleasewaituntilthepumphascooledbeforehandling.

●

Be sure to remove the chamber block and the actuating rod before replacing the

electromagnet.

●

Itisbettertoletanexperiencedtechnicianhandlethesolderingprocess.

Takeprecautionsagainstgettingburned.

7

ReplacingtheElectromagnet

HP

HP-

150

/

200

REPLACING THE ELECTROMAGNET

STEP

5

STEP

5

STEP

4

STEP

4

STEP

6

STEP

6

STEP

7

STEP

7

This completes the electromagnet replacement

procedure.

Insertthewireintothesilicontube,andtieupina

bundle.

Stripthecoatingoffeachwire.

(5-7mmfromtheend)

Connectthewirestotheterminals.

Solderthewirestotheterminals.

Thewirerequiresasolderedconnection.

Mountnewelectromagnetintheunit.

Fixframestaytemporarily.

(Do not tighten screw of frame stay and keep

themratherloose.)

Tightenuphexagonalnutswithnutdriver.

Fastenscrewsofframestay.

MOUNTING THE ELECTROMAGNET

InstalltheSPswitchtotheframewiththescrews.

●

Becarefulofthedirectionofswitchlever.(Refertothe

pictures)

8

HP

ReplacingtheElectromagnet

Other manuals for HP Series

3

This manual suits for next models

2

Table of contents

Other HIBLOW Pond Pump manuals