HIBLOW HP Series User manual

Other manuals for HP Series

3

This manual suits for next models

2

Table of contents

Other HIBLOW Water Pump manuals

Popular Water Pump manuals by other brands

ZM Bombas

ZM Bombas ZM 44 MAXXI instruction manual

Saci Pumps

Saci Pumps optima Installation and maintenance manual

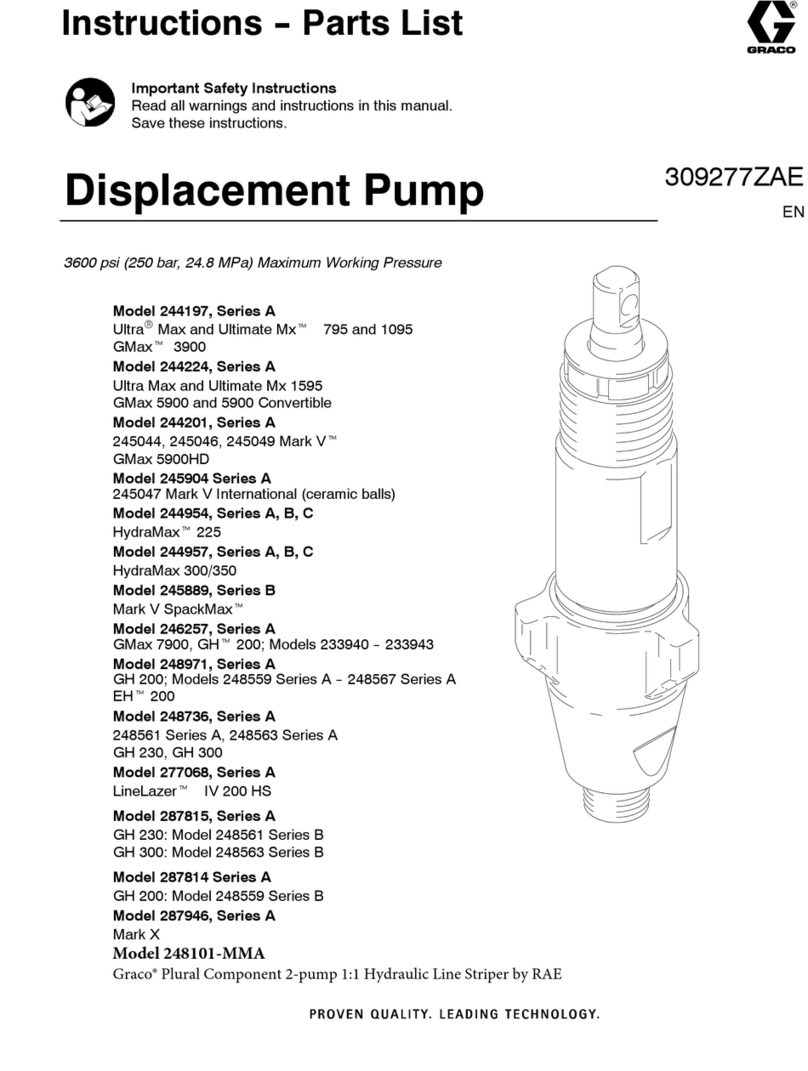

Graco

Graco Dyna-Star 77X100 Instructions, Repair and Parts

Toyo

Toyo DL-1-110 Installation, operation & maintenance instructions

Koshin

Koshin KTH-S Series Operating instructions & parts manual

Graco

Graco 970204 Instructions and parts list

PSG Dover

PSG Dover WILDEN A1 Accu-Flo Engineering, operation & maintenance

Enerpac

Enerpac EHF-65 instruction sheet

Tuthill

Tuthill HD Series Installation and service instructions

Reefe

Reefe RCE90 Exploded View & Instruction Manual

Zoeller

Zoeller 330 Series installation instructions

Black & Decker

Black & Decker BDXBTVAR150 instruction manual