Toyo DL-1-110 Guide

TOYO PUMPS NORTH AMERICA CORPORATION 1

INTRODUCTION

Thank you for selecting the Toyo submersible pump.

In order to ensure that you receive the maximum benefit of this equipment, it is required that this

INSTRUCTION & SERVICE MANUAL be thoroughly read prior to use, and that all instruction be carefully

followed.

WARNING!!

This is not explosion-proof or spark-proof.

It should not be operated in any area where flammable or

explosive gases, vapors, liquids or particles are or may be

present or where a spark could cause a danger or fire or

ex

p

losion.

These ruggedly built, portable, electrically powered submersible pumps are designed for trouble-free

operation in the removal of water from enclosed sumps, irrigation areas or serve a variety of general

dewatering/pumping chores (applications).

The pumps feature an oil-filled chamber between the pump section and the electric motor section that has

a high efficiency sealing system.

This sealing system prevents water from entering the motor and also permits extended dry running

without the concern for seal damage.

These pumps are also equipped with induction-type motors that have built-in overload protection to guard

against motor burn out due to over-current, over-heating or other mechanical over-load conditions.

Please fill in the information below and retain. These information will be necessary when requesting parts

or service. PUMP MODEL DL -1-110

SERIAL NO.

DATE OF PURCHASE

TOYO PUMPS NORTH AMERICA CORPORATION 2

TOYO SUBMERSIBLE PUMP

MODEL DL-1-110

OPERATING & MAINTENANCE INSTRUCTIONS

PRIOR TO OPERATION

1) UNPACKING AND INSPECTION

a) Always lift the pump by the handle-not the cabtyre cable.

If the pump must be suspended in a well or pit, a rope or chain should be attached to the pump

handle.

b) Check the nameplate information to ensure that the equipment received is that which was

ordered.

c) Carefully inspect the pump to be sure that shipping damage has not occurred.

2) INSPECTION OF PUMP

a) Check to determine that the power circuit and/or receptacle are adequate to handle

voltage/current rating of the motor-pump.

b) Ensure that cabtyre cable/extension cord is free from damage and that grounding wire/circuit is

operational.

CAUTION: Do not operate this pump unless it is connected to a properly wired grounding circuit

since serious personal injury may result from electrical shock. Disconnect the cabtyre

cable from the power source, before servicing this pump.

Do not use this pump in the water where person(s) is (are).

INSTALLATION & OPERATION

a) Be certain that the pump is mounted on a solid, flat base or suspended by a rope or chain

attached to the pump handle.

CAUTION: Do not use the electrical cable or discharge hose to suspended the pump.

Always attach suspension rope to the pump handle.

b) Use the shortest possible length of discharge hose to assure you minimize friction losses and

maximize your pump flow.

c) Make certain that the cable and/or receptacle from which it draws power is protected and away

from water or pump discharge hose to prevent accidental shock or electrical short circuiting.

d) The pump model has a built-in overload protector which senses over-current, over-heating, or

over-load conditions.

The operation of this protector is such that should any of these conditions exits, the power supply

will be interrupted until motor cooling has taken place. After cool-down has occurred, the pump

will automatically re-start and continue to be protected in this way as long as the condition exists,

but we request you to check and remove the cause.

TOYO PUMPS NORTH AMERICA CORPORATION 3

Note: This is a protection device and is not intended to replace external controls.

e) When cable extension is necessary, extended cable size must be adequate to avoid low voltage

conditions , which may cause motor burn out. Select the proper gauge size and minimize length

of the extension cable not to cause a large voltage drop. If you are not sure, it is recommended

to consult with the Toyo representative office or Toyo suppliers nearest you. When extending the

cable, be careful not to submerge the splice into the water to avoid the possibility of electrical

shock.

f) Connection to Power Source

DL-110: Plug in or connect to one phase power source.

CAUTION: Be sure to provide an adequate grounding and to use a ground leakage circuit

breaker.

AFTER OPERATION

To keep the pump in good condition and maintain high pumping efficiency the following inspections

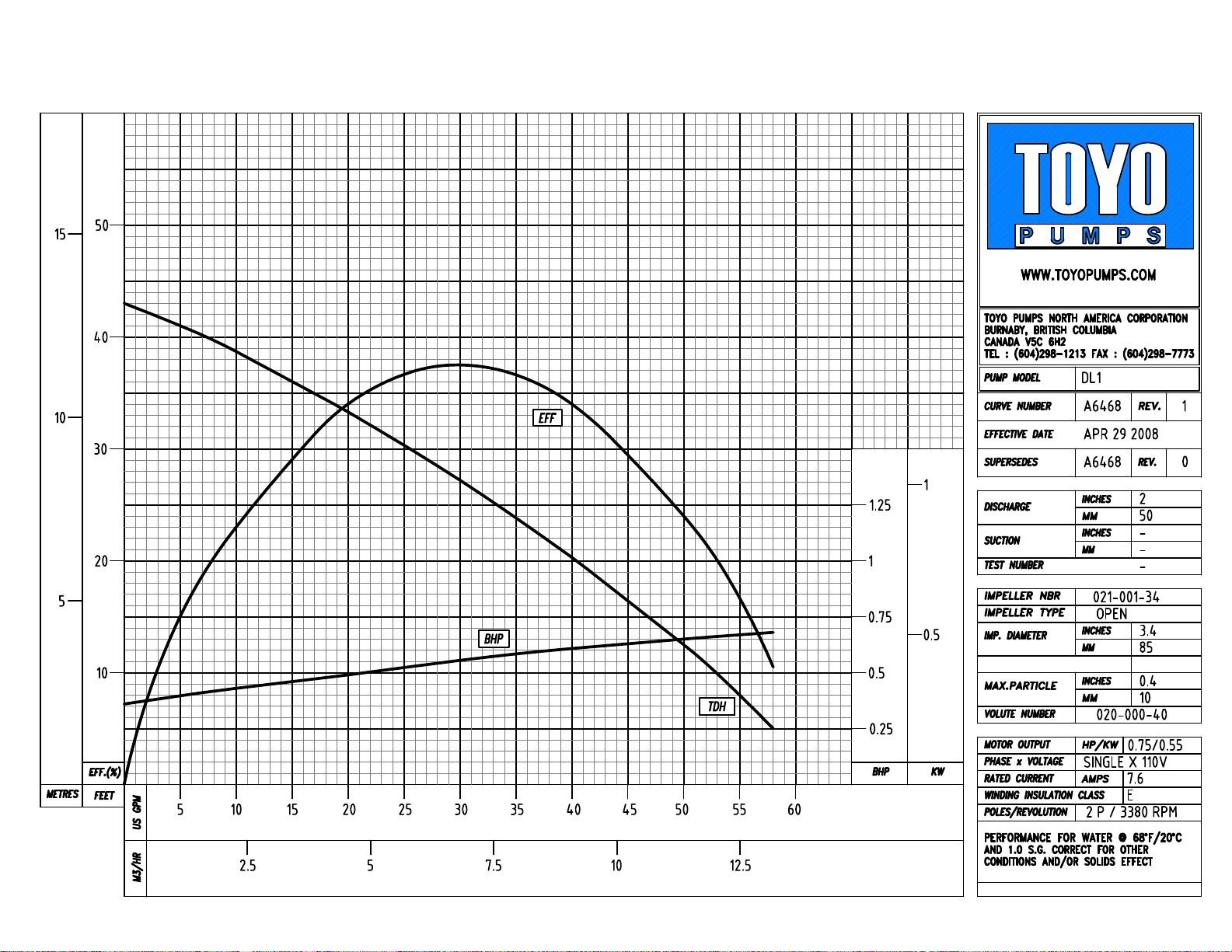

should be carried out after each fifty (50) hours of operation. (See Fig.A6470)

a) Remove Strainer-stand (item #23) and Pump Casing (#20). Clean out any solids and/or mud,

sand, stones or other foreign material which may have collected in the Pump Casing.

b) Check the Impeller (#21) for wear, obstruction or foreign material accumulation. If parts are

extremely worn, replacement should be made at the first opportunity.

c) After the inspections, clean the inside and outside of pump with clean water. When it is stored,

keep it in a dried condition.

REGULAR INSPECTION

1) LUBRICANT CHECK (See Fig.A6470)

Check the mechanical seal by inspecting the condition of the lubricant in the oil chamber. You may

readily determine the condition of the mechanical shaft seals based upon contamination level in the

oil.

a) Lay the pump on its side with Oil Plug (#35) facing upwards.

After unscrewing the plug, turn the pump over so that the hole faces downward. Drain and collect

the lubricant in a clean suitable container.

b) If the lubricant is clear and clean (not milky appearing or no water present), the seals should be in

a good condition.

c) Refill the chamber with fresh lubricant, using a good multiviscosity grade lubricant (Turbine Oil

ISO VG #32).

d) Extreme discoloration (milky appearing or yellowish-gray) or free water in the lubricant requires

immediate replacement of Mechanical Seal (#25) and V- Ring(#26).

e) When inspection is complete, replace the oil plug and carefully tighten to prevent leakage.

Note: Replace Packing of the oil plug, if it is found to be defective.

Periodic inspection and replacement of the oil should be made as follows:

*Inspection Cycle: Every 1,000 hours of running time

*Replacement Cycle: Every 2,000 hours of running time

But we recommend inspection once a year even if running time is less than above.

TOYO PUMPS NORTH AMERICA CORPORATION 4

Required lubricant volume is as follows and recommended lubricant is Turbine Oil ISO VG # 32. For your

convenience, other lubricants equivalent to ISO VG # 32 are listed as follows.

If it is difficult to get these turbine oils, engine-oil (10W-30/40) can be used alternatively.

Lubricant VOLUME

MODEL METRIC OZ US TYPE BRAND NAME

4.97 0.31 DTE Oil Light MobilDL-1-110 0.147 Victoria Oil 27 Shell

(liter) (oz) (pint) Energol THB 32 British PetroleumParamount 32 Gulf

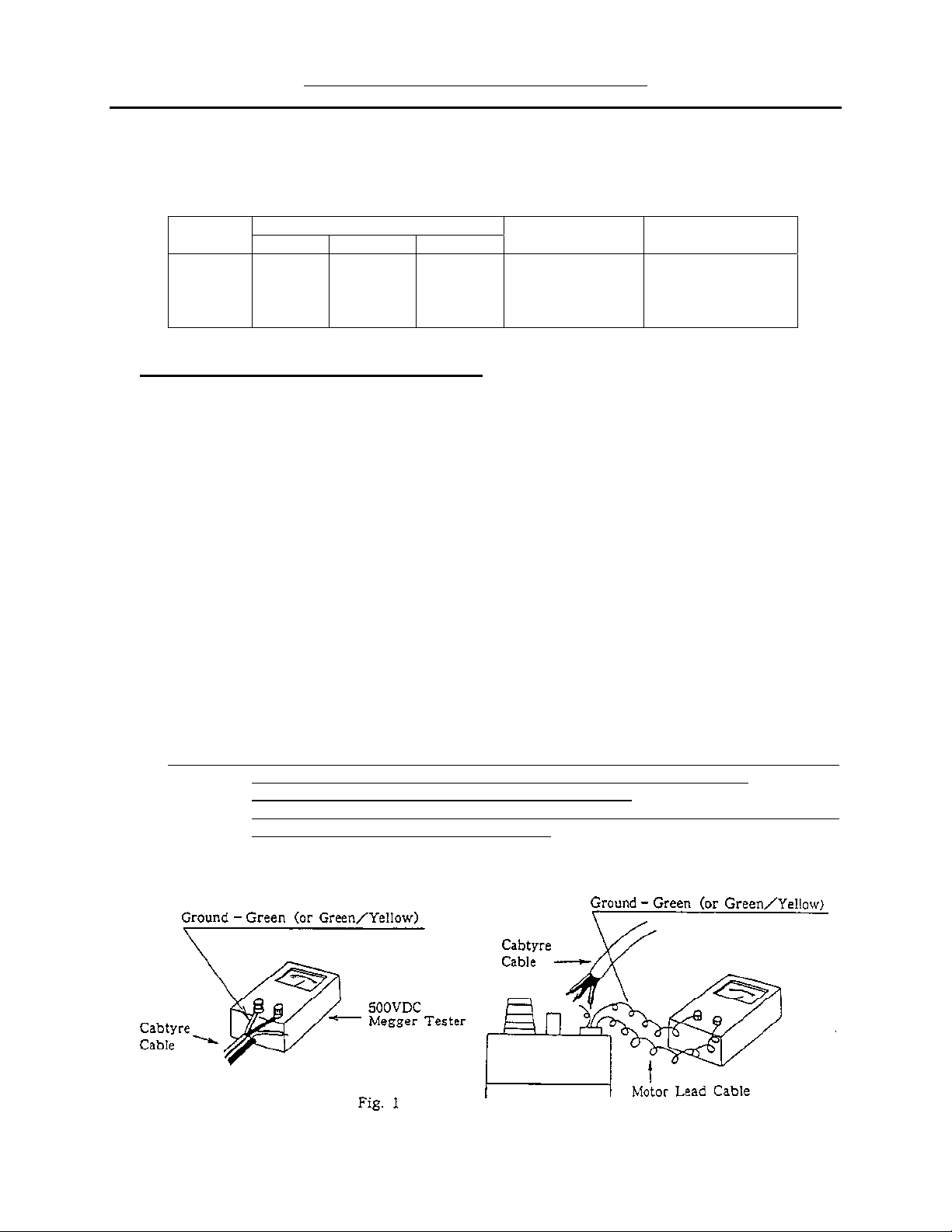

2) ELECTRICAL CHECK (MEGGER TEST)

Whenever the pump is serviced, it is a good maintenance/safety practice to check the insulation

strength of the motor and cabtyre cable in the following manner to prevent electrical shock

accident(s).

a) Disconnect the cabtyre cable from the power source.

b) Using the 500 VDC Megger Tester, check the electrical insulation of each leg of the wiring circuit

in combination with the ground lead (green or green/yellow).

c) If any reading is less than one (1) meg-ohms (M<), it indicates damage to the cabtyre cable

and/or the motor.

d) Disconnect the cabtyre cable from the motor and Megger Test the insulation strength of the motor

itself.

e) Any reading more than ten (10) meg-ohms (M<) requires immediate replacement of the Cabtyre

Cable.

Any reading less than ten (10) meg-ohms (M<) indicates electrical leakage due to the presence of

water or dampness in the motor in which case the motor must be dried thoroughly.

If after drying, the condition still exists, there is a strong probability that the motor is in need of

repair.

CAUTION: It is absolutely imperative that appropriate corrective action/repair be performed

before the pump is returned to service if it will not pass the Megger Test.

Serious personal injury can result from electrical shock.

The above maintenance inspection, if it is performed regularly, will result in greatly

improved pumping efficiency and pump life.

TOYO PUMPS NORTH AMERICA CORPORATION 5

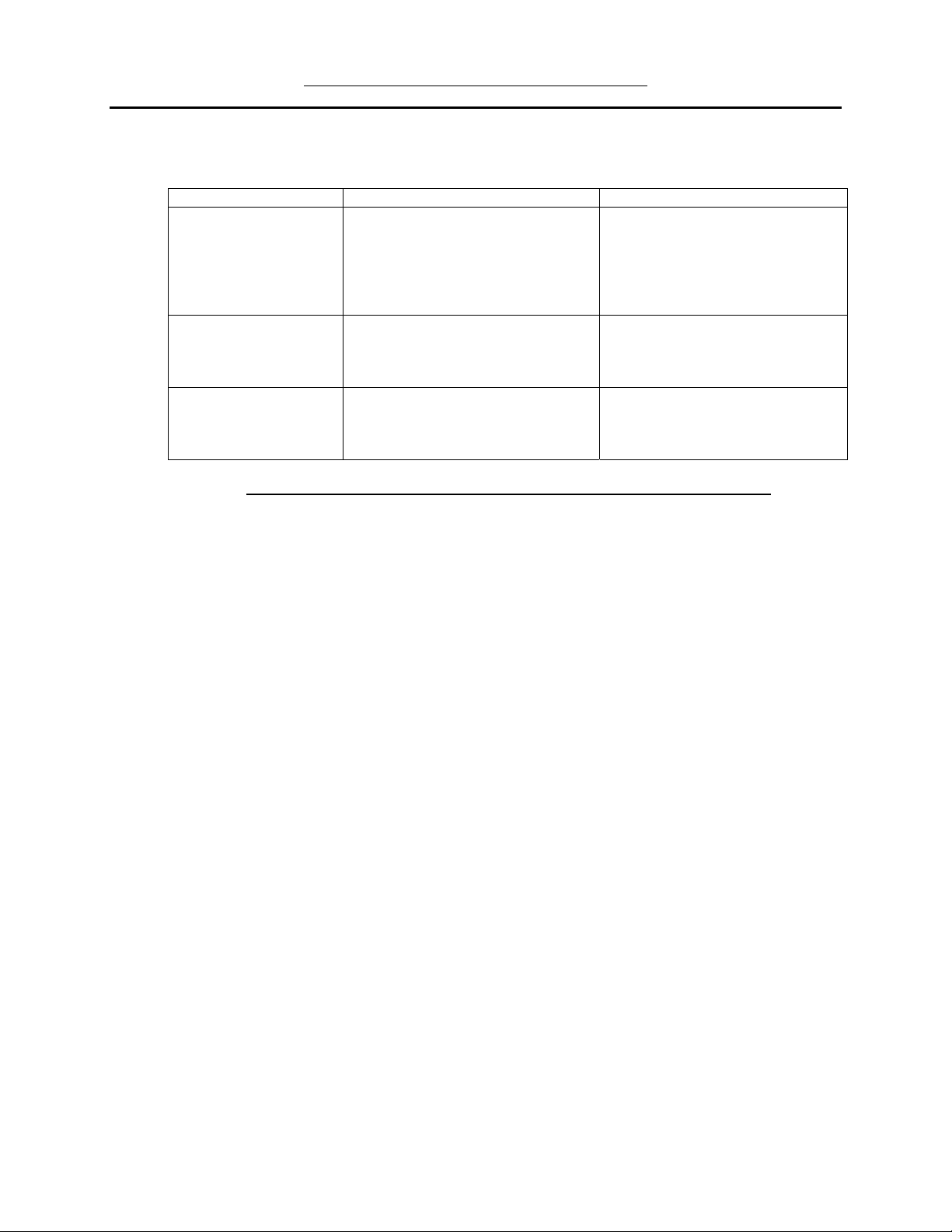

TROUBLE SHOOTING

FAULT POSSIBLE CAUSES CORRECTION

1. No electric power. Turn power on.

2. Cable cut/broken. Change cable.

Pump will not start. 3. Poor electric connection. Clean connection.

4. Low voltage. Check power source.

5. Impeller obstructed. Remove obstruction.

6. Overload relay actuated. Wait for motor to cool down.

1. Impeller obstructed. Remove obstruction.

Stop during operation. 2. Overload relay actuated. Wait for motor to cool down.

3. Low voltage. Check power source.

4. Liquid viscosity too high. Reduce viscosity.

1. Discharge hose kinked or

otherwise obstructed. Remove kink or obstructed.

Reduction in Capacity 2. Impeller worn. Change worn parts.

3. Strainer blocked. Remove obstruction.

CAUTION: Disconnect the cabtyre cable from the power source, before servicing pump.

TOYO PUMPS NORTH AMERICA CORPORATIO

N

2853 Douglas Road

Burnaby, BC V5C 6H2

Tel: (604) 298-1213 Fax: (604) 298-1224

Kit ITEMS ARE INCLUDED IN GASKET KIT

SR ITEMS ARE INCLUDED IN SEAL REPAIR KIT

PARTS LIST - DL1-110

Ref. Dwg. No. A6763 Rev.1 TPSD-001 Rev.0

Please use the part number when ordering. Effective: June 29, 2009

REF # PART # DESCRIPTION QTY

1 001-943-23 Power Cable 32' 1

2 010-163-16 Cable Clip Rubber 1

3 040 415 00 08105 Bolt 2

4 003-100-13 Gland 1

5 040 415 00 13900 Bolt 2

6 068-224-15 Handle 1

7 140-396-16 Bolt 3

8 051-000-10 Motor Head Cover 1

Kit 9 121-546-14 Gasket (H.Cover/M.Frame) 1

10 143-136-15 Truss Screw 2

11 053-000-63 Motor Protector 110/115/120V-60HZ 1

12 076-000-18 Capacitor 110/115/120V-60HZ 1

13 143-085-21 Pan Screw 1

14 127-000-12 Retainer (Capacitor) 1

15 009-000-44 Grounding Wire 1

16 143-203-14 Pan Screw 1

17 050-000-10 Motor Bracket 1

18 142-192-16 Wave Washer 1

19 052-100-15 Ball Bearing (Upper) 1

20 055-000-92 Rotor and Shaft 1

21 147-168-18 Key 1

22 061-178-12 Bearing Collar 1

SR 23 052-152-12 Ball Bearing (Lower) 1

24 056-002-03 Stator 110/115/120V-60HZ 1

25 064-000-50 Motor Frame 1

SR 26 025-291-10 Mechanical Seal 1

SR 27 030-159-11 Oil Lifter 1

Kit 28 122-133-17 O-Ring (M.Frame/O.Casing) 1

29 141-030-12 Acorn Nut 3

30 142-143-12 Washer 3

31 029-000-17 Oil Casing 1

Kit 32 121-246-11 Gasket (Oil Plug) 1

33 035-125-13 Oil Plug 1

Kit 34 121-000-20 Gasket (O.Casing/P.Casing) 1

35 140-256-13 Socket Bolt 3

SR 36 122-441-11 V-Ring 1

1

TOYO PUMPS NORTH AMERICA CORPORATIO

N

2853 Douglas Road

Burnaby, BC V5C 6H2

Tel: (604) 298-1213 Fax: (604) 298-1224

Kit ITEMS ARE INCLUDED IN GASKET KIT

SR ITEMS ARE INCLUDED IN SEAL REPAIR KIT

PARTS LIST - DL1-110

Ref. Dwg. No. A6763 Rev.1 TPSD-001 Rev.0

Please use the part number when ordering. Effective: June 29, 2009

REF # PART # DESCRIPTION QTY

SR 37 071-292-14 Shaft Sleeve 1

38 021-001-34 Impeller (60Hz) 1

38 021-001-35 Impeller (50Hz) 1

39 142-143-12 Washer 1

40 040 417 00 02037 Spring Washer 1

41 024-000-02 Agitator 1

42 140-057-12 Bolt 2

43 032-289-17 Hose Coupling NPT 2" (45 deg.) (STD.) 1

43 032-144-19 Hose Coupling Barb 2" 1

Kit 44 121-138-19 Gasket (Discharge Fitting) 1

45 020-000-40 Pump Casing 1

46 142-143-12 Washer 2

47 141-030-12 Acorn Nut 2

48 023-00046 Strainer Stand 1

49 140-062-10 Bolt 3

** SR 952 200 09 11915 Seal Repair Kit (includes gasket kit) 1

SR Kit 173-550-12 Gasket O-Ring Kit 1set

2

Table of contents

Other Toyo Water Pump manuals

Popular Water Pump manuals by other brands

Warren rupp

Warren rupp SANDPIPER MSA3 Service and operating manual

Interpump

Interpump General Pump EV Series Repair manual

J.E. Adams

J.E. Adams 9500 Series owner's manual

WOERNER

WOERNER PEK Translation of the original operation manual

JABSCO

JABSCO 30296 Series quick start guide

ALPHA DYNAMIC PUMPS

ALPHA DYNAMIC PUMPS Ruby 080 FDA Installation, operation and maintenance manual

Giant

Giant P400 Series Operating instructions/ repair and service manual

Graco

Graco Check-Mate 800 Instructions for use

SKF

SKF MAX-1-2-230-IF105-R-V2 Operating and maintenance instructions

Intex

Intex Quick-Fill AP636 owner's manual

LEYBOLD

LEYBOLD Sogevac Neo D Series Original instruction manual

Zoeller

Zoeller X621 owner's manual