HIBLOW hp-150 User manual

1

Instruction Manual

for

HIBLOW Air Pumps

Models

HP-150 and HP-200

FEATURES

We thank you very much for purchasing our TECHNO TAKATSUKI HIBLOW air pumps.

In order to ensure that you will receive many years of dependable service from your HIBLOW air

pumps as well as to fully utilize the pump performance for effective operation, be sure to read

through this instruction manual to gain full understanding before proceeding to actual operation.

Furthermore, when operating the pump, be sure to observe all the precautions and recommendations

contained in this manual.

After reading this manual, keep it for future reference in an easily accessible place.

ENERGY SAVING

Adopting an electromagnetic vibrating system designed for energy saving allows less power con-

sumption (on our product basis).

DURABILITY AND STABILITY

A diaphragm made of excellent special synthetic rubber is used along with a diaphragm ring, which

permits an extended period of continuous operation with increased stability in delivery capacity.

LOW NOISE LEVEL

The air circuit and pump structure are of noiseproof design, thus providing a low operating noise level.

AUTOMATIC STOP MECHANISM

A damage to the diaphragm will automatically stop the pump by means of a safety popping switch,

lessening occurrence of a secondary failure from occurring.

NO LUBRICATION REQUIRED

The pump structure that has no sliding parts and is totally oil-less provides oil-free, clean exhaust air.

COMPACT AND LIGHTWEIGHT DESIGN

Our unique design know-how has made it possible to achieve compact, lightweight and powerful air

pumps.

EASY MAINTENANCE

Repair parts can be easily replaced, and easy cleaning and replacement of air filters are also made

possible by adoption of a one-touch cover.

!WARNING Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

!CAUTION Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury or property damage.

An explanation of the two different types of hazards

紙色:オレンジ

2

ACCESSORIES

Prior to use, please check that all the following accessories are supplied.

Item Q’ty

• Pump unit .......................................................................... 1

• Straight hose (has different ends) ..................................... 1

• Hose band ........................................................................ 2

• Instruction manual ............................................................ 1

• Warranty card ................................................................... 1

STRUCTURE AND PARTS NAME

Diaphragm base

Diaphragm ring

Rod

Casing A

Casing B

(Value Chamber Cover)

Exhaust valve

Intake valve

Center plate

Teflon

Diaphragm rubber

Gap bearing Valve

chamber packing

SP Switch

(dotted line)

U-lock nut

Electromagnet

Frame

3

HOW IT WORKS

When the electromagnetic coils facing each other as show in the figures below are energized by AC

power (AC 100V/120V/220~240V), a magnetic force is generated. This magnetic force will then act to

induce the magnetic poles between the permanent magnets fixed to the rod, and the electromagnets,

causing magnetic actions of attraction and repulsion to move the rod in the respective directions as

shown in Figs. A and B below.

The rod vibrates at the AC power supply frequency, and air is exhausted by a change in volume of

the space enclosed by the casing and the diaphragm that is caused by diaphragm movements, and

by the repeated cycles of air intake and compression attained by the operation of the intake and

exhaust valves.

3,000 cycles/min. for 50 Hz of AC power supply frequency

3,600 cycles/min. for 60 Hz of AC power supply frequency

Fig. A

Fig. B

Exhaust

N

S

N

S

S

N

S

S

N

N

N

S

S

N

S SN

Permanent magnet

Electromagnet

Exhaust

N NS

Intake

Intake

Intake

Intake

4

!CAUTION PRECAUTIONS FOR INSTALLING THE PUMP

1. Installation Place

(1) Install the pump in a well-ventilated place.

(2) Choose a place which has no risk of inundation.

(3) Install the pump unit close to an aeration tank (within 5 meters).

(4) Avoid installing the pump in a bedroom or other places where noises may be a nuisance.

(5) Install the unit in a place that provides easy access for inspection and maintenance.

(6) This pump is designed for outdoor use, requiring no cover to be placed.

2. Installation method

(1) Make an installation foundation with a height of at least 10 cm from the ground, using con-

cretein a manner that its surface is flat and horizontal.

(2) Use a hard PVC tube VP-13 or VP-20 for tap water use as air piping.

(3) Place the pump unit properly on the foundation and check that it is horizontal. But, at this

stage,do not turn on the pump yet.

(4) Connect the PVC tube to the pump outlet with a straight hose as shown in the figure below,

then firmly tighten the connection with the hose band. When using VP-13, use a small diameter

end of a straight hose supplied as an attachment.

(5) The appliance must be grounded by a qualified electrician using the grounding terminal ( ) of

the pump.

(6) Provide a waterproof type plug socket for pump use only.

(7) Fill the water-purifier tank up to the specified level, then turn on the pump to supply air into

thetank.

Pump

Concrete

foundation

Hose band

PVC

connection

tube

Straight hose which has different ends (supplied)

5

REPLACING REPAIR PARTS

!CAUTION

!CAUTION

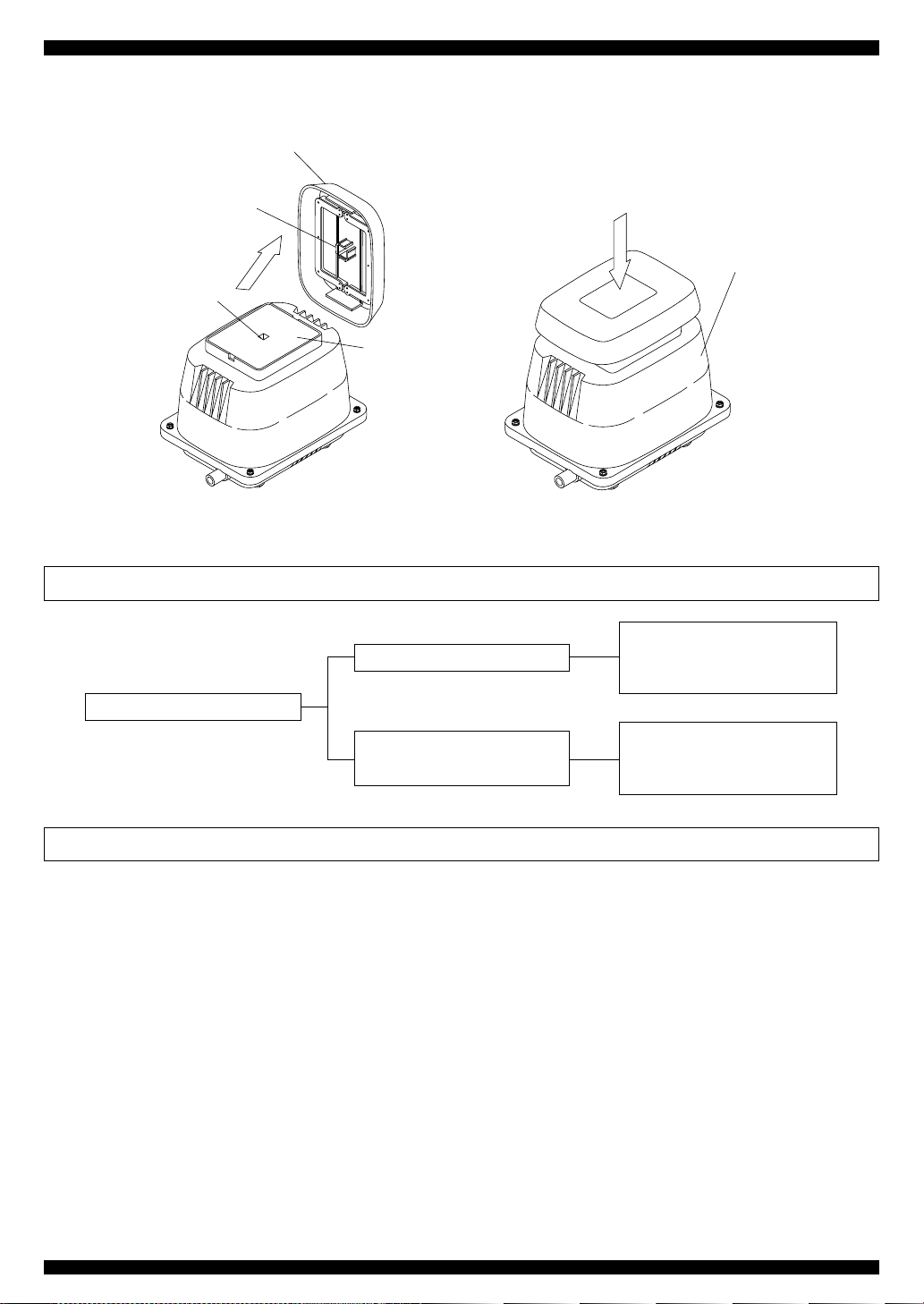

FILTER CLEANING AND REPLACEMENT

!CAUTION

To replace repair parts, proceed as follows: Be sure to use our designated genuine parts.

(1) When performing cleaning and/or replacement work, be sure to unplug the pump unit first.

(2) To remove the filter cover, put your fingers on one side of the cover and pull it up. (See Fig. 1.)

(3) Remove the filter from the upper housing, replace it with a new one or clean it. At this time, remove

any dust or foreign matter from the inlet of the filter cover, and the filter mounting surface and the

inlet of the filter. (The inlet is on the top of the upper housing and can be viewed when the filter is

removed.) If the filter is dirty, dust it off well. However, if it is heavily soiled, use a neutral detergent

to wash it down, rinse it well with water, and dry it out of the sun before reinstalling.

• When performing replacement work, the pump body may be still hot. Therefore, take care not to get

burnt.

• Clean the filter every three months. Clogged filters may result in abnormal heat generation or a

failure of the pump.

• Any dust or foreign matter attached on the pump inlet may cause abnormal noises or pump failure.

(4) Replace the filter, put the filter cover back on the upper housing as shown in the figure below,

align the fitting boss of the upper housing with its counterpart of the filter cover, then press the filter

cover downwards from above to fit it in. (See Fig. 2.)

• Take care not to press the filter cover in its improper position as it may be damaged.

• This pump is of a totally oil-less type. Therefore, never put oil or other liquids into the pump inlet.

6

Block Configuration

Chamber block

Diaphragm base

Diaphragm

Diaphragm ring

Casing

Valve

Valve chamber cover

Casing block

Diaphragm

mounting block

REPLACING THE CHAMBER BLOCKS

!CAUTION

• When performing the replacement work, the pump body may be still hot and you may get burnt.

So, wait until the pump has been allowed to cool.

• Replace the diaphragms and the valves with new ones once a year in order to maintain their initial

performance.

• For chamber block replacement, be sure to change both chamber blocks at the same time because

replacing only one of the two may cause a significant difference in life between the right- and left-

hand rubbers, making it impossible to maintain the performance of the pump.

• The rod employs powerful permanent magnets, and therefore be sure to remove your watch before

starting the work as it may fail due to their strong magnetic force.

• Do not put the rod close to a magnetic card, a magnetic disk or any other magnetic media as their

data may be lost.

Filter cover

Fitting boss

Fitting boss

Filter

Upper housing

Fig. 1 Fig. 2

7

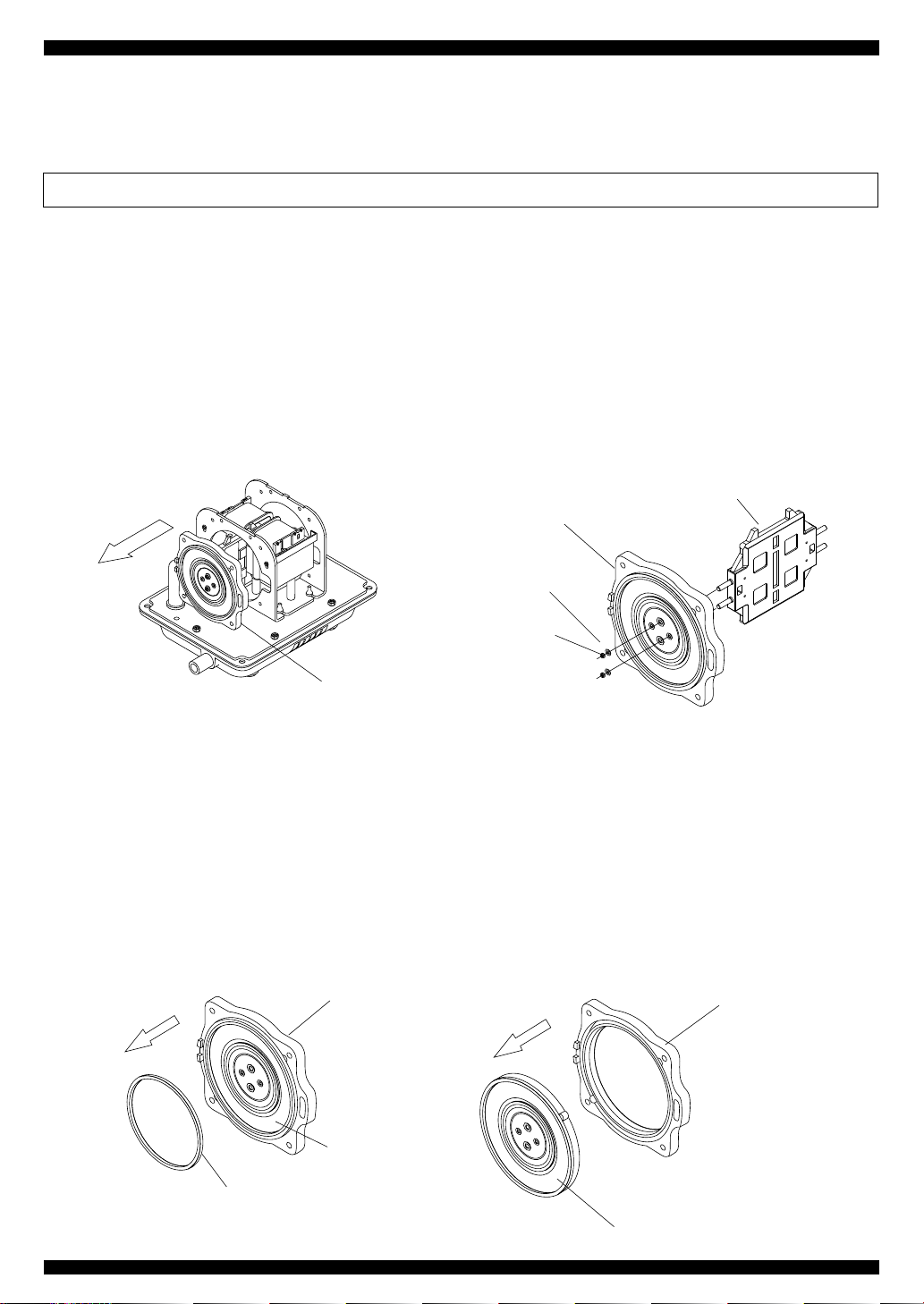

(1) Prior to starting the work, be sure to unplug the pump.

(2) Remove all screws from the four corners, and the upper housing. If it is difficult to remove it due

tothe heavily stuck internal seal packing, pry it open by inserting the tip of a screwdriver into the

clearance between the exhaust nozzle and the upper housing .

(Figs. 3 and 4)

(3) Remove the sound absorber, hold the hose band and remove the L-tube from the casing nozzle.

Then, loosen the installation screws of the casing block for removal of the latter. (Figs. 5 and 6)

Screw

Screwdriver

inserting

position

Upper housing

Sound absorber

Fig. 3 Fig. 4

Sound absorber Hose band

L-tube

Screw

Casing Block

Fig. 5 Fig. 6

8

(4) Loosen the U-lock nut and remove one of diaphragm mounting blocks from the rod, and pull out

the other diaphragm mounting block from the pump body together with the rod without loosening

its U-lock nut. (Figs. 7 and 8)

!CAUTION

• Since we use powerful permanent magnets for the rod, take care not to get your fingers pinched

by unexpectedly being attracted with its force.

• When pulling out the rod, take care not to allow the rod projection to accidentally to hit the lever of

the automatic stop switch, as this may result in the safety screw of the switch damaging or in its

malfunction.

(5) To replace the diaphragm of the removed diaphragm mounting block, with a new one, first

remove the diaphragm ring from the diaphragm, then the diaphragm from the diaphragm base.

The ring and the diaphragm can be easily removed by hand, and if it is difficult to do so, then

hold them using radio pliers or the like, and pull them out one by one. (Figs. 9 and 10)

Diaphragm ring

Diaphragm

Diaphragm base

Diaphragm

Diaphragm base

Fig. 9 Fig. 10

9

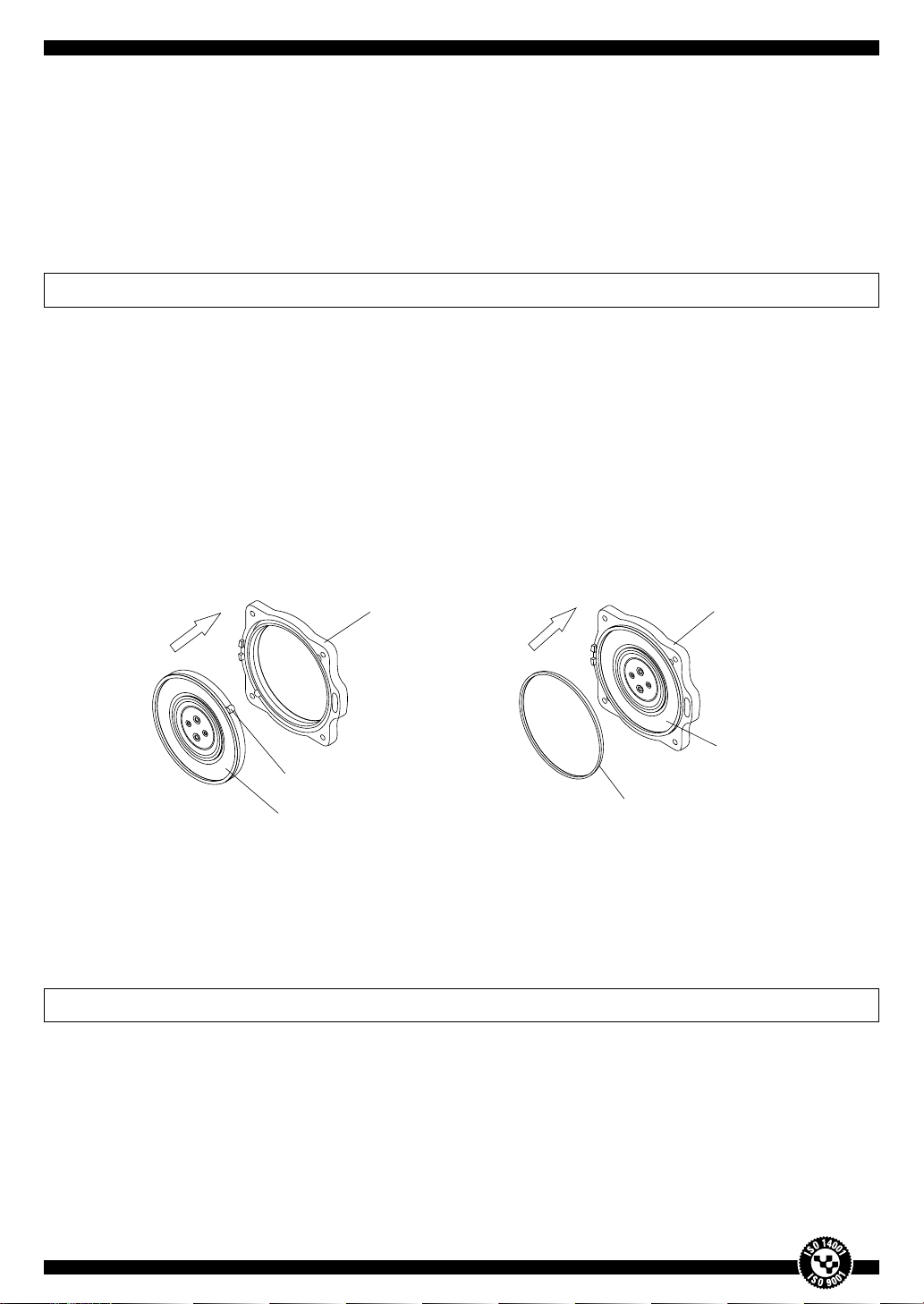

(6) To reinstall the diaphragm, first fit a new diaphragm in the diaphragm base groove while aligning

the two diaphragm projections with their counterparts of the diaphragm base. Then, replace the

diaphragm ring in the diaphragm thus fitted. At this time, this diaphragm ring must be a new one

supplied with the replacement diaphragm. (Figs. 11 and 12.)

This completes the diaphragm replacement procedure, and use this assembly as a new

diaphragm mounting block.

!CAUTION

• At the time of changing diaphragms, be sure to replace the diaphragm rings also with the supplied

new ones. Since the old diaphragm rings may be likely to break, you may get injured when attemp-

tingto refit them for reuse.

• Be sure to fit the diaphragm ring as pump performance and life will be greatly affected, possibly

resulting in a failure.

(7) Install a new diaphragm mounting block on one side of the rod, insert the rod in accordance with

the procedure reverse to that performed when the rod was removed from the pump.

(Figs. 13 and 14)

!CAUTION

• Do not use removed U-lock nut and washer again as they may be loosened, which causes failure

of the pump. Therefore, use new U-lock nut and washer every time for replacing diaphragms

without fail.

Fig. 11 Fig. 12

Diaphragm

Diaphragm ring

Diaphragm base Diaphragm base

Diaphragm

Projection

10

!CAUTION

• Take care not to install the rod with iron particles, screws and other metallic substances attached

on the permanent magnets. Failure to do so can result in damage to the permanent magnets and/

or the electromagnets, or even in a failure of the pump.

(8) After the new diaphragm mounting blocks have been installed, install new casing blocks. The

casing blocks can be used again as new if the valves are replaced with new ones. To replace the

valves of the removed casing block with new ones, undo the five screws of casing A (Exhaust

part side) to remove casing B (Air valve side) and valve chamber cover. (Figs. 15 and 16)

(9) Pull out four old valves from the casing A using radio pliers, insert each new valve into the center

hole of valve seat while paying attention to the intake and exhaust sides, and pull these valves for

firm fitting, using radio pliers or other similar means. (Figs. 17 and 18)

Fig. 15 Fig. 16

Screw

Casing Block

Casing A

Casing B

Valve chamber packing

11

!CAUTION

• When replacing the diaphragms, be sure to change the valves with new ones, too.

• When reinstalling the valves, take care to make sure that they are correctly fit in the exhaust and

intake sides. Wrong orientation may result not only in performance decreasing but in a failure of

the pump.

• Tighten each of five screws gradually and uniformly till they are firmly fastened.

If they are not tightened uniformly, it may cause leakage of air or failure of pump.

(10) After the valves have been inserted into the casing A, cut off their respective pulling ends using

scissors or nippers. Secure casing B and valve chamber packing to casing A by the five screws.

(Fig. 19 and 20)

This completes the valve replacement procedure, and use this assembly as a new casing block.

Fig. 17 Fig. 18

Casing A

Valve

Exhaust side

Intake side

Fig. 19 Fig. 20

Cut section

Cut section

12

!CAUTION

(11) After the diaphragm mounting blocks have been installed, fix the new casing blocks by tightening

the four screws evenly in the reverse order to that done for disassembling, fit the L-tube in the

casing nozzle, and fix it firmly using the hose band. (Figs.21 and 22).

(12) When all the reassembly work has been completed, check the rod for no contact with the

electromagnet(s) or the screws for tightness.

(13) As a final step, put the frame cover back on the frame, tighten the four screws uniformly, then

cover the frame with the sound absorber. Furthermore, do not forget to put the frame cover on,

tighten each of four screws gradually and uniformly until they are firmly fastened.

(Figs. 23 and 24)

• Tightening a single screw too tight will make it difficult to tighten the remaining screws firmly, result-

ingin damage to the screws if forcibly tightened. Therefore, fasten all the four screws uniformly.

Fig. 21 Fig. 22

Screw

Hose band

Fig. 23 Fig. 24

Screw

Sound absorber

13

pin

SAFETY AUTOMATIC STOP SWITCH (SP SWITCH)

!CAUTION

1. Structure

The switch is installed in frame, and trouble defection lever is installed on top part of rod.

When diaphragms work properly, the movement of the rod between right and left is always

constant. However, if the diaphragms become damaged, pump works in the incorrect way.

As the result, the rod would be bias or over-moving. In this case, the top of the rod touches

the L-shaped lever and breaks the resin pin, which anchors L-shaped lever and the electrode.

That makes the constant point of the switching off and the pump turns off automatically. This

method lessens further pump damage by diaphragms break.

2. How to replace

If consumable spare parts, such as diaphragms are damaged, automatic stop switch works and

the movement of pump stops. At that time, please replace both the safety pin and diaphragms.

Procedure

(1) When you work with pumps, please never fail to pull off the electricity plug before working

on them.

(2) Referring to Fig.25, please penetrate safety pin through the electrode, L-shaped lever and

beam in such order.

(3) After replacing safety pins, please tighten safety pin and insert locking collar from beam side.

In case the locking collar is set on the proper point, please push that collar into the point.

(4) Then the setting of the switch is completed. (Fig. 26)

●Please never fail to pull off the electricity plug before working on them. If the pump remains con-

nected to the electricity supply, moving parts may cause injury or there is a possibility of electric

shock.

●Please remove broken safety pin and broken locking collar after replacing. Otherwise it causes

electromagnet damaged or causes pump broken.

●Please never fail to replace new locking collar for the maintenance purpose. Once you have

used locking collar, please do not reuse the same one as that collar does not function.

●Please replace safety pin after replacement of consumable spare parts. If you change safety

pin first, safety pin would be damaged when you insert the rod.

14

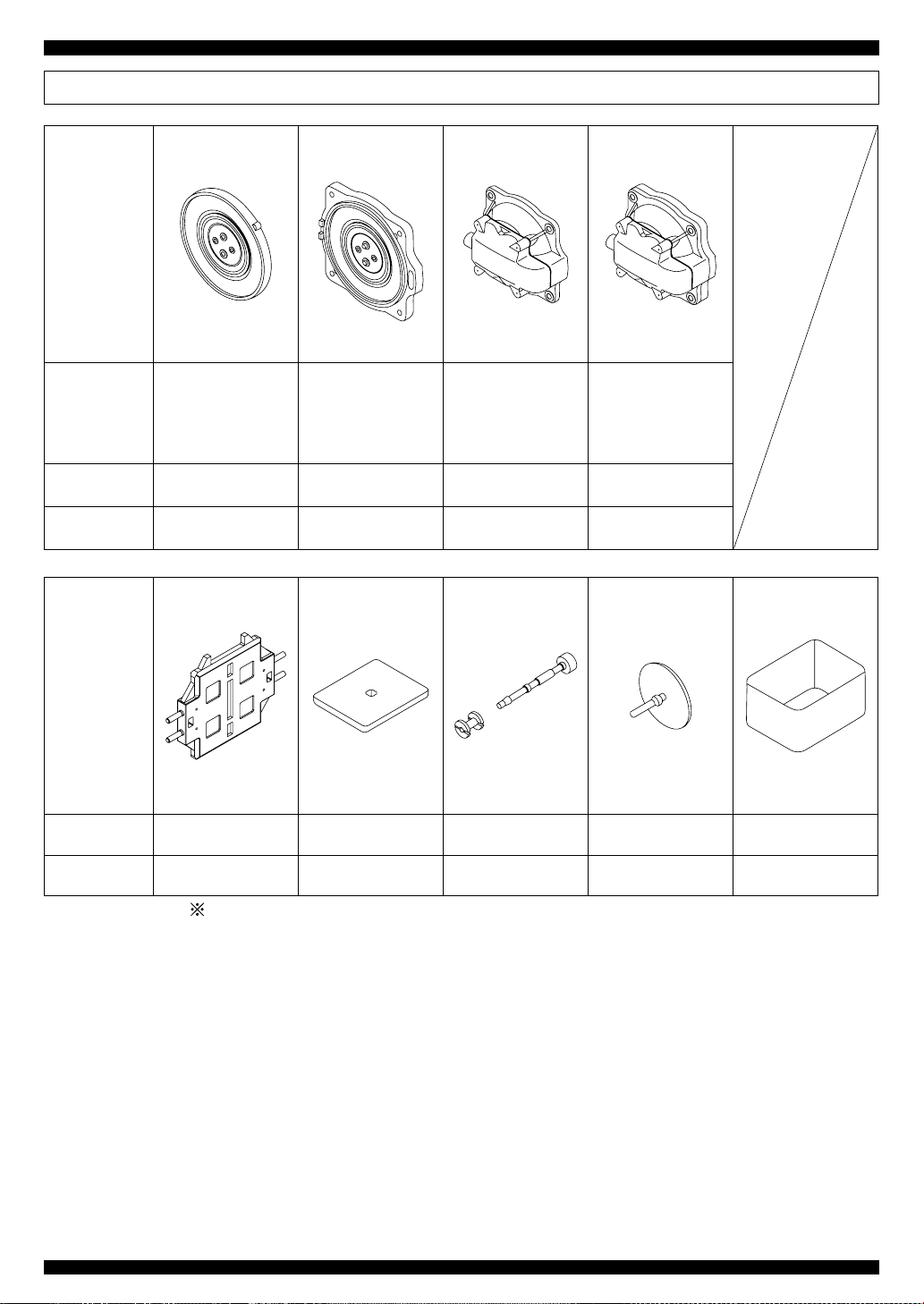

REPAIR PARTS

Furthermore, when you have lost or damaged the instruction manual, please contact us and we

will send you a copy at your cost. For inquires, please also contact our International Sales

Department.

Parts Name Diaphragm Block

2 pcs./set

Diaphragm

Mounting Block

2 pcs./set

Casing Block

2 pcs./set

Chamber Block

2 pcs./set

Consisting

of

• Diaphragm

• Diaphragm ring

• Diaphragm base

• Diaphragm

• Diaphragm ring

• Casing A

• Casing B

• Valve

• Valve chamber

packing

• Diaphragm

mounting block

• Casing block

Applicable

Models HP-150 & HP-200 HP-150 & HP-200 HP-150 & HP-200 HP-150 & HP-200

Order code 200DF00020 200PD00010 200PK00010 200PC00010

Parts Name Rod Filter Safety pin

for SP Switch

Valve Sound Absorber

Applicable

Models HP-150 & HP-200 HP-150 & HP-200 HP-150 & HP-200 HP-150 & HP-200 HP-150 & HP-200

Order code 200PR00300 120PA20010 PASPSW0400 200VV00010 QN09000100

When ordering parts, please specify the parts names and the corresponding order codes.

15

256 200

140 110

220

37

20

18

GENERAL VIEW AND DIMENSIONS

SPECIFICATIONS

(Unit : mm)

Specifications and design of these products are subject to change without notice for improvement.

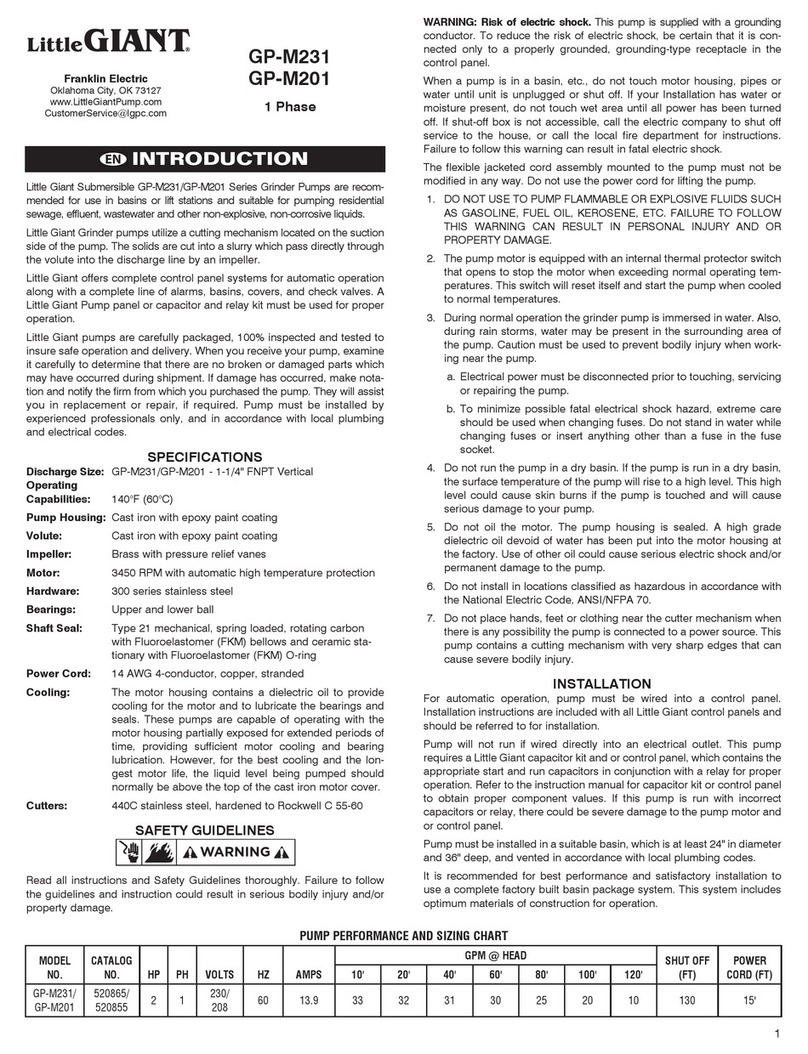

Model HP –150 HP–200

Rated voltage V AC100/120/220~240V

Power supply frequency Hz 50 60 50 60

Normal operating pressure kPa 20.0

* Exhaust air flow rate l/min 150 160 200 210

* Power consumption W 125 155 210 250

* Noise level dBA (1m) 47 50

Weight kg 9.0

Denotes typical values and not those guaranteed.

INTERNATIONAL APPROVAL STANDARD CERTIFICATE OBTAINED

AN ENTERPRISE AIMING ENDLESSLY AT ENHANCING QUALITY

TECHNO TAKATSUKI CO., LTD.

What is ISO14001 & 9001?

ISO (International Organization for Standardization) 14001 Environmental Management

Systems are intended to provide organizations including companies with the elements of

an effective and voluntary environmental management system which can be integrated

with other management requirements, to assist organizations to achieve environmental

goals. And the ISO-14001 is called as “The enviromental passport” in internationally approved

standards. On the other hand, the ISO-9000 was established by ISO in 1987.These inter-

nationally approved standards provide specifications not for products but for quality-assur-

ance systems. ISO 9000 consists of three separate standards: ISO 9001, 9002, and 9003.

Of these, ISO 9001 is the most rigorous, encompassing points ranging from design con-

trol to after-sales service. To qualify for an ISO 9001 certificate, applicants must first pass

in-company, customer, and third-party audits. After receiving ISO 9001 certification, regular

checks are then conducted to ensure that the company maintains the required standards.

In addition, management policies on product quality are documented and checked against

actual practice throughout the entire organization. In essence, the ISO 9001 standard certi-

fies that a company has not only established an outstanding quality-control record, but has

also proven capable of sustaining this record.

The Product Liability Law

Japan’s Product Liability Law was introduced in July 1995 in response to the increasing

difficulty consumers were having in evaluating the quality of high-technology products

and in claiming damages associated with product defects. With the Product Liability Law

making it easier for customers to claim damages, manufacturers must now assign a higher

priority to quality control.

At Techno Takatsuki Co., Ltd., our response to the above developments was to create a

program that ensured our products were in compliance with the Product Liability Law. At

the same time, we implemented a full range of safety measures. As a results of these

efforts, we received ISO9001 certification in December 1995, a testament to the high

quality of our product design and manufacturing systems. Despite this initial success, we

remain determined to further improve our quality-control system, and look forward to the

support of our customers as Techno Takatsuki continues to evolve in years to come.

(All rights reserved)

HEAD OFFICE

8−16 HATCHO-NISHIMACHI, TAKATSUKI, OSAKA, JAPAN 569−0095

TEL : +81-726-84-0805 FAX : +81-726-84-0807

04.09.3000M

Printed in Japan KA20002010

PHILIPPINE TECHNO TAKATSUKI INC.

TOKYO BRANCH HINO FACTORY

This manual suits for next models

1

Table of contents

Other HIBLOW Water Pump manuals

Popular Water Pump manuals by other brands

IN-ECO

IN-ECO LR 060-H06 operating instructions

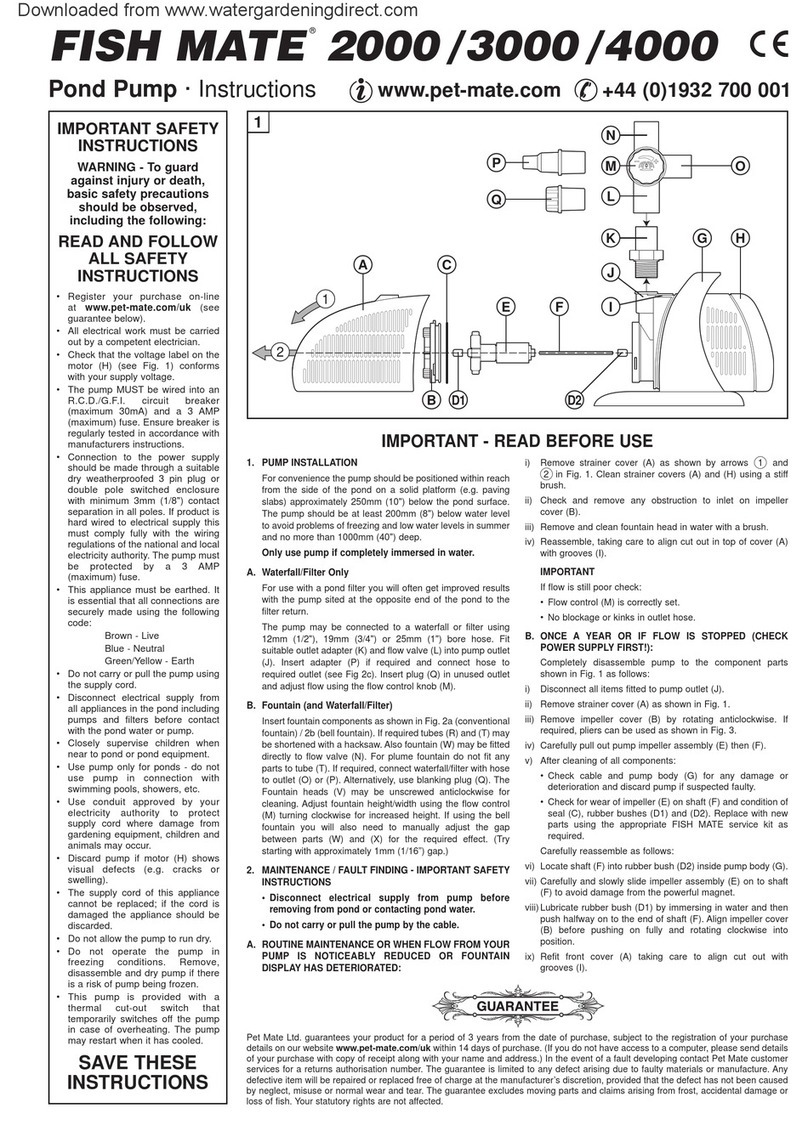

Little Giant

Little Giant CMD-100-3B owner's manual

Ecoplus

Ecoplus 727184 Instruction for installation and maintenance

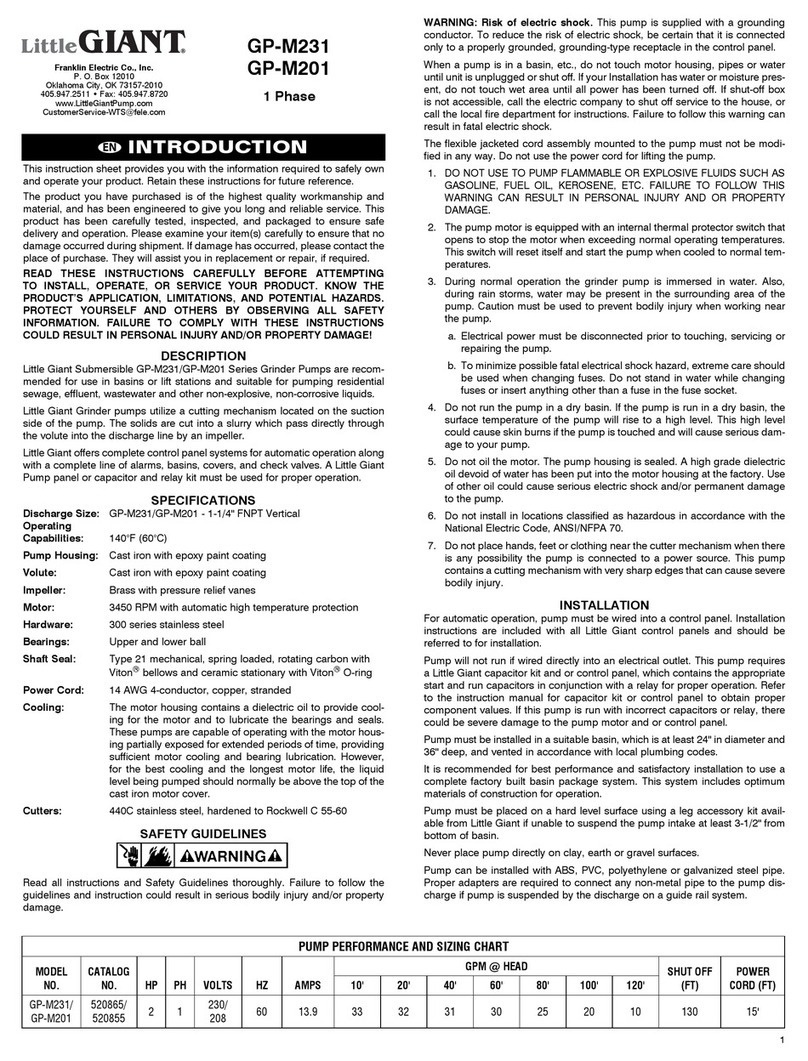

Little Giant

Little Giant 15SC-CIA-RF owner's manual

Flofab

Flofab 8FFSEHA Series Installation, operation & maintenance manual

WaterAce

WaterAce R100U owner's manual

red lion

red lion Engine-Driven Aluminum TRANSFER Pump manual

FLORABEST

FLORABEST FTP 400 C2 translation of original operation manual

FLORABEST

FLORABEST FGPS 1100 B2 translation of original operation manual

Alfalaval

Alfalaval LKHP instruction manual

Little Giant

Little Giant GP-M231 manual

Aqua PRO

Aqua PRO AP4800 instructions