High-End Technology F-20 User manual

1"

www.EJF.com"

High End Technology 90mm F-20

Assembly Manual

Specifications:

- Length: 57" 1430MM

- Wingspan: 29.5" 750MM

-Weight: 3lbs 6oz

- Full Intake/Exhaust ducting with NO cheater holes

- EDF - HET-9305 FAN

- Motor - HET-700-68-1400

- ESC ±HET-100HV

- Lipo ±10S±5000mah, 35C

- 8 servos ±2 ±Elevator, 2 ±Ailerons, 2±Flaps, 1 ±Rudder, 1 ±Steering

High%End%Technology%RC%Asia%Pacific%Ltd.%

Room$2202$Cheung$Tat$Centre$

18$Cheung$Lee$Street$Chaiwan$

Hong$Kong$

Phone:'852'2187'2622

www.HighEndRC.com"

2"

www.EJF.com"

Table of Contents

Introduction Pg 3

Out of the Box Pg.4

Wing Assembly Pg.5-7

Vertical Stabilizer and Rudder Assembly Pg.8-9

Elevator Assembly Pg.8- 10

Retract Mount Assembly Pg.11-14

Fan Mount Assembly Pg.14-15

Fan Unit and Thrust Tube Installation Pg.15-17

Final Equipment Placement Pg.13

Center of Gravity and Initial settings Pg.17-18

3"

www.EJF.com"

Introduction

Although the F-20 goes together very easily, there is still some construction involved, this is NOT a plane for

beginners, and you should have some experience with putting together ARFs. Please look carefully at the

pictures and explanations carefully before performing any work. There are many ways to build a plane, eg servo

mounting methods, it is up to the builder to fully test their airplane and flight controls before flight. As the

builder of the prototype airframe, I like to make servos serviceable as much as possible. Before you glue

anything to any surface, make sure it is clean and in the case of fiberglass parts, I sand first with 80 grit

sandpaper and then clean the area where glue will be applied. I often glue servos to surfaces, I make sure to use

tape around the servo so that when the servo is moved, you can also remove the glue by removing the tape. Try

to use a Single piece of tape around the servo as to provide more strength.

You will require some additional items before you can complete your F-20 constructions, along with some

common model building tools. The amount of channels required is a minimum of 6, but you have to be able to

mix and reverse channels, it is highly recommended that you have more than 6, the prototype model used a total

of 7, as follows: 1channles for flaps, 2 channel for elevators, 1 channel Rudder and otherwise you will DQG³<´

cable for Steering servo (I used a separate channel for steering), 1 channel retracts, 1 channel throttle

Additional Items Required

- HET-RC EDF9305 or similar

- Typhoon EDF motors 700-68-1400 or suitable for your power requirements

- HET-100HV

- 8 micro digital servos (2X Aileron, 2X Elevator, 2X Flaps, 1 Rudder and 1 Steering)

- Retracts

-6-8 ch. Computer Radio system w/ 8 servos.

- Lipo battery (Suitable for your motor and ESC)

-5 or 30 minute epoxy

-micro balloons

-CA Glue w/ accelerator

-Velcro.

Standard Model airplane building tools:

-Drill or Dremel tool

-Pliers/cutter

-Scissor

-Xacto Knife

4"

www.EJF.com"

OUT OF THE BOX

PICTURE ON LEFT: Top side of the plane place together for pictures. 1X fuselage, 2X Wings, 1X vertical stab and

rudder, 2X elevators, 2X Missile Rails, Ailerons, flaps and missiles not shown in the pictures

PICTURE ON RIGHT: Bottom of the airplane, Landing gear and servo locations already built into the plane.

PICTURE ON LEFT: Few formers needed to build, top and center are battery tray, the rest are Fan Mounting formers.

PICTURE ON RIGHT:, Vertical Fin and Rudder. Below are the Missile Rails, Missiles, Canopy Frame and Clear Canopy

.

5"

www.EJF.com"

WING CONSTRUCTION

The first thing to do is to sand all parts that will be glued; I used 80 grit sandpaper to remove the paint from the Fuselage

and then cleaned it with cleaning alcohol (denatured alcohol). The wing spar will need to be lightly sanded and so will the

wing; you may elect to remove some of the covering where the wing glues on to the fuselage. This is left to the discretion

of the builder. My Fuselage did not have a slot for the Aileron servo wire to go through, I used the wing to measure out

where the servo would exit and cut a slot. NOTE: When I received the F-20, the wings had already been glued to the

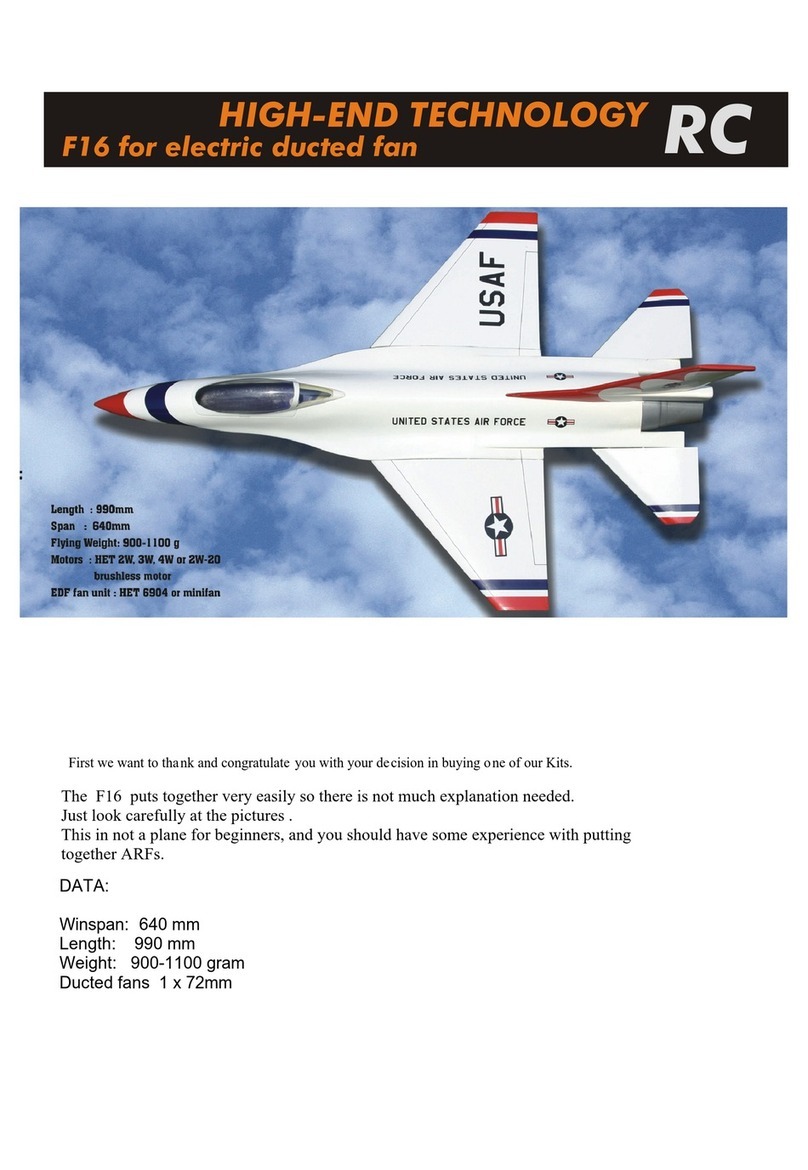

fuselage, I will use some pictures from the HET F-16 as reference.

PICTURE ON LEFT: The example above is from the HET F-16, but the procedure is the same. Sand the Spar lightly and

I used 30 minute epoxy, I used a small stick that can push epoxy inside the wing and provide glue all over the cavity in the

wing.

PICTURE ON RIGHT: Do not try to force the wing spar too far into the wing; you should feel it stop once it reaches

about 50% into the wing, clean off excess glue from where the spar meets the wing. Notice that there is no access for the

VHUYRZLUHRQWKHIXVHODJHLILW¶VQRWSUHVHnt already; this is the perfect time to cut one out.

PICTURE ON LEFT: The whole cut out after the wing was joined, it is best to cut it on the fuselage and the wing before

you glue the wing on the body.

PICTURE ON RIGHT: Test fit the wing with the Spar in place and make sure there are no GAPS before you glue the

wing to the fuselage. Trim the spar if needed. NOTE: Carbon Fiber Spar is very brittle, sand or cut the spar with dremmel

and cut off wheel, DO NOT use pliers, scissors or anything that will compress (crunch) the spar. Once you are satisfied

with the fit of the wing, glue the wings to the airplane with 30 min epoxy or glue of your choice.

6"

www.EJF.com"

WINGS CONTINUED

PICTURE ON LEFT: Check the Aileron and Rudder hinge slots to make sure the hinges fit properly. If needed, use and

exacto knife open up further just make sure to get them in the middle of the leading edge of the Aileron or Flap.

PICTURE ON RIGHT: I am checking the Hinge Slot or hole in the HET F-16 Aileron.

PICTURE ON LEFT: When the hinges are glued, I measure the pushrod to mark the servo location. Measure your servo

wire and add servo extension wire to reach your receiver.

PICTURE ON RIGHT: When gluing servos on a model airplane, I like to protect them using tape, I used a single piece of

tape that is able to wrap around the servo at least twice. I glued the Aileron servos directly to the wing. This example is

the HET-F16.

7"

www.EJF.com"

WINGS CONTINUED

PICTURE ON LEFT: With the servo in place I make balsa mounts for the cover.

PICTURE ON RIGHT: Aileron is done.

PICTURE ON LEFT: Made a mount for the Flap servo to have it removable.

PICTURE ON RIGHT: Glue in the Mount and Servo to the wing. NOTE the routing of the Aileron and Flap servo wiring

is not in the fuselage.

8"

www.EJF.com"

VERTICAL FIN / RUDDER

PICTURE ON LEFT: Use your servo to measure and cu the access for the servo, there are many ways to mount a servo.

PICTURE ON RIGHT: If you want to be able to service/access your servo, install it from inside the fuselage, you can

always remove and make changes. Two pieces of wood where glues to hold the servo screws in place.

PICTURE ON LEFT: Rudder Servo as viewed from inside the Fuselage.

PICTURE ON RIGHT: Place the Vertical FIN behind the servo so you can measure where you will need access for your

control Horn. At this point your Rudder servo should be centered using your radio.

9"

www.EJF.com"

PICTURE ON LEFT: Servo Control Horn Cut out on the Vertical stab

PICTURE ON RIGHT: Sand the fuselage and the inside of the Vertical Fin, the example above is the F-16 shown for

illustration. Test fit everything and then satisfied, Glue the vertical fin the body.

.

PICTURE ON LEFT: Connect your servo to the Rudder now that your vertical fin is glued to the body.

10"

www.EJF.com"

ELEVATORS

PICTURE ON LEFT: The elevator already comes built and ready to be mounted to the fuselage. The control Horn is

glued and then uses two screws for additional support, the two screws for the control horn can bind with the fuselage.

Sand the elevator rod lightly making sure you do NOT bend the rod.

PICTURE ON RIGH: You will need to add washers or spacers until your elevator moves freely, when satisfied with the

fit, Glue in the elevator to the rod with Epoxy.

PICTURE ON RIGHT: It is best to install the servos in the fuselage while no other equipment is in, this way you can have

access from the fan cover area and the rear of the plane. Add servo extensions as needed to reach your receiver and then

Mount the elevator servos to the bottom of the body/fuselage.

PICTURE ON LEFT: Once you mounted the servo, mark the location of your control horn and cut out the control horn

window. If you want to cut small openings use one of the servo covers from the wing to mark and cut-out on the bottom

of the fuselage.

11"

www.EJF.com"

ELEVATORS CONTINUED

PICTURE ON LEFT: The body has an access door where you could use to mount the servo, but there is enough room to

insert the servo through the Fan access door or the back of the jet.

PICTURE ON RIGHT: If you want to make the servo access door small, you can use the Aileron servo cover to mark the

size on the bottom of the fuselage. This example is from the F-16.

PICTURE ON LEFT: Center your servo with your Radio, and attach the servo horn to the arm and verify that the elevator

is still level.

PICTURE ON RIGHT: View of both elevators completed.

12"

www.EJF.com"

RETRACTS

PICTURE ON LEFT: Mark and tape the location of the NOSE gear door opening. There is a panel line on the front and

back where the door should be cut.

PICTURE ON RIGHT: The nose gear opening is about 1.75 inch wide (44.45mm), and .75 inch (19.05mm) from the

panel line in the fuselage. Once you cut the access door out, mount your nose gear retract when ready.

PICTURE ON LEFT: Test fit the retracts to the wing and mark the location where the air tube touches.

PICTURE ON RIGHT: Make a hole for the airline where the retract touches the wing.

13"

www.EJF.com"

RETRACTS CONTINUED

PICTURE ON LEFT: Connect the Air-Lines to the retracts, leave enough room on each so that you can pull them ou

through the fan access opening, make sure both Air lines are the same length.

3,&785(215,*+7<RXZLOOQHHGWRLQVWDOOWZR³7´FRQQHFWRUVFRQQHFWWKHWZRPDLQJHDUDQGWKHWKLUGZLOOJRWRWKH

IURQWUHWUDFWZKHUH\RXZLOOXVHWKHVHFRQG³7´&RQQHFWRU

PICTURE ON LEFT: Each tire comes with three plastic washers; You will need to add them to the axle to prevent the

wheel from touching the strut. I placed two washers on the inside and one on the outside.

PICTURE ON RIGHT: I always make a flat spot on the axle to prevent the wheel/axle from coming loose during

operation. At this point you can secure the main landing gear to the wings.

14"

www.EJF.com"

RETRACTS CONTINUED

PICTURE ABOVE: Connect your retracts as shown, I used two different color air-lines for illustration. The Red line

above goes to the retracts, the ILUVW³7´WKHQRQHVLGHWRWKHQRVHJHDUDQGWKHVHFRQGVLGHJRHVWRWKH0DLQ*HDULQWKH

wing.

FAN MOUNTING

PICTURE ON LEFT: This are the formers included with the prototype plane. Fan mounting former, there are four rails

and two formers, the four rails are doubled up/glued together to make two rails and then glue them to the two formers, you

can use CA or 5 minute Epoxy.

PICTURE ON RIGHT: Glue your FAN formers together from the three pieces as shown.

15"

www.EJF.com"

FAN MOUNTING CONTINUED

PICTURE ON LEFT: Sand the inside of the fuselage where the Fan mount will need to be glued to the fuselage, then

clean all dust to have it ready for the glue.

PICTURE ON RIGHT: Test fit the fan mount to the fuselage and make sure it does not touch any part of the intake, you

can at this time also check the fan you are going to use. Once satisfied with the fit, Glue the fan mount to the fuselage.

PICTURE ABOVE: The other two formers make up the front tray.

16"

www.EJF.com"

FAN MOUNTING CONTINUED

PICTURE ON LEFT: Assemble the Fan and motor of your choice, This is the HET 9305 Fan and the HET 700-68-1400

motor.

PICTURE ON LEFT: Fan and motor assembled and ready to install. This the perfect time to install the connectors for

your Speed Controller (ESC).

PICTURE ON LEFT: Measure your Trust tube, I always use the fan to measure it on front.

PICTURE ON LEFT: Cut two slots on the thrust tube for the ears of the fan to fit around.

17"

www.EJF.com"

FAN MOUNTING CONTINUED

PICTURE ON LEFT: You can use a Ruler to pull the tape on the inside of the thrust tube. The front diameter is

determined by your choice of fan. Wrap the plastic around the fan. The rear diameter should be about 80MM which is the

diameter of the tail cone of the F-20

PICTURE ON LEFT: Once you have it ready, fold the thrust tube into a "C" shape and insert from the back of the jet.

SETTINGS:

Ailerons .38 Low High.50 measured at the middle of the aileron.

Elevator .75 Low High 1inch (Trailing edge set so the bottom of the elevator is flush with the

bottom of the fuselage).

Rudder: 1 Inch or as much as you can get

Flaps: 1 Inch OPTIONAL (WARNING: The F-20 will climb when the flaps are lowered)

CG 9.00" 228.6MM Measured from the intake back into the wing.

PICTURE ON LEFT: Aileron LOW Rate travel measured half way out on Aileron.

PICTURE ON LEFT: CG is 9 inches from the INTAKE back.

18"

www.EJF.com"

W A RNIN G!

Although the F-20 is a stable airplane, it is not a trainer or first EDF airplane. This

airplane is capable of very high speeds and therefore can cause serious personal

injury and property damage. We strongly urge you to seek the help of an AMA

approved instructor if this is your first aircraft of this type. Please use common

sense.

F ly in suitableareasfor a high-speed aircraftsuch asan AMA approved field.

High-end Technology assumes no liability for the operation or performance of this product. It is

the responsibility of the operator to use this product in a safe and responsible manner.

tesddf

PICTURES ABOVE: Reference for your CG location. 9 inches from the intake, 1.75 inches back from the end of the

Wing extension on the Fuselage. And 1.25 inches forward of the Main landing gear cut out.

Table of contents

Other High-End Technology Toy manuals