High Voltage CDS Series Guide

Safety,Operation,andProcedureInstructionsfortheCDSSeriesof

CapacitorDischarge/HipotCableFaultLocators

Danger- Lethal Voltages:

Equipment to be used by trained personnel only

This Operator Manual contains instructions for the operation of a High Voltage power source. The operator of this equipment

must use good judgement and follow all safety precautions noted in this guide to ensure the protection of himself and others in

close proximity to the test area. Failure to follow the instructions could result in injury or

death. Proper grounding of the test set must be done prior to connecting this

unittoapowersource.

CD

S

SERIES

OperatorManual

©HIGH VOLTAGE, INC.

31CountyRoute7A

Copake,N.Y.12516

Phone518/329-3275• Fax 518/329-3271

http://www.hvinc.com

LAST SAVED 1/27/2009 10:45 AM, T:\PRODUCT\DOCUMENTS\Manuals\CDS\MANcdsURa_tdr1_2k9.doc

TableofContents

About the Operator Manual 1

SECTION 1

General Information 2

Theory of Operation 2

Features and Specifications 3,4

Controls and Indicators 6,7

SECTION 2

Setting up the Equipment 8

Operating the Equipment 9-17

Hipot / Burn Mode 9-11

Capacitor Discharge Fault Locating (Thumping) 12-14

Capacitor Discharge Fault Locating (TDR) 15-17

Blank Page for Notes 18

SECTION 3

Performing Special Operations 19

Miscellaneous 19

Return Material 20

Warranty 21,22

OPERATOR MANUAL

- 1 -

AbouttheOperatorManual

Important

ThisOperatorManual describesthefeatures andsafe operation

ofaHigh VoltageTestSet.The instructions areintended tobe

clear andsimple, but theoperator must betrained and qualified

according to established procedures forthe useof this typeof

equipment.

This Operator Manual is organized to provide information on the CDS Series in steps that

familiarizethe newoperator with theentire scopeof operation of thistest set.

Section1: Specifications andControls.

Section2: Setup andOperation.

Section3: Performing SpecialOperations.

TheFunctions,Features,andSpecifications oftheCDSSeriesofCapacitorDischarge/HipotCableFault

LocatorsarealsodiscussedintheCDSBrochureavailablefromHighVoltage,Inc.

OPERATOR MANUAL

- 2 -

GeneralInformation

Thissection familiarizes theoperator withthe features andspecificationsof the

CDS Series of Capacitor Discharge/Hipot Cable Fault Locators manufactured by HIGH

VOLTAGE, INC.

Operation of this unit with standard TDR fault locating devices is possible using the internal Arc

Reflection Filter.

TheoryofOperation

With the use of buried underground cables in primary feed electrical installations, it is necessary to

locate faults and repair the cable the cable as quickly as possible to restore power to affected

areas. The CDS Series of Capacitor Discharge/Hipot Cable Fault Locators uses an energy

storage capacitor to provide a pulse of energy to create an audible sound at the fault location for

tracing. HVI CDS series fault locators all have built in Arc reflection filters for use with most TDR’s

(RADAR)on the marketat thumpvoltages upto 25 kV.

SECTION

1

OPERATOR MANUAL

- 3 -

FeaturesandSpecifications

The CDS Series of cable fault locating test sets provide continuously adjustable output voltages for the test

and location of faults in primary cables. The constant energy design provides the maximum energy at the

lowestvoltage to quickenfault locationwhile notoverstressing the cablesand terminations.

Standardfeatures ofthe CDSSeries of CapacitorDischarge/Hipot FaultLocator

•Continuouslyadjustable output voltage

•“Zero Start” Interlock provision

•Singlerange volt meter

•Singlerange current meter

•Single-cycleor continuous CapacitorDischarge operation

•Adjustabledischarge timing, 3-9 seconds

•MotorizedOutput VoltageTapSwitch

•Manuallyoperated Coupler Switchwith Radarand Directposition

•Twointernal dischargesolenoids, one forthe outputcable, one forthe internalcapacitorbank

•Onepiece design

•Transitprotected meters preventmeter damagebetween test sites

•Shieldedhigh voltage outputcables includedon all models.

•4 AWG Braided ground cable forsecure groundconnection

OPERATOR MANUAL

- 4 -

OPTIONS AVAILABLE

•Storage Reel system available forOutputand GroundCables

•CDS-36available with 3.2kJdischarge capacitor

OPERATOR MANUAL

- 5 -

CDS MODEL SPECIFICATIONS

See last page of parts list for

Specifications

OPERATOR MANUAL

- 6 -

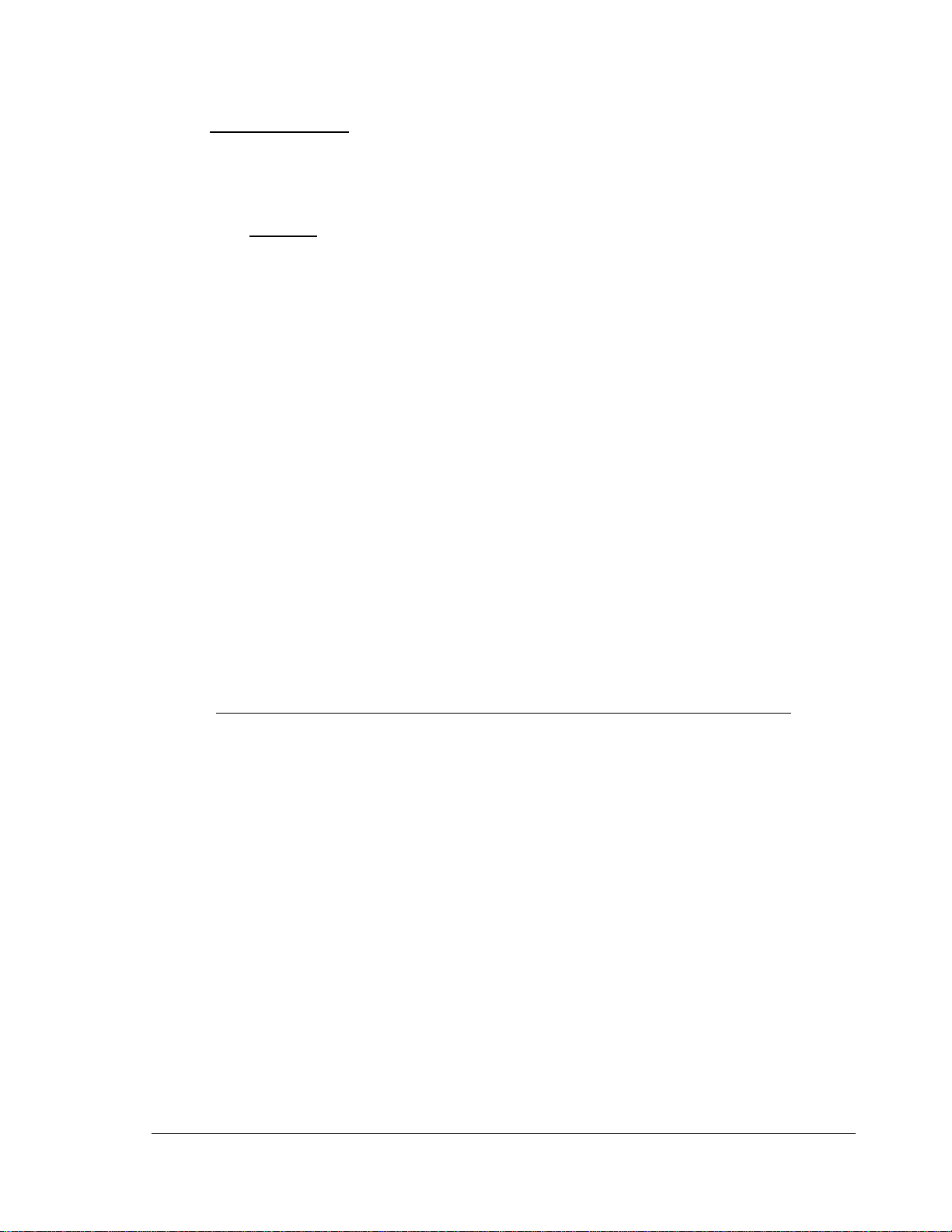

DISCHARGE

SINGLE

CONTINUOUS

MODE

PULSE

OPERATING

HIPOT/

BURN

MODE

CAP

DISCHARGE

OUTPUT

ADJUST

HEATER

MAIN

POWER

ON

OFF

STOP START

50

40

30

20

10

0

60

70

80

90

100

MODEL CDS-36 CONSTANT ENERGY CAPACITOR DISCHARGE SYSTEM

COUPLER MODE

DIRECT RADAR

OFF

OUTPUT TAP

18kV OFFOFF

9kV 36kV

INTLK

EXT DISCHARGE

TIMING

3 SEC 9 SEC

Figure1CDS36U Seriesfront panel controls.

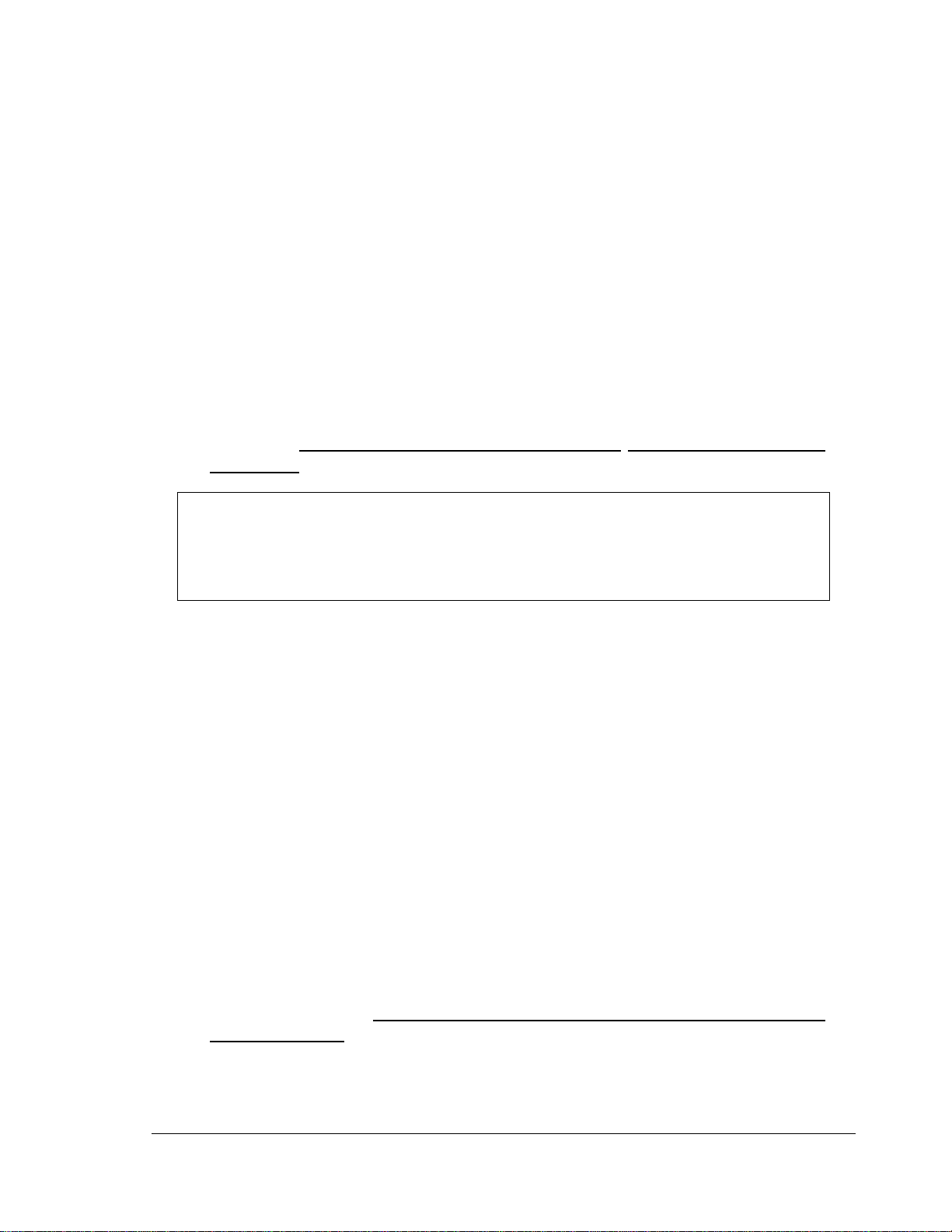

G

S

R

E

M

E

E

N

C

Y

T

O

P

HEATER

MAIN

POWER

MODEL CDS-2010

DISCHARGE

MODE MODE

OPERATING

SINGLE

PULSE HIPOT/

BURN

CONTINUOUS CAP

DISCHARGE

OUTPUT

ADJUST

STOP START

CONSTANT ENERGY CAPACITOR DISCHARGE SYSTEM

50

40 60

70

80

90

100

30

20

10

0

ON

OFF

INTLK

EXT

DIRECT

COUPLER MODE

RADAR

OFF 10kV

OUTPUT TAP

OFF

5kV 20kV

OFF DISCHARGE

TIMING

3 SEC 9 SEC

Figure2CDS20U Seriesfront panel controls.

OPERATOR MANUAL

- 7 -

MAIN POWER

The MAIN POWER circuit breaker provides the power to the control and power circuits. The MAIN POWER

pilot light will light when the power is on and voltage is available through the input line cord. The power

supplied to the input line cord must be from a grounded source rated to match the input power specifications

notedin Table-1.

HEATER

The HEATER circuit provides assistance in keeping the internal components from accumulating moisture in

dampenvironments. The pilotlight will illuminatewhen the circuitis powered.

START/STOP

The START/STOP pushbuttons activate (de-activate) the high voltage power circuits. The LED indicators

provide long life positive indication of the circuit status. The RED (START) LED lights when high voltage is

energized, the GREEN (STOP) LEDlightswhen the highvoltage isde-energized.

OUTPUT ADJUST

The OUTPUT ADJUST control variable transformer sets the output voltage. The 0-100% markings on the

knob indicate the low to high setting. The control must be at ZERO (0) to energize the high voltage circuits.

The output control must always be returned to zero at the completion of testing, prior to de-

energizing the output.

VOLTMETER

The KILOVOLT METER indicates the output voltage. 1-% precision resistors minimize the need for re-

calibrationdue to agingshift.

CURRENT METER

The CURRENT METER provides output current readings for the HIPOT/BURN function and capacitor

charge current in CAPACITOR DISCHARGE mode.

CAPACITOR DISCHARGE MODE

The CAPACITOR DISCHARGE MODE switch presets the control circuits for a single pulse (for use with

TDR)or allows thecircuit torun continuouslyin pulsemode.

OPERATING MODE

The OPERATING MODE switch controls the connection of the capacitor discharge bank and capacitor

discharge solenoids. The HIPOT position is used for high voltage testing without the energy discharge

capacitors in the circuit. The HIPOT mode also connects a current limiting reactor for burning down cables

and limit follow through current in a fault. The CAPACITOR DISCHARGE mode for fault locating cable

connectsthe capacitorbank intothe high voltage circuit and enablesthe dischargesolenoids.

OPERATOR MANUAL

- 8 -

COUPLER MODE

The COUPLER MODE switch is used to connect the internal radar coupler into the output circuit. The

COUPLER MODE must be in either RADAR (thump voltages up to 25 kV) or DIRECT position or the high

voltage cannot be energized. If the switch is operated to another position when the high voltage is energized,

theoutput will turnoff.

OUTPUT TAP

The OUTPUT TAP switch provides maximum output voltage selection while configuring the discharge

capacitor bank for the output voltage selected. The use of this switch provides a constant energy for capacitor

discharge even at lower output voltages. When in any one of the OFF positions, the high voltage cannot be

energized. If the switch is operated during testing, the output will de-energize. When changing tap positions

allow20 seconds forthe motorizedswitch toachieve finalposition.

EXT INTLK

The EXT INTLK external interlock socket provides a safety interlock to disable the high voltage control

circuits. A normally closed switch from a test cage or foot switch can be wired to this connector to provide

accesscontrol orelectricallockout ability.The circuitis within the120Vac control circuit.

Note regarding the use of MC connectors:

The MC connector requires the operator to pushIN before pulling OUT when disconnecting.

OPERATOR MANUAL

- 9 -

SETTINGUPTHEEQUIPMENT

The setup of this equipment has been minimized by careful consideration for the operator during design. The

CDS Series’ one-piece FIELDPORTABLE constructionmakesthis thepreferred unitfor faultlocating.

1. Select a location for the unit that will allow easy viewing of the meters at a safe distance

fromthe testcable.

Caution!!

Before making any cable connections, ensure that the cable being

tested has been properly identified, de-energized, and grounded!

2. Be sure that all the controls are off,in their de-energized or fully counterclockwise

position.

3. Unspool the cables onto the ground. Separate the input line cord, ground lead and

outputcables from eachother.

4. Secure the ground test lead to the cabinet.TheGroundstud on the rear panel of the

unit must be used for that purpose. A 4 AWG braided copper lead has been provided for the

ground connection. Proper grounds are essential when fault locating with a capacitor

discharge device. Connect the ground lead cable clamp to the station ground of the cable

beingtested.

SECTION

2

OPERATOR MANUAL

- 10 -

OperatingtheEquipment

This section provides step-by-step instruction on various test methods. Many facilities have their own

in-house test procedures, and this manual is not to supercede these. The purpose of this section is

toexplain thecapabilities of thistest setin real-world applications.

DC InsulationTesting of Cables in the Hipot/Burn Mode

When testing cables, either single or three phase, there are certain steps that must be observed to ensure

safeoperation.

1. Ensure that all the steps listed in Setting up the Equipment have been accomplished.

Take special note to ground the unit to a solid earth ground using the supplied 4 AWG

braided copper lead. Connect the ground lead cable clamp to the station ground of the

cable being tested.

Caution!!!

Before making any cable connections, ensure that the cable being

tested has been properly identified, de-energized, and grounded!

2. Make sure that all insulators, stress cones, and pot heads are clean and free of moisture.

Thiswill prevent flashoverand minimizeleakage.

The shields of all cables must be securely tied to ground at the

nearest end of the cable.

3. Isolate the far end of the conductors under test for the test voltage; that may mean

separating some of the conductors in a multi-conductor cable from each other and their

shields.

4. Any conductors or wires in the cable or the vicinity not being tested must be grounded to

avoida buildup ofcharge andpossible shock hazard.

5. Connect the RETURN clamp totheneutral orshield ofthe cable beingtested.

6. Connect the HV lead clamp tothe center conductorof thecable beingtested.

Note: If an output cable reel is being used, connect the high voltage MC connector to the

center plug on the reel. The MC connector requires the operator to push IN before pulling

OPERATOR MANUAL

- 11 -

OUT to disconnect. Connect the return ring terminal to the brass return stud on the reel.

Make all load test connections to the cable from the reel leads as noted in steps 5 and 6.

7. Connect the input power cord to a grounded power source (see specifications for input

voltage and frequency). If the distance to a power source is greater than the cord provided,

agrounded extension cord ofsufficient ampacitywill work.

8. Operate the MAIN POWER circuit breaker to energize the control circuits. (Check

emergencystop button isout andfor External Interlockplug orswitch ifapplicable.)

9. Placethe OPERATING MODE switch intheHIPOT/BURN position.

10. Voltage must be applied according to specifications from the cable manufacturer or any

otherapplicable test standards.

11. Choose the appropriate OUTPUT TAP (9/18/36 kVdc, 5/10/20 kVdc) for the cable being tested.

When changing tap positions the switch must be in position to energize high voltage, allow 20

secondsfor themotorized switch toachieve finalposition.

12. Besure toplace theCOUPLER MODE switch inthe DIRECT position.

***CAUTION***

POTENTIALLY LETHAL VOLTAGES

MAY BE PRESENT

13. With the OUTPUT ADJUST at zero (zero start interlock engaged), depress the START

pushbutton.The START light willglow.

14. Increase the output by rotating the OUTPUT control slowly clockwise until the desired

outputvoltage isreached.

15. Maintain the output voltage for the test time specified in your standard procedures. Leakage

current may be read on the current meter at this time. Should the test cable arc or fail, the

outputwill collapse toa lower valueand thecurrent meterreading will increase.

16. Burning of the cable for THUMPING can be accomplished at this time by allowing the fault

toburn until theoutput voltageis at thedesiredthumping voltage.

OPERATOR MANUAL

- 12 -

17. At completion of test or operation, the depress the STOP pushbutton, the output cable load

will be discharged through an internal discharge resistor. Turn off the MAIN POWER circuit

breaker.

18. Always use a GROUND HOOK to ground the cable(s) prior to disconnecting the

output cable.

OPERATOR MANUAL

- 13 -

Capacitor Discharge Fault Locating (thumping)

High Voltage Cables

When testing cables, either single or three phase, there are certain steps that must be observed to ensure

safeoperation.

1. Ensure that all the steps listed in Setting up the Equipment have been accomplished.

Take special note to ground the unit to a solid earth ground using the supplied 4 AWG braided

copper lead. Connect the ground lead cable clamp to the station ground of the cable

being tested.

Caution!!!

Before making any cable connections, ensure that the cable being

tested has been properly identified, de-energized, and grounded

2. Make sure that all insulators, stress cones, and pot heads are clean and free of moisture. This

willprevent flashover inareasother thanthefaultsite.

The shields of all cables must be securely tied to ground at the

nearest end of the cable.

3. Isolate the far end of the conductors under test for the test voltage; that may mean separating

someof the conductorsin amulti-conductor cablefrom each otherand theirshields.

4. Any conductors or wires in the cable or the vicinity not being tested must be grounded to avoid a

buildupof charge andpossible shockhazard.

5. Connect the RETURN clamp totheneutral orshield ofthe cable beingtested.

6. Connect the HV lead clamp tothe center conductorof thecable beingtested.

Note: If an output cable reel is being used, connect the high voltage MC connector to the

center plug on the reel. The MC connector requires the operator to push IN before pulling

OUT to disconnect. Connect the return ring terminal to the brass return stud on the reel.

Make all load test connections to the cable from the reel leads as noted in steps 5 and 6.

OPERATOR MANUAL

- 14 -

7. Connect the input power cord to a grounded power source (see specifications for input voltage

and frequency). If the distance to a power source is greater than the cord provided, a grounded

extensioncord of sufficientampacity will work.

8. Operate the MAIN POWER circuit breaker to energize the control circuits. (Check emergency

stopbutton is outand forExternal Interlock plug or switch if applicable.)

9. Placethe OPERATING MODE switch intheCAP DISCHARGE position.

10. Voltage must be applied according to specifications from the cable manufacturer or any other

applicabletest standards.

11. Choosethe appropriate OUTPUT TAP voltage(9/18/36 kVdc,5/10/20 kVdc) forthe cablefault being

tested.When changing tappositions theswitch must bein positionto energize highvoltage, allow 20

secondsfor themotorized switch toachieve finalposition.

12. Assurethat the COUPLER MODE switchisinthe DIRECT position.

13. Choose the discharge timing (3-9 seconds). This adjustment can be re-adjusted during test if

desired.

14. Placethe CAPACITOR DISCHARGE MODE in CONTINUOUS position.

***CAUTION***

POTENTIALLY LETHAL VOLTAGES

MAY BE PRESENT

STORED ENERGY LEVELS IN THE CABLE

GREATLY INCREASE THE RISK OF FATAL

INJURY IF CONTACT IS MADE WITH THE LOAD

WHILE AT ANY VOLTAGE.

15. With the OUTPUT ADJUST at zero (zero start interlock engaged), depress the START

pushbutton.The START light willglow.

16. Increase the output by rotating the OUTPUT ADJUST slowly clockwise until the desired

Capacitor Discharge (Thumping) voltage is reached. The OUTPUT ADJUST percentage

markings will provide a good guide to the level the output will reach. The cable fault will break

OPERATOR MANUAL

- 15 -

over ('Thump') at the fault location and acoustical devices can be used to pinpoint the resulting

sound.

17. Uponlocating thefailure point, depressthe STOP pushbuttontointerrupt thetest cycling.

18. At completion of test or operation, the depress the STOP pushbutton, the internal capacitor(s)

and output cable load will be discharged through two internal discharge resistors. Turn off the

MAIN POWER circuitbreaker.

19. Always use a GROUND HOOK to ground the cable(s) prior to disconnecting the output

cable.

OPERATOR MANUAL

- 16 -

Capacitor Discharge Fault Locating

High Voltage Cables Using aTDR Device

When testing cables, either single or three phase, there are certain steps that must be observed to ensure

safeoperation.

Please Note: The TDR Coupler is always active. When in the DIRECT MODE, the TDR can

operateasa TDR-RADAR,butthe Arc-Reflection Mode ofthe TDR will not work in DIRECT.

1. Ensure that all the steps listed in Setting up the Equipment have been accomplished.

Take special note to ground the unit to a solid earth ground using the supplied 4 AWG braided copper

lead.Connect the ground lead cable clamp to the station ground of the cable being tested.

2. The TDR or Radar device should be plugged directly into the AC receptacle on the side panel of

the CDS cabinet. The TDR signal input is connected to the BNC connector (on the control panel) marked

TDR SIGNAL. TheTDR trigger input(if onTDR) connectsto theBNC marked TDR TRIGGER.

3. Operatethe COUPLER switch totheRADAR position.

Caution!!!

Before making any cable connections, ensure that the cable being

tested has been properly identified, de-energized, and grounded!

4. Make sure that all insulators, stress cones, and pot heads are clean and free of moisture. This

willprevent flashover inareasother thanthefaultsite.

The shields of all cables must be securely tied to ground at the

nearest end of the cable.

5. Isolate the far end of the conductors under test for the test voltage; that may mean separating

someof the conductorsin amulti-conductor cablefrom eachother and theirshields.

6. Any conductors or wires in the cable or the vicinity not being tested must be grounded to avoid a

buildupof charge andpossible shockhazard.

7. Connect the RETURN clamp to theneutral orshield ofthecable beingtested.

8. Connect the HV lead clamp tothe center conductorof thecable beingtested.

OPERATOR MANUAL

- 17 -

Note: If an output cable reel is being used, connect the high voltage MC connector to the

center plug on the reel. The MC connector requires the operator to push IN before pulling

OUT to disconnect. Connect the return ring terminal to the brass return stud on the reel.

Make all load test connections to the cable from the reel leads as noted in steps 7 and 8.

9. Connect the input power cord to a grounded power source (see specifications for input voltage

and frequency). If the distance to a power source is greater than the cord provided, a grounded

extensioncord of sufficientampacity will work..

10. Operate the MAIN POWER circuit breaker to energize the control circuits. (Check emergency

stopbutton is outand forExternal Interlock plug or switch if applicable.)

11. Voltage must be applied according to specifications from the cable manufacturer or any other

applicabletest standards.

12. Choosethe appropriate OUTPUT TAP voltage(9/18/36 kVdc, 5/10/20kVdc)for the cablefault being

tested.When changing tappositions theswitch mustbe inposition toenergizehigh voltage,allow 20

secondsfor themotorized switch toachieve finalposition.

13. Placethe OPERATING MODE switch inthe CAP DISCHARGE position.

14. Makesure theDISCHARGE MODE switch isinthe centerposition.

15. Set up the TDR in accordance with manufacturer’s instructions. At this time you should see a

lowvoltage trace onthe screenand the TDRshould be“armed”.

16. With the OUTPUT ADJUST at zero (zero start interlock engaged), depress the START

pushbutton.The START light willglow.

17. Increase the output by rotating the OUTPUT ADJUST slowly clockwise until the desired

Capacitor Discharge (Thumping) voltage is reached. The OUTPUT ADJUST percentage markings will

providea good guideto the levelthe outputwill reach.

18. Push the DISCHARGE MODE switch upward to the single pulse position. The CDS will

dischargeone pulse. If thecable fault brokeover, youshould see adeflection on theTDR screen. Ifnot,

you may need to repeat this stepata higher voltage.

19. Once you have pre-located the fault with the TDR, put the coupler switch in DIRECT MODE and

the discharge mode switch to the CONTINUOUS position. The cable fault will break over ('Thump') at

the fault location and acoustical devices can be used to pinpoint the resulting sound. Refer to pages 13-

15for further instructiononthumping indirect mode.

20. Uponlocating thefailure point, depressthe STOP pushbuttontointerrupt thetest cycling.

This manual suits for next models

6

Table of contents

Popular Industrial Electrical manuals by other brands

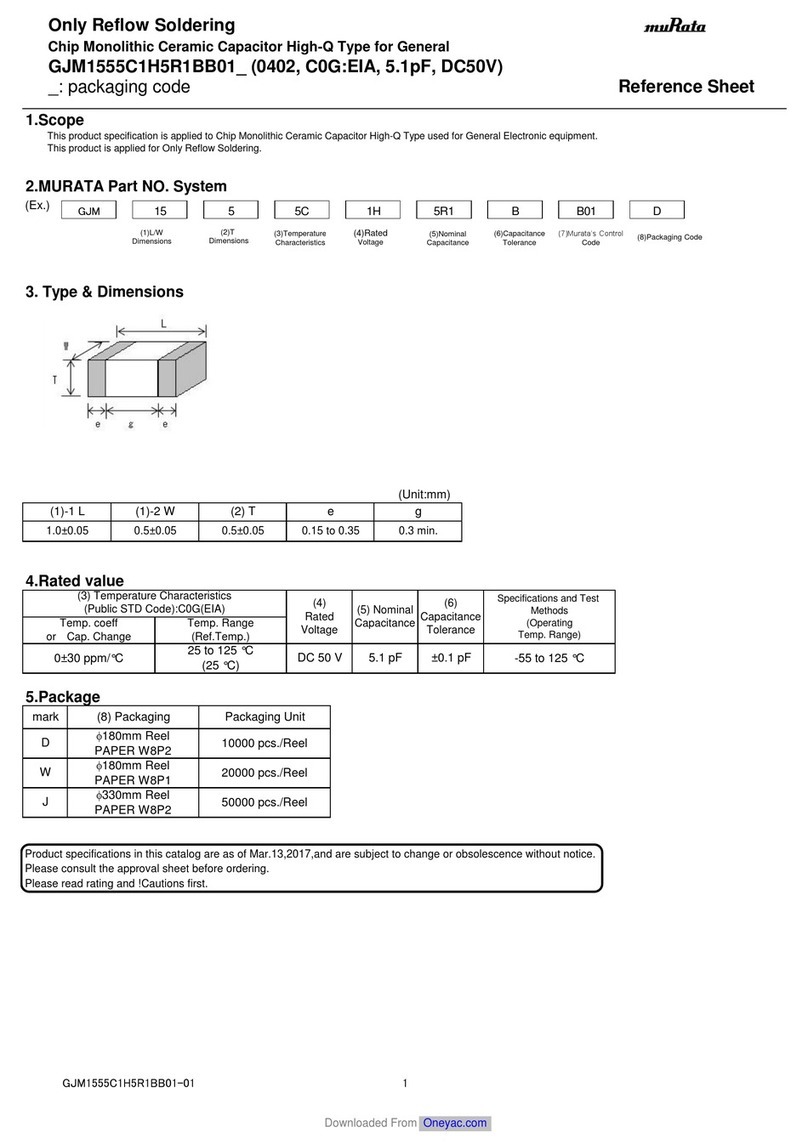

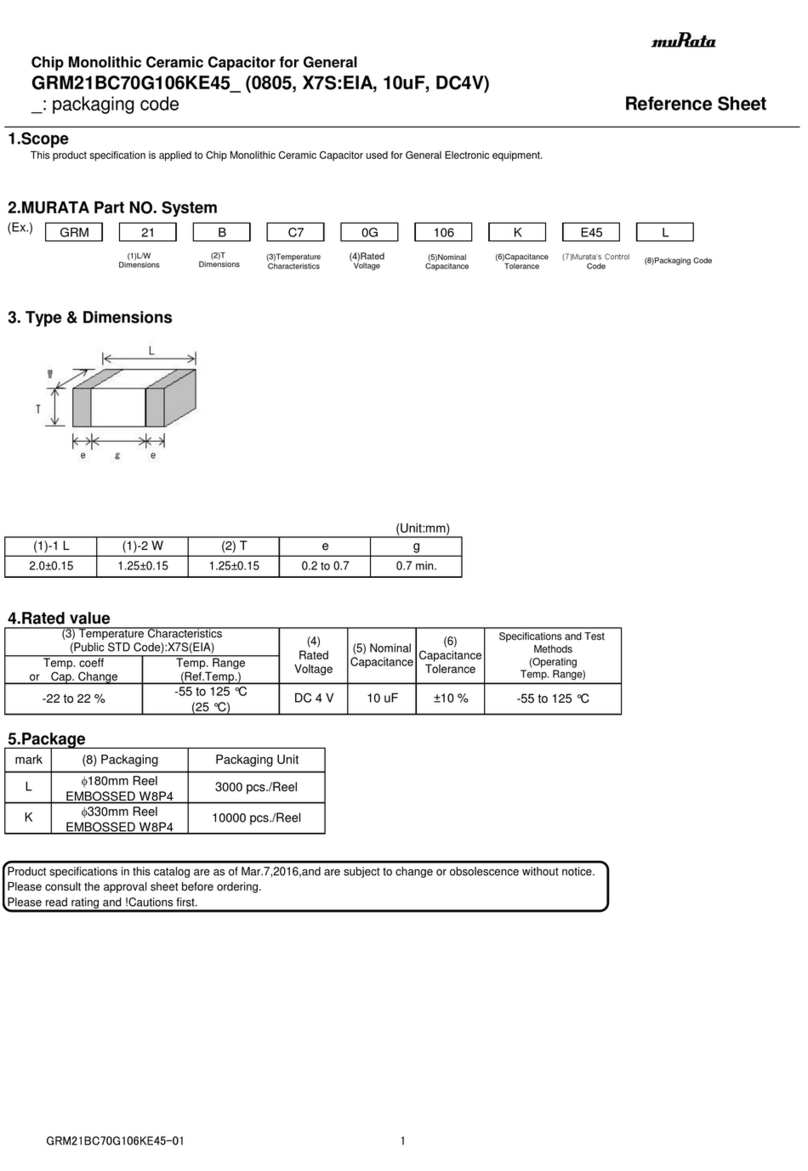

Murata

Murata GRM2165C1H332JA01 Series Reference sheet

Knick

Knick ProLine P224 P1 Series User and safety manual

Murata

Murata GRT188R6YA225KE13 Series Reference sheet

Murata

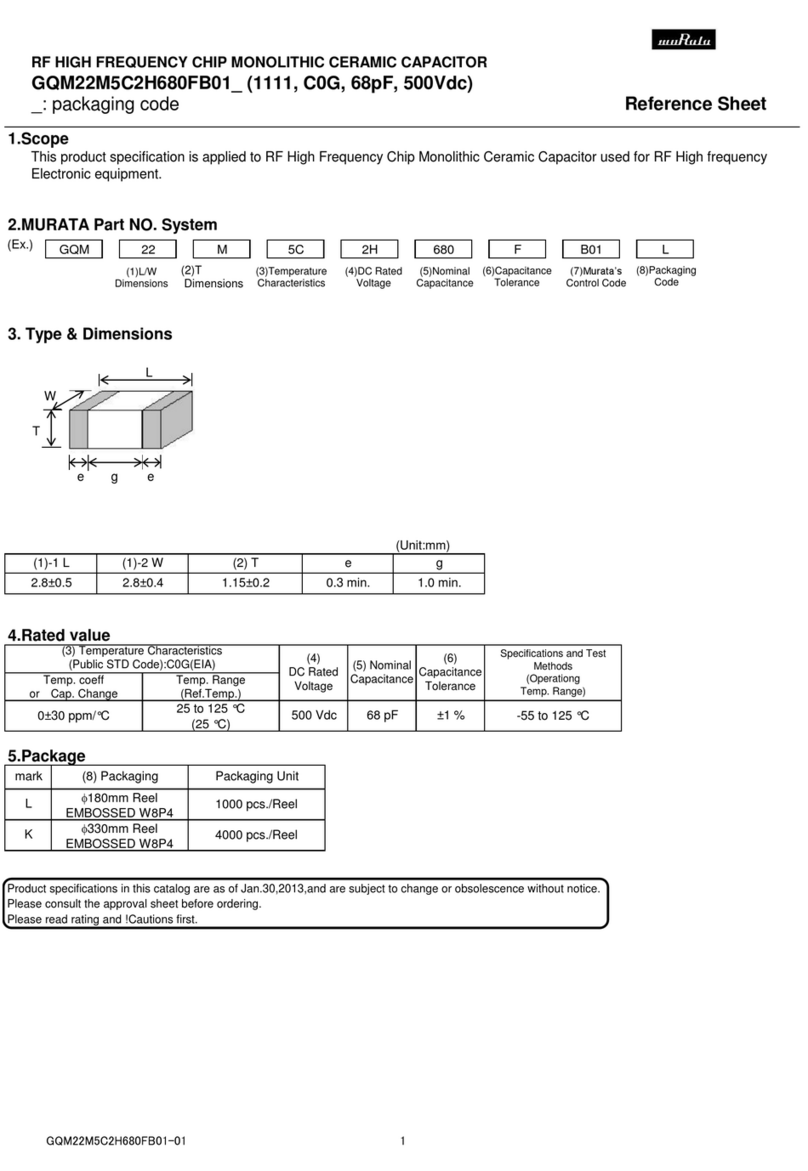

Murata GQM22M5C2H680FB01 Series Reference sheet

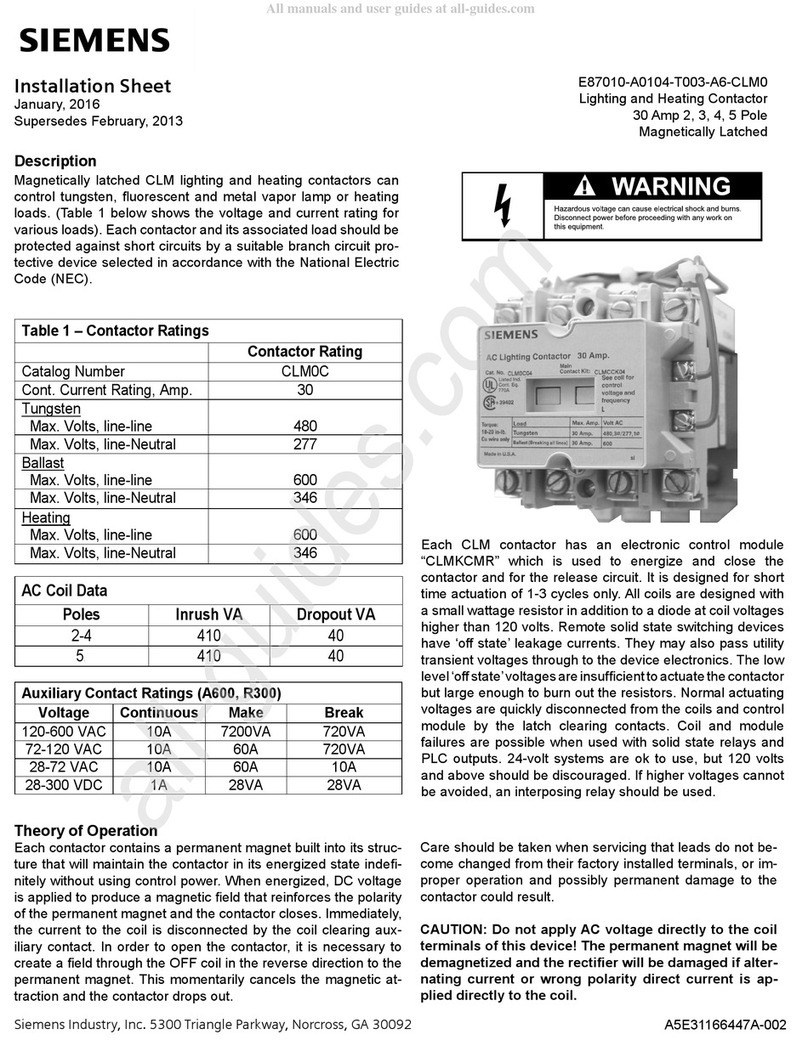

Siemens

Siemens P1 400A installation instructions

Murata

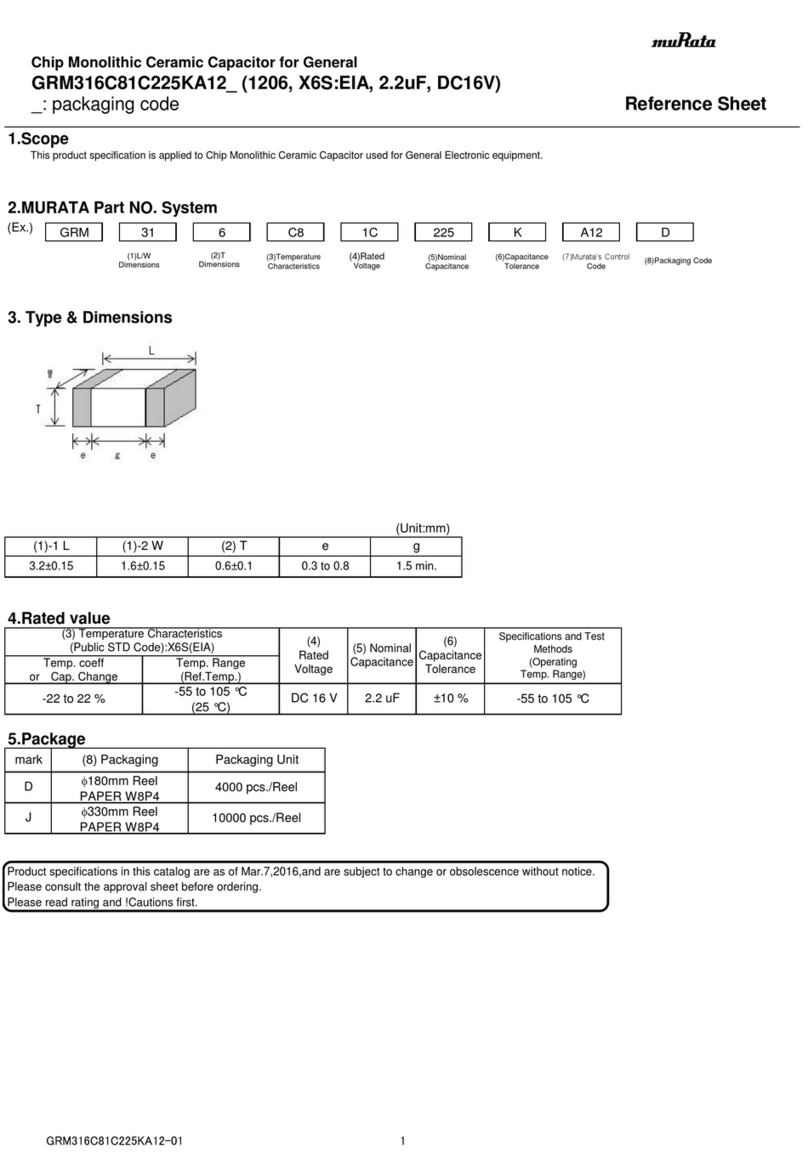

Murata GRM316C81C225KA12 Series Reference sheet