Hill 3900 User manual

Model 3900 Downow

Service Manual

IMPORTANT: Fill in Pertinent Information on Page 3 for Future Reference

Table of Contents

IMPORTANT PLEASE READ:

The information, specications and illustrations in this manual are based on the latest information available at the time of

printing. The manufacturer reserves the right to make changes at any time without notice.

This manual is intended as a guide for service of the valve only. System installation requires information from a number of

suppliers not known at the time of manufacture. This product should be installed by a plumbing professional.

This unit is designed to be installed on potable water systems only.

This product must be installed in compliance with all state and municipal plumbing and electrical codes. Permits may be

required at the time of installation.

If daytime operating pressure exceeds 80 psi, nighttime pressures may exceed pressure limits. A pressure reducing valve must

be installed.

Do not install the unit where temperatures may drop below 32°F (0°C) or above 110°F (43°C).

Do not place the unit in direct sunlight. Black units will absorb radiant heat increasing internal temperatures.

Do not strike the valve or any of the components.

Warranty of this product extends to manufacturing defects of the vessel and controller, not the membrane. Misapplication of this

product may result in failure to properly condition water, or damage to product.

A prelter should be used on installations in which free solids are present.

In some applications local municipalities treat water with Chloramines. High Chloramine levels may damage valve components.

Correct and constant voltage must be supplied to the control valve to maintain proper function.

•

•

•

•

•

•

•

•

•

•

•

•

Job No. ___________________________________________________________________________________

Model No. _________________________________________________________________________________

Water Test _________________________________________________________________________________

Capacity Per Unit ___________________________________________________________________________

Mineral Tank Size _____________ Diameter ____________ Height _______________

Brine Tank Size & Salt Setting per Regeneration ___________________________________________________

2900s Control Valve Specications

1. Type of Timer

A. 7 Day or 12 Day

B. 3,750 to 63,750 Gallon Meter or

18,750 to 318,750 Gallon Meter or

Other ________________________________

C. Meter Wiring Package

1. System #4 - 1 Tank, 1 Meter, Immediate or Delayed Regeneration

2. System #5 - 2 Tanks, 2 Meters, Interlock

3. System #6 - 2 Tanks, 1 Meter, Series Regeneration

4. System #7 - 2 Tanks, 1 Meter, Alternator

2. Timer Program Settings

A. Backwash _________________________ Minutes

B. Brine & Slow Rinse __________________ Minutes

C. Rapid Rinse ________________________ Minutes

D. Brine Tank Rell _____________________ Minutes

3. Drain Line Flow Control __________________ gpm

4. Brine Line Flow Controller ________________ gpm

5. Injector Size # _________________________

6. A. Hard Water Bypass

B. No Hard Water Bypass

Page 3

Job Specication Sheet

Page 4

General Commercial Pre-Installation Check List

WATER PRESSURE: A minimum of 25 pounds of water pressure is required for regeneration valve to operate

effectively.

ELECTRICAL FACILITIES: A continuous 115 volt, 60 Hertz current supply is required. Make certain the current

supply is always hot and cannot be turned off with another switch.

EXISTING PLUMBING: Condition of existing plumbing should be free from lime and iron buildup. Piping that is

built up heavily with lime and/or iron should be replaced. If piping is clogged with iron, a separate iron lter unit

should be installed ahead of the water softener.

LOCATION OF SOFTENER AND DRAIN: The softener should be located close to a drain.

BY-PASS VALVES: Always provide for the installation of a by-pass valve.

CAUTION: Water pressure is not to exceed 125 p.s.i., water temperature is not to exceed 110° F, and the unit

cannot be subjected to freezing conditions.

Installation Instructions

1. Place the softener tank where you want to install the unit making sure the unit is level and on a rm base.

(Maximum 4 feet apart for twin units)

2. All plumbing should be done in accordance with local plumbing codes. The pipe size for the drain line should

be the same size as the drain line ow control connection. Water meters are to be installed on soft water

outlets. Twin units with 1 meter shall be installed on common soft water outlet of units.

3. Solder joints near the drain must be done prior to connecting the Drain Line Flow Control tting. Leave at

least 6” between the DLFC and solder joints when soldering when the pipes are connected on the DLFC.

Failure to do this could cause interior damage to the DLFC.

4. Teon tape is the only sealant to be used on the drain tting. The drain from twin units may be run through a

common line.

5. Make sure that the oor is clean beneath the salt storage tank and that it is level.

6 Place approximately 1” of water above the grid plate (if used) in your salt tank. Salt may be placed in the unit

at this time.

7. Place in by-pass position. Turn on the main water supply. Open a cold soft water tap nearby and let run a few

minutes or until the system is free from foreign material (usually solder) that may have resulted from the

installation.

8. Place the by-pass in service position.

9. Manually index the softener control into “service” position and let water ow into the mineral tank. When water

ow stops, close inlet valve, place control in “backwash” position to relieve head of air, then gradually open

inlet valve to purge remaining air in tank. Return control to service position.

10. Electrical: All electrical connections must be connected according to codes. Use electrical conduit if

applicable. Plug into power supply.

Page 5

3200 Timer Setting Procedure

How To Set Days On Which Water Conditioner Is To

Regenerate:

Rotate the skipper wheel until the number “1” is at the

red pointer. Set the days that regeneration is to occur

by sliding tabs on the skipper wheel outward to expose

trip ngers. Each tab is one day. Finger at red pointer is

tonight. Moving clockwise from the red pointer, extend

or retract ngers to obtain the desired regeneration

schedule.

How To Set The Time Of Day:

1. Press and hold the red button in to disengage the

drive gear.

2. Turn the large gear until the actual time of day is at

the time of day pointer.

3. Release the red button to again engage the drive

gear.

How To Manually Regenerate Your Water

Conditioner At Any Time:

1. Turn the manual regeneration knob clockwise.

2. This slight movement of the manual regeneration

knob engages the program wheel and starts the

regeneration program.

3. The black center knob will make one revolution in

the following approximately three hours and stop in

the position shown in the drawing.

4. Even though it takes three hours for this center knob

to complete one revolution, the regeneration cycle of

your unit might be set only one half of this time.

5. In any event, conditioned water may be drawn after

rinse water stops owing from the water

conditioner drain line.

How to Adjust Regeneration Time:

1. Disconnect the power source.

2. Locate the three screws behind the manual

regeneration knob by pushing the red button in and

rotating the 24 hour dial until each screw appears in

the cut out portion of the manual regeneration knob.

3. Loosen each screw slightly to release the pressure

on the time plate from the 24 hour gear.

4. Locate the regeneration time pointer on the inside

of the 24 hour dial in the cut out.

5. Turn the time plate so the desired regeneration time

aligns next to the raised arrow.

6. Push the red button in and rotate the 24 hour dial.

Tighten each of the three screws.

7. Push the red button and locate the pointer one more

time to ensure the desired regeneration time

is correct.

8. Reset the time of day and restore power to the unit.

Page 6

3210 Timer Settings

Typical Programming Procedure

Calculate the gallon capacity of the system, subtract

the necessary reserve requirement and set the gallons

available opposite the small white dot on the program

wheel gear.

NOTE: Drawing shows 8,750 gallon setting. The

capacity (gallons) arrow denotes remaining gallons

exclusive of xed reserve.

How To Set The Time Of Day:

Press and hold the red button in to disengage the

drive gear.

Turn the large gear until the actual time of day is

opposite the time of day pointer.

Release the red button to again engage the drive

gear.

1.

2.

3.

How To Manually Regenerate Your Water

Conditioner At Any Time:

Turn the manual regeneration knob clockwise.

This slight movement of the manual regeneration

knob engages the program wheel and starts the

regeneration program.

The black center knob will make one revolution in

the following approximately three hours and stop in

the position shown in the drawing.

Even though it takes three hours for this center

knob to complete one revolution, the regeneration

cycle of your unit might be set for only one half of

this time.

In any event, conditioned water may be drawn after

rinse water stops owing from the water conditioner

drain line.

Immediate Regeneration Timers:

These timers do not have a 24 hour gear. Setting the

gallons on the program wheel and manual regeneration

procedure are the same as previous instructions.

1.

2.

3.

4.

5.

NOTE: To set meter capacity

rotate manual knob one - 360°

revolution to set gallonage.

Page 7

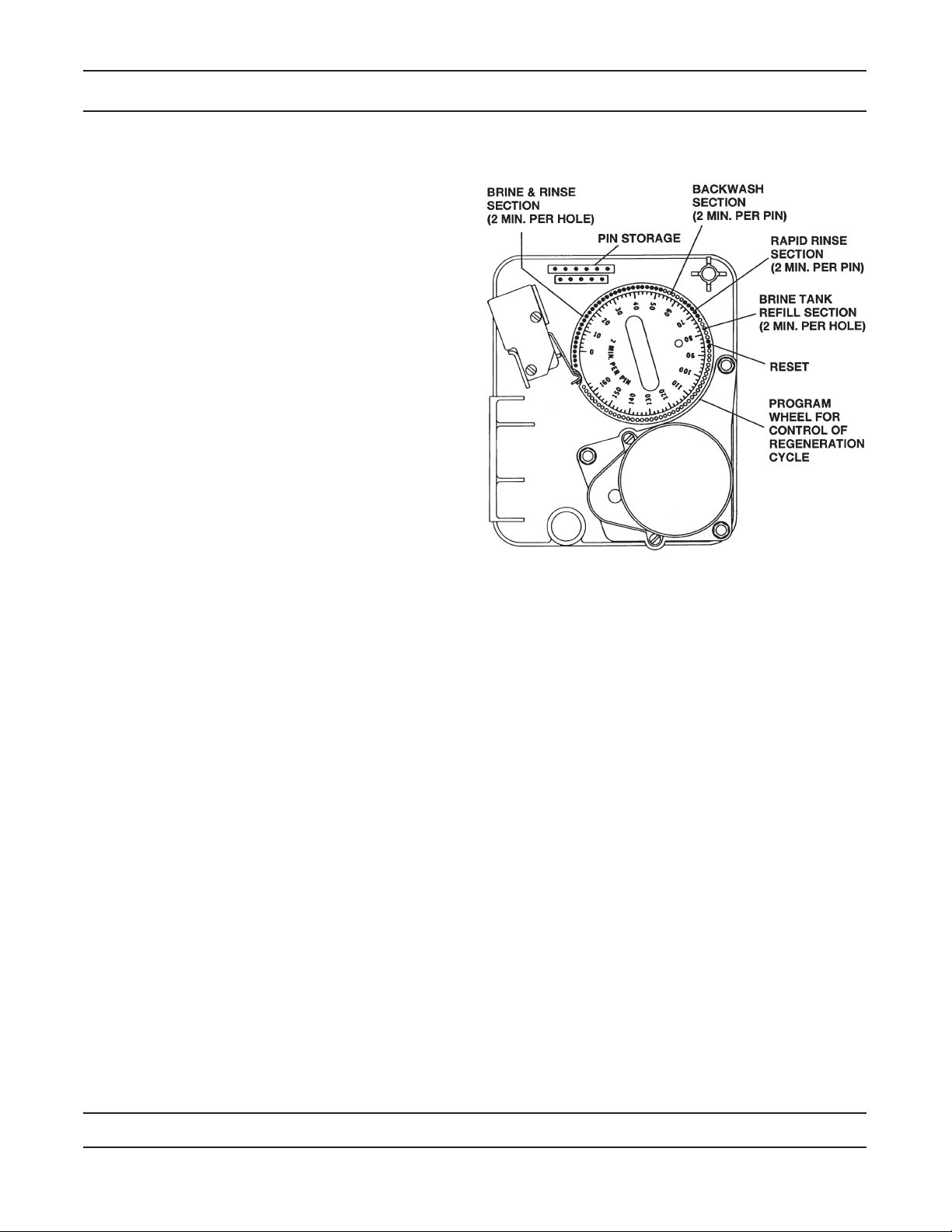

3200 & 3210 Timer Series

How To Set The Regeneration Cycle Program:

The regeneration cycle program on your water

conditioner has been factory preset, however,

portions of the cycle or program may be lengthened or

shortened in time to suit local conditions.

3200 & 3210 Series Timers (Figure to Right)

To expose cycle program wheel, grasp timer in

upper left-hand corner and pull, releasing snap

retainer and swinging timer to the right.

To change the regeneration cycle program, the

program wheel must be removed. Grasp program

wheel and squeeze protruding lugs toward center,

lift program wheel off timer. (Switch arms may

require movement to facilitate removal)

Return timer to closed position engaging snap

retainer in back plate. Make certain all electrical

wires locate above snap retainer post.

Timer Setting Procedure for 3200 & 3210

Timer

How To Change The Length Of The Backwash

Time:

The program wheel as shown in the drawing is in the

service position. As you look at the numbered side of

the program wheel, the group of pins starting at zero

determines the length of time your unit will backwash.

EXAMPLE: If there are six pins in this section, the time

of backwash will be 12 min. (2 min. per pin). To change

the length of backwash time, add or remove pins as

required. The number of pins times two equals the

backwash time in minutes.

How To Change The Length Of Brine And Rinse

Time:

The group of holes between the last pin in the

backwash section and the second group of pins

determines the length of time that your unit will

brine and rinse (2 min. per hole.)

To change the length of brine and rinse time, move

the rapid rinse group of pins to give more or fewer

holes in the brine and rinse section. Number of

holes times two equals brine and rinse time in

minutes.

1.

2.

3.

1.

2.

How To Change The Length Of Rapid Rinse:

The second group of pins on the program wheel

determines the length of time that your water

conditioner will rapid rinse. (2 min. per pin.)

To change the length of rapid rinse time, add or

remove pins at the higher numbered end of this

section as required. The number of pins times two

equals the rapid rinse time in minutes.

How To Change The Length Of Brine Tank Rell

Time:

The second group of holes in the program wheel

determines the length of time that your water

conditioner will rell the brine tank (2 min. per hole.)

To change the length of rell time, move the two

pins at the end of the second group of holes as

required.

The regeneration cycle is complete when the outer

microswitch is tripped by the two pin set at end of

the brine tank rell section.

The program wheel, however, will continue to rotate

until the inner micro-switch drops into the notch on

the program wheel.

1.

2.

1.

2.

3.

4.

Regeneration Cycle Program Setting Procedure - Downow

Page 8

3200 & 3210 Timer Series

How To Set The Regeneration Cycle Program:

The regeneration cycle program on your water

conditioner has been factory preset, however,

portions of the cycle or program may be lengthened or

shortened in time to suit local conditions.

3200 & 3210 Series Timers (Figure to Right):

To expose cycle program wheel, grasp timer in upper

left-hand corner and pull, releasing snap retainer and

swinging timer to the right

To change the regeneration cycle program, the

program wheel must be removed. Grasp program

wheel and squeeze protruding lugs toward center, lift

program wheel off timer. (Switch arms may require

movement to facilitate removal.)

Return timer to closed position engaging snap retainer

in back plate. Make certain all electrical wires locate

above snap retainer post.

Timer Setting Procedure for 3200 & 3210

Timer

How To Change The Length Of The Backwash

Time:

The program wheel as shown in the drawing is in the

service position. As you look at the numbered side of

the program wheel, the group of pins starting at zero

determines the length of time your unit will backwash.

EXAMPLE: If there are six pins in this section, the time

of backwash will be 12 min. (2 min. per pin). To change

the length of backwash time, add or remove pins as

required. The number of pins times two equals the

backwash time in minutes.

How To Change The Length Of Brine And Rinse

Time:

The group of holes between the last pin in the

backwash section and the second group of pins

determines the length of time that your unit will brine

and rinse (2 min. per hole.)

To change the length of brine and rinse time, move the

rapid rinse group of pins to give more or fewer holes in

the brine and rinse section. Number of holes times two

equals brine and rinse time in minutes.

How To Change The Length Of Rapid Rinse:

The second group of pins on the program wheel

determines the length of time that your water

conditioner will rapid rinse. (2 min. per pin.)

To change the length of rapid rinse time, add or remove

pins at the higher numbered end of this section as

required. The number of pins times two equals the

rapid rinse time in minutes.

How To Change The Length Of Brine Tank Rell

Time:

The second group of holes in the program wheel

determines the length of time that your water

conditioner will rell the brine tank (2 min. per hole.)

To change the length of rell time, move the two pins at

the end of the second group of holes as required.

The regeneration cycle is complete when the outer

microswitch is tripped by the two pin set at end of the

brine tank rell section. The program wheel, however,

will continue to rotate until the inner micro-switch drops

into the notch on the program wheel.

Regeneration Cycle Program Setting Procedure - Upow

Page 9

Notes

Page 10

3210 Timer Assembly

61502-3210_REVA

For Service Assembly Numbers, See the Back of this Manual

Page 11

3210 Timer Assembly

Item No. Quantity Part No. Description

1..................1...................13870 ......................Housing, Timer, 3200

2..................1...................13802 ......................Gear, Cycle Actuator

3..................1...................40096-02.................Dial 2AM Regen Assy, Black

4..................1...................13886 ......................Knob, 3200

5..................4...................13296 ......................Screw, Hex Wsh, 6-20 x 1/2

6..................2...................11999 ......................Label, Button

7..................1...................60405-50.................Program Wheel, w/2” Std Label

8..................1...................13806 ......................Retainer, Program Wheel

9..................1...................13748 ......................Screw, Flat Head St, 6-20 x 1/2

10................1...................14265 ......................Clip, Spring

11................1...................15424 ......................Spring, Detent, Timer

12................1...................15066 ......................Ball, 1/4” Delrin

13................1...................13018 ......................Pinion, Idler

14................1...................13312 ......................Spring, Idler Shaft

15................1...................13017 ......................Gear, Idler

16................1...................13164 ......................Gear, Drive

17................1...................13887 ......................Plate, Motor Mounting

18................1...................18743-1...................Motor, 120V, 60Hz 1/30 RPM, 5600

19................1...................13278 ......................Screw, Fillister Hd, 6-32 x .156

20................1...................13830 ......................Pinion, Program Wheel Drive

21................1...................13831 ......................Clutch, Drive Pinion

22................1...................14276 ......................Spring, Meter, Clutch

23................1...................14253 ......................Retainer, Clutch Spring

24................3...................11384 ......................Screw, Phil, 6-32 x 1/4

25................1...................13881 ......................Bracket, Hinge Timer

26................3...................14087 ......................Insulator

27................1...................10896 ......................Switch, Micro

28................1...................15320 ......................Switch, Micro, Timer

29................2...................11413 ......................Screw, Pan Hd Mach, 4-40 x 1 1/8

30................1...................14198 ......................Label, Indicator

31................1...................15465 ......................Label, Caution

32................1...................14007 ......................Label, Time of Day

33................1...................14045 ......................Label, Instruction

34................1...................13902 ......................Harness, 3200

35................2...................40422 ......................Nut, Wire, Tan

36................1...................15354-01.................Wire, Ground, 4”

37................1...................19210 ......................Program Wheel Assy

38................17 .................41754 ......................Pin, Spring, 1/16 x 5/8 SS, Timer

39................1...................13911 ......................Gear, Main Drive, Timer

40................1...................15354-01.................Wire, Ground 4”

For Service Assembly Numbers, See the Back of this Manual

Page 12

Powerhead Assembly

For Service Assembly Numbers, See the Back of this Manual

Page 13

Powerhead Assembly

For Service Assembly Numbers, See the Back of this Manual

Page 14

Powerhead Assembly

For Service Assembly Numbers, See the Back of this Manual

Page 15

Powerhead Assembly

For Service Assembly Numbers, See the Back of this Manual

Page 16

Control Valve Assembly

For Service Assembly Numbers, See the Back of this Manual

10

13 14

5

2

8

6

4

1

3

16

25

17 16

17

19

8

13

22

11

24

12

9

13 7

14 13

151314

131413

15

1314

20

21

18

16

17

23

23

Page 17

Control Valve Assembly

For Service Assembly Numbers, See the Back of this Manual

Item No. Quantity Part No. Description

1................... 1.................... 16067-02.................VALVE BODY,3900,AUX TAP

2................... 1.................... 15114 ......................VALVE BODY,3150

3................... 1.................... 16258......................FLOW STRAIGHTENER,3900

4................... 1.................... 15112 ......................SEAL,3150 ADAPTER BASE

5................... 2.................... 40118 ......................SCREW,SCKT HD,1/2-13 UNC

6................... 1.................... 16088......................PLUG,BRASS,2”,NPT,3900

7................... 1.................... 16078......................O-RING,-149,3900

8................... 1.................... 16074......................COUPLING,ADAPTER,3900

9................... 1.................... 16077......................O-RING,-140

10................. 1.................... 16130......................PISTON,HIGH BACKWASH

11................. 1.................... 15125......................ROD,PISTON,3150

12................. 2.................... 14818......................RING,PISTON ROD,SNAP

13................. 8.................... 11720 ......................SEAL,PISTON,2900/3150

14................. 5.................... 10369......................SPACER,2”,2900/3150

15................. 2.................... 10368......................SPACER,NARROW,3150/3900

16................. 4.................... 16068......................SEAL,3900

17................. 2.................... 16069......................SPACER,3900

18................. 1.................... 16070......................SPACER,3900

19................. 1.................... 16071......................SPACER,3900

20................. 1.................... 16072......................ROD,PISTON,3900,LOWER

21................. 1.................... 16076......................O-RING,-042,3900

22................. 1.................... 15118-01 .................PLUG,END,3150,NATURAL,MACHINED

23................. 2.................... 11242 ......................QUAD RING,-112,560CD

24................. 1.................... 14922......................O-RING,-035,PISTON

25................. 1.................... 16073-01.................PLUG,END,NATURAL

3900 Mounting Kits (Options):

............................................ 60190......................Flange Kit, Park & Structural

............................................ 60192......................Flange Kit, Welded

............................................ 60193......................Flange Kit, 6” Threaded

............................................ 61417......................Fixed Sidemount (NPT)

............................................ 61417-22.................Fixed Sidemount (BSP)

Page 18

1800 Brine Assembly

For Service Assembly Numbers, See the Back of this Manual

60036_REVA

Page 19

1800 Brine Assembly

For Service Assembly Numbers, See the Back of this Manual

Item No. Quantity Part No. Description

1................... 1.................... 16340......................Body, Injector, 1800 D/F

2................... 1.................... 15128-xx .................Injector Nozzle

3................... 1.................... 15127-xx .................Injector Throat

4................... 3.................... 15246......................O-ring, -116

5................... 1.................... 16341-01.................Cap, Injector, 1800

6................... 8.................... 12473......................Screw, Hex Wsh, 10-24 x 5/8

7................... 1.................... 16341-02.................Plug, Injector, 1800

8................... 1.................... 13303-01.................O-ring, -021, 560CD

9................... 1.................... 16497-01.................Stem Assy, 1800, Brine Valve

10................. 1.................... 18713......................Brine Valve Body, 1800

11................. 1.................... 11772 ......................Spring, 3150 Brine Valve

12................. 1.................... 11774 ......................Ring, Retaining

13................. 1.................... 16498-01.................Stem Guide Assy, Brine

14................. 1.................... 16387......................Plug, Pipe, 1/2” NPT

15................. 2.................... 18702......................Fitting, Tube, 1/2 NPT 5/8

16................. 1.................... 18703......................Tube, Brine, 5/8 OD Annealed

17................. 1.................... 60009-00.................Air Check, #900, Commercial Less Fittings

60009-01.................Air Check, #900, Commercial, HW Less Fittings

Not Shown ... 1.....................................................Flow Control (Specify Flow Rate)

Option Without Brine Valve

1..............................16605......... Retainer Plate

1..............................19860......... Fitting, Brine Valve, 1800

Delete: Items 9 through 16

Injector Throat

15127-04.................#4............... Green

15127-05.................#5............... Red

15127-06.................#6............... White

15127-07.................#7............... Blue

15127-08.................#8............... Yellow

15127-09.................#9............... Violet

15127-10.................#10............. Black

Injector Nozzle

15128-04.................#4............... Green

15128-05.................#5............... Red

15128-06.................#6............... White

15128-07.................#7............... Blue

15128-08.................#8............... Yellow

15128-09.................#9............... Violet

15128-10.................#10............. Black

Page 20

3” Brass Meter Assembly

For Service Assembly Numbers, See the Back of this Manual

Item No. Quantity Part No. Description

1................... 1.................... 16254......................Meter Body

2................... 1.................... 16279......................Impeller Shaft

3................... 1.................... 16575......................Impeller Assembly

4................... 1.................... 16400......................Meter Cover Assembly - Std.

..................... 1.................... 16401......................Meter Cover Assembly - Ext. Range

5................... 3.................... 15707......................O-Ring - 236

6................... 6.................... 12112 ......................Screw - Hex Hd.

..................... 6.................... 15886......................Screw - Hex Hd. (Metric)

7................... 1.................... 16280......................Flow Straightener

8................... 2.................... 16328......................Connecting Flange

9................... 8.................... 40118 ......................Screw - Hex Hd.

..................... 8.................... 17122......................Screw - Hex Hd. (Metric)

10................. 8.................... 16386......................Nut - 1/2-13

11................. 1.................... 16574......................Stainless Steel Washer

Table of contents

Popular Water Dispenser manuals by other brands

Aqua To Go

Aqua To Go Argento Cleaning instructions

DS Services of America

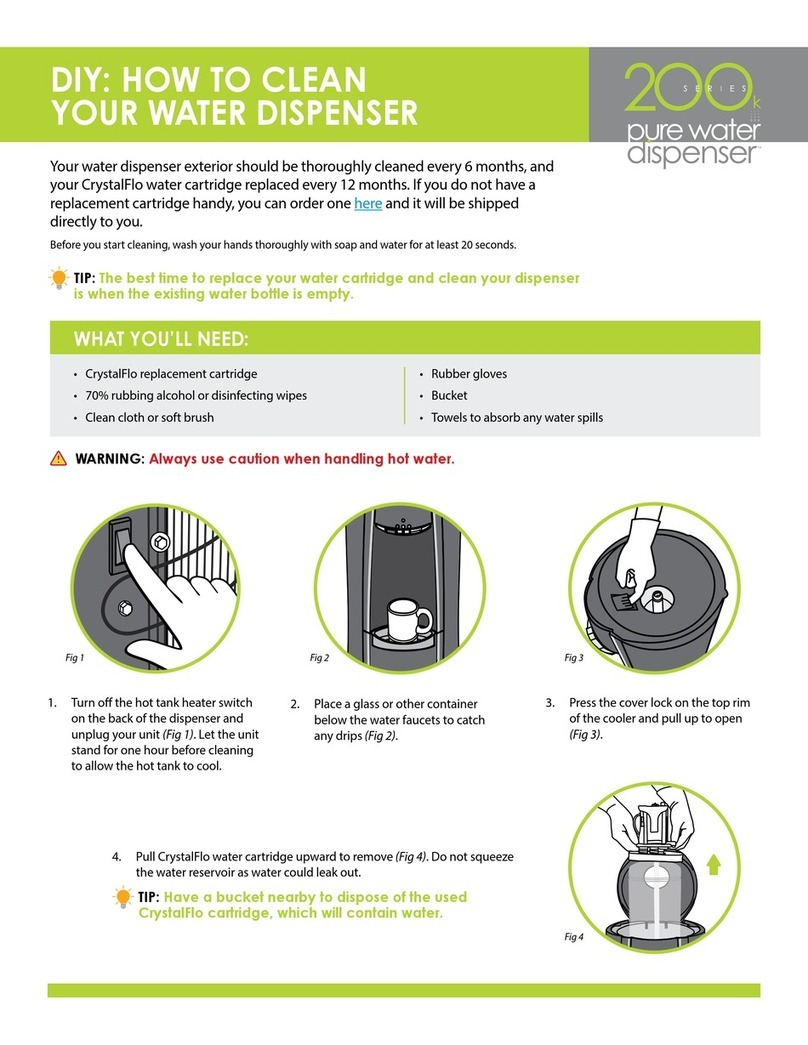

DS Services of America 200K Series How to Clean

BRIO

BRIO CLCTPOU720UVF3 Setup manual

Pelican Water Technologies

Pelican Water Technologies PS48 owner's manual

TZS First AUSTRIA

TZS First AUSTRIA FA-5448-6 instruction manual

Follett

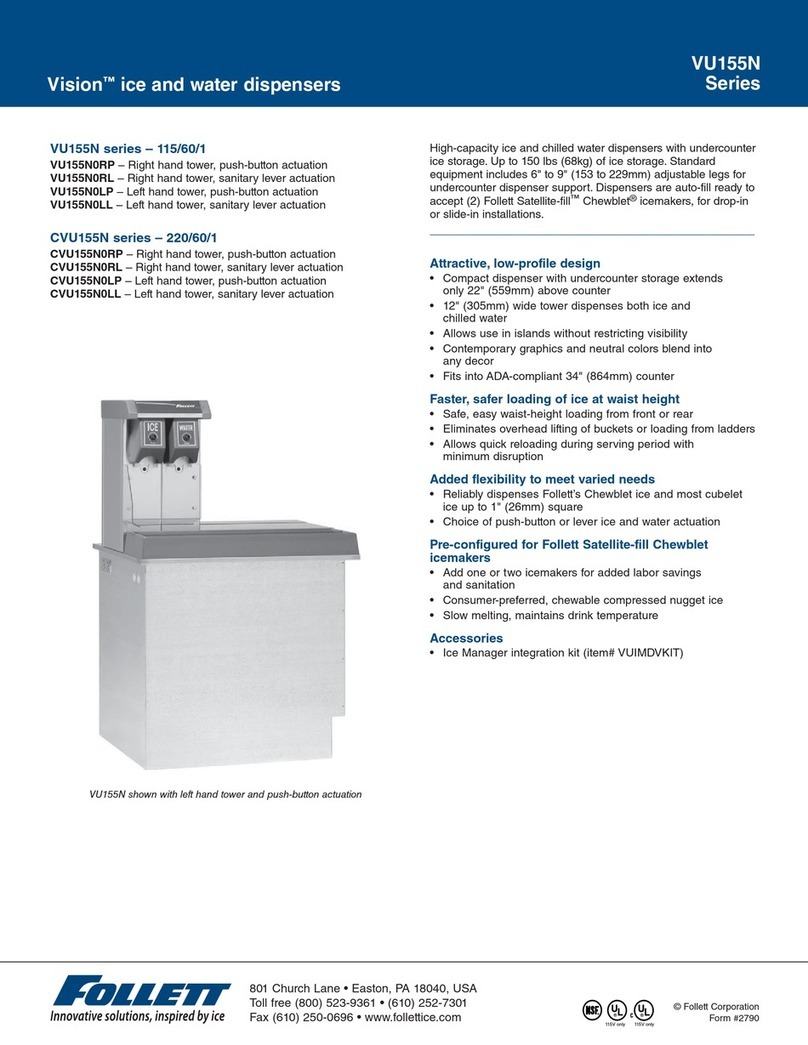

Follett VU155N Series Specifications

Lancaster

Lancaster City Soft Plus XFactor Series Installation, operating and service manual

SYR

SYR IT 4000 Instructions for use

Oasis

Oasis POU_1RREC Series Installation & service instructions

Zip

Zip 801912UK user manual

MrCool

MrCool MTWB05 Owners & installation manual

Bunn

Bunn H5E Installation & operating guide