hilscher PKV 30-DPS Application guide

Device manual

PKV 30-DPS

Protocol converter for PROFIBUS-DP slave

Hilscher Gesellschaft für Systemautomation mbH

Rheinstraße 78

D-65795 Hattersheim

Germany

Tel. +49 (0) 6190/9907-0

Fax. +49 (0) 6190/9907-50

Sales: +49 (0) 6190/9907-0

Hotline and Support: +49 (0) 6190/9907-99

e-mail: [email protected]

Homepage: http://www.hilscher.com

Index Date Device Device

number Chapter Revision

116.08.96 PKV 30-DPS 9604001 all translated from german manual

222.08.96 PKV 30-DPS 9604002 2 PROFIBUS-DP slave address selectable by code switch

pictures and tables updated

306.05.98 PKV 30-DPS 9604002 2 Activation of the diagnostic/configuration mode described mor

detailed

429.01.99 PKV 30-DPS 9604002 2.4 revision

516.11.01 PKV 30-DPS 9604002 2.1.2 Selection of the Bootstart Mode or Normal Mode

Although this appliance has been developed with great care and intensively tested, Hilscher Gesellschaft

für Systemautomation mbH cannot guarantee the suitability of this appliance for any purpose not confir-

med by us in writing.

Guarantee claims shall be limited to the right to require rectification. Liability for any damages which

may have arisen from the use of this appliance or its documentation shall be limited to cases of intent.

We reserve the right to modify our products and their specifiactions at any time in as far as this contribu-

tes to technical progress. The version of the manual supplied with the appliance applies.

Revision 2

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

1 Introduction ...................................................................................... 4........

1.1 Purpose ....................................................................................... 4........

2 General Device Description ....................................................................... 5........

2.1 Configuration ................................................................................ 6........

2.1.1 Selection of Serial Interface Type ....................................................... 6........

2.1.2 Selection of the Bootstart Mode or Normal Mode ........................................ 7........

2.1.3 Selection of the PROFIBUS Slave Station Address ...................................... 7........

2.2 Connection of the Power Supply (X1) ........................................................ 8........

2.3 Serial Interfaces ............................................................................... 9........

2.3.1 First Serial Interface (X3) ............................................................... 9........

2.3.2 Potential free RS485 PROFIBUS Interface (X2) ......................................... 11.......

2.4 Diagnostic Interface ........................................................................... 13.......

2.4.1 Activation of the Diagnostic/Configuration Mode ....................................... 14.......

2.5 Status Displays - LED ......................................................................... 15.......

2.6 Physical Dimensions .......................................................................... 16.......

3 Appendix ........................................................................................ 17.......

3.1 Technical Data ............................................................................... 17.......

Table of contents 3

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

1 Introduction

1.1 Purpose

There is often a need to transfer data between controllers from different manu-

facturers or exchange them with a higher level host computer. Each system has its

own transfer protocol. Implementation of an alien protocol is often impossible or

only possible at great cost. This results from the following background

conditions:

The interface drivers do not match

The interface controller does not meet the requirements

Insufficient or lacking computer power

Real time requirements cannot be fulfilled

No facility for making additional configuration data available

Missing or insufficient commissioning and diagnosis aids

In some cases, the protocol is only required for a single system. Nevertheless the

implementation has to satisfy extreme quality demands. The effects of a software

error in the transfer protocol can lead to faults ranging up to the standstill of the

entire system and thus cause unpredictable costs.

Experience shows that implementation testing and inspection in particular only

take place in the laboratory or on a system which is hardly capable of

functioning. In spite of the greatest possible care, it then happens that an error on-

ly becomes apparent when the plant is in service. Particularly when the error oc-

curs sporadically or depends on particular plant conditions, location of the error

without an integrated diagnostic function is a matter of luck.

Practical experience shows that most problems are created not by errors in the

implementation but by inadequate agreements on the user level. Message mat-

ching between the linked units is in some cases incomplete or is not complied

with. As a result, messages which have not been sent are expected, or messages

are sometimes mixed up. If the message traffic can be transcribed, the problem

can be rapidly rectified.

The protocol converter is a device developed specifically for these problems,

whose operating system provides all functions necessary for the rational and re-

liable implementation of coupling protocols.

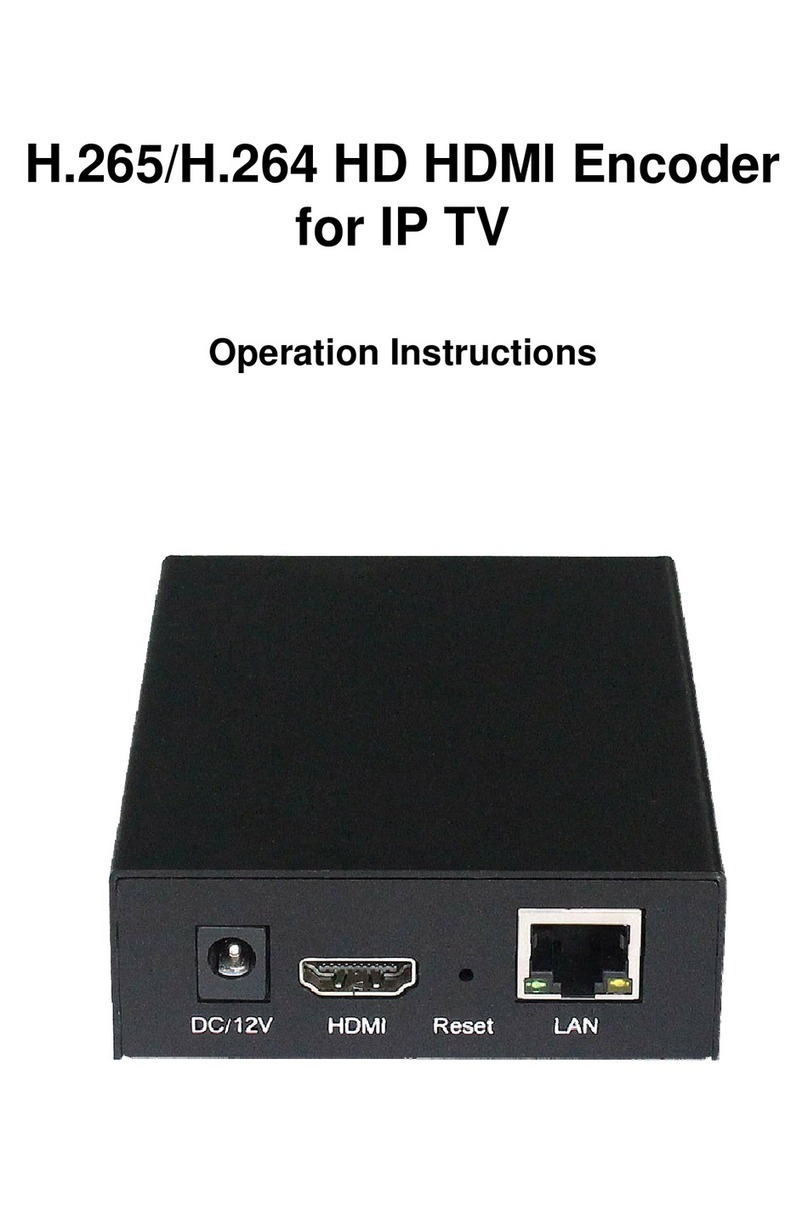

The device is supplied in various versions. The protocol converter PKV 30-DPS

has two communications interfaces and one of them is for PROFIBUS-DP slave

and the other one is for general protocols.

Introduction 4

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

2 General Device Description

The protocol converter consist of a main board and a power supply board, with

the DC/DC converter which generates all internal voltages.

The main board has an 80C188 microprocessor. It has an internal timer, interrupt

and DMA controllers, and therefore requires only a few external components.

The computing power is sufficient to process even large quantities of data. In ad-

dition, the 16-bit processor facilitates efficient software development in a high

level language. The firmware and the configuration data are stored in a flash

EPROM. This can be programmed in the circuit and retains its data even when

the power supply is switched off.

The serial interfaces are realized by the SCC controller AM85C30 and the ASIC

SPC3. For the connection of a device with the converter there is a non-isolated

interface wich can be configured as RS232, RS422 or RS485-type. The second

isolated interface is designed for the PROFIBUS-DP.

The correct function of the protocol converter and its internal power supply are

monitored by a watchdog circuit with the MAX 705 component. In the case of er-

ror, this triggers a reset on the processor.

The internal power supply is provided by a switching controller. Its input voltage

is filtered through a current compensated annular core reactor and filter capaci-

tors. A transient diode is provided as overvoltage and reverse polarity protection.

In the case of a fault, the internal semiconductor fuse switch off until the fault

disappears. In addition, there is a charging capacitor which blocks voltage drops

such as those which occur on switching of contactors.

Valid operation and an error state from the serial interfaces are displayed by

LEDs.

Block diagram of the protocol converter PKV 30-DPS

General device description 5

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

2.1 Configuration

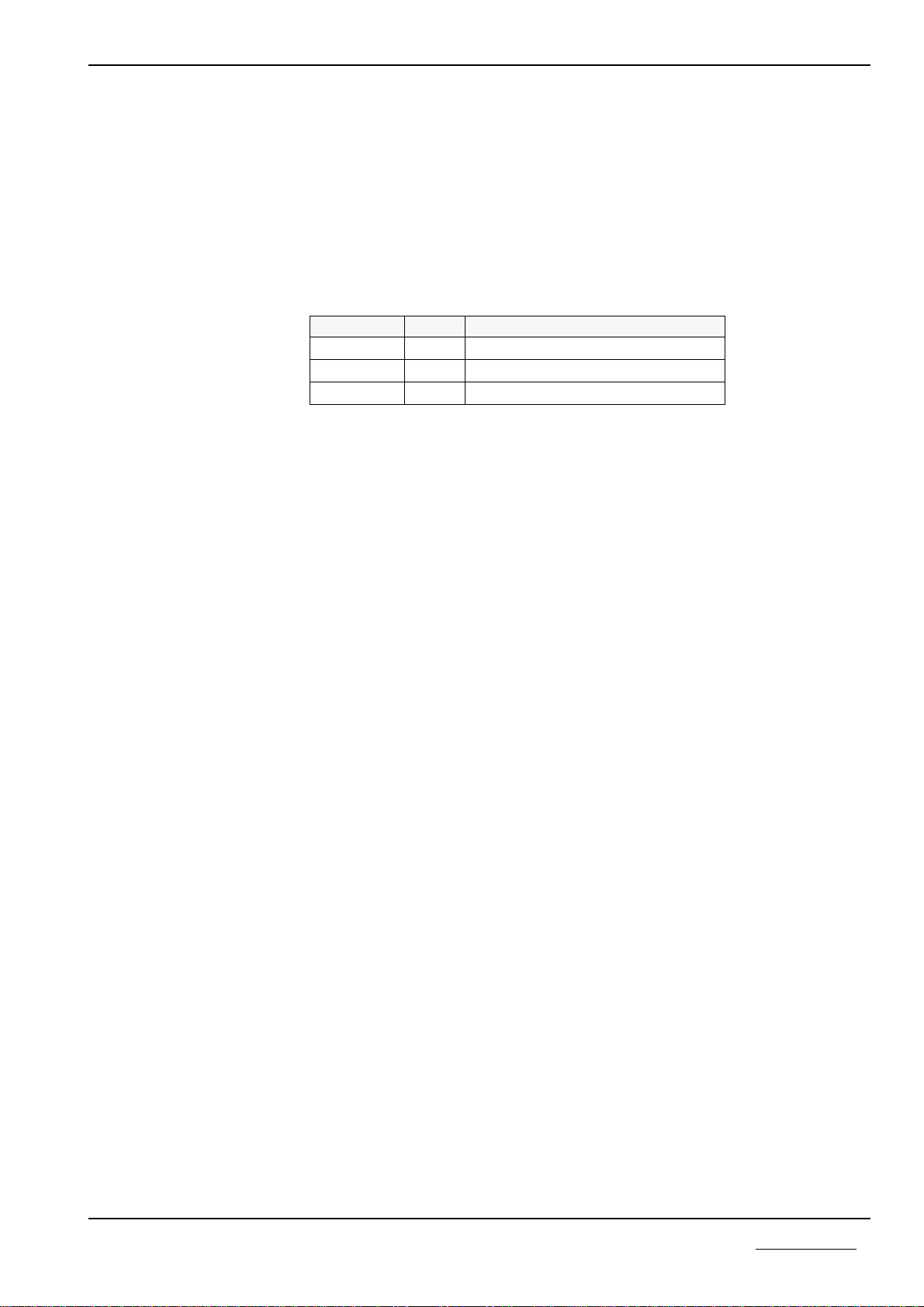

2.1.1 Selection of Serial Interface Type

The hardware of the converter has jumper J2, to switch between the different

types of serial interfaces. This jumper is accessable if you open the side plate on

the side where there are both serial interfaces. This is be done by removing four

screws. The following picture will show the position of the jumper seeing from

the side of the converter. With the help of the table you can chose the right type

of interface.

selection jumper J2 interface

open RS232

3-4 RS485

1-2, 3-4 RS422

Selection of serial interface type

connector male connector female

14 3 2

jumper row

Side viewing of PKV 30-DPS with jumper row

serial interface PROFIBUS interface

14 3 2

General device description 6

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

2.1.2 Selection of the Bootstart Mode or Normal Mode

Setting J1 Meaning

open Normal Mode (Default Setting)

closed Bootstart

J1 is open in the default setting. The device starts the normal mode (communica-

tion mode) after the power supply was switched on.

To activate the diagnostic/configuration mode see the description in section Acti-

vation of the Diagnostic/Configuration Mode in this manual. In this mode the

firmware and the configuration can be downloaded.

The bootstart mode can be activated when J1 is closed. The device activates the

bootstart mode when the power supply is reconnected. In this mode only a firm-

waredownload can be done. Other functions are not possible in this mode.

Jumper J1 can be reached by opening the housing from the bottom side.

2.1.3 Selection of the PROFIBUS Slave Station Address

The selcetion of the slave address is done with two code switches. Please refer to

chapter 'Physical dimensions' in this manual.

General device description 7

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

2.2 Connection of the Power Supply (X1)

The protocol converter requires a 24V power supply. For maximum load of the

current see chapter technical data in this manual. A three-phase rectifier or simple

rectifier circuit with charging capacitor are sufficient. The power supply must be

earth grounded.

The power supply are connected by means of a plug-in screw terminal. A 3-way

COMBICON plug from PHOENIX (MSTB 2.5/3-ST-5.08) is used.

pin symbol signal

1+24V +24V supply voltage

20V reference potential

3PE earth ground

Pin assignment of the X1 power supply connector

General device description 8

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

2.3 Serial Interfaces

The PKV 30-DPS has two independent serial interfaces.

First serial interface (X3). The first interface can be used for communication to

another device as RS232, RS422, or RS485 interface or for diagnostic/configura-

tion. The settings of the communication interface as RS232, RS422, or RS485 in-

terface is done with jumper J2. (see chapter configuration).

Second serial interfcae (X2). The second interface is the connection for the DP

slave to the PROFIBUS network.

2.3.1 First Serial Interface (X3)

The serial interface uses a pin D-Sub connector for the connection to an device

with a serial RS232, RS422, or RS485 interfaces. The interface is configurable

with jumpers.

This interface is also used for diagnostic/configuration of the protocol converter.

The activation of the diagnostic/configuration mode is described in chapter acti-

vation of the diagnostic/configuration mode in this manual.

4

3

1

2

6

7

4

3

1

2

6

7

7

14

2

1

6

5

4

3

15

10

11

12

13

7

9

43

4

1

6

5

9

2

8

11

10

12

9

1

3

4

5

14

7

13

8

2

6

1

2

3

4

3

N1

R17

N2

R27

X3

D7

D9

R26

R15

R14

X3

X3

X3

R11

C15

C14

C13

C16

X3

X3

X3

X3

D4

J2

X3

R18

D

DE

R

RE

A

B

D

DE

R

RE

A

B

MUX

Y

Y

3

2

1

0

EN

3

2

1

0

EN

3

0G1

0

1

C1+

C1-

C2+

C2-

V+

V-

74HCT153

74HCT04

MAX202

ADM485AR

10k

ADM485AR

10k10k

10k

10k

100

100n

100n

100n

100n

10k

P9604S12.HP

RXD1B

RX/TXD1A

GND

GND

GND

GND

GND

GND

TXDA

EN422

EN485

RXD1A

CTSA

RTS1

RTSA

RX/TXD1B

RXDA

+5V

+5V

+5V

RGND1

CTS1

TXD1

RXD1

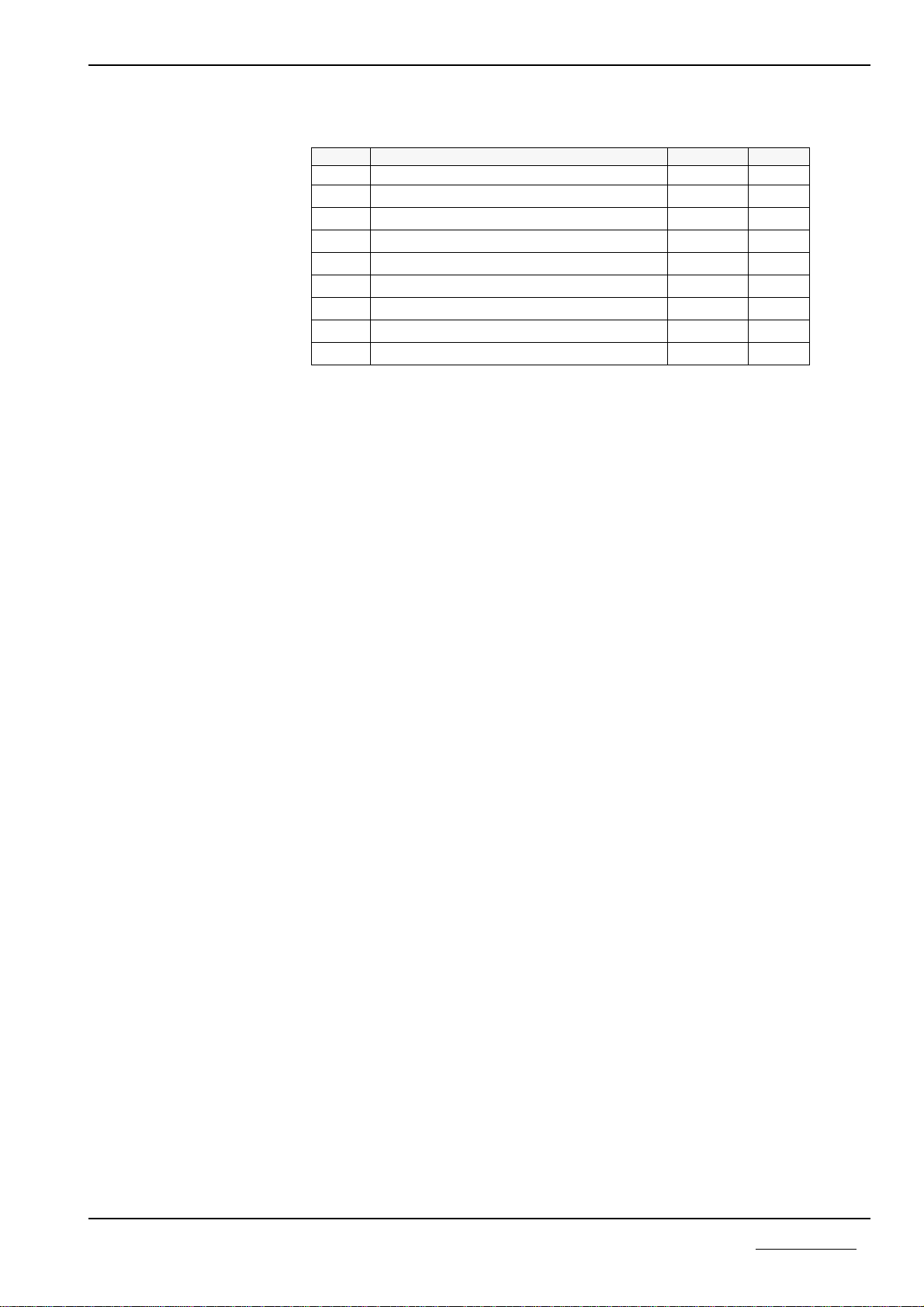

Output scematic of the serial device interface at connector X3

General device description 9

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

The resistors R14, R18 and R15, R17 are necessary to get a defined potential on

the RS485/RS422-bus if there is no active transmitter or the connector is left

open. All resistance have a value of 10 kOhm.

The following table describes the signals of the different kind of interfaces. It is

not allowed to make any connections to the other signals of the not used kind of

interfaces.

pin input/

output signal

name signal RS

485 RS

422 RS

232

1input/

output RXD/TXD-N

TXD-N transmit data inverted RS 422

data inverted RS485 ü ü

2input RXD receive data RS 232 ü

3output TXD transmit data RS 232 ü

4input RXD-P receive data RS 422 ü

5RGND reference potential accros

100 Ohm ü ü ü

6input/

output RXD/TXD-P

TXD-P transmit data RS 422

data RS 485 ü ü

7output RTS ready to send ü

8input CTS clear to send ü

9input RXD-N receive data inverted RS 422 ü

Pin assignment of the serial device interface X3

Using the RS232 interface use the pins only that are marked with a check in the

table.

General device description 10

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

2.3.2 Potential free RS485 PROFIBUS Interface (X2)

The RS485-interface has the connector with the pinout in accordance with the

PROFIBUS standard EN 50170. There is no configuration necessary.

5

8

2

3

7

6

3

6

1

4

3

1

2

6

7

P9604S21.HP

VP

&

&

R37

X2

X2

&

U3

R33

X2

X2

X2

N3

R23

R35

R3 R31

R24

R32

R1

R2

D

DE

R

RE

A

B

HCPL7101

HCPL7101

1,2k

HCPL0601

100

SN75ALS176

470

680

1,2k

100k

470

100k

470

1,2k

RXD/TXD-N

ISO+5V

ISO+5V

ISO+5V

ISO+5V

DGNDDGND

+5V

+5V

GND

RGND2

RXD/TXD-P

ISOGND

ISOGND

ISOGND

TX

RTS

RX

RS485-PROFIBUS-interface at connector X2

Resistors R31 and R32 set a closed level on the RS485 bus. This ensures a de-

fined level when the plugs are removed.

The cable shield of the bus plug is directly connected to the case of the converter.

The grounding follows over the chasis of the PKV.

The PROFIBUS can only con-

nected at connector X2.

General device description 11

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

Pin Signal Symbol Type

1 reference potential over 100 Ohm resistor RGND2

2 not connected

3 send / receive data RxD/TxD-P RS485

4 not connected

5 reference potential DGND

6 positive supply voltage VP

7 not connected

8 send / receive data inverted RxD/TxD-N RS485

9 not connected

Pinning of the 9-way D-Sub plug for the PROFIBUS-DP on X2

Pin 1 in not for the connection of the protection earth for earthing the shield.

General device description 12

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

2.4 Diagnostic Interface

This interface facilitates the connection of a PC to the protocol converter. It con-

forms to the RS232C standard to CCITT or DIN. Only the necessary signals are

provided.

The control signals are produced and evaluated as follows:

RTS is switched to high on readiness for operation and not changed.

CTS must be connected internal with Pin 4 and 8 of D-Sub connector

A 9-way D-Sub connector to DIN 41652 is used.

Data transfer between the PC and the protocol converter takes place at 9600 Baud

and uses the following data format: 8 data bits, 1 stop bit and even parity. The

3964R protocol is used as the transfer protocol.

The PC is connected by a three-way cable which must not be longer than 15 m.

The wiring of the cable is shown below.

Diagnostic cable between the protocol converter and the PC

General device description 13

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

The interface on connector X3 of the PKV 30-DPS is designed for

communication

respectively for

diagnostic/configuration

If the power of the protocol converter is switched on, it checks the serial interface

if the diagnostic/configuration mode should be activated, otherwise it starts the

communication mode.

2.4.1 Activation of the Diagnostic/Configuration Mode

Connect the diagnostic cable on X3 of the protocol converter and to COM1 (or

COM2) of the PC.

Start the program ComPro

COMPRO /S:1 respectively. COMPRO /S:2

(for COM1 respectively COM2).

Select menu online - system - bootstart. A windows appears that shows The sy-

stem will be reseted and the bootloader becomes active without starting any

firmware.

Turn off power of the protocol converter and wait at least 10 seconds.

Accept the message The system will be reseted and the bootloader becomes acti-

ve without starting any firmware with press the Enter key. A red window appears

that shows Waiting for hardware receipt.

Power on the protocol converter.

The red window disappears.

To test if the protocol converter is in diagnostic/configuration mode select menu

online system - firmware. If a window appears and shows the name of the firm-

ware, then the diagnostic/configuration mode is active. If the message Connection

could not be established or connection lost appears, then try to activate the dia-

gnostic/configuration mode again according to the steps described above.

If the interface is configured as

RS422 or RS485 it is not

necessary to change for the dia-

gnostic mode.

General device description 14

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

2.5 Status Displays - LED

On the PKV 30-DPS exists 4 LEDs.

Anzeige Farbe Zustand Bedeutung

If the device is defective, it is pos-

sible that the watchdog responds

cyclically, what results also in a

cyclically flashing of the

RDY-LED.

RDY yellow on

flashing cyclic

flashing non cyclic

off

PKV ready

bootstrap loader active

hardware or system error

hardware error

RUN green on

flashing non cyclic (see

below)

off

communication running

parameter error

no communication

ERR1, ERR2 red on error on serial line

When switched on, the PKV performs a self-test. If this is performed without er-

ror, the yellow RDY LED is switched on. Otherwise, the LED starts to flash, and

further running of the program is aborted.

If no firmware has been loaded in the PKV, the bootstraploader displays this by

regular flashing of the RDY LED at one second intervals. The flash frequency is

increased to approx. 5 Hz while the firmware is being loaded.

Stays the LED off the may be a defect.

If a parameterization error is detected by a protocol task, the task is displayed by

the RUN LED as shown in the illustration below.

If no error occurs and communication has started, the RUN LED is switched on.

Is this LED blinking cyclic, no parameterization error has been detected, but the

communication on the bus has not been established.

If communication is blocked, e.g. by the 'System start' parameter, the RUN LED

remains off.

The red LED ERR1 and ERR2 displays data transfer errors at the communicati-

ons interface to the connected devide.

Start

detec-

tion

Data bits with separation

detection -> 1 sec. <- Start

again

Display by the LED is from left to

right

RCS

with

DBM

error

Task 1

without

error

Task 2

without

error

Task 3

with

error

Task 4

without

error

Task 5

with

error

Task 6

with

error

Task 7

not

implem-

ented

Display of the task which reports a parameterization error

General device description 15

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

2.6 Physical Dimensions

The protocol converter is installed in an aluminium enclosure. This facilitates di-

rect installation in the cabinet on a mounting rail (TS35 to DIN EN 50022). As an

alternative, an enclosure variant for direct screw fitting on an assembly wall is

available.

The physical dimensions and the arrangement of the plug connectors are shown

in the drawings below.

Connector arrangement on the protocol converter

Physical dimensions of the protocol converter for snap mounting to a mounting rail

The overall height of the converter is approx. 80 mm.

Open the top of the protocol

converter if you want to

change the serial interface

type -------------->

105

105

General device description 16

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

3 Appendix

3.1 Technical Data

Processor 16 Bit with timer, interrupt and DMA controllers

Memory range 32 / 128 kByte RAM, 128 / 512 kByte FLASH

Serial interface configurable as RS232C, RS422, RS485-interface,

non-isolated,

max. data transmission 19.2 kBaud,

asynchronous, synchronous, NRZ, NRZ, SDLC, HDLC

also used as diagnostic interface

PROFIBUS interface RS485 PROFIBUS DP interface,

potential-free,

max. data transmission 12 MBaud

Display-LEDs system running and communication running,

or communication error on serial interface

Operating voltages 18V - 30V, max. 0,15 A at 24 V

Operating temperature 0 to 50 degrees Celsius

Safety type IP50

Dimensions (LxHxD) 105 x 105 x 80 mm

Mounting rail mounting DIN EN 50022

Appendix 17

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30DPS#5E

Table of contents

Other hilscher Media Converter manuals

Popular Media Converter manuals by other brands

Altimium

Altimium CVA3 user manual

Shenzhen Shunxun Electronics

Shenzhen Shunxun Electronics SX-HE02 Operation instructions

Musical Surroundings

Musical Surroundings MYDAC II operating manual

Allied Telesis

Allied Telesis AT-MC1004 Specifications

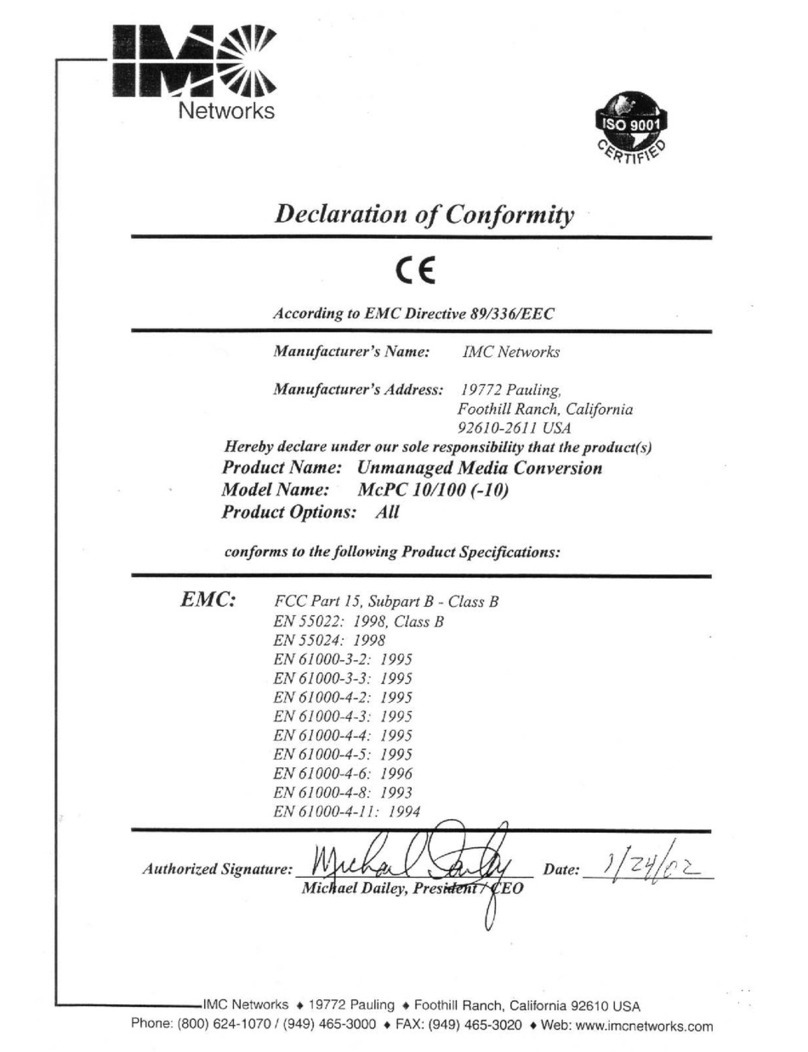

IMC Networks

IMC Networks McPC 10/100 supplementary guide

TDT

TDT RV2 manual

Kramer

Kramer VP-426C quick start guide

Hall Research Technologies

Hall Research Technologies EX-HDU-WP user manual

Z3 Technology

Z3 Technology Z3-MVE-10 User instructions

Audio Note

Audio Note DAC5 Special Owner's Information

Siemens

Siemens SINAMICS G120X operating instructions

Monoprice

Monoprice 12288 user manual