hilscher PKV 30-COS Application guide

Device manual

PKV 30-COS

Protocol converter for CANopen Slave

Hilscher Gesellschaft für Systemautomation mbH

Rheinstraße 15

D-65795 Hattersheim

Germany

Tel. +49 (0) 6190/9907-0

Fax. +49 (0) 6190/9907-50

Sales: +49 (0) 6190/9907-0

Hotline and Support: +49 (0) 6190/9907-99

Homepage: http://www.hilscher.com

Index Date Device Device

number Chapter Revision

227.09.99 PKV 30-COS G9918001 All Translation from german manual

316.11.01 PKV 30-COS G9918001 2.31 Remark to CTS signal by RS232 physic added

Although this device has been developed with great care and intensively tested, Hilscher Gesellschaft für

Systemautomation mbH cannot guarantee the suitability of this device for any purpose not confirmed by

us in writing.

Guarantee claims shall be limited to the right to require rectification. Liability for any damages which

may have arisen from the use of this device or its documentation shall be limited to cases of intent.

We reserve the right to modify our products and their specifications at any time in as far as this contribu-

tes to technical progress. The version of the manual supplied with the device applies.

List of Revisions 2

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

1 Introduction ...................................................................................... 4........

1.1 Scope of Performance ......................................................................... 4........

2 General Device Description ....................................................................... 5........

2.1 Configuration ................................................................................ 6........

2.1.1 Settings of the Serial Interface Type ..................................................... 6........

2.1.2 Setting the CANopen Station Address ................................................... 6........

2.2 Connecting the supply voltage (X1) ........................................................... 7........

2.3 Serial Interfaces .............................................................................. 8........

2.3.1 First non-floating interface (X3) ........................................................ 8........

2.3.2 Potential-Free CANopen Interface (X2) ................................................. 10.......

2.3.3 CANopen Cable and Connection ........................................................ 11.......

2.3.4 Bus Termination ........................................................................ 11.......

2.4 Diagnostic ................................................................................... 12.......

2.4.1 Activating the diagnostic/configuration operation ....................................... 13.......

2.5 Status Displays ............................................................................... 14.......

2.6 Mechanical Dimensions ...................................................................... 15.......

3 Appendix ......................................................................................... 16.......

3.1 Selection of the Line for the Individual Interfaces .............................................. 16.......

3.2 Installation Technique ......................................................................... 17.......

3.2.1 Installation Technique- RS232 Interface ................................................. 17.......

3.2.2 Installation Technique - RS485 / RS422 ................................................. 18.......

3.3 Grounding the Cable shield ................................................................... 19.......

3.4 Technical Data ................................................................................ 20.......

List of Revisions 3

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

1 Introduction

1.1 Scope of Performance

The task often consists of exchanging data between controls of various manu-

facturers or with a host computer. Every system has its own transfer protocol for

this purpose. The implementation of a protocol that is foreign to the system is of-

ten not possible or only with an unreasonable amount of difficulty. This is caused

by the following border conditions:

The interface drivers do not agree

The interface controller is not up to the task

Missing or insufficient computing capacity

Real time requirements cannot be met

Lack of possibility of providing additional configuration data

Missing or insufficient starting up and diagnostic aids

Sometimes the protocol is only used for a single installation. Yet, the implemen-

tation must satisfy extreme quality requirements. The effects of a software error

in the transfer protocol can lead to the stoppage of the whole plant and cause un-

foreseen costs.

Experience has shown that it is just these tests and acceptance of implementation

that are carried out partly only in the laboratory or on a hardly functional installa-

tion. Despite great care, it can then occur that an error is first discovered in the

proper operation of the plant. Especially when the error occurs sporadically or is

dependent on particular plant conditions then an error localization without inte-

grated diagnosis functions is only possible with the greatest of luck.

Practice has shown that most of the problems arise not through errors in imple-

mentation but through poor agreement at the user level. Partly the telegram lan-

guages between the coupling partners are incomplete or are not adhered to. Thus,

for instance, telegrams are expected that have not been sent at all or a telegram

has been interchanged. If the telegram traffic can also be written, then the pro-

blem is quickly solved.

The Protocol Converter is a device that has been specially developed for this pur-

pose and with its operating system makes all the functions available that are

necessary for a rational and reliable implementation of coupling protocols.

The PKV 30-COS Protocol Converter possesses two communication interfaces,

of which one is designed as a CANopen interface.

Introduction 4

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

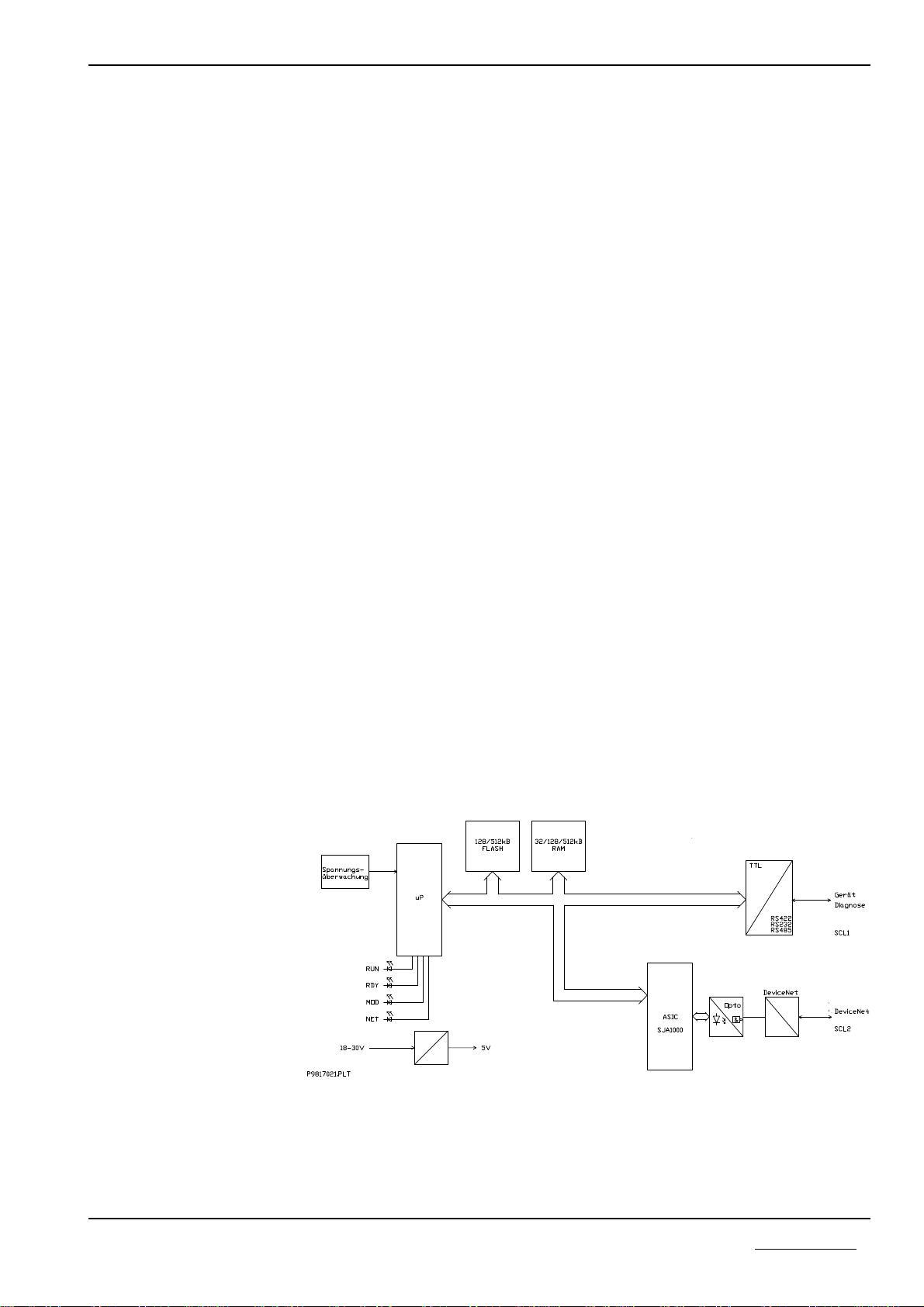

2 General Device Description

The Protocol Converter consists of a basic circuit board and a power supply

circuit board with DC/DC transformers in which all the required auxiliary volta-

ges are created.

The AM188ES processor is inserted on to the basic circuit board. It contains a

built-in timer, interrupt- and DMA-Controller, 2 serial interfaces and thus requi-

res only a few external nodules. The computing power is adequate for processing

even large quantities of data. Furthermore, the 16 Bit processor ensures efficient

software development in a high level language.

The Firmware and the configuration data are stored in a FLASH-EPROM. This

can be programmed within the circuits and retains its data even when the opera-

ting voltage is switched off.

The serial interfaces are realized by the microprocessor and the ASIC SJA1000.

The device to be connected is linked with the first non-floating interface. A

choice can be made between a RS232C, RS422- or a RS485 interface with the aid

of a plug-in jumper. The second potential-free interface is designed for use at the

CANopen.

The proper function of the Protocol Converter is monitored by the internal

Watchdog of the micro- processor and the internal operating voltage by means of

the MAX809 module. In the case of error, these monitors trigger a Reset at the

processor.

The internal supply voltage is generated by means of a switched mode regulator.

Its input voltage is filtered via a current-transformed toroidal choke and filter ca-

pacitors. A transient diode is available as spike and polarity reversal protection.

In the case of malfunction, a semiconductor fuse switches the device down to a

low residual current until the malfunction is cleared. This means that the chan-

ging of an internal sensitive fuse is dispensed with. Besides this, a charging ca-

pacitor is available that blocks the voltage dips that occur in the switching of

fuses.The operational readiness and an error in the communication interface of

the Protocol Converter as well as the CANopen status are displayed by LEDs.

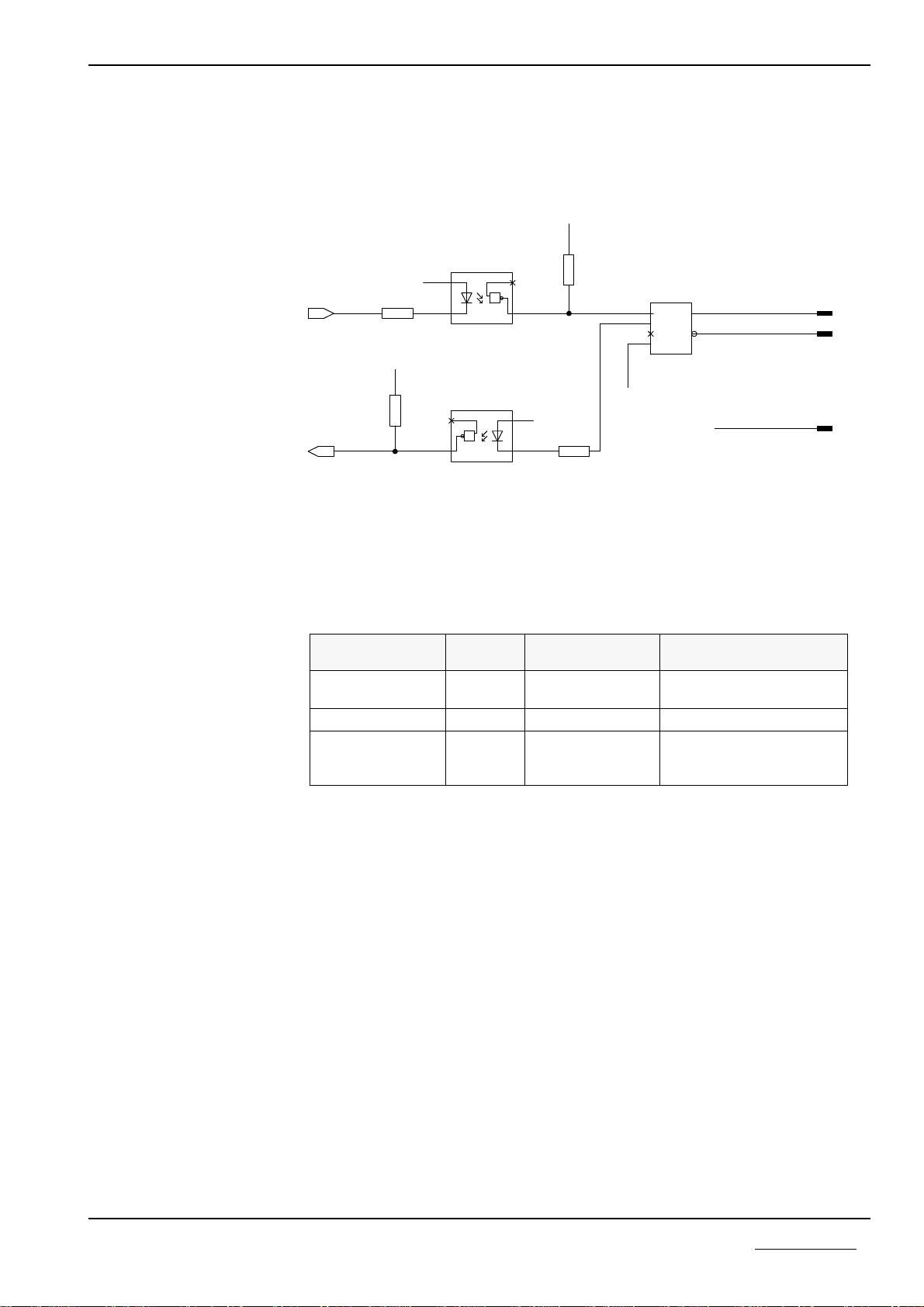

Block diagram of the PKV30-COS Protocol Converter.

Spannumgsüberwachung = Voltage supervision. Gerät diagnose = Device diagnostic

General Device Description 5

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

2.1 Configuration

2.1.1 Settings of the Serial Interface Type

The hardware of the PKV need only be configured via a J5 plug-in jumper rail in

order to set the various interface types. This rail can be reached when the front

face of the PKV 30-COS facing the two serial interfaces is removed. For this pur-

pose the four screws at the corners of the front face must be released. The sketch

below shows the position of the plug-in jumper rail as seen from the front face.

The interface type can be selected with the aid of the table. The various interface

types are discussed in greater detail in the following chapters.

Setting Jumper J5 Interface type

open RS232

3-4 RS485

1-2, 3-4 RS422

Settings of the serial interface type

2.1.2 Setting the CANopen Station Address

The setting of the CANopen station address (1-127) is carried out by means of

the two coding switches. The assignment is shown in the chapter “Mechanical

Dimensions”.

Plug 9-pole DSub Plug

14 3 2

Plug rail

Front face view of the PKV 30-COS with plug rail

Seriel Interface CANopen Interface

14 3 2

General Device Description 6

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

2.2 Connecting the supply voltage (X1)

The Protocol Converter requires a supply voltage of 24 Volt. The maximum po-

wer consumption is given in the chapter on “Technical Data”. A three-phase

rectified supply or a simple rectified switching with charge capacitor is sufficient.

The supply voltage must be led to ground. It is connected by means of a plug-in

screwed clamp. Use is made of a 3-pole COMBICON plug from the PHOENIX

company (MSTB 2,5/3-ST-5,08).

Connection Symbol Signal

1+24V +24V supply voltage

20V Reference potential

3PE Equipment grounding conductor

Connector pin assignment of the operating voltage connection X1

General Device Description 7

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

2.3 Serial Interfaces

The PKV 30-COS possesses two independent interfaces.

First Serial Interface (X3). The first interface cab be selected to operate as a

communication RS232C-, RS422-, or RS485 interface or as a diagnosis / configu-

ration interface. The setting of the communication interface takes place over

plug-in jumpers at J5 (see also chapter “Configuration”).

Second Serial Interface (X2). The second serial interface is designed for opera-

tion at the CANopen.

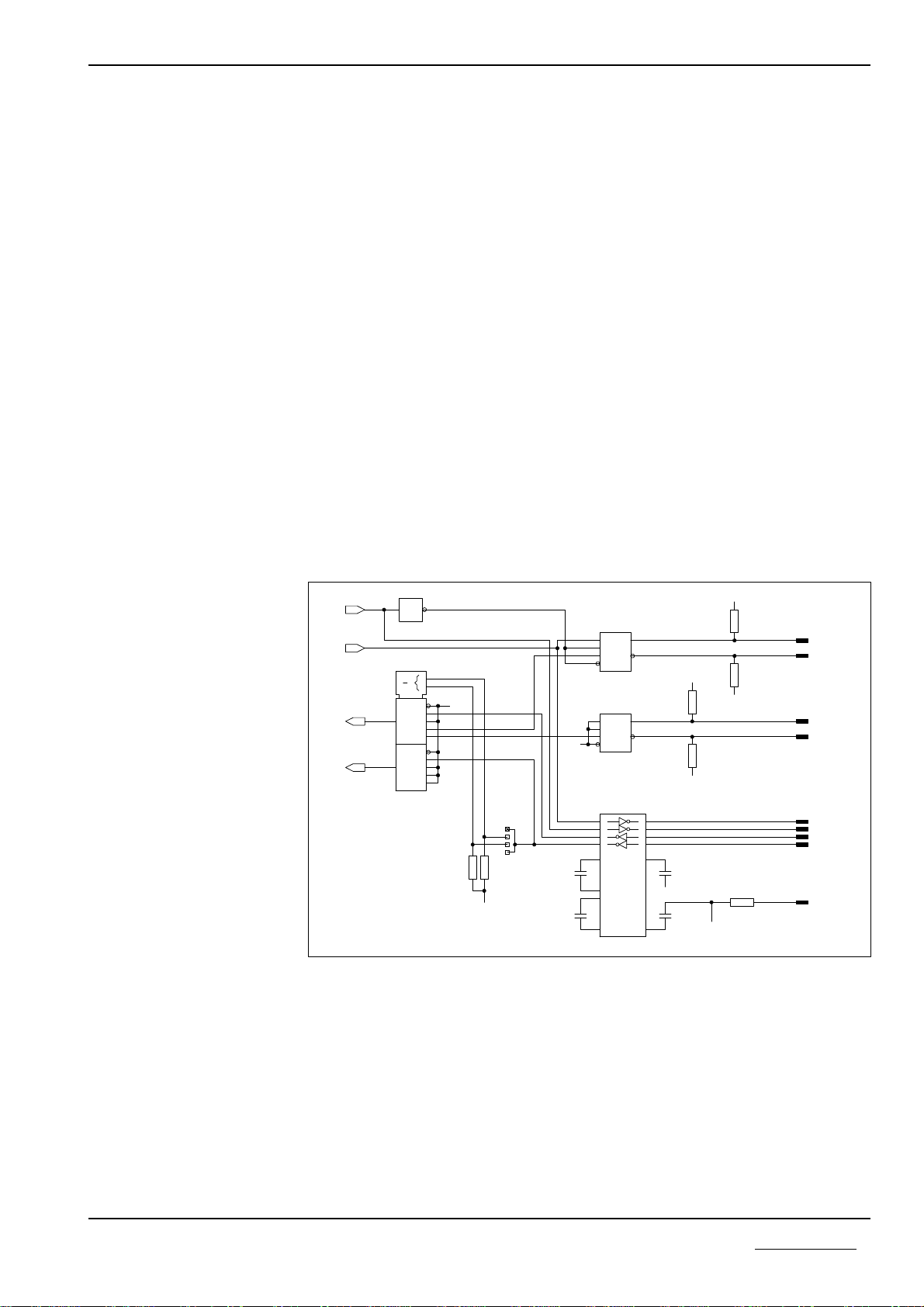

2.3.1 First non-floating interface (X3)

This interface with a 9 pole D-Sub plug to DIN 41652 serves for connecting a de-

vice and can be configured as RS232-, RS422-, or RS485 interface. The setting

takes place over plug-in jumpers at J5 (see also “Configuration”).

In the same way a diagnosis/configuration of the device is possible. The activati-

on of the diagnosis/configuration operation is described in the chapter “Acti-

vating the Diagnostic/Configuration Operation” in this manual.

3

1

2

3

4

8

2

9

5

6

1

4

89

14

2

1

6

5

4

3

15

10

11

12

13

7

9

7

4

3

1

2

6

7

4

3

1

2

6

7

11

10

12

9

1

3

4

5

14

7

13

8

2

6

R29

X3

J5

X3

X3

X3

X3

C13

C15

C12

C14

R34

X3

X3

X3

R30

R32

R35

D7

D8

X3

R36

N2

R33

N1

D6

1

MUX

Y

Y

3

2

1

0

EN

3

2

1

0

EN

3

0G1

0

D

DE

R

RE

A

B

D

DE

R

RE

A

B

C1+

C1-

C2+

C2-

V+

V-

74HCT04

74HCT153

MAX202E

10k

100n

100n

100n

100n

100

10k

10k

10k 10k

ADM485JR 10k

ADM485JR

P9809S12.HP

RXD1

TXD1

CTS1

RGND1

RX/TXD1B

RTSA

RTS1

RXD1A

EN485

EN422

TXDA

RX/TXD1A

RXD1B

GND

GND

GND

GND

GND

GND

CTSA

RXDA

+5V

+5V

+5V

Output circuit of the first serial interface X3

General Device Description 8

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

In the following table the pin assignment of the signals used for the various inter-

face types is shown. All unused signals must not be used. The Bus terminators

must be selected in accordance with the application and must be soldered into the

plug. The resistors R29 and R30 as well as R32 and R33 in the output circuit ser-

ve for setting the quiescent point circuit on the RS485-/RS422 Bus. All resistors

have a resistance value of 10 kOhm.

Connection Input/

Output Signal-

designation Signal RS

485 RS

422 RS

232

1Input/

Output RXD/TXD-N

TXD-N Send data inverted RS 422

Data inverted RS 485 ü ü

2Input RXD Receive data RS 232 ü

3Output TXD Send data RS 232 ü

4Input RXD-P Receive data RS 422 ü

5RGND Reference potential over 100

Ohm ü ü ü

6Input/

Output RXD/TXD-P

TXD-P Send data RS 422

Data RS485 ü ü

7Output RTS Switch on send portion ü

8Input CTS Send readiness ü

9Input RXD-N Receipt data inverted RS 422 ü

Pin assignment of the first interface for X3

Remarks:

When using the RS232 interface, only the connections that are marked with a

tick are to be used.

When using the RS232 interface, the signal CTS (pin 8, Send readiness) must

be activated, this mean pulled up to +5V. For example, this could happen by

connecting the pins 4, 6 and 8 in the plug. This connections are realized also

in the diagnostic cable CAB-SRV of company Hilscher.

General Device Description 9

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

2.3.2 Potential-Free CANopen Interface (X2)

The potential-free CANopen interface is led outward via a 9 pole Dsub

connection.

Circuit of the CANopen interface X2

Connection

DSub Input/

Output Signal

CANopen Signal

2Input/

Output CAN_Low Receive/Send data Low

3ISOGND Data reference potential

7Input/

Output CAN_High Receive/Send data High

Pin assignment of the CANopen interface X2

X2

N4

R22

&

U3

R20

R21

R19

&

U2

X2

X2

L

H

Rs

REF

RX

TX

PCA82C251

680 HCPL0601

680

680

680

HCPL0601

RX

TX 71

4

5

8

7

6

2

3

7

6

2

3

7

6

3

2

12

12

1

2

1

2

ISO+5V

ISO+5V

ISOGND

ISOGND

CAN_HIGH

CAN_LOW

+5V

+5V

General Device Description 10

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

2.3.3 CANopen Cable and Connection

Only cable types specially certified for CANopen should be used as cable con-

nections. The following figure shows the minimum wiring between two network

participants. Please note that at the end and at the start of the Bus line closing re-

sistances of each 120 Ohm must be attached.

Connecting cable between Protocol Converter and the CANopen Master

2.3.4 Bus Termination

The 120 Ohm closing resistors of the network must be connected for correct ope-

ration of the two Bus lines.

General Device Description 11

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

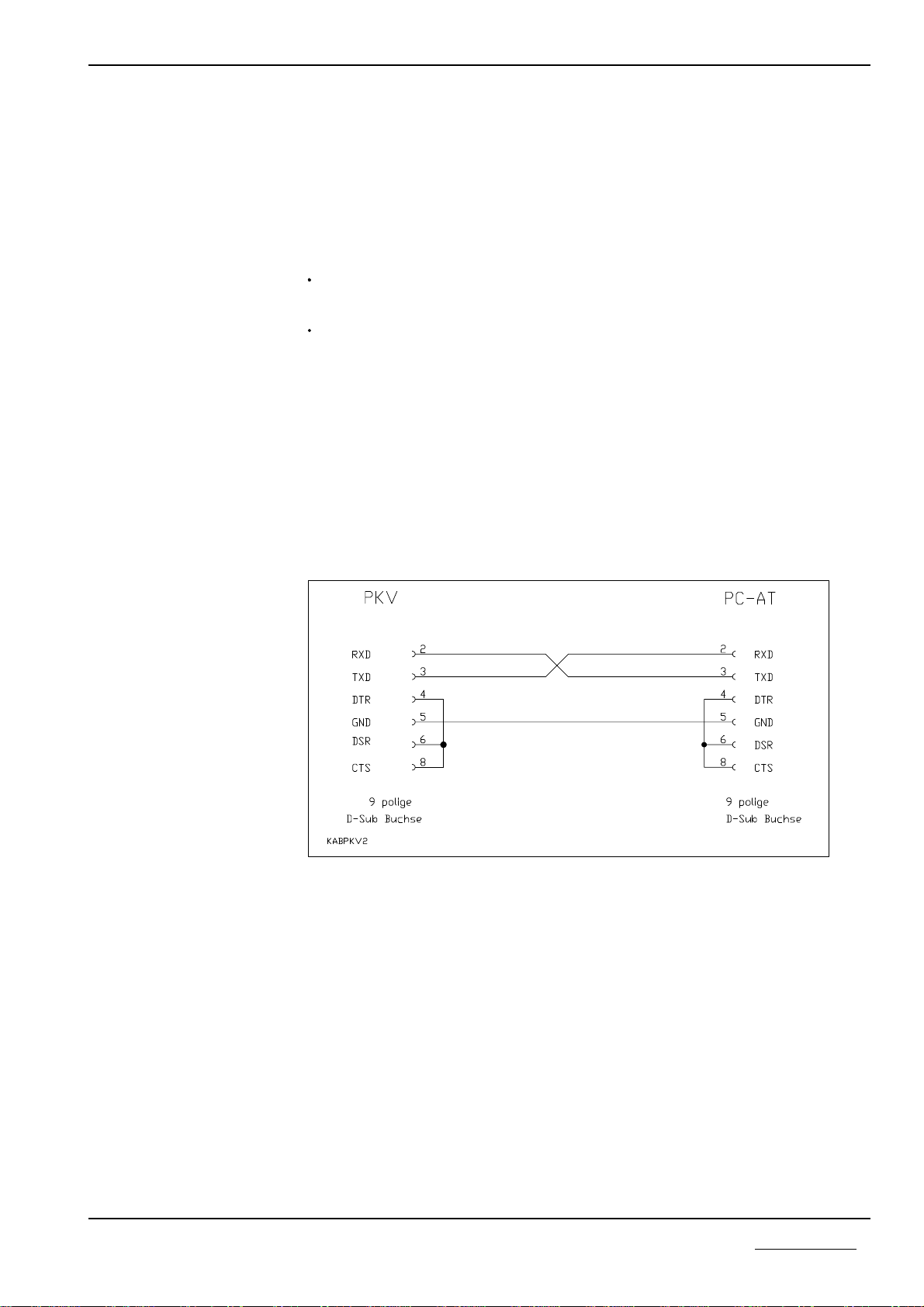

2.4 Diagnostic

The connection of a PC to the Protocol Converter is also possible over the first

serial interface (X3). It corresponds to the RS232C standard according to CCITT

or DIN. Here, only the necessary signals are available.

The following control signals are processed or evaluated as follows:

RTS is set to High in accordance with the functional readiness and is not

changed again.

CTS must be connected via a wire bridge with pins 4 and 8 of the D-Sub plug.

The transfer between PC and Protocol Converter is carried out at 9600 Baud and

the following data format: 8 data Bits, 1 Sop Bit and even parity. The A3964R

procedure is used as transfer protocol.

The connection of the PC is carried out by means of a three-pole cable which

must not be longer than 15 meters. The wiring of the cable is shown below. For

better interference rejection, the cable shield should be grounded on the PC side

to the plug housing.

Connecting cable between Protocol Converter and PC

General Device Description 12

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

The connection X3 of the PKV 30-COS is meant for

communication operation

or for

diagnostic/configuration operation

When switching on the 30-COS a check is carried out at the X3 connection whe-

ther the diagnosis/configuration operation is to be started. In the other case, com-

munication operation is taken up.

2.4.1 Activating the diagnostic/configuration operation

The diagnosis cable must be connected to X3 at the Protocol Converter and to the

COM1 (or COM2) of the PC.

Start ComPro program with

COMPRO /S:1 or.COMPRO /S:2

(for COM1 or COM2).

Select menu Online - System - Bootstart first. The window with the: The system

will be reseted and the bootloader becomes active without startinmg any firmwa-

re message appears.

Now switch off the currant at the Protocol Converter and wait at least for 10

seconds.

In the ComPro confirm the: The system will be reseted and the bootloader be-

comes active without startinmg any firmware message with Return. A red win-

dow appears with the message: Waiting for hardware receipt.

Then the voltage at the Protocol Converter is switched on again.

The red window in the ComPro must disappear.

In order to test whether the Protocol Converter is in diagnostic operation, select

the Online - System - Firmware menu sequence. When the information of the

Firmware in the Converter appears, then the diagnostic/configuration operation

has been successfully activated. If the: No connection could be built up message

appears, then the steps described for activating the diagnostic/configuration ope-

ration must be carried out again.

When the interface type

RS422 or RS485 is configu-

red, it is not necessary to

change this configuration for

diagnostic operation.

General Device Description 13

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

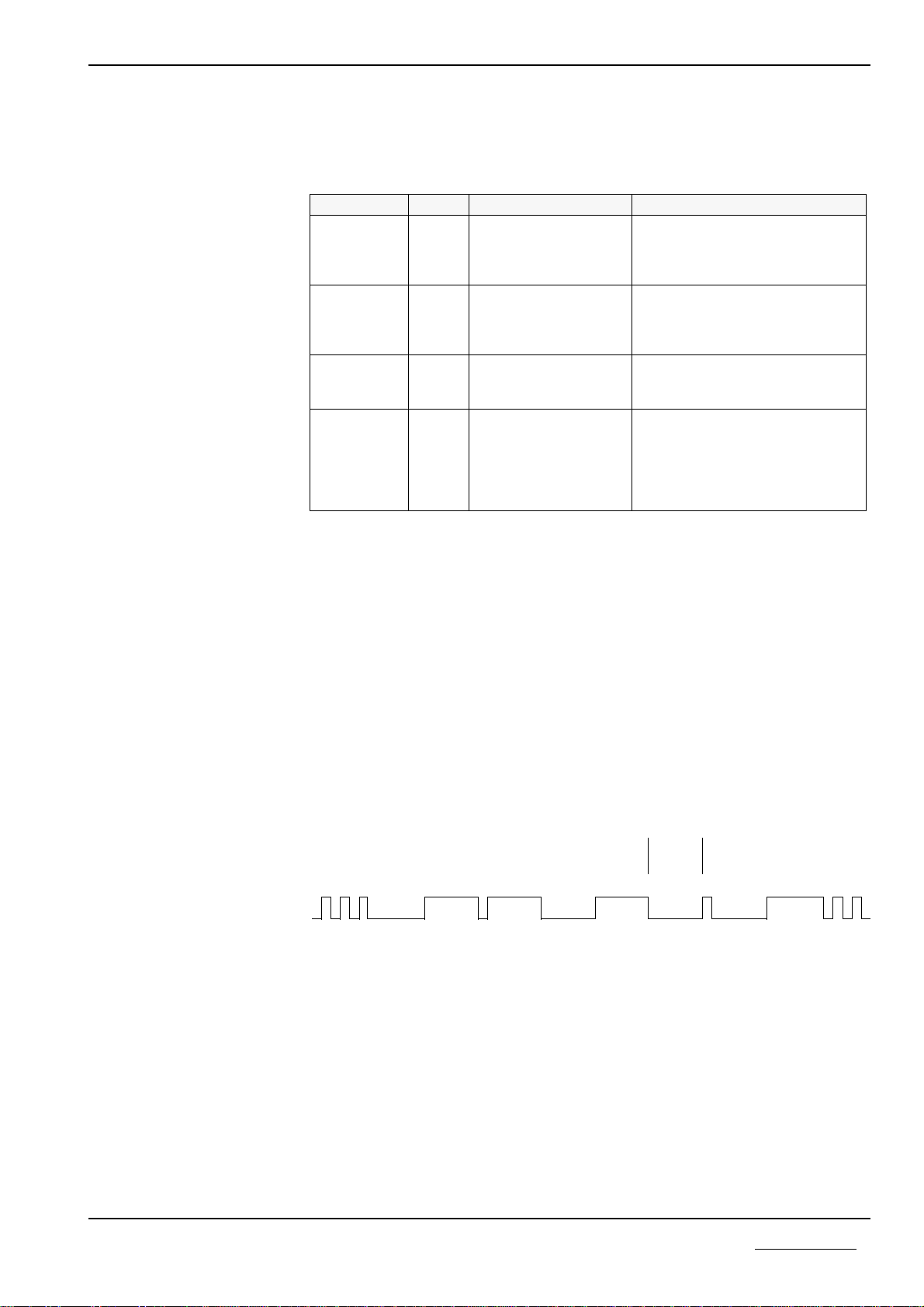

2.5 Status Displays

There are four LEDs available of the PKV 30-COS for status displays:

Display Color Condition Meaning

With a device defect, the conti-

nuous accessing of the Watchdog

Supervision can also lead to a cy-

clic blinking of the RDY-LED.

RDY yellow On

Blinks cyclically

Blinks irregularly

Off

PKV ready

Bootstraploader active

Hardware- or system error

Hardware defective

RUN green On

Blinks irregularly

see below

Off

Communication running

Parameter error

no communication

ERR 1 yellow Lights up briefly CAN message sent

- No error shows communication

operation is on

ERR 2 red on The device is not currently in an

operational condition but did once

reach operational readiness. This

means that a running

communication to the Master has

been interrupted.

After switching on, the PKV carries out a self-test. If this has been run through

successfully, then the yellow RDY-LED is switched on. Otherwise the LED be-

gins to blink irregularly and the further processing of the program is aborted.

If no field bus Firmware is loaded on the PKV, then the Bootstrap loader shows

this by a cyclical blinking of the RDY-LED in a 1-second rhythm.. During the

loading of the Firmware, the blink rhythm increases to approximately 5 Hz.

If the LED remains off, then there is a defect of the PKV.

If a Protocol Task recognizes parametrizing error, then the Task is displayed by

the RUN-LED in accordance with the following figure. If there is no error and

communication could be started, then the RUN-LED is switched on. If the com-

munication operation is blocked, then the RUN-LED remains off.

Start

identifier Data bits with depatartion identifier -> 1 sec. <- starts

again

The display on the LED is carried

out from left to right

RCS

with

DBM

error

Task 1

without

error

Task 2

without

error

Task 3

with

error

Task 4

without

error

Task 5

with

error

Task 6

with

error

Task 7

not confi-

gured

Display of the tasks that have indicated a parametrizing error

General Device Description 14

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

2.6 Mechanical Dimensions

The Gateway is built into an aluminum profile housing. This permits direct instal-

lation into the switching cupboard on a carrier rail (TS35 according to DIN EN

50022). The mechanical dimensions and the allocation of the pins are shown in

the following figures.

LED-Anzeige = LED display, Spannungsversorgung = Voltage supply,

serielle Schnittstelle = serial Interface

Pin assignment on the Protocol Converter

Mechanical dimensions of the Protocol Converter for clipping on to a carrier rail

The depth of the converter is approximately 80 mm.

To set the interface type, open

the top cover ------------>

105

105

General Device Description 15

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

3 Appendix

3.1 Selection of the Line for the Individual Interfaces

The following table contains a review of the achievable transfer rates of the X3

interface. This depends to a large extent on the length of the transfer distance and

the line used.

Interface Line max.

Distance max.Transfer-

rate

RS232C LIYCY 3x0.25 sq. mm 15 m 19.2 kBd

RS422 LIYCY-CY 2x2x0.25 sq. mmsurge

impedance 100-150 OhmCapacitance

per unit length approx. 60 pF/m

200 m 500 kBd

1200 m 19.2 kBd

RS485 LIYCY-CY 1x2x0.25 sq. mmsurge

impedance 100-150 OhmCapacitance

per unit length approx. 60 pF/m

200 m 500 kBd

300 m 375 kBd

1200 m 62.5 kBd

Overview of the maximum transfer rate of the individual interfaces

Only cables specially certified for CANopen should be used as connecting cable

for CANopen.

Appendix 16

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

3.2 Installation Technique

The following sections contain information for wiring the individual interface

types.

3.2.1 Installation Technique- RS232 Interface

The RS232 or V24 interface is the standard interface for a point-to-point con-

nection between two communication devices. The RS232 interface hardly offers

freedom from interruption and is only designed for short line lengths (max. 15m).

Basically, a distinction must be made whether the serial RS232C interface is con-

nected potential-free or galvanically with the chassis of the devices. A connection

to the device chassis is only useful for the non-floating connected RS232C inter-

face. With the CIF, PKV or Gateway, this is the first serial interface that is

available fixed on the base circuit board.

The RS232C interface is designed for relatively short lengths (max. 15m) . It is

assumed that both devices are earthed to the same protective conductor potential.

If, despite this, equalizing currents over the chassis connection in the non-floating

model still occur, then they are limited by the built-in 100 Ohm resistance. If the

devices are situated further apart, than we recommend that the data are transmit-

ted over the distance with RS422 level. For connected devices, the signals are

then converted to RS232C level via an interface modem. In this way distances up

to 100 m can be bridged.

Interface modems are offered, among others by the Phoenix company, e.g. model

PSM-V24/V11-P.

Appendix 17

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

3.2.2 Installation Technique - RS485 / RS422

Under certain conditions, the RS485 as well as the RS422 interfaces are very free

from interference and are suitable for longer distances. Both interface types per-

mit the networking of several communication participants. The data transfer oc-

curs as a differential signal between the data line Data/Data¯¯¯¯. In contrast to the

RS485 interface, the RS422 interface utilizes separate data lines for sending and

receiving directions, thus a total of four conductors (TxData/TxData¯¯¯¯¯¯ and RxDa-

ta/RxData¯¯¯¯¯¯). The differential signal is always transferred over twisted wire pairs.

A Bus structure with RS485/RS422 has the following form:

Typical Form of a RS485/RS422 Bus structure

The main line determines the length of the communication path. It is terminated

at both ends with the terminators and preferably at the end with the level

resistance.

The Spur lines should not exceed a length of 2.5m. They are branched off via

Bus branches from the main line. In practice, so-called Bus clamps (e.g. from

Siemens) or T-pieces (e.g. from the Weidmüller company) are used as branches.

There are several possibilities regarding the wiring of the reference potential.

These have a plug for the input and output of the main line and a plug for the spur

line. As a rule in the branches, the level and/or the end resistors can be switched

on or off via Dip switches.

Wiring by means of screw clamps should be avoided as these usually lead to

transfer interferences with high Baud rates.

When using finished Bus branches, special account must be taken with the shiel-

ding concept and the pin assignment of the clamps!

Main line

Spur line (<2.5m)

Communication device

Branch / Bus clamp

2-wire RS485

4-wire RS422

End of the

main line

End of the

main line

Appendix 18

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

3.3 Grounding the Cable shield

Basically, a shielded cable should be used for each interface type for improving

the EMC. The best effect is achieved with a shield that is grounded at both ends.

Both ends grounded

If the communication devices are distributed over a large area, for instance in dif-

ferent rooms, then there is a danger that equalization currents flow between the

individual protective conductor potentials. In this case, it is recommended to gro-

und directly at one end only and at the other end, or at all ends, of spur lines, to

connect to the protective conductor via a foil capacitor of 100 nF/400V. This pre-

vents equalization flows as the interference currents are only grounded capacitati-

vely.

Grounding with long transfer distances and interference influences

For short transfer distances or little interference influences, a one-sided ground is

sufficient.

Grounding for short transfer distances or little interference influences

The threaded screws and the housing of the Dsub plug connections are connected

to the housing of the device and thus to its ground conductor. If a metallic plug

housing as well as a plug connector with shielding springs is utilized, then the

shield can be grounded with this. Otherwise the shield must be connected with

the protective ground by means of a separate line (worse solution).

If a capacitative connection is to be created to the protective earth, we recom-

mend that the capacitor is introduced into the separate chassis line and to envelo-

pe this with a shrink hose.

If the cable shield is misused as a reference potential, usually with RS485 inter-

faces (worse but economical solution), then special care must be taken.

Appendix 19

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

3.4 Technical Data

Processor 16 Bit with Timer, Interrupt- and DMA-Controller,

2 serial Interfaces, Watchdog

Memory structure 512 KByte RAM, 512 KByte FLASH

serial Interface configurable as non-floating

Diagnostic interface

RS232C-, RS422-, RS485-Interface,

max. transferrate 19.2 kBaud

Transfer formats Asynchron / Synchron

CANopen Interface ISO High Speed,

potential free,

max. transfer rate 1 MBaud

LED-Displays Operating and communication readiness of the conver-

ter, error on the serial interface SCL1,

Status CANopen

Operating voltage 18 - 30 V

Power consumption max. 0.20 A at 24 V

Operating temperature 0 - 50 Grad

Type of protection IP50

Dimensions (L x B x H) 105 x 105 x 80 mm

Installation Carrier rail DIN EN 50022

Appendix 20

Copyright * Hilscher Gesellschaft für Systemautomation mbH * Hotline/Support: +49(0)6190/9907-99 * De:P30COS#3E

Table of contents

Other hilscher Media Converter manuals

Popular Media Converter manuals by other brands

H&B

H&B TX-100 Installation and instruction manual

Bolin Technology

Bolin Technology D Series user manual

IFM Electronic

IFM Electronic Efector 400 RN30 Series Device manual

GRASS VALLEY

GRASS VALLEY KUDOSPRO ULC2000 user manual

Linear Technology

Linear Technology DC1523A Demo Manual

Lika

Lika ROTAPULS I28 Series quick start guide

Weidmuller

Weidmuller IE-MC-VL Series Hardware installation guide

Optical Systems Design

Optical Systems Design OSD2139 Series Operator's manual

Tema Telecomunicazioni

Tema Telecomunicazioni AD615/S product manual

KTI Networks

KTI Networks KGC-352 Series installation guide

Gira

Gira 0588 Series operating instructions

Lika

Lika SFA-5000-FD user guide