Himel HAV SP Series User manual

Smart Pump User Guide

Himel Drives

Smart Pump – HAV SP Series

Variable Speed Drives for Asynchronous Motors

User Manual

07/2022

© 2022 HIMEL

Himel

www.himel.com

July 2022 www.himel.com

1

Preface

Thank you for purchasing the HAV-SP series drive developed and produced by Himel

HAV-SP drives are full-featured dedicated drives for parabolic load applications like pumps,

fans, and chillers. HAV-SP has a wide range of integrated features like multi-pump control, dry run

protection, sensor-less flow and energy calculation, pump cleaning, fire override mode, frost,

condensation and hammer effect protections to meet the needs of pump, fans and chillers for

modern buildings. HAV-SP also has functions like PID control, simple PLC, multi-speed control

and other functions to meet different process requirements.

Before using this drive, the users and relevant technicians shall read this manual carefully to

ensure that the drive can be properly installed and operated, so that the drive can perform its best

performance.

If there is any change to this user manual, please refer to the new version without notice.

High-performance Drive

User Manual

Version: V1.4

2

This product implements standards:

The design and production of this product refer to the latest national standards (GB or GB/T),

International Electrotechnical Commission Standards (IEC) and International System of Units (SI).

The technical parameters of the relevant parts can meet the requirements of national standards (GB

or GB/T) and International Electrotechnical Commission Standards (IEC). Main standards:

GB/T 12668.2-2002 Adjustable Speed Electrical Power Drive Systems - Part 2: General

Requirements - Rating Specifications for Low Voltage Adjustable Frequency AC Power Drive

Systems

GB 12668.3-2012 Adjustable Speed Electrical Power Drive Systems - Part 3: EMC

Requirements and Specific Test Methods

GB 12668.501-2013 Adjustable Speed Electrical Power Drive Systems - Part 5: Safety

Requirements - Electrical, Thermal and Energy

GB/T 2423.1-2008 Environmental Testing for Electric and Electronic Products - Part 1: Test

Methods Tests A: Cold

GB/T 2423.2-2008 Environmental Testing for Electric and Electronic Products - Part 2: Test

Methods Tests B: Dry Heat

GB/T 2423.3-2006 Environmental Testing - Part 2: Testing Method - Test Ca: Damp Test,

Steady State

GB/T 2423.4-2008 Environmental Testing for Electric and Electronic Products - Part 2: Test

method - Test Db: Damp heat, cyclic (12h+12h Cycle)

GB/T 2423.9-2006 Environmental Testing for Electric and Electronic Products - Part 9: Test

Methods Tests Cb: Constant damp heat for equipment

GB/T 2423.7-1995 Environmental Testing for Electric and Electronic Products - Part 7: Test

Methods Tests Ed: Free Fall

GB/T 2423.22-2012 Environmental Testing for Electric and Electronic Products - Part 2: Test

method - Test N: Change of Temperature

GB/T4798.1-2005 Environmental Conditions Existing in the Application of Electric and

Electronic Products - Storage

GB/T4798.2-2008 Environmental Conditions Existing in the Application of Electric and

Electronic Products - Transport

GB/T4798.3-2007 Environmental Conditions Existing in the Application of Electric and

Electronic Products - Work

3

Danger

The drive must be reliably grounded. If the drive is not reliably grounded, there may be

a potential danger of personal injury in the device.

Readers

This user manual is suitable for the following readers.

Drive installers, engineering technicians (electrical engineers, electrical operators, etc.),

designers, etc. Please ensure that this user manual reaches the end users.

Notational conventions in this manual

Caution: Moderate or minor injuries may occur due to failure to operate as required.

Danger: Deaths or serious injuries may occur due to failure to operate as required.

4

Table of Contents

Chapter I Product Specification and Ordering Instructions ............6

1.1 Drive series models ................................................. 6

1.2 Product appearance and installation dimensions .......................... 7

1.3 Dimensions of optional base .......................................... 9

1.4 Keypad size ....................................................... 9

1.5 Installation of remote keypad ........................................ 11

1.6 Name of each part of this series drives ................................. 12

1.7 Braking resistors .................................................. 13

Chapter II Installation and Wiring of Drive .........................16

2.1 Drive installation environment ....................................... 16

2.2. Removal and installation of drive panel ............................... 20

2.3 Wiring of main circuit terminals ......................................22

2.4 Control circuit configuration and wiring ............................... 26

Chapter III Operation Instructions of Drive .........................32

3.1 Key function description ............................................ 32

3.2 Keypad operation methods .......................................... 32

Chapter IV Function Parameter Table .................................35

4.1 Function parameter table ............................................35

4.2 Monitoring parameter group U0 ...................................... 97

4.3 Fault record parameter group U1 .................................... 100

4.4 Fault code summary table .......................................... 101

Chapter V Basic Operation Instructions .............................102

5.1 Start operation mode .............................................. 102

5.2 Start-stop control ................................................. 105

5.3 Frequency setting .................................................108

5.4 Analog input .................................................... 110

5.5 Analog output ................................................... 112

5

5.6 Digital input ..................................................... 114

5.7 Digital output .................................................... 119

5.8 Simple PLC ..................................................... 123

5.9 Multistage speed operation ......................................... 127

5.10 PID control .....................................................131

5.11 Multi-pump control ...........................................136

5.12 Troubleshooting .................................................144

Appendix I Communication Protocol ..................................151

Appendix Ⅱ Multi-pump control expansion card applications .........156

6.1 Multi-pump control expansion card installation instructions .............. 156

6.2 Multi-pump control expansion card terminal function description .......... 156

6.3 Fault countermeasures and exception handling ......................... 157

6

Chapter I Product Specification and Ordering Instructions

1.1 Drive series models

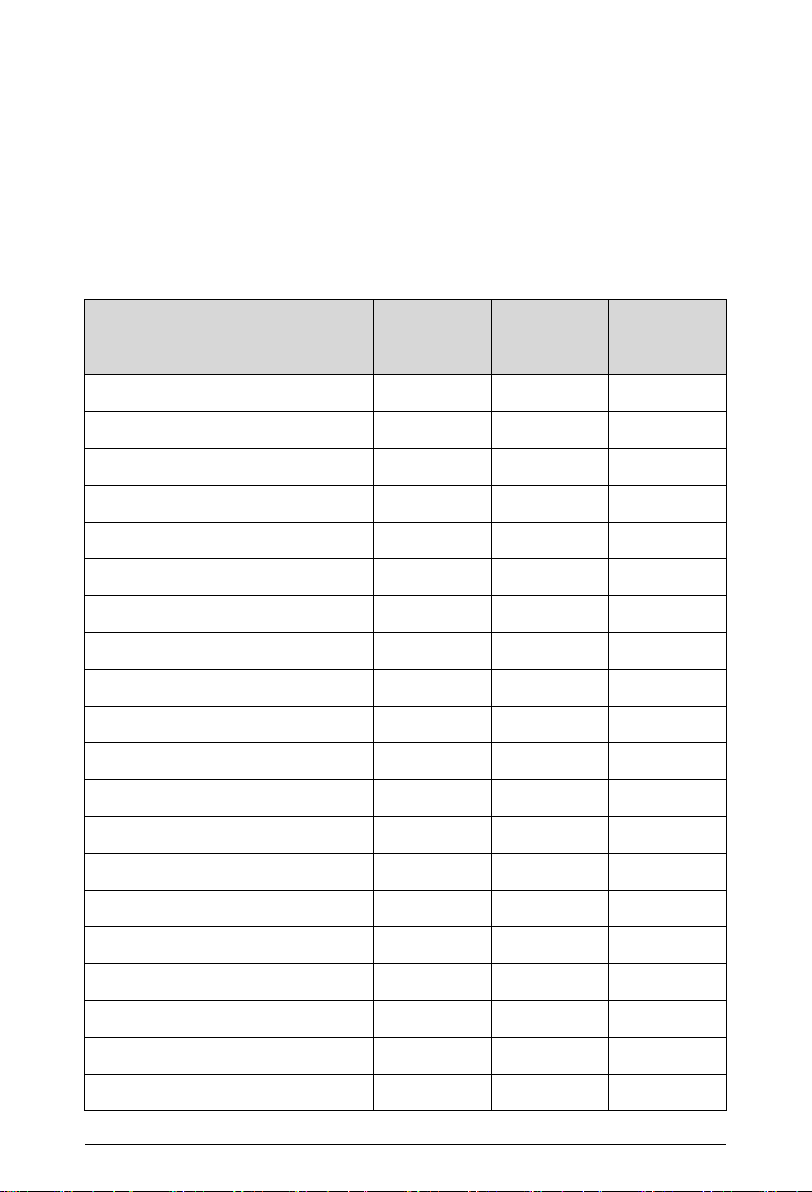

The input voltage range of this drive is 380V-440VAC and 220V-240V. The adaptive motor

power range is 2.2 kW ~ 160 kW. The models of this series drives are shown in Table 1-1.

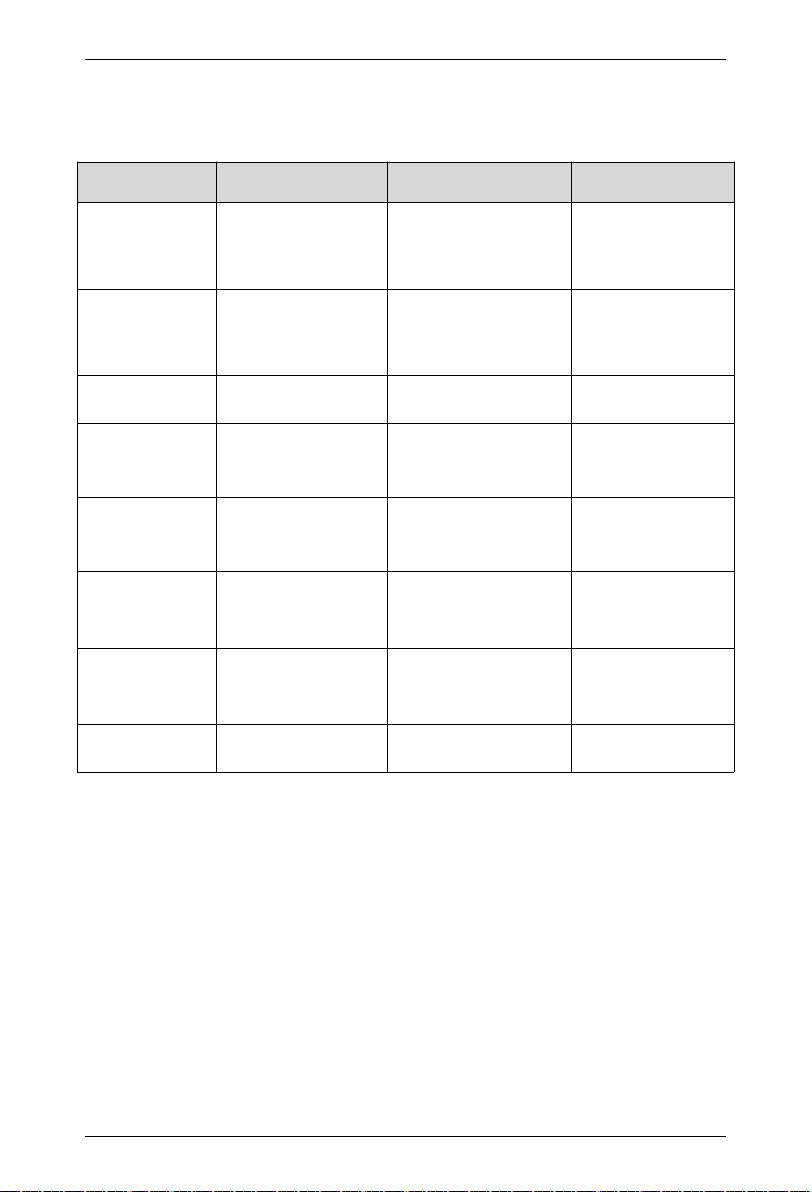

Table 1-1 Drive Models

Drive model

Rated capacity

(kVA)

Rated output

current

(A)

Adaptable motor

(kW)

HAV-SP-4T0022P

3.7

5.0

2.2

HAV-SP-4T0030P

4.9

7.5

3.0

HAV-SP-4T0040P

7.5

8.8

4.0

HAV-SP-4T0055P

8.5

13

5.5

HAV-SP-4T0075P

11

17

7.5

HAV-SP-4T0110P

17

25

11

HAV-SP-4T0150P

21

32

15

HAV-SP-4T0185P

24

37

18.5

HAV-SP-4T0220P

30

45

22

HAV-SP-4T0300P

40

60

30

HAV-SP-4T0370P

50

75

37

HAV-SP-4T0450P

60

90

45

HAV-SP-4T0550P

72

110

55

HAV-SP-4T0750P

100

157

75

HAV-SP-4T0900P

116

180

90

HAV-SP-4T1100P

138

214

110

HAV-SP-4T1320P

167

256

132

HAV-SP-4T1600P

200

307

160

HAV-SP-2T0022P

3.7

10.08

2.2

HAV-SP-2T0030P

4.9

11.5

3.0

Chapter I Product Specification and Ordering Instructions

7

Drive model

Rated capacity

(kVA)

Rated output

current

(A)

Adaptable motor

(kW)

HAV-SP-2T0040P

7.5

16.2

4.0

HAV-SP-2T0055P

8.5

20.3

5.5

HAV-SP-2T0075P

11

26.7

7.5

HAV-SP-2T0110P

17

39

11

HAV-SP-2T0150P

21

52.5

15

HAV-SP-2T0185P

24

62.4

18.5

HAV-SP-2T0220P

30

73.6

22

HAV-SP-2T0300P

40

98.7

30

HAV-SP-2T0370P

50

121

37

HAV-SP-2T0450P

60

147

45

Note: If you need models of other power ranges, please consult the manufacturer before

ordering!

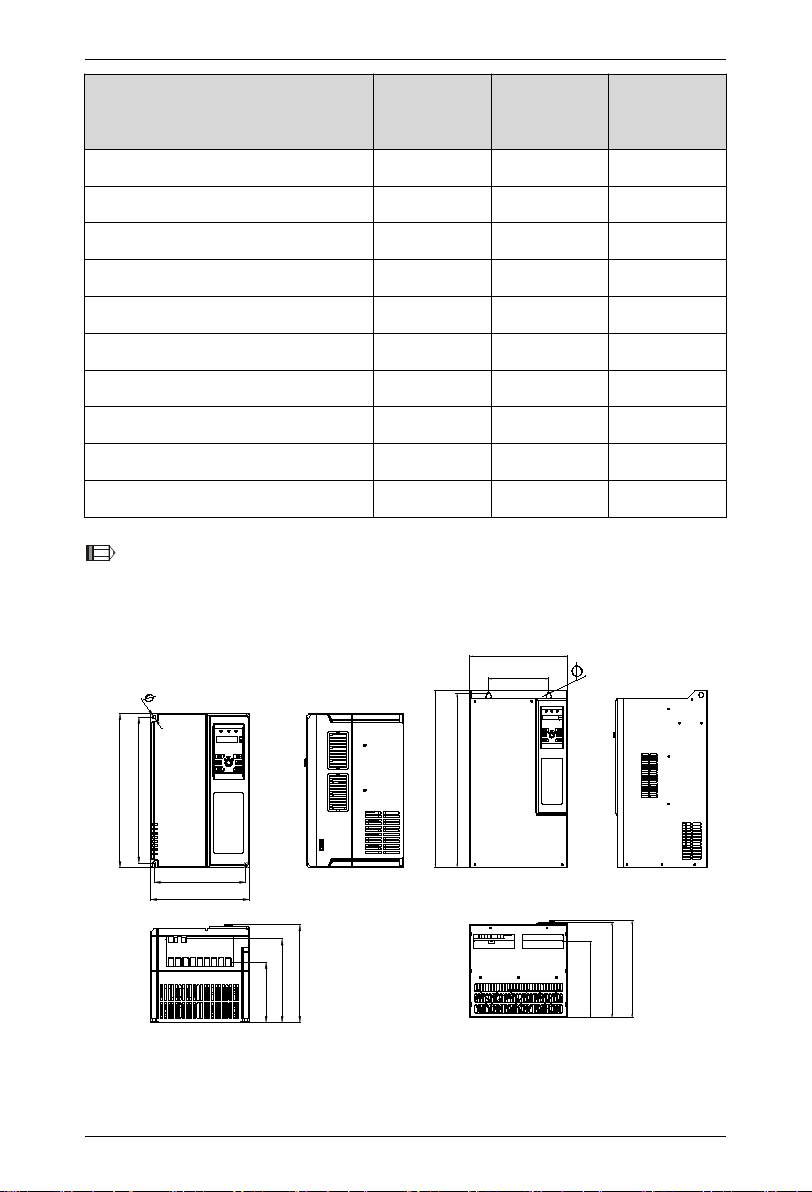

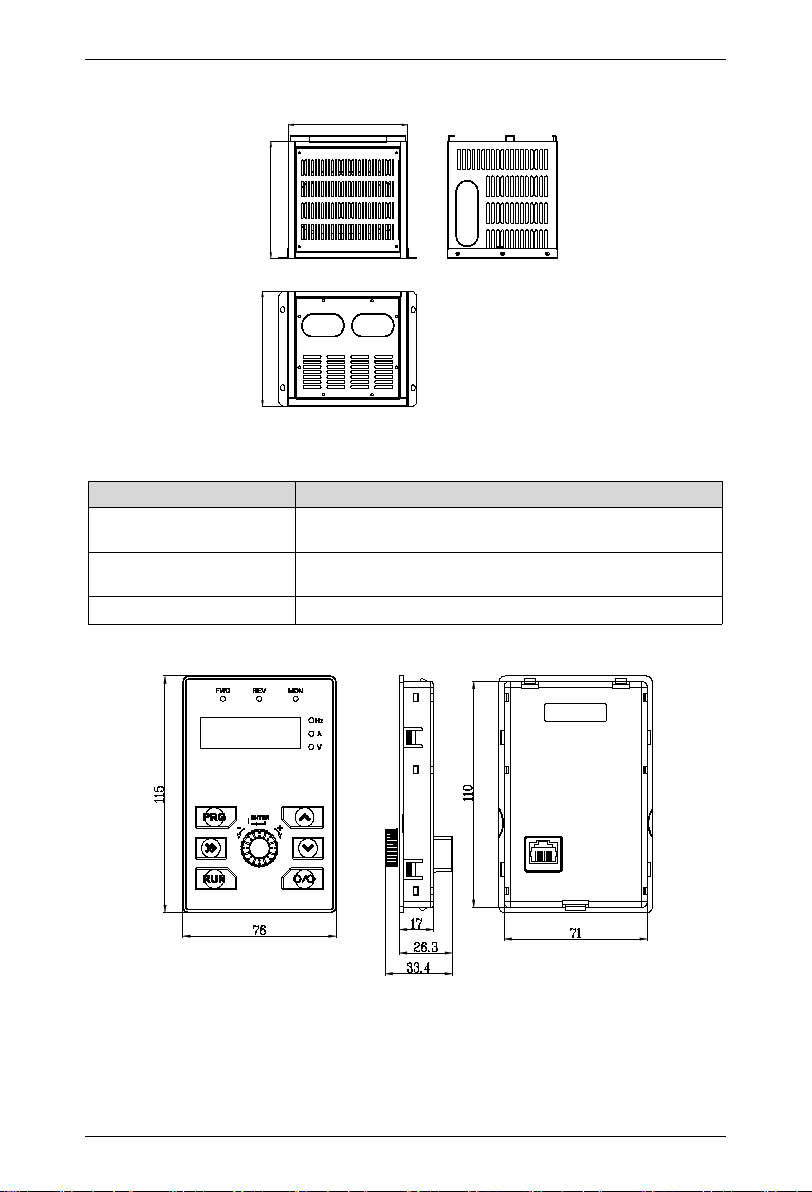

1.2 Product appearance and installation dimensions

W1

W

H1

H

D2

D1

D

W1

W

H1

H

D

D2

D1

(a) A specification (b) B specification

8

Table 1-2 Drive Appearance and Installation Series Dimensions (Unit: mm)

Drive Model

W

W1

H

H1

D

D1

D2

Mounting hole

diameter

(Φ)

Reference

picture

HAV-SP-4T0022P

120

109

215

204

163

133

85

5.5

(a)

HAV-SP-4T0030P

HAV-SP-4T0040P

HAV-SP-4T0055P

HAV-SP-4T0075P

HAV-SP-2T0022P

HAV-SP-2T0030P

HAV-SP-2T0040P

HAV-SP-4T0110P

150

138

259

248

181

150

104

5.5

(a)

HAV-SP-4T0150P

HAV-SP-2T0055P

HAV-SP-2T0075P

HAV-SP-4T0185P

205

188

322

305

215

176

130

6.5

(a)

HAV-SP-4T0220P

HAV-SP-2T0110P

HAV-SP-4T0300P

235

218

370

350

235

200

146

7

(a)

HAV-SP-4T0370P

HAV-SP-2T0150P

HAV-SP-2T0185P

HAV-SP-4T0450P

305

200

490

470

275

270

211

10

(b)

HAV-SP-4T0550P

HAV-SP-2T0220P

HAV-SP-2T0300P

HAV-SP-4T0750P

320

197

560

543

307

302

240

10

(b)

HAV-SP-4T0900P

HAV-SP-4T1100P

HAV-SP-2T0370P

HAV-SP-2T0450P

HAV-SP-4T1320P

355

240

678

659

319

314

261

11

(b)

HAV-SP-4T1600P

Note: 1. The base of HAV-SP-4T0450P~HAV-SP-4T1600P and HAV-SP-2T0220P~HAV-SP-2T0450P

are optional.

Chapter I Product Specification and Ordering Instructions

9

1.3 Dimensions of optional base

W

H-300mm

D

Note: The dimensions of the base in W and D directions are consistent with the corresponding

model, as shown in Table 1-2, and the H dimension is fixed at 300mm.

Table 1-3 Base Matching Table

Base jacking model

Adaptable models

HAV-XS-4T0370DZ

HAV-SP-4T0450P~HAV-SP-4T0550P

HAV-SP-2T0220P~HAV-SP-2T0300P

HAV-XS-4T0750DZ

HAV-SP-4T0750P~HAV-SP-4T1100P

HAV-SP-2T0370P~HAV-SP-2T0450P

HAV-XS-4T1100DZ

HAV-SP-4T1320P~HAV-SP-4T1600P

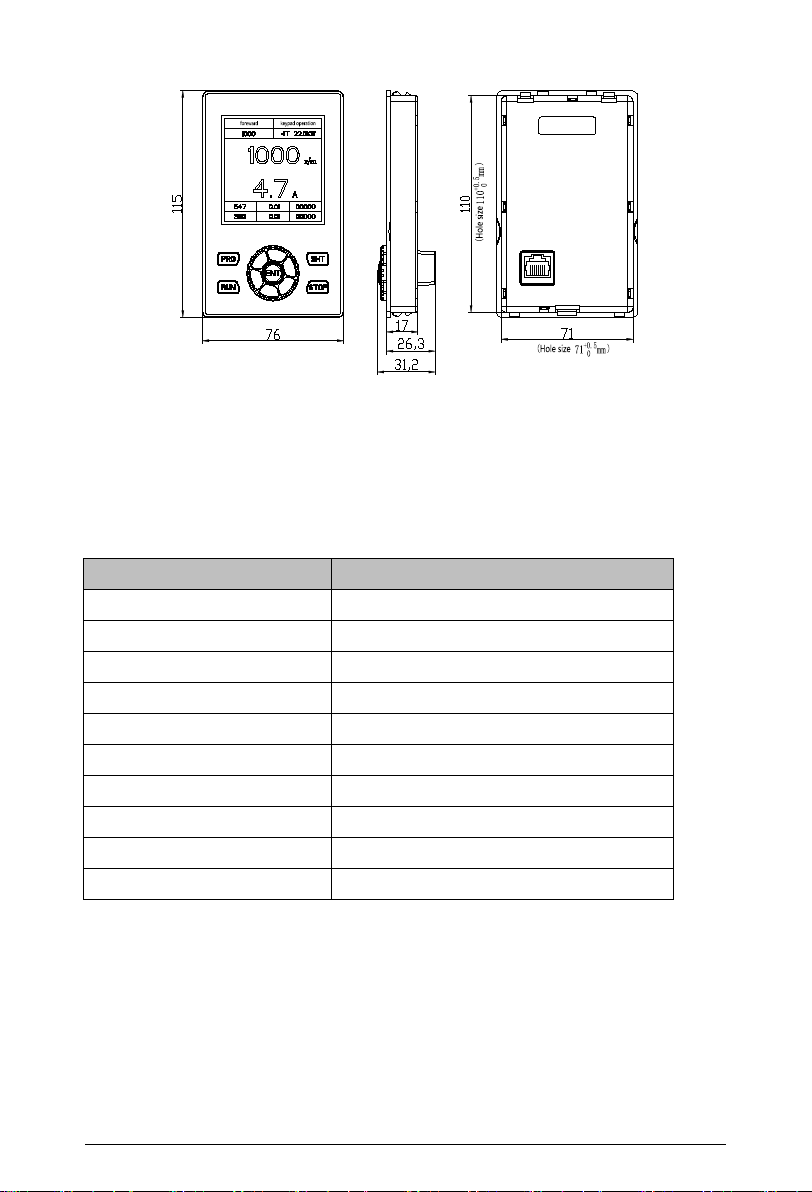

1.4 Keypad size

Figure 1-1 Keypad HAV-SP-LKD Size

10

Figure 1-2 Keypad HAV-SP-LCD Size

Table 1-4 Datasheet of HAV-SP-LCD

Item

Description

Display screen size

55*55mm

Display resolution

160*160

Display mode

Blue screen

Keypad interface

RJ45 interface

USB interface

Micro USB

Humidity

Less than 90%RH, no condensation

Vibration

Less than 5.9m/s2

Environment temperature

-10°C~+50°C

Storage temperature

-40℃~+60℃

Protection class

IP20

Chapter I Product Specification and Ordering Instructions

11

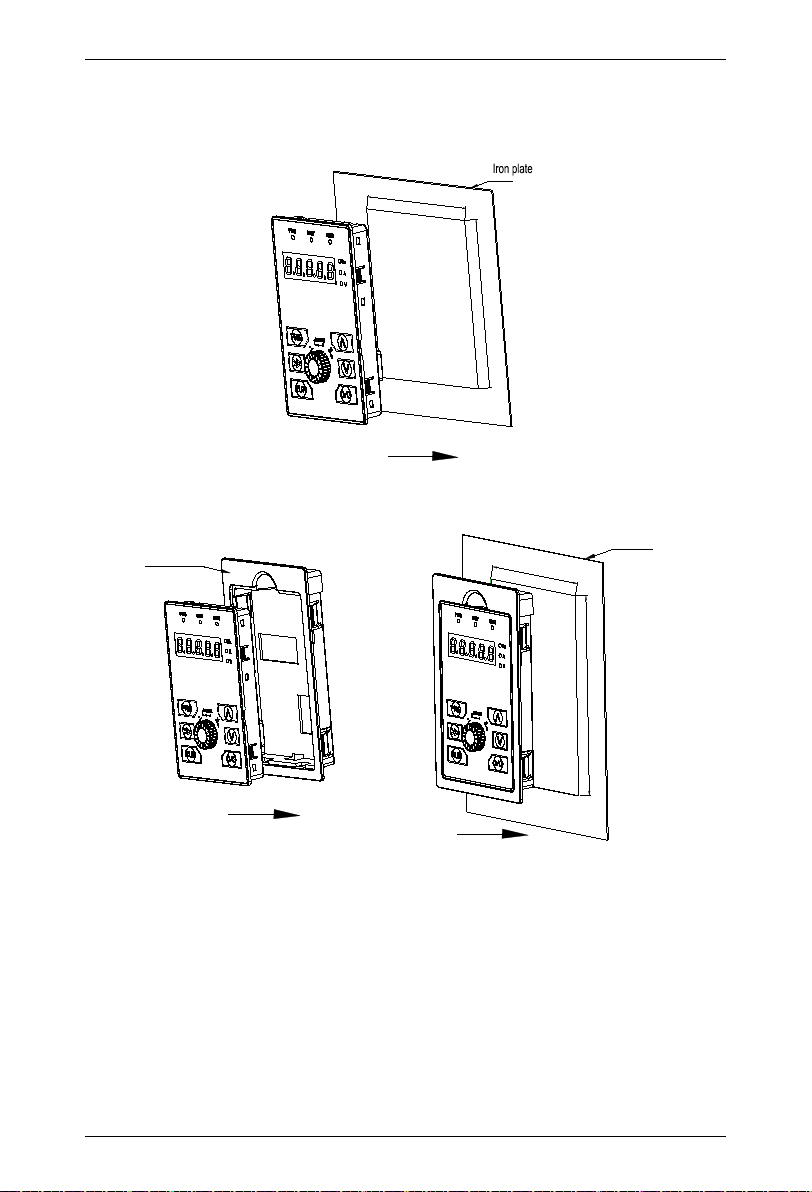

1.5 Installation of remote keypad

The remote keypad can be installed in two ways, one is directly installed on an iron plate, and the

other is installed on an optional keypad tray.

Opening size71.5mm±0.3mm

Opening size111.0mm±0.3mm

When the remote keypad is installed on an iron plate, the installation process is shown in the figure.

Press down the keypad in the direction of the arrow until a "click” sound is heard.

Keypad tray

Iron plate

Opening size 81±0.3mm

Opening size 130±0.3mm

When the remote keypad is installed on an optional keypad tray, the installation process is

shown in the figure. Place the keypad into the tray in the direction of the arrow, and press down the

entire keypad in the direction of the arrow, until a "click” sound is heard.

1.5.1 Dust-proof sticker for optional parts (schematic diagram of outlet position of outgoing

keypad line)

12

Panel dustproof sticker

Remote control of

local keypad Remote control of

local keypad

External keypad line

Table 1-5 Dustproof Sticker Model

Dustproof sticker model

Adaptable models

HAV-XS-FCT

HAV-SP-4T0022P~HAV-SP-4T1600P

HAV-SP-2T0022P~HAV-SP-2T0450P

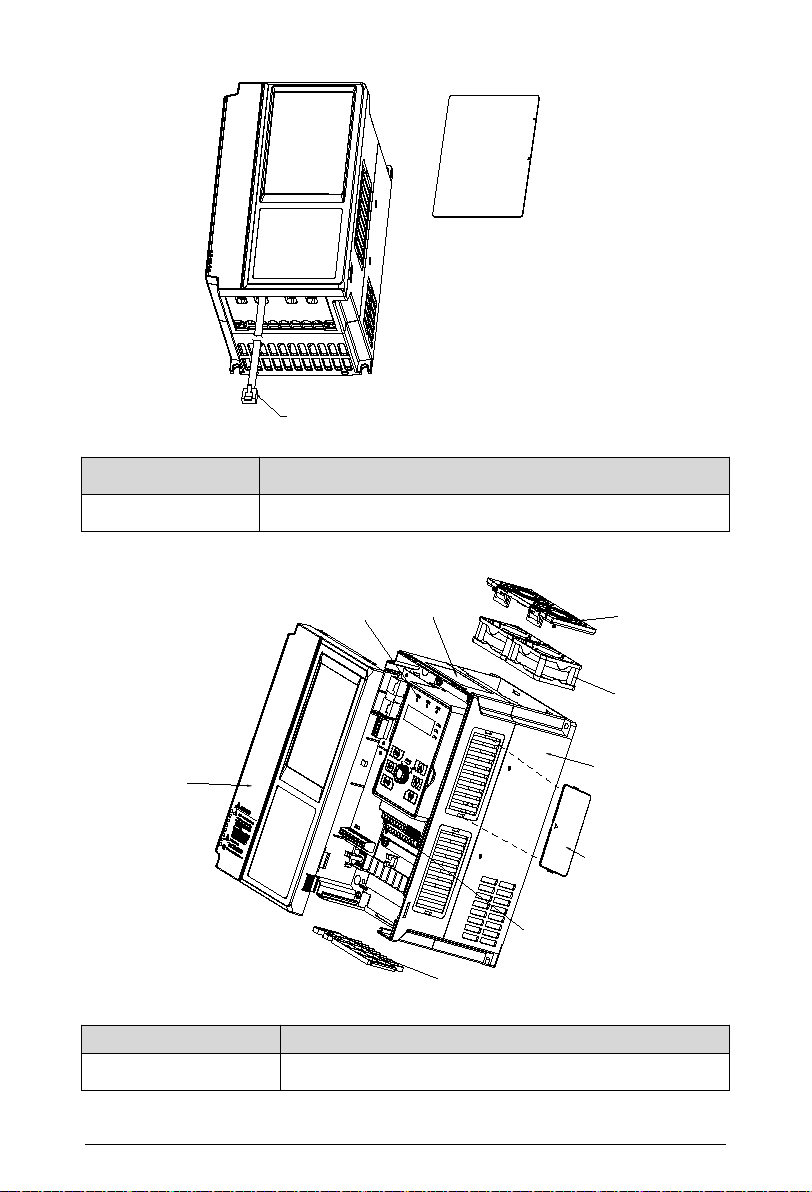

1.6 Name of each part of this series drives

Housing

Fan

Fan

cover

Wire slot

plate

Shell

Keypad

Control

terminal

Drive's

nameplate

Dustproof

cover plate

(optional)

Table 1-6 Dustproof Cover Plate Model

Dustproof cover plate model

Adaptable models

HAV-XS-4T0220 (black)

HAV-SP-4T0022P~HAV-SP-4T0370P

HAV-SP-2T0022P~HAV-SP-2T0185P

Chapter I Product Specification and Ordering Instructions

13

1.7 Braking resistors

Please select energy consumption braking resistors according to Table 1-6. The wiring of the

braking resistors is shown in Figure 1-2.

Figure 1-3 Drive and Braking Assembly Wiring Diagram

Note:

1. The power derating of the braking resistor shall not exceed 30%, otherwise there is a risk of

fire.

2. For braking standard products of 37kW and below, the built-in braking unit can be used; for

braking those of 45kW and above, an external braking unit needs to be added.

3. The wiring length of the braking resistor shall be less than 5m. During the energy

consumption braking process, the braking resistor will cause temperature rise due to energy

consumption. During installation, pay attention to safety protection and sound ventilation.

The braking resistor resistance and the power are selected according to the actual situation.

The greater the system inertia, the shorter the deceleration time required, the more frequent the

braking, the greater the power required by the braking resistor and the smaller the resistance

required. Table 1-6 is recommended based on general applications.

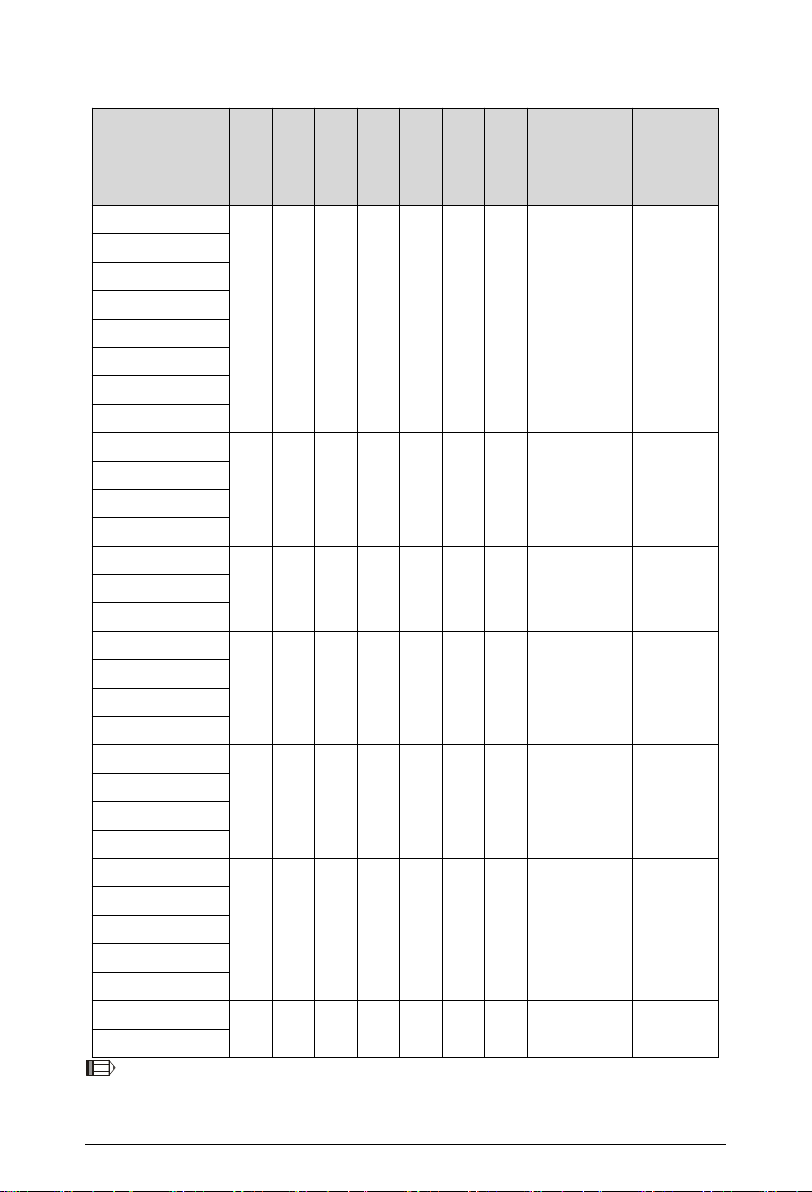

Table 1-7 Braking Resistor Selection Table(380V)

Specification

Suitable motor

power (kW)

Braking resistor

recommendation

Resistance (Ω)

Braking resistor

recommendation

Power (W)

HAV-SP-4T0022P

2.2

200

100

HAV-SP-4T0030P

3.0

200

200

HAV-SP-4T0040P

4.0

200

300

HAV-SP-4T0055P

5.5

200

300

HAV-SP-4T0075P

7.5

≥80

750

HAV-SP-4T0110P

11

≥50

1100

HAV-SP-4T0150P

15

≥50

1500

HAV-SP-4T0185P

18.5

≥45

1800

14

Specification

Suitable motor

power (kW)

Braking resistor

recommendation

Resistance (Ω)

Braking resistor

recommendation

Power (W)

HAV-SP-4T0220P

22

≥45

2200

HAV-SP-4T0300P

30

≥24

3000

HAV-SP-4T0370P

37

≥24

3000

Table 1-8 Braking Resistor Selection Table(220V)

Specification

Suitable motor

power (kW)

Braking resistor

recommendation

Resistance (Ω)

Braking resistor

recommendation

Power (W)

HAV-SP-2T0022P

2.2

≥100

200

HAV-SP-2T0030P

3.0

≥75

300

HAV-SP-2T0040P

4.0

≥75

300

HAV-SP-2T0055P

5.5

≥50

400

HAV-SP-2T0075P

7.5

≥45

750

HAV-SP-2T0110P

11

≥30

1100

HAV-SP-2T0150P

15

≥30

1100

HAV-SP-2T0185P

18.5

≥18

1800

Chapter I Product Specification and Ordering Instructions

15

1.8 Accessary of HAV-SP

If you need the accessories as follow, please specify when ordering.

Name

Reference

Short Description

Applicable Product

Dust cover

HAV-SP-FCB

Prevent dust from entering

the drive

HAV-SP-4T0022P~H

AV-SP-4T0370P

HAV-SP-2T0022P~H

AV-SP-2T0185P

Keypad tray

HAV-SP-JPT

Use when an external

keypad is installed

All series

LCD Keypad

HAV-SP-LCD

LCD keypad

All series

Simple IO

expansion card

HAV-XS-IO-3DI-R

Expand 3 DI, 1 relay

HAV-SP-4T0022P~H

AV-SP-4T1600P

HAV-SP-2T0022P~H

AV-SP-2T0450P

IO expansion card

HAVSPIO3DI3R

Expand 3 DI, 3 relay

HAV-SP-4T0022P~H

AV-SP-4T1600P

HAV-SP-2T0022P~H

AV-SP-2T0450P

Mounting bracket

HAV-XS-4T*

For embedded installation

of drive

*:For detailed model

and power matching,

please refer to Table

2-2

Mounting base

HAV-XS-4T*

Used for cabinet

installation

*:For detailed model

and power matching,

please refer to Table

1-4

Dustproof sticker

HAV-SP-FCT

Use when an external

keypad is installed

All series

Chapter II Installation and Wiring of Drive

16

Chapter II Installation and Wiring of Drive

2.1 Drive installation environment

2.1.1 Installation environment requirements

(1) Install in a well-ventilated indoor place. The ambient temperature is required to be within the

range of -10ºC-40ºC. If the temperature exceeds 40ºC, external forced cooling or derating is

required.

(2) Avoid installing in places with direct sunlight, dusty, floating fibers and metal powder.

(3) Do not install in places with corrosive or explosive gases.

(4) The humidity is required to be lower than 90%RH, without condensation of water droplets.

(5) Install in places where the plane fixed vibration is less than 5.9 m/s2.

(6) Try to keep away from electromagnetic interference sources and other electronic instruments

and equipment that are sensitive to electromagnetic interference.

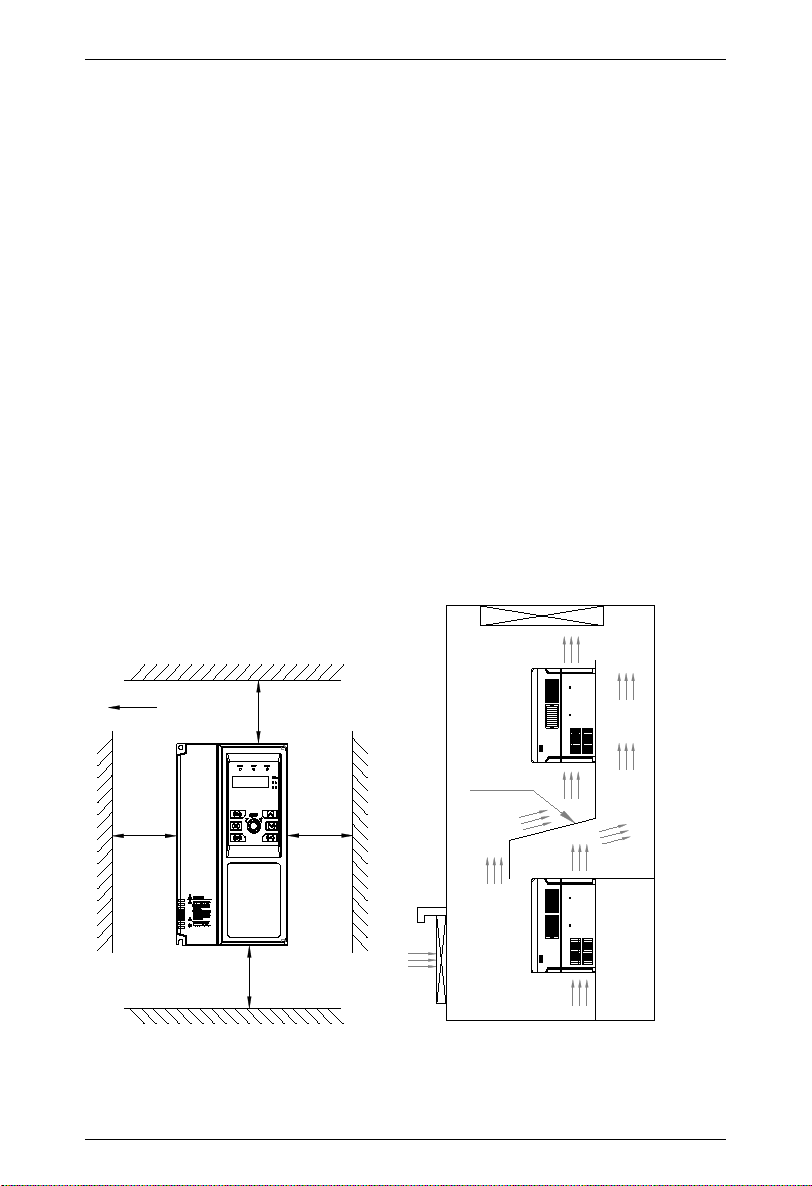

2.1.2 Installation direction and space

(1) Generally, vertical installation shall be adopted.

(2) Minimum installation intervals and distances are shown in Figure 2-1.

(3) When multiple drives are installed up and down, the baffle applied in the middle is shown in

Figure 2-2.

B

Fan exhaust

B

AA

Deflector

DriveDrive

Figure 2-1 Installation Diagram Figure 2-2 Installation Diagram of Multiple Drives

Chapter II Installation and Wiring of Drive

17

Table 2-1 Installation Space Requirements

Drive model

Installation space (mm)

A

B

HAV-SP-4T0022P~HAV-SP-4T0550P

HAV-SP-2T0022P~HAV-SP-2T0300P

≥50

≥100

HAV-SP-4T0750P~HAV-SP-4T1600P

HAV-SP-2T0370P~HAV-SP-4T0450P

≥50

≥200

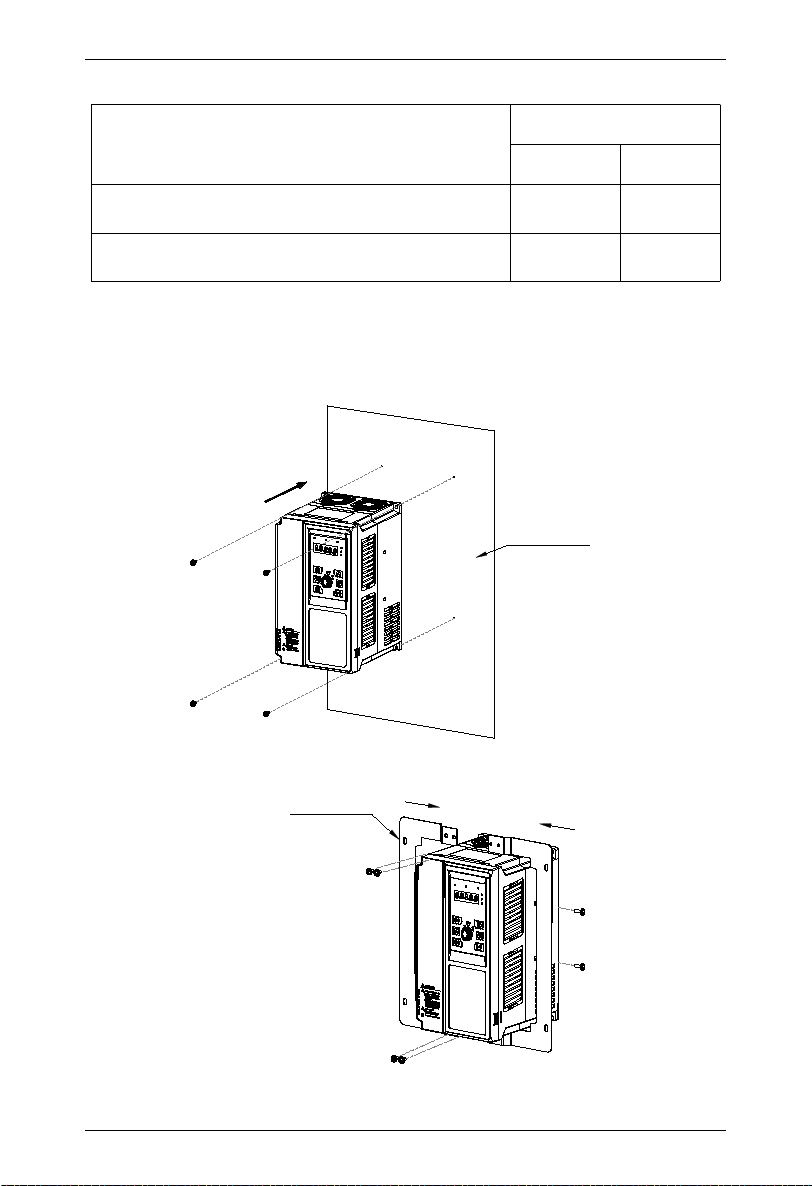

2.1.3 Mechanical installation methods and steps

According to different power levels, HAV-SP series has two structures namely plastic and

sheet metal. According to different installation applications, there are two installation methods:

Wall-mounted and embedded.

1. Wall mounting of plastic structure

Install from front

Control cabinet

mounting plate

Figure 2-3 Wall-mounted Installation Diagram of Plastic Structure

2. Embedded installation of plastic structure

Embedded installation support

Figure 2-4 Embedded Support Installation Diagram of Plastic Structure

Chapter II Installation and Wiring of Drive

18

Install from front

Control cabinet

mounting plate

Figure 2-5 Embedded Installation Diagram of Plastic Structure

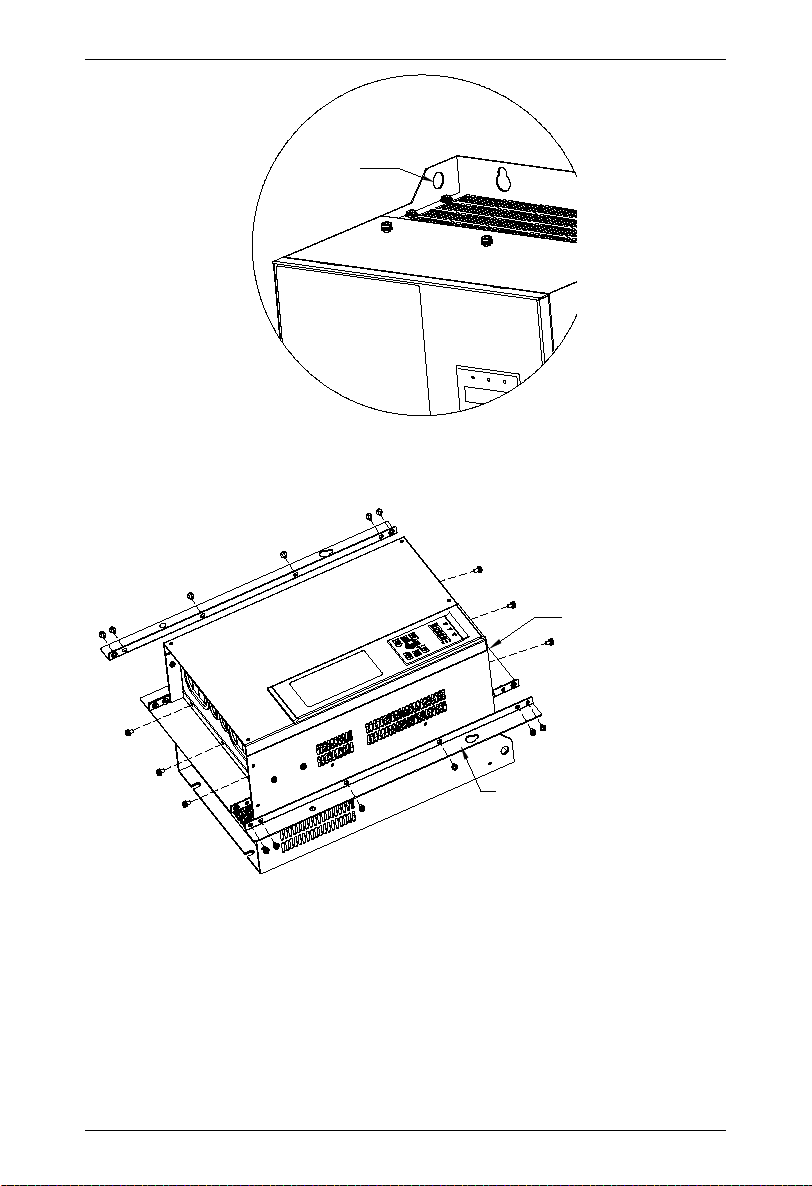

3. Wall mounting of sheet metal structure

Hoisting

hole

Control cabinet

mounting plate

Install from front of

control cabinet

Fix with 4 screws

Figure 2-6 Wall-mounted Installation Diagram of Sheet Metal Structure

Chapter II Installation and Wiring of Drive

19

Hoisting hole

Figure 2-7 Hoisting Diagram of Sheet Metal Structure

4. Embedded installation of sheet metal structure

Embedded installation

support

Embedded installation support

Figure 2-8 External Support Diagram of Sheet Metal Structure

This manual suits for next models

20

Table of contents

Popular Water Pump manuals by other brands

Pentair

Pentair STA-RITE D Series owner's manual

Grundfos

Grundfos UP 15 series instructions

Ferro

Ferro GPA II Installation and operation manual

Pentair

Pentair Hypro 9200 Series Installation and operation manual

Zoeller

Zoeller QWIK JON CHOICE 200 installation instructions

Linde

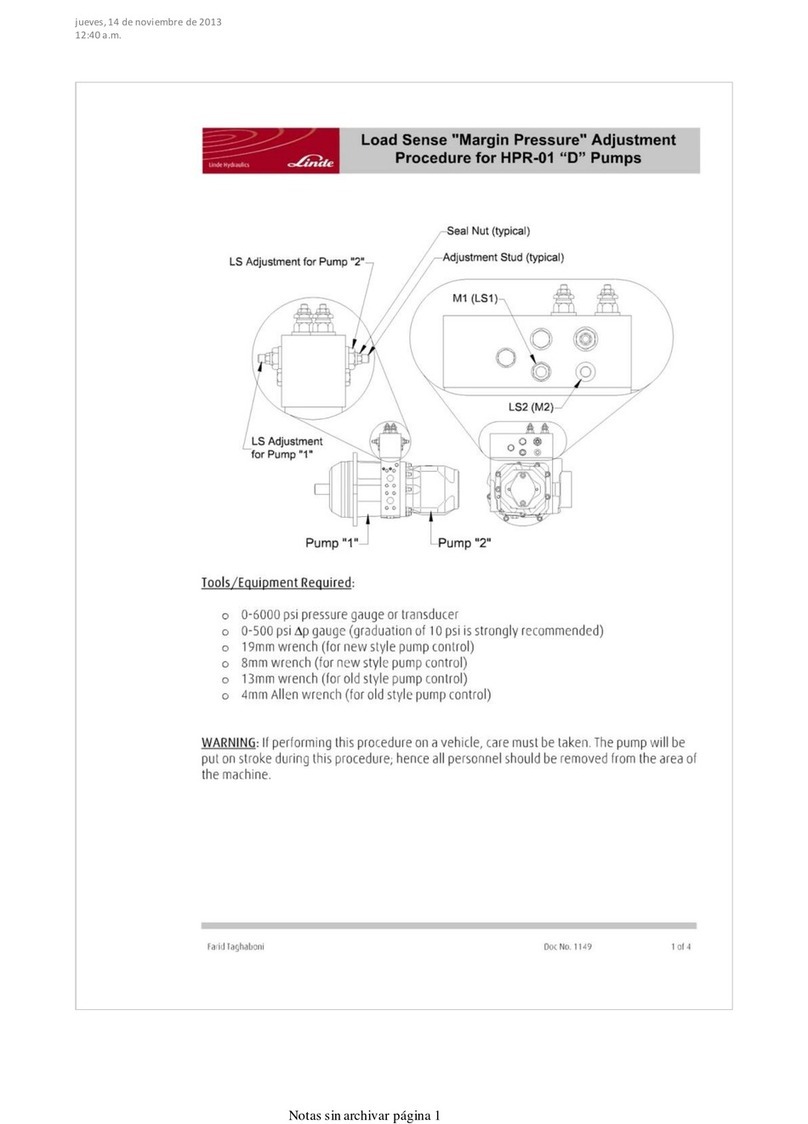

Linde HPR-01 D ADJUSTMENT PROCEDURE