6.4.1 Preliminary checks before starting work ...........................................Page 70

6.4.2 Starting the petrol/diesel engine .........................................................Page 71

6.4.3 Starting the electric motor ....................................................................Page 72

6.4.4 Stopping the engine/motor ...................................................................Page 74

6.4.5 Stopping the motor lithium version ....................................................Page 74

6.4.6 Travel ........................................................................................................Page 75

6.4.7 Jib arm movement for travel .................................................................Page 78

6.4.8 Parking the machine on a slope or on uneven ground ....................Page 80

6.4.9 Stabilising and levelling the machine ..................................................Page 80

6.4.10 Automatic lowering and raising of the stabilisers ............................Page 84

6.4.11 Track gauge extension............................................................................Page 86

6.4.12 Moving the basket .................................................................................Page 87

6.4.13 Manually levelling the basket ..............................................................Page 91

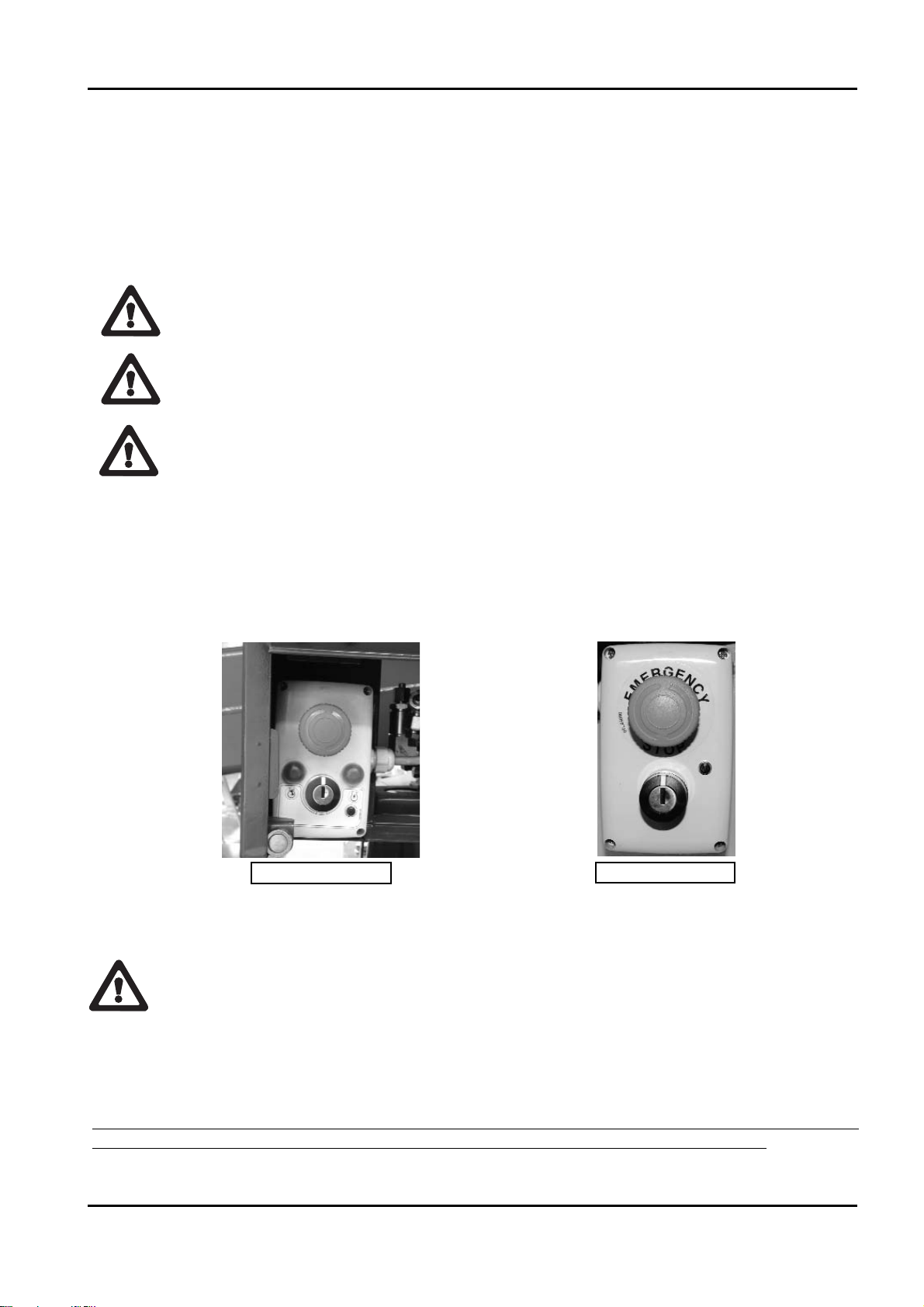

6.5 Emergency operations on the aerial part ...........................................Page 92

6.5.1 Emergency descent controlled from the basket ........................................Page 92

6.5.2 Operating the machine from the emergency control position

on the ground if the operator is taken ill ............................................Page 93

6.5.3 Emergency descent in the case where the stabilisers are

accidentally retracted .............................................................................Page 94

6.5.4 Emergency descent controlled from the ground using the hand

pump in the event of faults on all energy supply systems .............Page 96

6.5.5 Emergency operations on the carriage: moving the platform

stabilisers using the hand pump to allow the machine

to be transported.....................................................................................Page 98

6.5.6 Emergency operation of the undercarriage in the event of

movements of the aerial part ................................................................Page 99

6.6 Electrical disconnection of the remote control ..................................Page 101

6.7 Recharging the battery ..........................................................................Page 102

6.8 Main intended uses of the platform ....................................................Page 106

6.8.1 Systems.....................................................................................................Page 106

6.8.2 Closed environments .............................................................................Page 106

6.8.3 Pruning.....................................................................................................Page 106

6.8.4 Repair and maintenance of roofing and gutters ................................Page 107

6.8.5 Painting, sand‑blasting and plastering................................................Page 107

6.8.6 Use in marine environments ................................................................Page 107

CHAPTER 7 MAINTENANCE....................................................................................Page 108

7.1 Safety instructions for greasing and lubrication ................................Page 108

7.2 Table of recommended lubricants........................................................Page 108

7.3 Greasing points .......................................................................................Page 110

7.4 Greasing the telescopic arm ..................................................................Page 111

7.5 Safety instructions for maintenance operations.................................Page 111

7.6 Operating the machine from the second control position on the

ground using the optional second remote control during

maintenance ............................................................................................Page 112

7.7 Periodic maintenance intervals ............................................................Page 113

7.8 Electric motor .........................................................................................Page 115

7.8.1 Electric motor maintenance ..................................................................Page 115

7.9 Inspection and maintenance ................................................................Page 116

7.10 General periodic checks ........................................................................Page 118

7.11 Maintenance on the rubber tracks .......................................................Page 119

7.11.1 Checking the track tension....................................................................Page 119

7.11.2 Loosening/tightening the tracks...........................................................Page 119

7.11.3 Checking the rubber tracks ...................................................................Page 120

7.11.4 Replacing the rubber tracks ..................................................................Page 122

7.12 Checking tightness of nuts and bolts...................................................Page 123

7.13 Checking the hydraulic oil level...........................................................Page 127

7.13.1 Hydraulic oil............................................................................................Page 127

7.14 Checking for leaks in the hydraulic system........................................Page 127

2MULL177520113

SELF‑PROPELLED TRACKED PLATFORM LL1775

HINOWA