Hinowa LightLift 17.75 3S User manual

1

TECHNICAL COURSE

BOOKLET

LightLift 17.75 3S

LightLift 20.10 3S

PERFORMANCE

TTPE1720021602

2

COURSE CONTENTS

1. INTRODUCTION ...................................................................... 4

2. PERFORMANCE DATAS ............................................................ 5

2.1 PERFORMANCE TECHINCAL SPECIFICATIONS: ........................ 5

2.2.1 LL17.75 3S DIMENSIONS ........................................................ 6

2.2.2 LL17.75 3S WORKING AREA - 230 KG CAPACITY .................... 7

2.3.1 LL20.10 3S DIMENSIONS ........................................................ 8

2.3.2 LL20.10 3S WORKING AREA - 230 KG CAPACITY .................... 9

2.4 SERIAL NUMBER LOCATION .................................................. 10

3. SUMMARY OF REMOTE CONTROL FUNCTIONS ....................... 11

4. MACHINE IGNITION.............................................................. 12

4.1 GASOLINE ENGINE PRE-HEATING ......................................... 13

5. OPERATION AND SAFETY FEATURES OF THE MACHINE ......... 14

5.1 FUNCTIONING OF THE GROUND PART................................... 15

5.1.1 TRACKS OPERATION……………………………………………………….15

5.1.2 OUTRIGGER MOVEMENT………………………………………………….21

5.2 FUNCTIONING OF THE AERIAL PART..................................... 24

5.3 STOP BUTTONS ..................................................................... 26

5.4 PEDAL (OPTIONAL)............................................................... 27

6. EMERGENCY OPERATION ...................................................... 27

6.1 EMERGENCY OPERATIONS OF THE AERIAL PART .................. 29

6.1.1 GRAVITY EMERGENCY DESCENT............................................ 29

6.1.2 OPERATIONS FROM GROUND CONTROL POSITION............... 30

6.1.3 EMERGENCY DESCENT WITH SAFETIES BY-PASS .................. 31

6.1.4 EMERGENCY DESCENT WITH HAND PUMP............................. 32

6.2 EMERGENCY MOVEMENTS OF THE GROUND PART ................. 35

6.2.1 TRACK MOVEMENT WITH SAFETIES BY-PASS........................ 35

6.2.2 OUTRIGGERS MOVEMENT WITH THE MANUAL PUMP............. 36

6.3 ENGINES EMERGENCY START PROCEDURES .......................... 42

7. HYDRAULIC SYSTEM ............................................................. 45

7.1 COMPONENTS LOCATION ...................................................... 45

7.2 GROUND PART FUNCTIONING............................................... 48

7.3 AERIAL PART FUNCTIONING................................................. 51

8 ELECTRICAL SYSTEM............................................................. 55

8.1 CAN-BUS SYSTEM.................................................................. 55

8.2 CAN BUS DEVICES CONNECTION SCHEME ............................. 58

8.3 SAFETY DEVICES NOT IN CAN-BUS ....................................... 59

8.4 SAFETY DEVICES NOT IN CAN-BUS CONNECTION SCHEME.... 62

3

8.5 ELECTRONIC BOARDS LIGHT MEANINGS............................... 63

8.5.1 ECM1 (MASTER BOARD FRONT MODULE) LED CODE .............. 63

8.5.2 ECM2 (MASTER BOARD BACK MODULE) LED CODE ................ 64

8.5.3 ECM3 (LOAD CELL BOARD) LED CODE ................................... 64

8.5.4 110÷230V BOARD LED COD .................................................. 65

8.5.5 MODEM LED COD ................................................................... 65

9 ELECTRONIC BOARDS REPLACEMENT AND SETTING ............. 66

9.1 ELECTRONIC BOARDS SOFTWARE UPLOADER ....................... 66

9.2 ELECTRONIC BOARDS SOFTWARE INSTALLATION ................ 67

9.3 ELECTRONIC BOARDS SOFTWARE UPDATING ....................... 68

9.4 MASTER BOARD (ECM1-2) PARAMETERS SETTING ................ 69

9.5 LOAD CELL BOARD (ECM3) PARAMETERS SETTING ............... 69

10 POWER SUPPLY AND ELECTRIC MOTOR ................................ 69

10.1 ELECTRIC MOTOR.................................................................. 69

10.2 BATTERY CHARGE SYSTEM .................................................... 70

11 REMOTE CONTROL................................................................. 71

11.1 DISPLAY ICONS .................................................................... 71

11.2 ERROR MESSAGES –SELF DIAGNOSIS .................................. 72

11.3 DIAGNOSTICS ON THE DISPLAY ........................................... 73

11.4 FUNCTIONING OF THE REMOTE CONTROL ON THE GROUND . 81

11.5 LOAD CELL ............................................................................ 82

12. POWER SYSTEM .................................................................... 82

12.1 GASOLINE ENGINE HONDA IGX440....................................... 83

12.2 DIESEL ENGINE HATZ 1B40 (FOR 17.75 DIESEL) .................. 89

12.3 DIESEL ENGINE PERKINS 402.05 (FOR 20.10 DIESEL) ......... 92

12.4 LITHIUM VERSION (48V FOR 17.75, 72V FOR 20.10)............ 96

APPENDIX 1 - HYDRAULIC SYSTEM .................................................. 101

APPENDIX 2 - REMOTE CONTROL JOYSTICK REPLACEMENT ............. 104

APPENDIX 3 - CAN-BUS DIAGNOSTICS AND TROUBLESHOOTING .... 105

APPENDIX 4 - CURRENTS AND RAMPS SETTING............................... 112

APPENDIX 5 - LOAD CELL SYSTEM CALIBRATION PROCEDURE ........ 114

APPENDIX 6 - ACCELEROMETERS CALIBRATION PROCEDURE .......... 116

APPENDIX 7 - LIGHT INDICATION ON ELECTROVALVES………………..115

APPENDIX 8 - REMOTE CONTROL STOP BUTTON BY-PASS…… …..115

APPENDIX 9 - FREQUENTLY ISSUES SOLVING.................................. 118

APPENDIX 10 - MK2 PDATINGS…………………………….……………………121

4

THE PRESENT MANUAL HAS TO BE CONTEMPLATE SIMPLY WITH

INDICATIVE PURPOSE, IT DOESN'T REPLACE ANYHOW THE USE AND

MAINTENANCE MANUAL OF THE MACHINE.

THEREFORE ALWAYS REFER TO USE AND MAINTENANCE MANUAL FOR

ORDINARY AND EXTRAORDINARY USAGE, FOR MAINTENANCE, FOR

PROBLEM SOLVING AND GENERALLY FOR ANYTHING REGARDING THE

MACHINE.

1. INTRODUCTION

This booklet describes the technical and safety features, the electrical system

and the hydraulic system of the Hinowa LightLift 17.75 3S and 20.10 3S

Performance.

It does not include how to operate the machine, for this purpose see the

Operation and Maintenance Manual.

The first two digits of numerical part of the LightLift name identify the

maximum working height of the machine in meters, while the last two digits

indicate the maximum outreach in decimeters.

The aerial platform is equipped with an hydraulic system and an electrical

system that interact to ensure safe operating in any situation. The two systems

are described below, the present manual describes also how they interact.

Remember that the operating position of the machine is established from

inside the basket, which is positioned in the rear. See the diagram below.

All the machine movements are controlled by the machine remote control

supplied with the machine. Usually, the remote control is positioned in the

specific seat in the basket, anyway there are others options illustrated and

described later.

Left Side

Right Side

Front

Side

Rear

Side

5

2. LL17.75 3S AND 20.10 3S PERFORMANCE DATAS

2.1 LL17.75 3S AND 20.10 3S PERFORMANCE TECHINCAL

SPECIFICATIONS:

LL1775

LL2010

Platform capacity

230 Kg

230 Kg

Max height (basket floor level)

14,96m

18.05m

Max working height

17,06m

20.15m

Basket dimensions (standard 2 persons

basket)

1335x690mm

134x69

Max working horizontal extension

7,00m

9,20m

Undercarriage width (Retracted/Extended)

798 / 1086mm

795 / 1095mm

Rotation (non-continuous)

360°

360°

Basket rotation

124° (+/- 62°)

124° (+/- 62°)

Max pressure on the ground for tracks

0,64 daN/cm²

0,67 daN/cm²

Max pressure on the ground for outrigger

2,45 daN/cm²

3,04 daN/cm2

N° of operators

2

2

N° operators for optional 1 person basket

1

1

Jib function

89° (+0° / -89°)

89° (+0° / -89°)

Max aerial part working inclination

1°/ 1,75%

1°/ 1,75%

Max slope tolerance

12°

15°

Petrol version dry weight (indicate in CE plate)

2190 Kg

2840 Kg

Petrol machine operating weight (without

operator)

2230 Kg

2880 Kg

Lithium machine operating weight (without

operator)

2300 Kg

2980 Kg

Max drive speed with thermic engine (with

double speed)

0,7 / 1,8 / (optional

3,6) Km/h (*)

0,5 / 1,3 / (standard

2,5) Km/h

Angle of attack

20° / 36,4%

20° / 36,4%

Max admitted translation inclination

16° / 28,7%

16° / 28,7%

Max wind speed

12,5 m/s

12,5 m/s

Max manual force allowed

400N

400N

Hydraulic pressure of ground part (tracks-

outriggers)

165bar

165bar

Hydraulic pressure aerial part

185bar

185bar

Hydraulic oil tank capacity

40 liters

40 liters

Electric system tension

12V

12V

Battery

12V 55Ah (*)

12V 55Ah (*)

AC electric motor

110V or 220V

50 Hz, 2.2KW

110V or 220V

50 Hz, 2.2KW

(*) (FROM LL17.75/4 and LL20.10/3 read APPENDIX 9)

6

2.2.1 LL17.75 3S PERFORMANCE DIMENSIONS

NOTE : standard version

with 2 persons basket

7

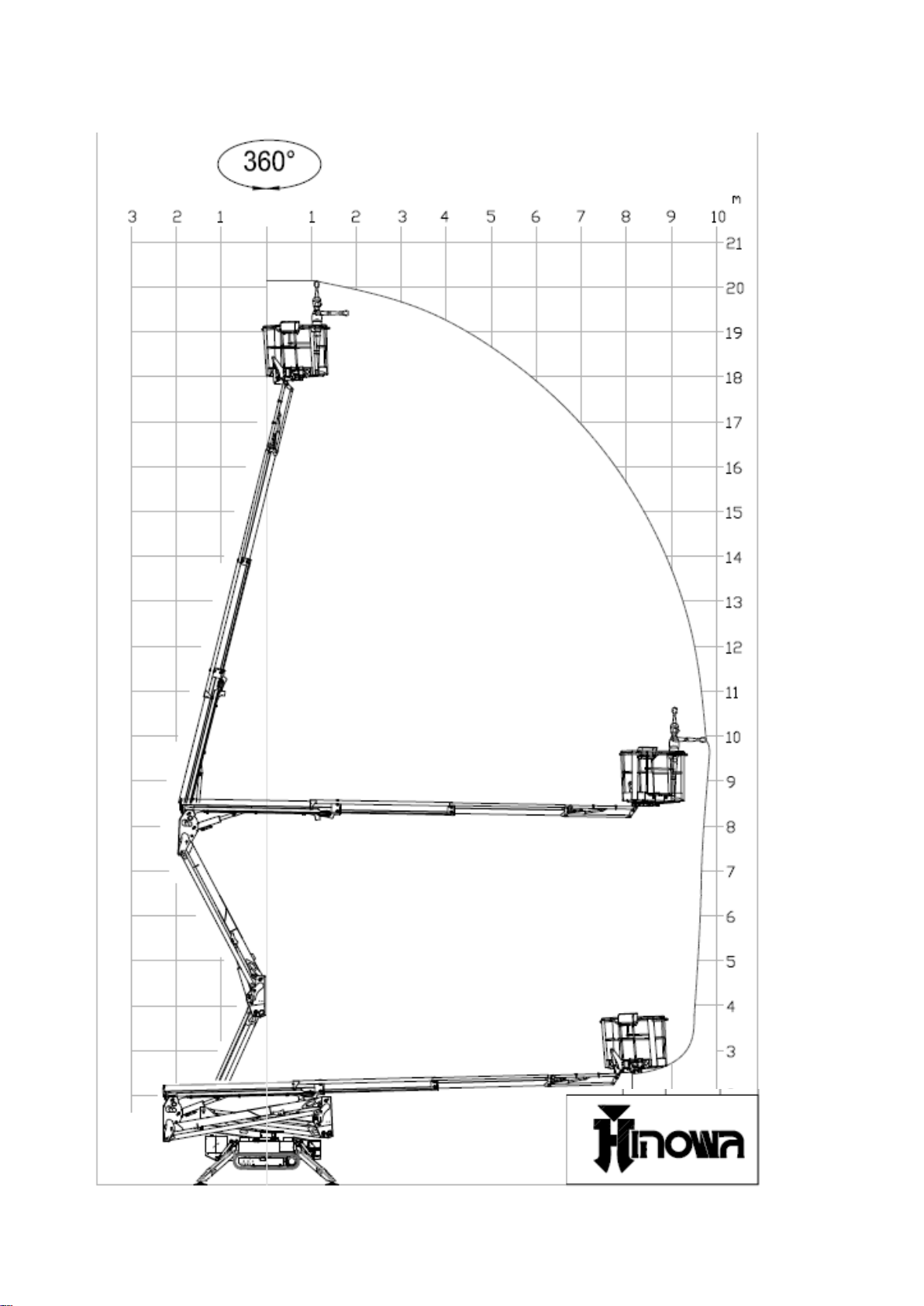

2.2.2 LL17.75 3S PERFORMANCE WORKING AREA - 230 KG CAPACITY

8

2.3.1 LL20.10 3S PERFORMANCE DIMENSIONS

NOTE : standard version

with 2 persons basket

9

2.3.2 LL20.10 3S PERFORMANCE WORKING AREA - 230 KG CAPACITY

10

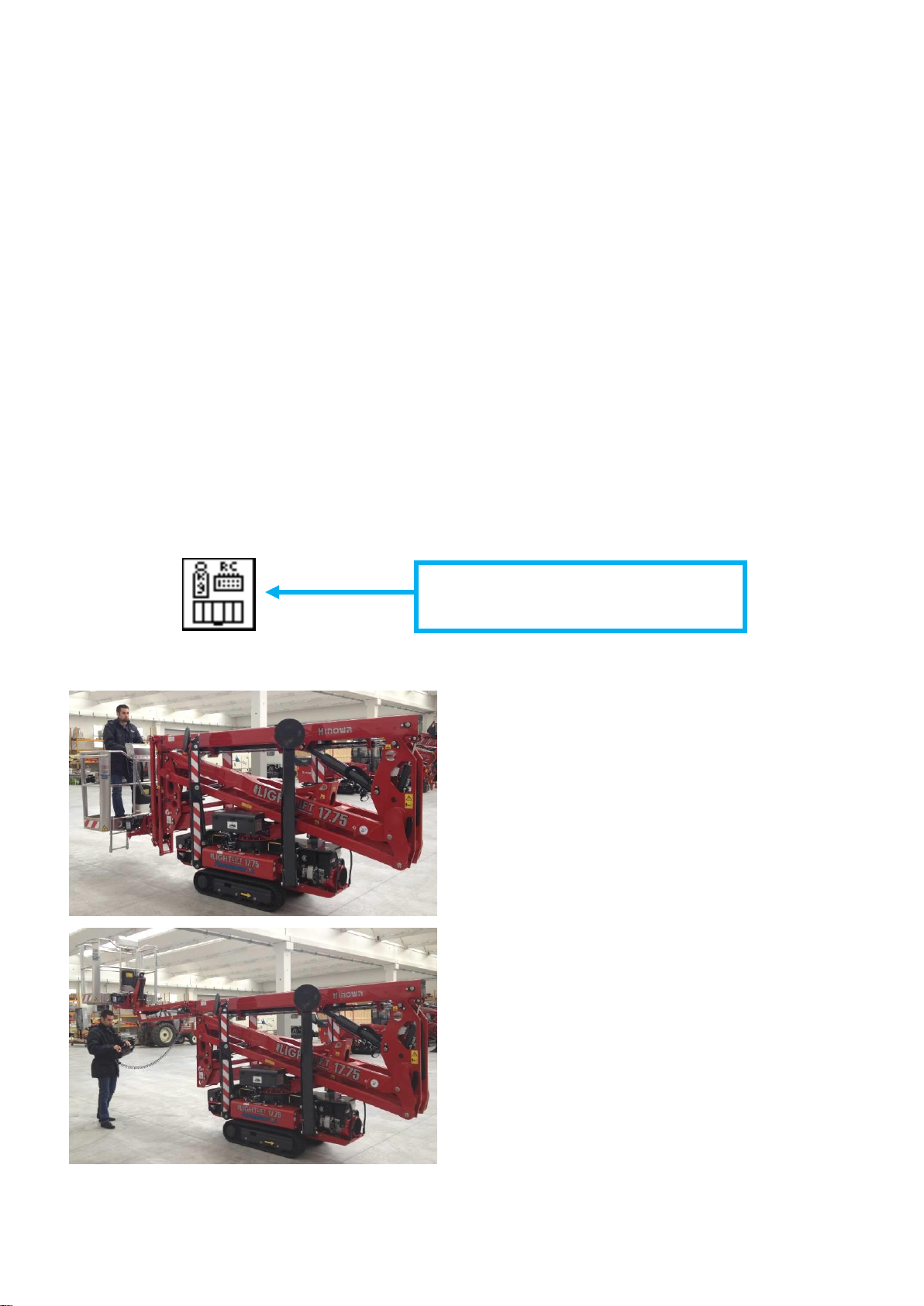

2.4 SERIAL NUMBER LOCATION

A serial number plate is affixed on to the frame of the machine. The

following illustrations showing its location.

SERIAL NUMBER

PLATE LOCATION

11

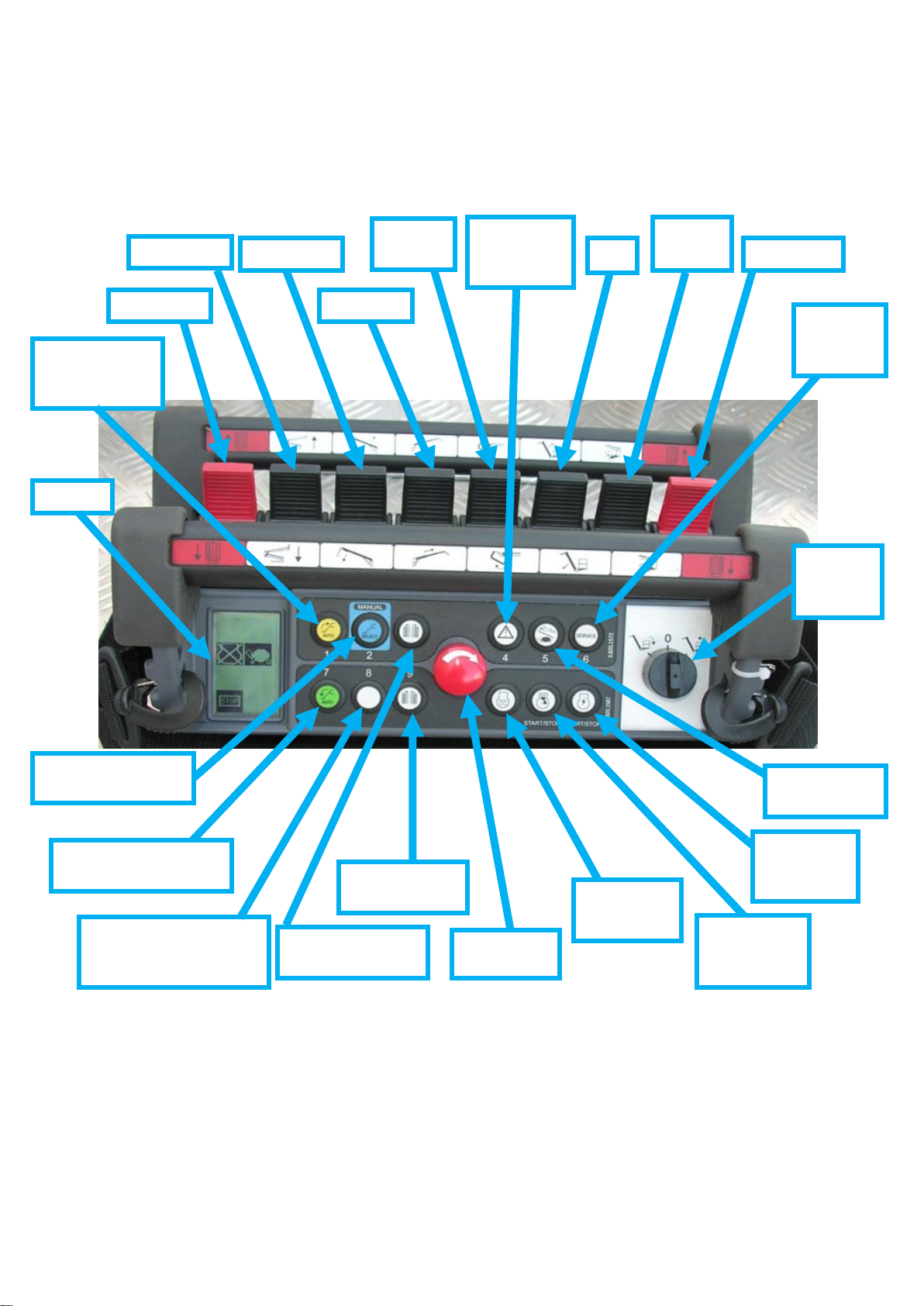

3. SUMMARY OF REMOTE CONTROL FUNCTIONS

The remote control functions (commands and signals) of the LightLift 17.75 3S

and 20.10 3S Performance are briefly summarized below.

Engine

preheat

STOP

button

Gravity

emergency

descent

Automatic

destabilization

selector

Left track

1-2 arms

Jib

Turret

rotation

Right track

Main boom

Basket

rotation

Extension

Basket

leveling

key

Electric

motor

(start-stop)

Thermic

engine

(start-stop)

Undercarriage

closing

Automatic

stabilization selector

Undercarriage

widening

Engine speed

selector

Stabilizers manual

operating

Service

menu

selector

Display

Permission of aerial

part operation from

ground

12

The remote control is critical for the machine: it displays all the information on

the platform status and any error message in case of incorrect use of the

controls. It is also possible to access the SERVICE menu, which indicates any

anomalies or malfunctioning of machine components.

The icons on the display appear in 8 different positions, as illustrated above.

4. MACHINE IGNITION

(FOR LL17.75/4 and LL20.10/3 read APPENDIX 9)

To start up the machine, the battery cutter switch must be active, both the

stop buttons (the first on the remote control and the second on the ground

control box) must be released and ignition switch on the engine has to be

turned ON without start the engine.

To start the engine press remote control “thermic engine” button, to start the

electric motor press “electric motor“ button. With cold temperatures with petrol

engine it is recommended to press the preheat button after engine start and

wait 20 seconds before to start any movement. To stop the engine it is

possible to press a stop button or to press once again the button of engine

BATTERY

CUTTER

STOP

BUTTONS

IGNITION

SWITCH

TURNED “ON”

13

start. The display shows always in position 3 the motor selected, in case this

motor has been stopped the icon will be marked with an “X”.

If the operator tries to start up the machine with a

stop button pressed, the "ERROR STOP" message will

appear as illustrated here on side.

4.1 GASOLINE ENGINE PRE-HEATING

In case platform is equipped with gasoline engine, it is possible to pre-heat the

engine, increasing the rpm.

Pushing the “PREHEAT”button on the remote control engine runs for 20

seconds at 2200 rpm and the display visualizes the icon “PREHEAT

PROCEDURE IN PROGRESS”.

While preheating is in progress, any movement normally working at 2200 rpm

would work at 2200 rpm.

In case an aerial part movement working at 1500 or 3600 rpm is selected,

engine changes rpm to 1500 or 3600 and the heating procedure ends.

In case a track movement working at 1500 or 3600 rpm is selected, engine

changes rpm to 1500 or 3600 rpm, then it returns to 2200 rpm when

movement is released.

In case the power system is Lithium the rpm are different but the behavior will

be the same.

While preheating is in progress it’s not possible to move outriggers or to widen

the undercarriage.

ERROR

PREHEAT BUTTON

PREHEAT

PROCEDURE IN

PROGRESS

14

5. OPERATION AND SAFETY FEATURES OF THE MACHINE

The LL 17.75 3S and 20.10 3S Performance aerial platform are divided into two

main parts:

1. Ground part or undercarriage part

2. Aerial part

Operating in travel or stabilization mode, we are controlling the ground part;

on the other hand, moving the booms or the turret rotation we are controlling

the aerial part.

The ground or aerial part movements are managed by a control module

composed by different boards (indicated in the picture below) that interact

each other and with sensors or actuators installed in the machine. The load cell

board (ECM3) on the jib arm controls the weight in the basket and

communicates by CAN BUS with the master board (ECM1-2) located in the

electric component compartment on the ground part.

Another board (110÷230V BOARD) manages the functioning of the electric

motor and the charging of the battery when the machine is connected to the

110÷230V network.

This board communicates directly with the master board (ECM1-2).

A small board is located into the remote control (REMOTE CONTROL BOARD).

LOAD CELL BOARD

(ECM3)

MASTER BOARD (ECM1-2)

110÷230V BOARD

REMOTE CONTROL

BOARD

LOAD CELL BOARD

(ECM3)

MASTER BOARD (ECM1-2)

110÷230V BOARD

REMOTE CONTROL

BOARD

ON 20.10

ON 17.75

15

5.1 FUNCTIONING OF THE GROUND PART

5.1.1 TRACKS OPERATION

To allow tracks movement all the outriggers must be lifted from the ground.

When the operator is at the ground it is enough to act on the 2 outer red

joysticks to move the tracks. If the remote control is on the basket, it is

necessary to press the pedal (if pedal option is active) and act on the joystick

at the same time.

It’s possible to drive the tracks with the jib either closed or open in order to

move the machine on inclined slopes as well. To open the jib with machine not

stabilized, none of the outriggers can touch the ground and the operator must

control the machine from ground with remote control in hand (the remote

control cannot be in the support). It is enough to act on the joystick to move

the jib. If a joystick of another aerial part movement is operated an error

message appears on the display (“JIB ONLY”).

If there are more than 40 Kg weight in the basket or the remote control is in

its support in the basket, it is not possible to move the jib and on the display

appears an error message icon “REMOTE CONTROL OR LOAD ON BASKET”.

THE TRANSLATION WITH JIB

CLOSED IS POSSIBLE FROM

GROUND OR BASKET.

THE TRANSLATION WITH

OPENED JIB IS POSSIBLE

ONLY WITH OPERATOR AT THE

GROUND.

“REMOTE CONTROL OR LOAD

ON THE BASKET” ICON

16

MOVEMENT SPEED SELECTION FOR THE GROUND PART

Button 5 on remote control allows the operator to select the speed of the

ground part movement. To modify the movement speed, the machine changes

the rpm of the engine (electronically controlled). On the machine equipped

with the double speed drive gear motors, it is available one speed more

(HARE) acting on the chamber of the drive gear motors (slow gear- fast gear).

Pushing button 5 to select the speed, the speed icon will appear in position 4 of

the display. If no movement is made the engine keeps the minimum speed

(1500 rpm for gasoline engine).

THERMIC ENGINE (GASOLINE –DIESEL)

a) TURTLE:

b) NORMAL:

c) HARE:

NOTE: Auxiliary electric motor works always at minimum speed (1500 rpm).

LITHIUM SYSTEM

a) TURTLE:

b) NORMAL:

c) HARE:

AUTOMATIC SPEED CONTROL FOR STABILITY REASON

LL17.75 and LL20.10 are provided with a special system that automatically

reduces tracks speed or stops the movement in case of stability risks.

This control depends automatically on different factors:

-Weight in the basket

-Jib opened or closed

-Tracks widened or not

-Slope inclination gradient in axles X and Y

OPTIONAL: If equipped with double speed drive

gear motors the engine runs always at 3600

rpm for the undercarriage part and the drive

gear motors switch to high speed (max 3,6

Km/h).

The engine runs always at 3600 rpm for the

undercarriage part but the drive gear motors

keep the slow speed (max 1,8 km/h).

The engine runs at 1500 rpm (1850 on diesel).

OPTIONAL: If equipped with double speed drive

gear motors the engine runs always at 2550

rpm for the undercarriage part and the drive

gear motors switch to high speed.

The engine runs always at 2550 rpm for the

undercarriage part but the drive gear motors

keep the slow speed.

The engine runs at 1050 rpm.

17

The consequence of a stability emergency is, with increasing severity:

a) Tracks speed reduction

b) Tracks movement stopped, display icon

Moreover the buzzer on the remote control could be activated.

WARNING: To move the tracks when the machine is stopped by those

conditions it’s necessary to press button 8 on remote control, a counter-down

of 10 seconds will be activate on the display and in the meantime tracks

movement is allowed in turtle speed with beeper ON. During that by-pass the

operator can bring machine back to stability condition.

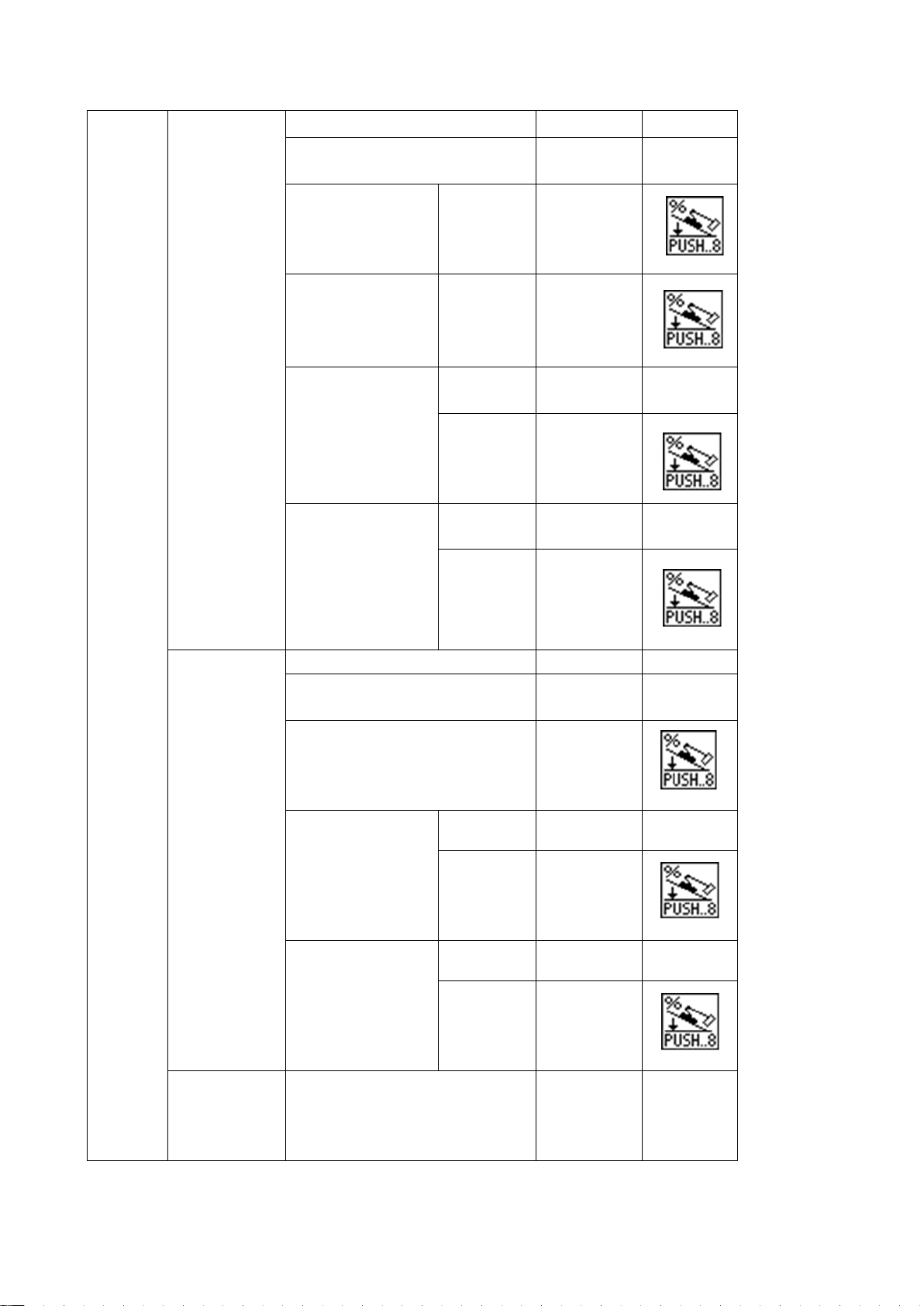

SPEED CONTROL POSSIBLE CONDITIONS ON THE LL17.75

JIB

OPEN

Not possible

to select

HARE

X or Y >5°

TURTLE

Y>7°

TURTLE +

BUZZER

Y>13°

BUZZER +

MOVEMENT

STOPPED+

ALARM

ICON

UNDERCARRIAGE

CLOSED

X>6°

TURTLE +

BUZZER

X>10°

BUZZER +

MOVEMENT

STOPPED+

ALARM

ICON

UNDERCARRIGE

WIDENED

X>10°

TURTLE +

BUZZER

X>15°

BUZZER +

MOVEMENT

STOPPED+

ALARM

ICON

AXLE X

AXLE Y

18

JIB

CLOSED

Weight inside

basket

<=120Kg

Possible to

select HARE

X or Y >8°

TURTLE

Y>10°

TURTLE +

BUZZER

Weight inside

basket <=40kg

Y>16°

BUZZER +

MOVEMENT

STOPPED +

ALARM

ICON

Weight inside

basket

>40kg<=120Kg

Y>13°

BUZZER +

MOVEMENT

STOPPED +

ALARM

ICON

UNDERCARRIAGE

CLOSED

X>6°

TURTLE +

BUZZER

X>10°

BUZZER +

MOVEMENT

STOPPED +

ALARM

ICON

UNDERCARRIAGE

OPEN

X>10°

TURTLE +

BUZZER

X>15°

BUZZER +

MOVEMENT

STOPPED +

ALARM

ICON

Weight inside

basket

>120<=230Kg

Not possible

to select

HARE

X or Y >5°

TURTLE

Y>7°

TURTLE +

BUZZER

Y>13°

BUZZER +

MOVEMENT

STOPPED +

ALARM

ICON

UNDERCARRIAGE

CLOSED

X>6°

TURTLE +

BUZZER

X>10°

BUZZER +

MOVEMENT

STOPPED +

ALARM

ICON

UNDERCARRIAGE

OPEN

X>10°

TURTLE +

BUZZER

X>15°

BUZZER +

MOVEMENT

STOPPED +

ALARM

ICON

Weight inside

basket

>230Kg

MAX

WEIGHT

ALARM +

MOVEMENT

STOPPED

19

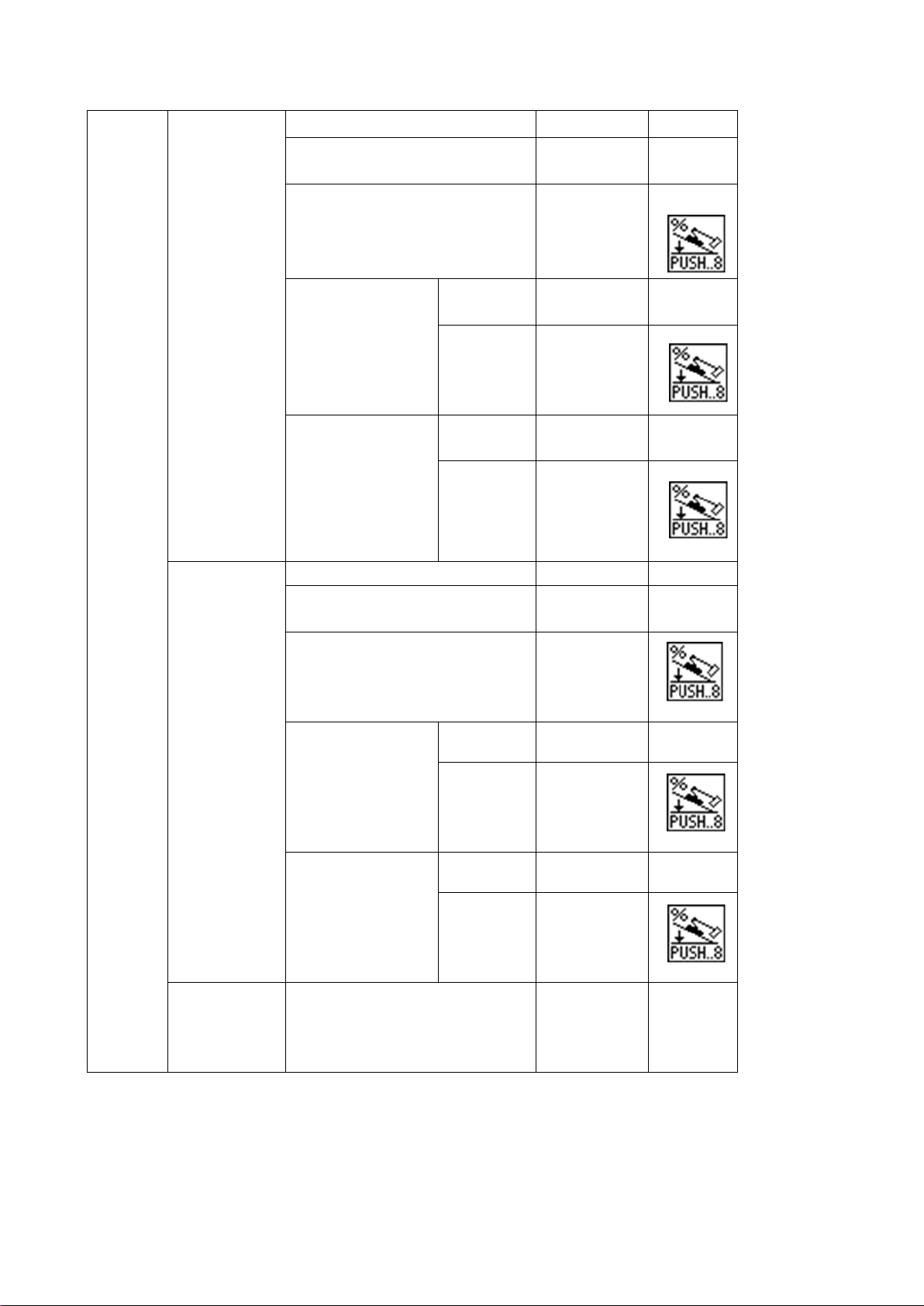

SPEED CONTROL POSSIBLE CONDITIONS ON THE LL20.10

JIB

OPEN

Not possible

to select

HARE

X or Y >6°

TURTLE

Y>13°

TURTLE +

BEEPER

Y>20° BASKET DOWNSTREAM

OR

Y>16° BASKET UPSTREAM

BEEPER +

MOVEMENT

STOPPED+

ALARM

ICON

UNDERCARRIAGE

CLOSED

X>8°

TURTLE +

BEEPER

X>10°

BEEPER +

MOVEMENT

STOPPED+

ALARM

ICON

UNDERCARRIGE

WIDENED

X>10°

TURTLE +

BEEPER

X>15°

BEEPER +

MOVEMENT

STOPPED+

ALARM

ICON

20

JIB

CLOSED

Weight inside

basket

<=120Kg

Possible to

select HARE

X or Y >6°

TURTLE

Y>13°

TURTLE

+BEEPER

Y>20° BASKET DOWNSTREAM

OR

Y>16° BASKET UPSTREAM

BEEPER +

MOVEMENT

STOPPED +

ALARM

ICON

UNDERCARRIAGE

CLOSED

X>8°

TURTLE +

BEEPER

X>10°

BEEPER +

MOVEMENT

STOPPED +

ALARM

ICON

UNDERCARRIAGE

OPEN

X>10°

TURTLE +

BEEPER

X>15°

BEEPER +

MOVEMENT

STOPPED +

ALARM

ICON

Weight inside

basket

>120<=230Kg

Not possible

to select

HARE

X or Y >6°

TURTLE

Y>10°

TURTLE +

BEEPER

Y>15°

BEEPER +

MOVEMENT

STOPPED +

ALARM

ICON

UNDERCARRIAGE

CLOSED

X>8°

TURTLE +

BEEPER

X>10°

BEEPER +

MOVEMENT

STOPPED +

ALARM

ICON

UNDERCARRIAGE

OPEN

X>10°

TURTLE +

BEEPER

X>15°

BEEPER +

MOVEMENT

STOPPED +

ALARM

ICON

Weight inside

basket

>230Kg

MAX

WEIGHT

ALARM +

MOVEMENT

STOPPED

This manual suits for next models

3

Table of contents

Other Hinowa Boom Lift manuals

Popular Boom Lift manuals by other brands

Genie

Genie Z-45/25 Operator's manual

Terex

Terex Z4525XCF-101 Operator's manual

Genie

Genie ZX-135/70 with Jib-Extend Service and repair manual

Oshkosh Corporation

Oshkosh Corporation JLG E600 Operation and safety manual

Mec

Mec TITAN Boom 40-S Operator's manual

Genie

Genie Z-45/25 operators manual with maintenance information