9

English

Before fueling, clean the tank cap area carefully, to ensure that

no dirt falls into the tank. Make sure that the fuel is well mixed by

shaking the container, before fueling.

Starting

Open the fuel cock (17). (Fig. 12-B)

Move the throttle lever to start position A. (Fig. 14)

NOTE

Starting with full throttle causes sudden high revolution of

Blade, which is dangerous, so please avoid it.

Set the choke lever (18) to CLOSED position. (Fig. 13-A)

Pull the recoil starter briskly, TAKING CARE TO KEEP THE

HANDLE in your grasp, while not allowing it to snap back.

When you hear combustible sounds a couple of times, move the

choke lever to OPEN position. Then pull the recoil starter briskly

again.

After starting the engine, allow it about 2 - 3 minutes to warm up

before subjecting it to any load.

CAUTION

Blade may turn and flexible shaft may swing as engine starts.

Do not let the blade touch any object when engine starts.

After starting the engine, wear the backpack.

Cutting (Fig. 15, 16)

○When cutting, operate engine at over 6500 min-1. Extended

time of use at low rpm may wear out the clutch prematurely.

○Cut grass from right to left.

○When working on a slope, the blade should allow the contour

from top to bottom, with the operator looking down to the left.

○Blade thrust may occur when the spinning blade contacts a

solid object in the critical area.

A dangerous reaction may occur causing the entire unit and

operator to be thrust violently. This reaction is called blade

thrust. As a result, the operator may lose control of the unit

which may cause serious or fatal injury. Blade thrust is more

likely to occur in areas where it is difficult to see the material to

be cut.

○The blade turns counter-clockwise, therefore, be advised to

operate the unit from right to left for efficient cutting. Keep

onlookers out of working area at least 15 m.

WARNING

○If the cutting attachment should strike stones or other debris,

stop the engine and make sure that the attachment and related

parts are undamaged. When grass or vines wrap around

attachment, stop engine and attachment and remove them.

Stopping (Fig. 17)

Decrease engine speed and run at an idle for a few minutes, then

turn offignition switch (19).

After stopping the engine, close the fuel cock (17). (Fig. 12-A)

WARNING

A cutting attachment can injure while it continues to spin after

the engine is stopped or power control is released. When the

unit is turned off, make sure the cutting attachment has stopped

before the unit is set down.

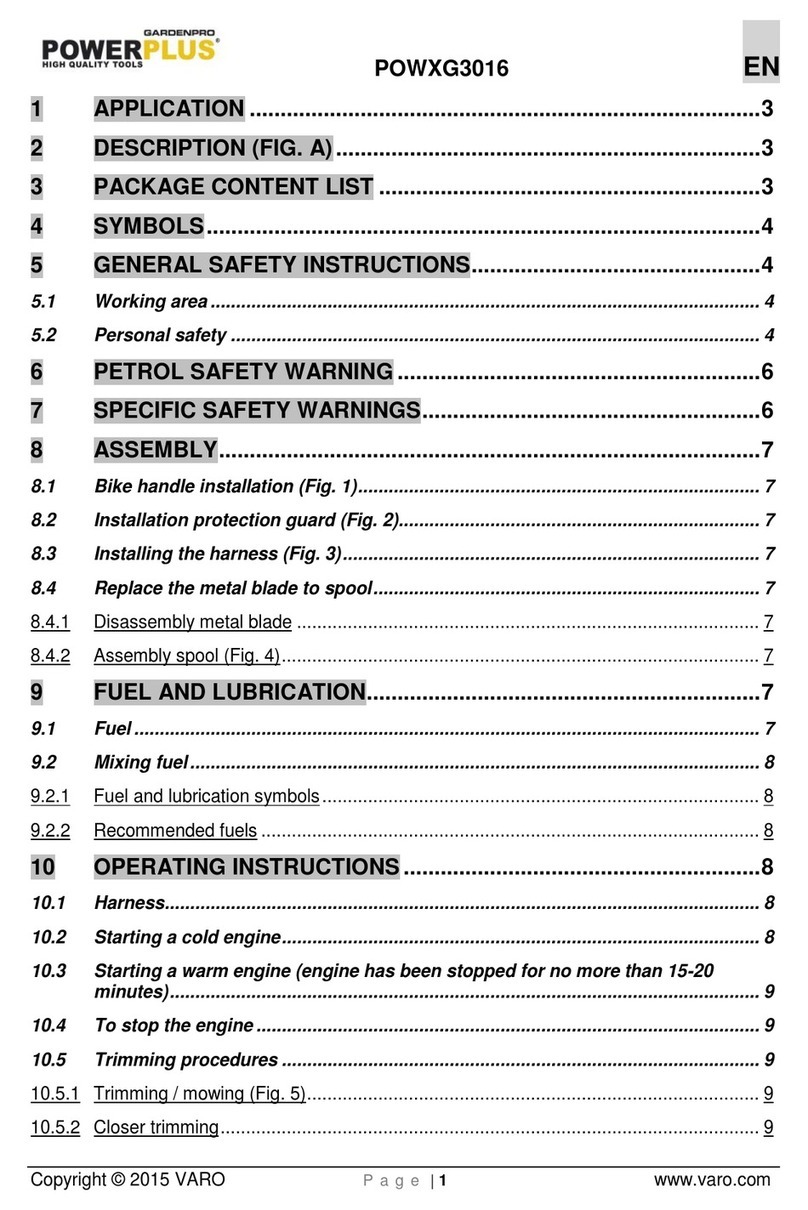

MAINTENANCE

MAINTENANCE, REPLACEMENT OR REPAIR OF THE EMISSION

CONTROL DEVICES AND SYSTEMS MAY BE PERFORMED

BY ANY NON-ROAD ENGINE REPAIR ESTABLISHMENT OR

INDIVIDUAL.

Carburetor adjustment (Fig. 18)

WARNING

○The cutting attachment may be spinning during carburetor

adjustments.

○Never start the engine without the complete clutch cover and

tube assembled! Otherwise the clutch can come loose and

cause personal injuries.

In the carburetor, fuel is mixed with air. When the engine is test

run at the factory, the carburetor is basically adjusted. A further

adjustment may be required, according to climate and altitude. The

carburetor has one adjustment possibility:

T = Idle speed adjustment screw.

Idle speed adjustment (T)

Check that the air filter is clean. When the idle speed is correct, the

cutting attachment will not rotate. If adjustment is required, close

(clockwise) the T-screw, with the engine running, until the cutting

attachment starts to rotate. Open (counter-clockwise) the screw

until the cutting attachment stops. You have reached the correct

idle speed when the engine runs smoothly in all positions well

below the rpm when the cutting attachment starts to rotate.

If the cutting attachment still rotates after idle speed adjustment,

contact your Hitachi dealer.

NOTE

Standard Idle rpm is 2500–3000 min-1.

WARNING

When the engine is idling the cutting attachment must under no

circumstances rotate.

Air filter (Fig. 19)

The air filter must be cleaned from dust and dirt in order to avoid:

○Carburetor malfunctions

○Starting problems

○Engine power reduction

○Unnecessary wear on the engine parts

○Abnormal fuel consumption

Clean the air filter daily or more often if working in exceptionally

dusty areas.

Cleaning the air filter

Remove the air filter cover and the filter (20). Rinse it in warm soap

suds. Check that the filter is dry before reassembly. An air filter

that has been used for some time cannot be cleaned completely.

Therefore, it must regularly be replaced with a new one. A damaged

filter must always be replaced.

Spark plug (Fig. 20)

The spark plug condition is influenced by:

○An incorrect carburetor setting

○Wrong fuel mixture (too much oil in the gasoline)

○A dirty air filter

○Hard running conditions (such as cold weather)

These factors cause deposits on the spark plug electrodes, which

may result in malfunction and starting difficulties. If the engine

is low on power, difficult to start or runs poorly at idling speed,

always check the spark plug first. If the spark plug is dirty, clean it

and check the electrode gap. Re-adjust if necessary. The correct

gap is 0.6 mm. The spark plug should be replaced after about 100

operation hours or earlier if the electrodes are badly eroded.

Muffler (Fig. 21)

Remove the muffler and clean out any excess carbon from the

exhaust port or muffler inlet every 100 hours of operation.

Cylinder (Engine cooling) (Fig. 22)

The engine is air cooled, and air must circulate freely around engine

and over cooling fins on cylinder head to prevent overheating.

Every 100 operating hours, or once a year (more often if conditions

require), clean fins and external surfaces of engine of dust, dirt and

oil deposits which can contribute to improper cooling.

NOTE

Do not operate engine with engine shroud or muffler guard

removed as this will cause overheating and engine damage.

Angle transmission (Fig. 23)

Check angle transmission or angle gear for grease level about

every 50 hours of operation by removing the grease filler plug on

the side of angle transmission.

If no grease can be seen on the flanks of the gears, fill the

transmission with quality lithium based multipurpose grease up to

3/4. Do not completely fill the transmission.

Flexible shaft

When lubricating flexible shaft, apply grease in the flexible pipe of

clutch case side. (It is recommended to apply grease after every 15-

20 hours of use.)

01EngCG40EBF(L)SA.indd901EngCG40EBF(L)SA.indd9 2009/11/2015:28:382009/11/2015:28:38