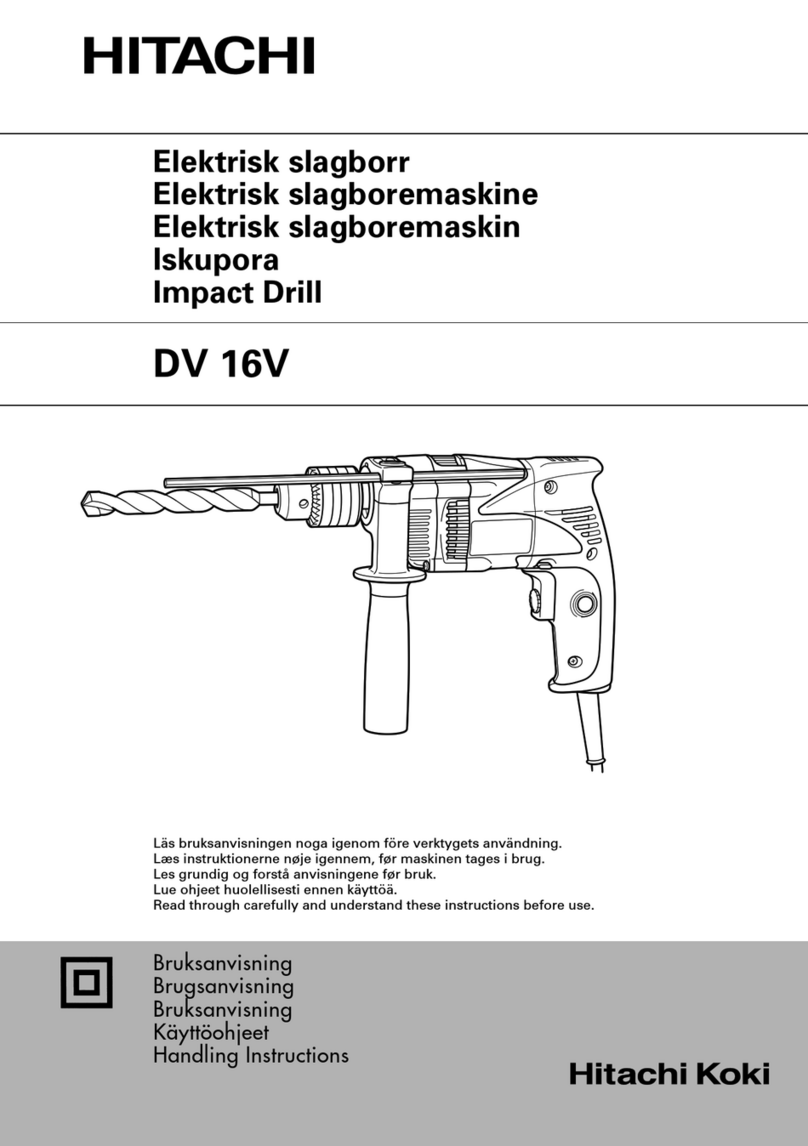

Hitachi DV 20V User manual

Other Hitachi Drill manuals

Hitachi

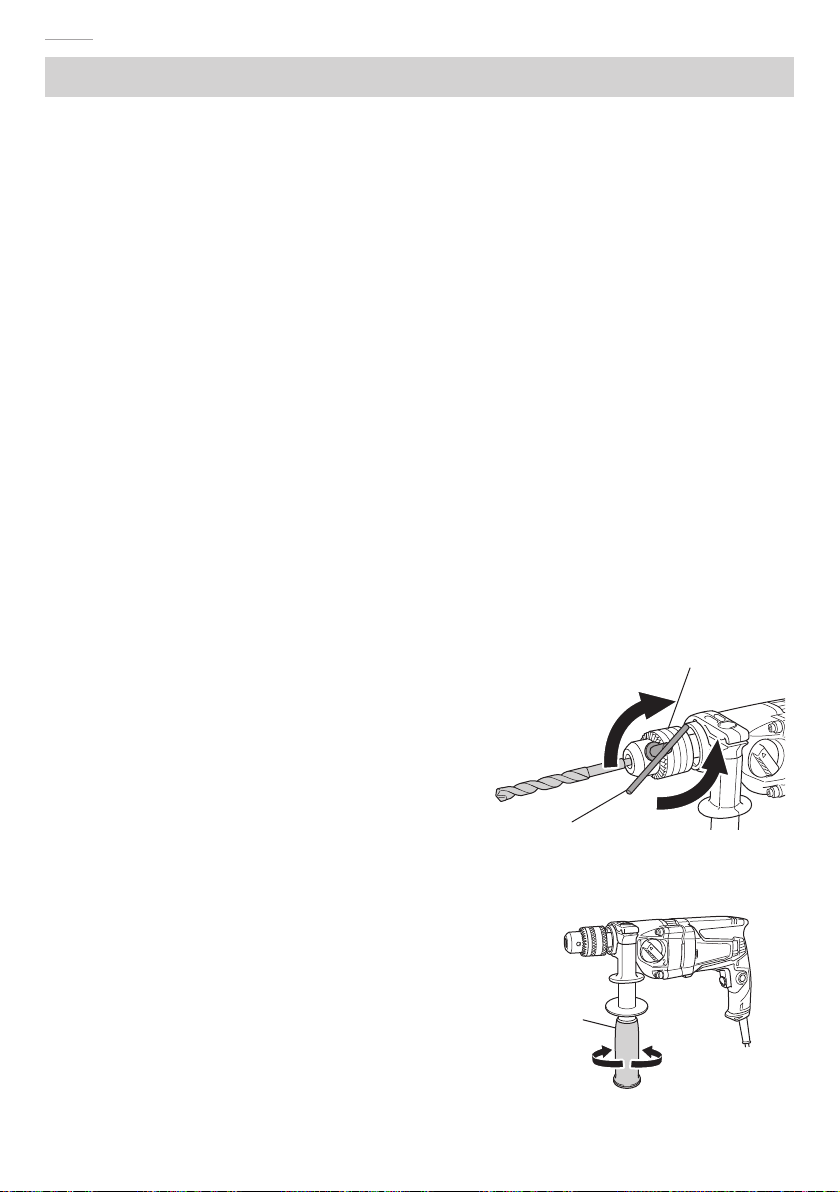

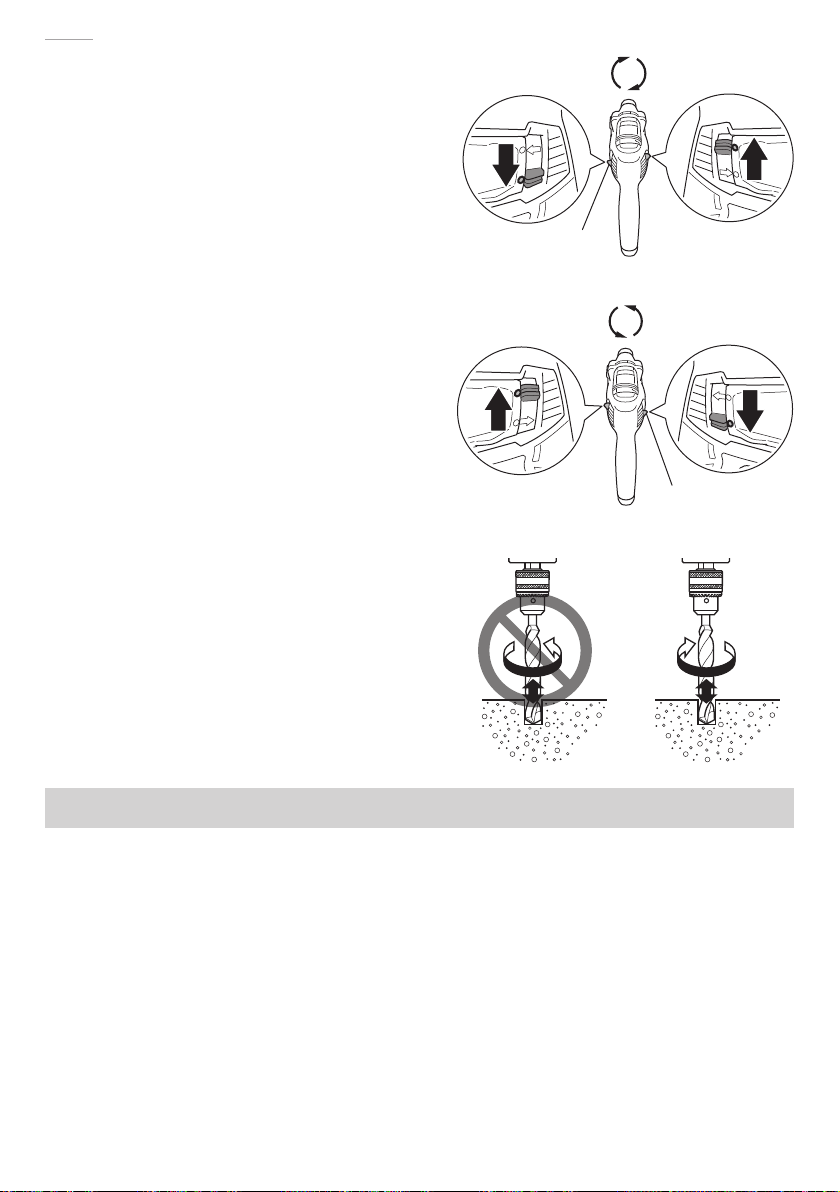

Hitachi D 10VST (L) User manual

Hitachi

Hitachi DB3DL Manual

Hitachi

Hitachi DS 14DSL Manual

Hitachi

Hitachi VTP-16A User manual

Hitachi

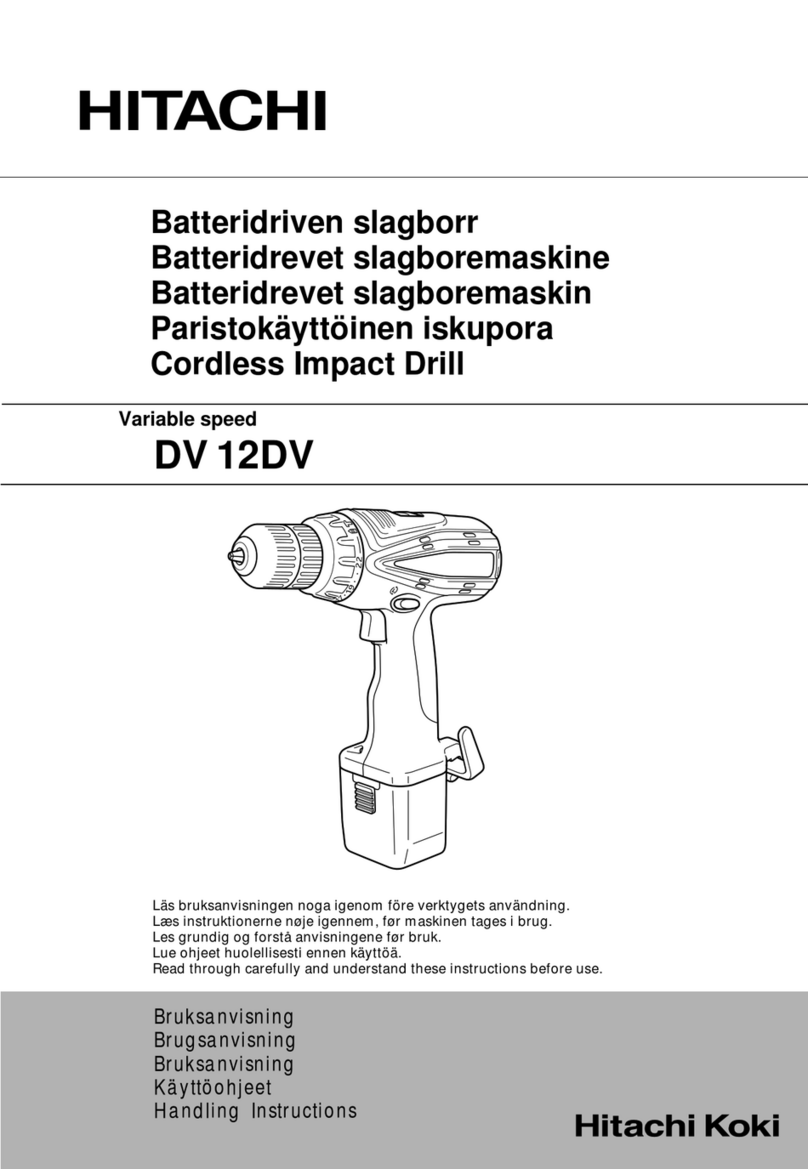

Hitachi DV 12DV User manual

Hitachi

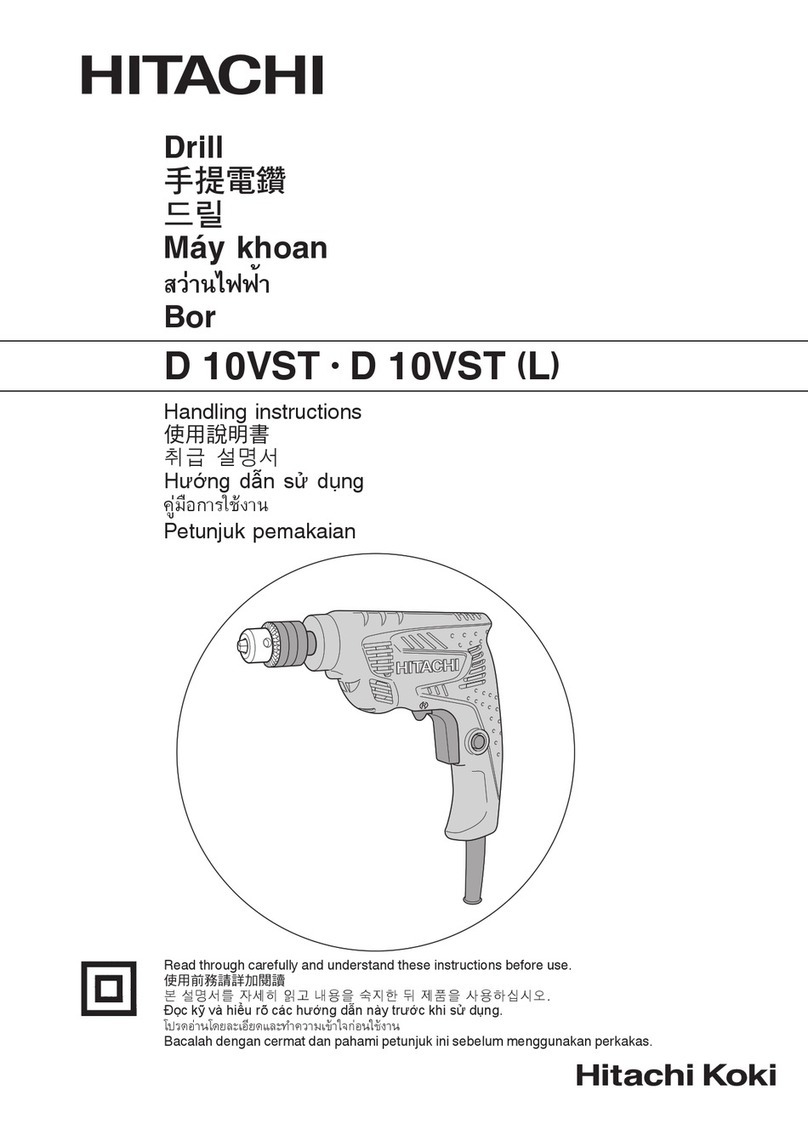

Hitachi D 10VST User manual

Hitachi

Hitachi DV 12DV Manual

Hitachi

Hitachi DH 15DV User manual

Hitachi

Hitachi DH 25PA User manual

Hitachi

Hitachi DS 14DVB User manual

Hitachi

Hitachi DN 10DSA User manual

Hitachi

Hitachi DS 14DSFL Manual

Hitachi

Hitachi DH 24PC User manual

Hitachi

Hitachi DN12DY User manual

Hitachi

Hitachi DW25EF User manual

Hitachi

Hitachi DN12DYK User manual

Hitachi

Hitachi DV 18DSFL User manual

Hitachi

Hitachi DV 10DVA User manual

Hitachi

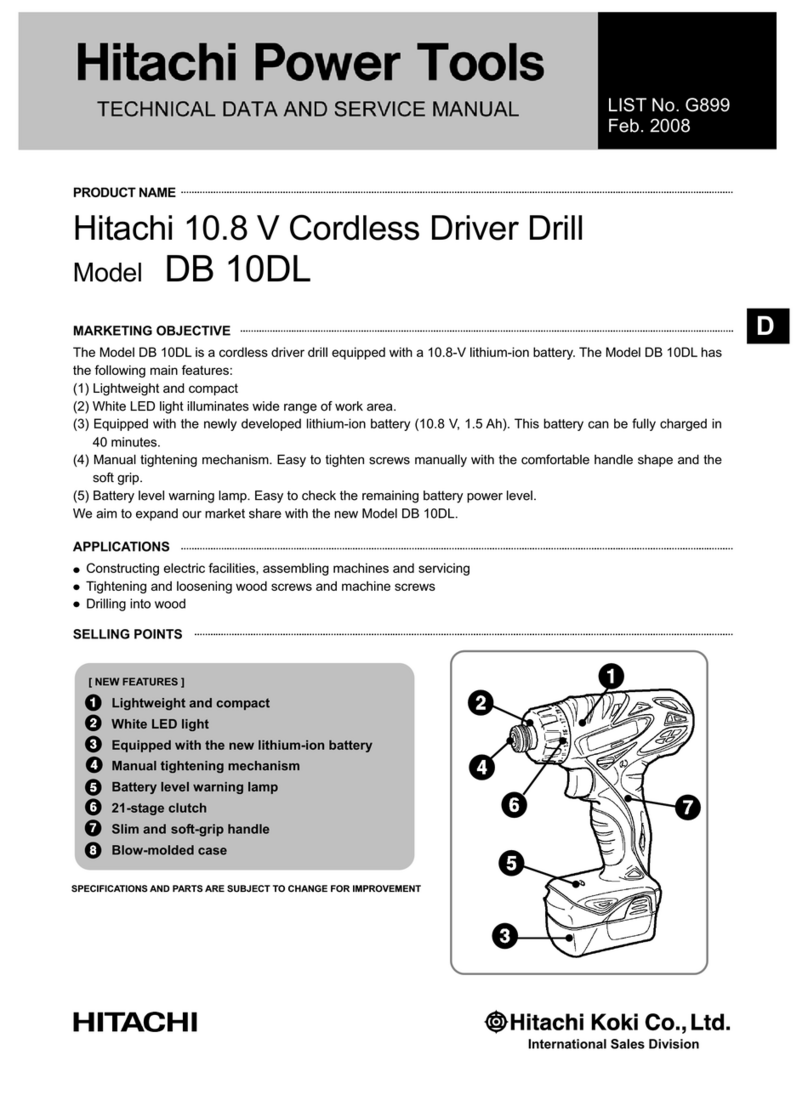

Hitachi DB10DL Manual

Hitachi

Hitachi DS 14DV Operator's manual