HiTT POROUS HPL-100 Series User manual

1

POROUS

LARGE CAPACITY HAND PRINTERS

ALL MODELS

HPL-16006

OWNER’S MANUAL

INSTALLATION - OPERATION - MAINTENANCE

Hitt Marking Devices

3231 W. MacArthur Blvd., Santa Ana, CA 92704

PH: (714) 979-1405 FAX: (714) 979-1407

E-Mail: [email protected] Website: www.hittmarking.com

2

IMPORTANT NOTE

UNIVERSAL products are manufactured to exacting standards and every available step has been taken to assure your

complete satisfaction. It is most important, for best results, that you read and carefully follow the instructions contained in this

manual. Failure to do so may result in unsatisfactory performance, damage to the equipment and personal injury.

- LIMITED WARRANTY -

UNIVERSAL Porous Large Capicity Hand Printers are guaranteed to be free from defects in materials and workmanship

for a period of 90 days from the date of purchase. Components found to be defective during this time will be repaired free

of charge if returned to the factory. Damage resulting from use of improper inks, improper installation, or operation is not

covered under the scope of this warranty. For warranty service please contact our Customer Service Department.

PREFACE

SPECIFICATIONS

HPL-100 Series

HPL-200 Series

HPL-300 Series

HPL-400 Series

Indexing & Non-Indexing Models

Printing on Non-Porous Surfaces

Printing Dies

Metric Printing Dies

Ink Rolls

QUICK START

Pre-inking XF Neoprene Ink Rolls

Installing the Pre-inked Roll

Printing Die Positioning for Indexing Applications

Installing the Printing Dies

Optional Type Blocking Kit

Adjusting the Ink Roll / Die Face Contact Pressure

MAINTENANCE

Cleaning the Printer / Cleaning the Printing Dies

Pre-inking Microcell Rolls

PRINT DRUM INDEX MECHANISM MAINTENANCE

Print Drum Index Mechanism Disassembly/Assembly

Replacing Print Drum Index Springs

Removing & Replacing Index Block “B”

PARTS DIAGRAMS AND PARTS LISTS

TABLE OF CONTENTS

3

4

5

6

7

8

8

9

9

10

11

12

14

14

15

15

16

17

18

19

20

22

3

PREFACE

The specification section includes drawings with the basic dimensions of the printers, the net weights, maximum

die capacities, maximum print width and print drum circumferences. This section also lists the specifications for

the printing dies and an explanation of the indexing and non-indexing models.

PRINTER SPECIFICATIONS

1- Indexing (spot printing) and non-indexing (continuous printing) models with print areas up to 3-15/

16" x 17-1/2".

2- Universal’s die system allows text information to be set using individual characters or one piece logo

dies.

3 - Custom logo dies can also be produced from camera ready copy.

4 - Precision machined from aircraft grade aluminum alloys and stainless steel for mimimal maintanance

and superior long term performance.

5 - Baseplate has a black anodized finish for corrosion resistance.

6 - Permanently lubricated, sealed ball bearings which provide for extremely accurate, low friction drum

rotation.

7 - Stainless steel shafts for durability even in harsh environments.

8 - Indexing mechanism with dual compression springs mounted over stainless steel guide rods mini-

mizes spring breakage and provides unsurpassed indexing speed and accuracy.

The Universal HPL Hand Printer has been designed to print lot numbers, date codes, and text information on

cartons, web materials, and other conveyed products. Universal HPL Hand Printers are precision engineered to

give years of reliable service under the most demanding conditions.

QUICK START

SEE PAGE 11

This manual was written with a full understanding that very few people like to read manuals or have the

time to do so. To accommodate those who have little time to spare we have included a Quick Start

section which will get your printer operating in just a few minutes.

FEATURES

4

SPECIFICATIONS

HPL PRINTER SPECIFICATIONS

HPL-100 SERIES

Model Shown: HPL-100

NET WEIGHT: 6.1 LBS. (2.8 KG)

MAXIMUM DIE SIZE - US STANDARD: 1” (7 RIBS) X 16-15/16” LENGTH

MAXIMUM DIE SIZE - METRIC CODERS ONLY: 25.4 MM (7 RIBS) X 430.2 MM LENGTH

PRINT DRUM CIRCUMFERENCE: APPROXIMATELY 18" (457 MM) MEASURED AT DIE FACE

17.19”

(436.6 MM)

16.41”

(416.8 MM)

6.71”

(170.4 MM)

3.68”

(93.5 MM)

1.04”

(26.4 MM)

8.45”

(214.6 MM)

5.74”

(145.8 MM)

DUST COVER REMOVED

TO SHOW INDEX MECHANISM

5

SPECIFICATIONS

HPL PRINTER SPECIFICATIONS

HPL-200 SERIES

Model Shown: HPL-200

NET WEIGHT: 6.9 LBS. (3.1 KG.)

MAXIMUM DIE SIZE - US STANDARD: 1-15/16” (14 RIBS) X 16-15/16” LENGTH

MAXIMUM DIE SIZE - METRIC CODERS ONLY: 49.2 MM (13 RIBS) X 430.2 MM LENGTH

PRINT DRUM CIRCUMFERENCE: APPROXIMATELY 18" (457 MM) MEASURED AT DIE FACE

17.19”

(436.6 MM)

16.41”

(416.8 MM)

6.71”

(170.4 MM)

5.58”

(141.7 MM)

1.95”

(49.5 MM)

8.45”

(214.6 MM)

5.74”

(145.8 MM)

DUST COVER REMOVED

TO SHOW INDEX MECHANISM

6

NET WEIGHT: 8.0 LBS. (3.6 KG.)

MAXIMUM DIE SIZE - US STANDARD: 2-15/16” (21 RIBS) X 16-15/16” LENGTH

MAXIMUM DIE SIZE - METRIC CODERS ONLY: 74.6 MM (20 RIBS) X 430.2 MM LENGTH

PRINT DRUM CIRCUMFERENCE: APPROXIMATELY 18" (457 MM) MEASURED AT DIE FACE

HPL PRINTER SPECIFICATIONS

HPL-300 SERIES

Model Shown: HPL-300

17.19”

(436.6 MM)

16.41”

(416.8 MM)

6.71”

(170.4 MM)

6.58”

(167.1 MM)

2.9”

(73.7 MM)

8.45”

(214.6 MM)

5.74”

(145.8 MM)

DUST COVER REMOVED

TO SHOW INDEX MECHANISM

SPECIFICATIONS

7

NET WEIGHT: 9.1 LBS. (4.1 KG.)

MAXIMUM DIE SIZE - US STANDARD: 3-15/16” (29 RIBS) X 16-15/16” LENGTH

MAXIMUM DIE SIZE - METRIC CODERS ONLY: 100 MM (27 RIBS) X 430.2 MM LENGTH

PRINT DRUM CIRCUMFERENCE: APPROXIMATELY 18" (457 MM) MEASURED AT DIE FACE

HPL PRINTER SPECIFICATIONS

HPL-400 SERIES

Model Shown: HPL-400

17.19”

(436.6 MM)

16.41”

(416.8 MM)

7.58”

(192.5 MM)

3.94”

(100.1 MM)

8.45”

(214.6 MM)

5.74”

(145.8 MM)

DUST COVER REMOVED

TO SHOW INDEX MECHANISM

SPECIFICATIONS

8

SPECIFICATIONS

INDEXING AND NON-INDEXING MODELS

Universal HPL Hand Printers are available in both indexing and non-indexing models.

FIGURE 1

Indexing printers feature a print drum indexing mechanism

which provides print registration capabilities when carton print-

ing. When the printer is lifted off the surface, after the print

operation, the print drum automatically rotates back to the

same starting or “home” position. Printing with an indexing

printer will allow the imprint on each carton to be registered in

the same position relative to the position where the print drum

first contacts the carton.

STAINLESS STEEL

GUIDE ROD

COMPRESSION

SPRING

Non-indexing printers provide random print registration capabilities. These printers have print drums which

simply rotate on bearings and repeat the print at an interval equal to the circumference of the print drum. If your

application requires the print to be repeated at shorter intervals than the circumference print drum, duplicate sets

of dies can be installed on the print drum. Non-indexing printers are generally used for web printing applications

where the print drum stays in contact with the web over long distances.

PRINTING ON NON-POROUS SURFACES

Universal HPL Hand Printers are intended for use on porous surfaces, however, the use of slow drying alcohol

base inks is possible with the XF Neoprene Ink Rolls. Slow drying pigmented stencil inks such as Universal Type

D Ink and some of those made by other manufacturers will work in these printers. The XF Neoprene Ink Rolls are

not compatible with MEK solvent based inks and a number of other non-porous ink solvents. Some of these

solvents will casue extreme swelling of the ink rolls.

It is importatnt to note that even compatible alcohol based inks will dry out in the ink rolls if left on the printer for

extended periods of time. The ink rolls should be removed from the printer and stored in a sealed container after

each use. Regular re-inking of the roll will be necessary when using alcohol base inks in these units and and

occassional addition of ink solvent to the roll may be required to keep it working properly.

9

SPECIFICATIONS

FIGURE 2

BEARER RING

.015 - .016”

PRINTING DIE

DRUM COVER

FIGURE 3

RIBtype® PRINTING DIES

CODER MODELS DESIGNED FOR METRIC RIBtype® PRINTING DIES

Printing dies are manufactured to precision thickness tol-

erances which are very critical to the performance of these

coders. When installed, the face of the printing die should

extend only .015” - .016” beyond the radius of the Bearer

Rings as shown in Figure 3. Using dies that do not meet

the design specifications will result in poor print quality

and possible damage to the transfer roll.

Although there are several competitive rib backed die sys-

tems available, it is very important to note that they are not

all made to the same rib spacing or thickness specifica-

tions and they are not interchangeable.

Universal also offers Metric RIBtype® die systems for use in countries where metric character sizes are the

standard. The Metric dies are thicker and the rib spacing differs slightly from the standard printing dies therefore

the two versions are not compatible. To accommodate the differences, the print drums for Metric dies are

machined to a slightly different diameter from the U.S. versions.

The coder model numbers on Metric coders will have a “-T” suffix and the Metric Drum Covers have a distinct

pink color.

Universal HPL Hand Printers are designed to use RIBtype® printing

dies which have a molded rib backing. The ribs on the back of the die

snap into mating ribs in the Drum Cover on the print drum as shown

in Figure 4.

The standard printing dies are available in sets with many sizes and

character styles. The sets are a combination of individual alphabetic

and numeric characters or in sets containing numeric characters

only. These character sets or “sorts” can be used to make up text

messages and code numbers as necessary.

Printing dies are also available in “logo” form in which a complete text message, company logos or trademarks

are produced on a single piece of rib backed rubber. These “logo” dies are photographically reproduced from

black and white art work. Due to their unitized construction, these dies generally produce better print quality and

are much faster to change in the field. For details on ordering custom logo dies, please contact our Customer

Service Department.

10

SPECIFICATIONS

INK ROLLS

MICROCELL INK ROLLS - OPTIONAL

XF NEOPRENE INK ROLLS

Microcell ink rolls are the most durable rolls available on

the market today. This material is an extremely tough,

hard density urethane foam which will last up to a year or

more under normal conditions. The rolls are re-inkable

for maximum economy and are recommended for use

with Universal #1150 Ink for printing on corrugated car-

tons and other porous surface materials.

Universal’s XF Neoprene Ink Rolls are made from an ex-

tra firm density neoprene material. The extremely fine cell

structure of these rolls provides exceptionally good print

quality particularly when using small character printing

dies. Due to their greater ability to compensate for slight

die thickness variations, these rolls are also recommended

to correct print quality problems when multiple lines of text

are required.

Universal offers two ink roll options for the HPL Hand Printers. Each has a unique characteristic suitable for a

specific printing application. The printers are designed to accommodate both types of ink rolls without modifica-

tion. A detailed review of your printing requirements will determine the best choice of ink rolls for your particular

application.

FIGURE 4

Unless otherwise specified, XF Neoprene Ink Rolls are supplied with all new HPL Printers.

FIGURE 5

11

QUICK START

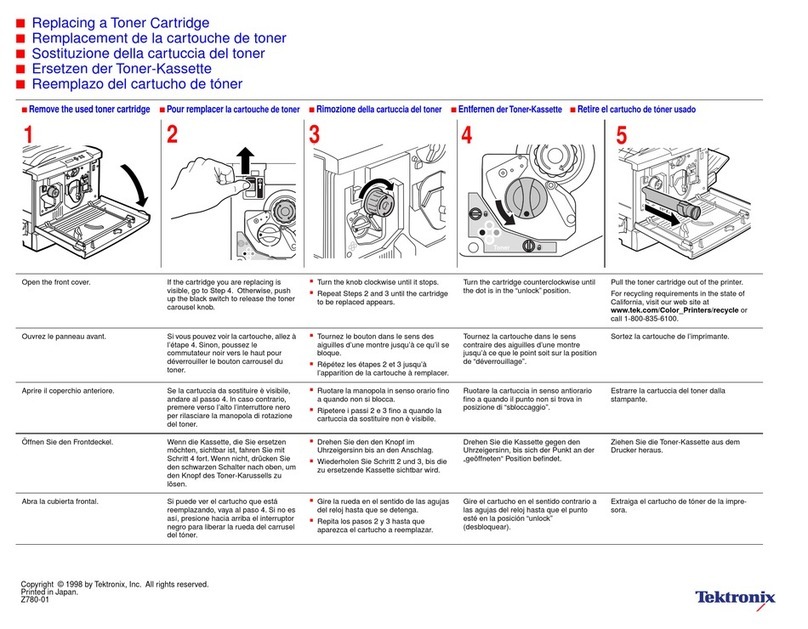

PRE-INKING XF NEOPRENE INK ROLLS

3- Using a round shaft or screwdriver, remove the roll from the

container. Roll the ink roll across a clean piece of paper or

cardboard to remove the excess ink.

Inks will stain clothing, furniture, carpeting and your hands. Rubber gloves should be worn during the following

procedures.

1- Remove the dry roll from the plastic bag. Pour ink into a clean

container large enough to accommodate the size of the ink

roll.

2- Place the roll on it’s side into the container. Using your finger

tips, press down firmly on the side of the roll. Continue to

press down on the roll while rotating it in the container. Flip

the roll over in the container and repeat the process until all of

the ink is absorbed.

As you press down on the ink roll you are forcing the air out of

the roll material which allows the ink to be absorbed.

It is important to the performance of the printer that the ink

roll is fully saturated but not dripping wet.

For a 1-1/8” face roll pour approximately 4 ozs. of ink into the

container, for a 2” face - 8 ozs., 3” face - 12 ozs. and 4” face - 16

ozs. The ink rolls must be pre-inked manually prior to installation

on the printer.

FIGURE 6

FIGURE 7

FIGURE 8

Universal HPL Hand Printers are shipped from the factory fully assembled and, unless otherwise specified,

includes a dry XF Neoprene Ink Roll. The ink roll must be manually pre-inked prior to use. The initial inking

of any dry roll is critical to the preformance of the Printer. Follow the inking instructions below to insure that your

rolls are properly inked.

If you received a pre-inked ink roll with your printer, skip this procedure and go to the next page for instructions on

roll installation.

12

QUICK START

INSTALLING THE PRE-INKED ROLL

1- To install the ink roll, first loosen the 8-32 set screw in the

cover retaing knob using a 5/64” hex wrench.

2- Remove the cover retaining knob.

FIGURE 10

FIGURE 11

Inks will stain clothing, furniture, carpeting and your hands. Rubber gloves should be worn during the following

procedures.

FIGURE 9

All pre-inked rolls are shipped oversaturated with ink, before installation the excess ink must be removed. Roll

the ink roll across a clean piece of paper or cardboard to remove the excess ink.

FIGURE 12

3- Remove the ink roll cover.

4- Loosen the plastic knob and slide the ink roll mount away from

the print drum.

13

6- Replace the roll cover. Note that the notch in the cover must

be aligned with the tab on the base plate.

QUICK START

FIGURE 13

FIGURE 14

FIGURE 15

FIGURE 16

5- Place the ink roll on the Axle. Do not allow the ink roll to con-

tact the Print Drum Bearer Rings during installation.

7- Replace the cover retaining knob.

8- Lightly tighten the 8-32 set screw in the cover retaining knob

using a 5/64” hex wrench.

14

Non-indexing models of the HPL Hand Printer do not offer print registration capabilities, therefore mounting the

printing dies at a specific location on the print drum is not important. On indexing machines, the position of the

die on the print drum will determine the location of the print on the carton.

The drawing illustrates the best die position for

carton printing. Note that the leading edge of the

printing die should be positioned, rotationally, up-

stream of the ink roll. When the print drum is

placed against the susface of the carton and

pushed forward, the drum begins to rotate in a

counter-clockwise direction. The printing die trav-

els a short distance and then contacts the ink roll

where ink is applied to the die face. When the

die contacts the carton, the mark is applied. The

printer should remain in contact with the surface

of the product and be pushed forward through

one complete revolution of the print drum. When

it is lifted off the surface of the product, the print

drum will automatically return to the same start-

ing position.

INK ROLL

LEADING EDGE OF DIE

FIGURE 17

PRINTING DIE POSITIONING FOR INDEXING APPLICATIONS

Install the Printing Die on the Print Drum by aligning the

ribbed backing on the die with the mating drum cover on

the Print Drum. Press firmly until they are completely en-

gaged.

Individual character codes or text messages are installed

in a mirror image of normal written text. In other words

install in a right to left direction as shown. When printed,

codes or text installed in this orientation will print in normal

left to right order.

INSTALLING THE PRINTING DIES

To make die installation easier, moisten a sponge with water containing a small amount of liquid dish detergent.

Lightly moisten the back of the printing die and then immediately press the die into the drum cover.

Note: Do not apply too much liquid or the dies will slip during printing.

FIGURE 18

QUICK START

15

When using small individual characters with only a two or

three rib backing, an optional Type Blocking Kit (Stock No.

UR-BK) should be used to support the leading and trail-

ing ends of the type as shown.

Characters which have only a 2 or 3 rib backing do not

have the stability of the larger character sizes when

snapped into the drum cover. Adding the rib backed type

blocks on either side of the code will provide added stabil-

ity and prevent the characters from shifting during print-

ing. The Type Blocks are not as thick as the Type and will

not pick up ink from the Ink Roll.

OPTIONAL TYPE BLOCKING KIT

FIGURE 19

1- With the Dies installed on the print drum, rotate the print drum

to a position where the printing dies will contact the ink roll.

Then loosen the position adjusting knob and move the ink roll

into contact with the face of the printing dies. Tighten the posi-

tion adjusting knob when the ink roll contacts the face of the

printing die with just enough pressure to fully ink the die face.

The ink roll should never be positioned so close that it con-

tacts the Drum Covering on the Print Drum or the relief areas

of the printing die.

ADJUSTING THE INK ROLL / DIE FACE CONTACT PRESSURE

The pressure the ink roll exerts on the face of the printing dies should be just enough to rotate the ink roll and

completely ink the face of the dies as they pass during printing. Excessive contact pressure will cause smudging

of the impression, premature failure of the ink roll, and restriction of the print drum rotation.

FIGURE 20

QUICK START

16

If proper installation procedures are followed, the maintenance of your new printer will be limited to periodic

cleaning to remove dust and any ink residue which may accumulate during operation. The frequency of this

maintenance procedure is dependent upon the environmental conditions and proper inking of the printer. To

remove ink contamination from the surface of the printer, moisten a soft cloth with a light solution of detergent and

water and wipe away any contamination. During printing, the dies will tend to pick up both airborne dust and any

dust or dirt on the surface of the material being printed. After some period of use, the accumulation of contami-

nates on the dies will cause degradation of the print quality. When this happens, the dies should be cleaned or

replaced. Cleaning the dies is a very easy process and, excluding excessive wear to the die face, will restore the

print quality of the die to like new condition.

CLEANING THE PRINTER / CLEANING THE PRINTING DIES

Universal #1150 Ink is a glycol base ink which can be easily cleaned from the dies without the use of solvents.

The easiest method of cleaning dies is to scrub the die face with a toothbrush using liquid dish detergent and

water. Since the ink residue will stain, it is highly recommended that you wear a pair of rubber gloves, safety

glasses and an apron to protect your clothing. (Naturally, the toothbrush will never be suitable for oral hygiene

use after this process.)

1- Place the contaminated die on top of several layers of paper

towels to absorb the excess liquid. Pour just enough soapy

water on the face of the printing die to cover the die face.

2- Using the toothbrush, carefully scrub the face of the die to

remove the contamination and old ink as shown. Add more

soapy water as necessary and repeat the process until the die

is clean. Rinse the dies in clean water.

3- Blot the surface of the die with a clean paper towel to dry and

reinstall the clean dies on the printer.

FIGURE 21

FIGURE 22

FIGURE 23

MAINTENANCE

17

The optional Microcell Ink Roll is available for specific applications. Because of the harder density of this material

the inking process of the roller must be done slowly. The following instructions will guide you through the proper

inking process to insure maximum performance of your printer.

Microcell Ink Rolls are designed for use with Universal #1150

Ink for marking on porous surfaces. The ink rolls must be pre-

inked manually prior to installation on the printer.

2- Carefully place the ink roll into the ink. Do not force the roll to

submerge. The top surface of the roll must remain dry during this

process.

3- As the roll absorbs ink it will begin to sink into the container. When

the top surface becomes fully saturated the roll has absorbed as

much ink as possible. Using a round shaft or screwdriver, remove

the roll from the container.

4- To remove excess ink from the roller, use a round shaft or screw-

driver, and roll the inked roller across a clean piece of paper or

cardboard.

1- Remove the ink roll from the plastic bag. Fill a clean dry container

with enough ink to allow the ink roll to fully submerge.

The roll should be allowed to float, undisturbed, in the container

of ink. Leaving the top surface of the roll dry allows air to

escape as the ink is absorbed from the bottom. Forcing the

roll under the surface of the ink will prevent the roll from absorb-

ing ink properly.

This process normally takes 20-25 minutes for a 1-1/8” face roll,

longer for the larger rolls. Proper inking of a dry roll is critical to

ensure good performance of the roll.

FIGURE 24

FIGURE 25

FIGURE 26

FIGURE 27

Inks will stain clothing, furniture, carpeting and your hands. Rubber gloves should be worn during the following

procedures.

PRE-INKING MICROCELL ROLLS

1-1/8" face roll will hold approximately 4 ounces (118 ml.).

2" face roll will hold approximately 8 ounces (236 ml).

3" face roll will hold approximately 12 ounces (354 ml).

4" face roll will hold approximately 16 ounces (473 ml).

Approximate roll capicity when fully saturated:

MAINTENANCE

18

4- Lift the spring block assembly straight up off the stain-

less steel posts.

Important Note: The Print Drum Axle is machined with

thread relief so the tip of the set screw will not damage

the threads. To completely remove the Index Ring from

the Axle, the Brass Tip Set Screw must be loosened at

least 2 full turns to prevent damage to the threads.

1- Using a 5/64” hex wrench, loosen the Nylon Tip Set Screw

located in the top rim of the Print Drum and remove the

dust cover.

FIGURE 28

FIGURE 29

FIGURE 30

3- Using a small screwdriver, remove the two E-Rings from

the stainless steel posts to enable removal of the spring

block assembly.

FIGURE 31

2- To relieve the spring tension on the index mechanism, ro-

tate the Print Drum approximately 3/4 turn. The Index Com-

pression Springs will now be in the fully extended (relaxed)

position.

FIGURE 32

.04

BRASS TIP

SET SCREW

PRINT DRUM AXLE

RECESS AREA

PRINT DRUM INDEX MECHANISM DISASSEMBLY / ASSEMBLY

PRINT DRUM INDEX MECHANISM MAINTENANCE

19

PRINT DRUM INDEX MECHANISM MAINTENANCE

FIGURE 33

FIGURE 34

FIGURE 35

5- Using a 1/8" hex wrench, loosen the Brass Tipped Set Screw

located in the side of the Index Ring. This screw must be turned

counterclockwise at least two full revolutions.

6- Remove the Index Ring from the axle by turing it in a Counter-

Clockwise direction. If the Index Ring does not turn freely, loosen

the set screw an additional turn as indicated in Step 5 above.

7- The print drum can now be lifted off the axle.

FIGURE 37

FIGURE 36

1- Holding onto the Index Assembly Block “A”, pull the Index Assembly

Block “C” off the guide shafts. Remove the Drum Index Springs

2- Install new Index Springs over the stainless steel guide shafts and

replace Index Block “C”.

3- Reinstall the Index Spring Assembly in the Print Drum with the

large end of the white bushings facing up towards the open end of

the Print Drum.

4- Reinstall the two Snap Rings.

REPLACING PRINT DRUM INDEX SPRINGS

20

FIGURE 39

Before replacing Index Block “B”, ensure that the Index Ring

is properly adjusted.

2- Lift Index Block “B” straight up to remove.

The head of the Index Assembly Mounting Screw engages the T-Slot

in Index Block “B”. This mounting design facillitates height adjust-

ment of the Index Block during reassembly.

REMOVING AND REPLACING INDEX BLOCK “B”

1- To remove Index Block “B” from the Print Drum, roll down the

Drum Cover directly behind the Index Block to expose the In-

dex Assembly Mounting Screw. Using a screw driver, turn the

Mounting Screw in a clockwise direction until the Index Block

becomes loose and can be removed.

FIGURE 38

If the Indexing Assembly Block “B” is removed during disassembly it must be realigned using the fol-

lowing procedure.

FIGURE 40

3- Install the Index Ring by threading it onto the axle (turning it in a

Clockwise direction) until it contacts the shoulder of the axle.

PRINT DRUM INDEX MECHANISM MAINTENANCE

This manual suits for next models

3

Table of contents