Hix SubliPro-Ct User manual

10623 RV C_20201007

Contents

Introduction ..................................................................................................................... 2

General Information ........................................................................................................ 3

Unpacking And Placement .............................................................................................. 4

Installation ...................................................................................................................... 5

Control Panel................................................................................................................... 6

Preparation...................................................................................................................... 7

Home Screen................................................................................................................... 8

Time & Temp. Adjustment................................................................................................ 9

Settings.......................................................................................................................... 10

Preset Settings ...............................................................................................................11

Preset Storage............................................................................................................... 12

Cycle Count................................................................................................................... 13

Preferences ................................................................................................................... 14

Operation....................................................................................................................... 15

Cleaning & Maintenance ............................................................................................... 16

HIX Mug Wraps ............................................................................................................. 17

Using HIX Mug Wraps ................................................................................................... 18

Warranty ....................................................................................................................... 20

SubliPro-Ct

Electric Countertop Convection Oven

OWNER’S MANUAL

Installation, Operation and Care of HIX SubliPro-Ct

BEFORE warranty repair you MUST get Prior Authorization:

For Customer Service, Call 1-800-835-0606

or Visit www.hixcorp.com

2

INTRODUCTION

KEEP THIS MANUAL FOR FUTURE REFERENCE

Congratulation on the purchase of your Countertop SubliPro-Ct sublimation oven!

Sublimation is dened as the process of change from a solid to a gas state without

passing through a liquid phase. When heated, sublimation dyes bind permanently

with the molecules of the substrate. Under the right pressure and temperature

condition, the substrate molecules open up and allow the gaseous dye molecules to

become trapped upon cooling. This color “trapping” results in a nearly undetectable

“hand” or sensation of any physical change of the substrate. Dye sublimation shirts

retain the original feel of their fabric, breathability and wicking characteristics. Non-

textile substrates – mugs, cellphone cases, photo-imaging wooden or metal plates,

etc. – show their color designs in unusual vibrancy and color retention. Since color

is now also more than superimposed layer, the design is also generally better

protected against abrasion.

The sublimation works on polyester, either as a fabric or as a coating on non-textile

substrates. The process does not work on cotton except when the cotton is spun in

combination of a substantial percentage of synthetic material. However, since only

the polyester fabric traps the sublimation dye, there is a direct relationship between

the vivacity and longevity of the images and their synthetic content.

Dye sublimation inks are translucent. As a result, printing on dark substrates can

only occur if printing on a white underbase (in the case of fabric) or on a white panel

(in the case on non-textile).

Over the past 20 years, the use of inkjet printers to create sublimation dye transfers

has grown exponentially, partly because of its growing popularity, but also because

of the declining price of dedicated desktop-size sublimation printers. Popularization

of the technique has created such a demand that these printers have now become

accessible to any small business willing to expand into this eld.

Key among sublimation’s advantages is the ability to produce accurate colors, ne

detail and durable prints.

3

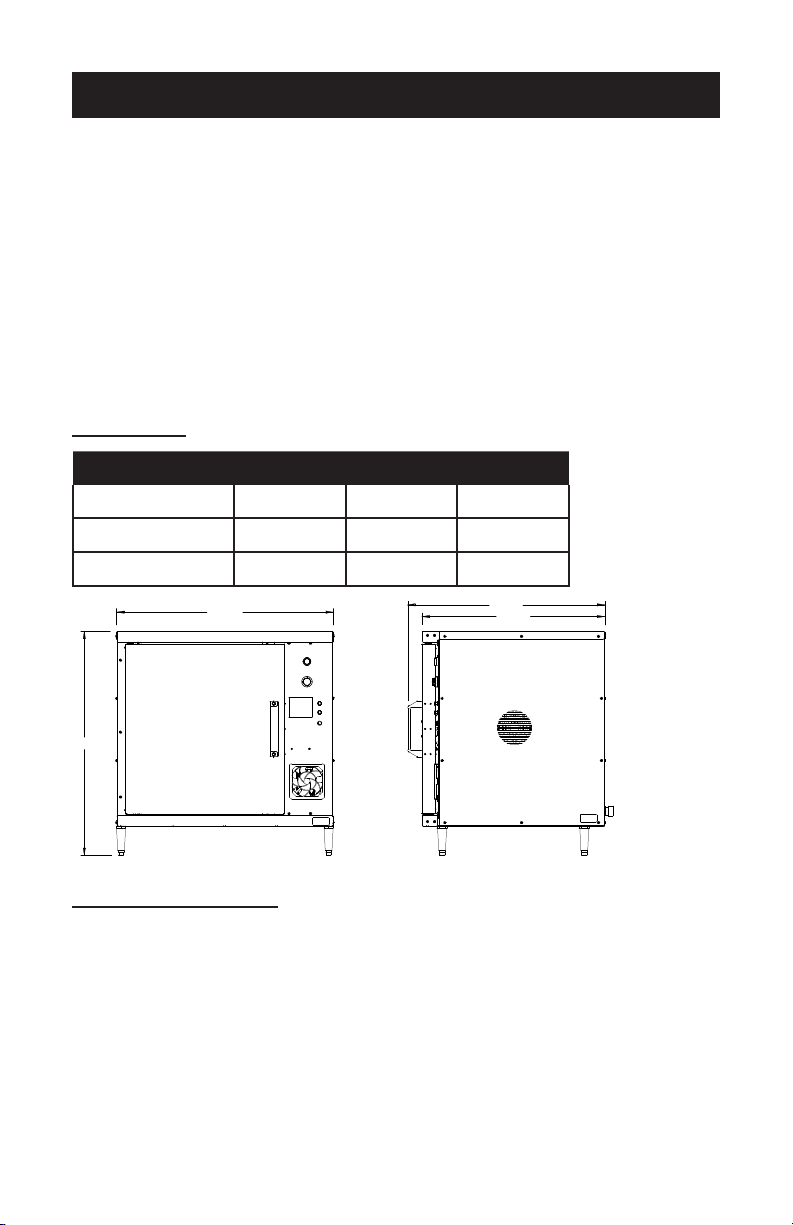

GENERAL INFORMATION

The SubliPro-Ct Electric Convection Oven is a single cavity oven and features a solid

state thermostat, digital timer, variable-speed 1/6 HP (0.124 KW) electric motor and

three racks as standard equipment. Each oven is provided with a standard 208 or

240 volt, 60 Hz., and 1- or 3-phase electrical service. Stainless steel oven interior

and exterior is standard.

A single oven may be installed on an open stand with lower storage rack (optional).

Legs are standard.

Your HIX SubliPro-Ct Electric Convection Oven is produced with quality workmanship

and material. Proper installation, usage and maintenance of your oven will result in

many years of satisfactory performance.

It is suggested that you thoroughly read this entire manual and carefully follow all

of the instructions provided.

DIMENSIONS

Width Height Depth

Exterior 30.0625” 31.125” 27.375”

Interior 15.219” 22” 21.188”

Wire Racks (3) 13” 20.125”

TEMPERATURE RANGE

Ambient – 450°F

FRONT VIEW SIDE VIEW

4

UNPACKING AND PLACEMENT

Before installing, verify that the electrical service agrees with the specications on

the oven rating plate, located on the inside of the top front cover. If the supply and

equipment requirements do not agree, do not proceed with installation. Contact

your HIX customer service representative immediately.

UNPACKING

This oven was inspected before leaving the factory. The transportation company

assumes full responsibility for safe delivery upon acceptance of the shipment.

Immediately after unpacking the oven, check for possible shipping damage. If this

oven is found to be damaged, save the packaging material and contact the carrier

within 15 days of delivery.

Do not use the door or its handle to lift the oven.

PLACEMENT

The placement of the oven needs to be on a stable level surface sufcient to support

the weight of the oven and must allow adequate clearances for servicing and proper

operation Installations on supports restricting air circulation around the oven is not

advisable and may void the warranty. A minimum of three inches of clearance on

all sides and top as well as clearance from any combustible surfaces is required.

3”

3”

3”

3”

5

INSTALLATION

ATTACHING LEGS

The included legs must be installed on the SubliPro-Ct oven to provide sufcient air

circulation for the bottom of the oven. The legs screw into the four threaded inserts

located in the corners on the underside of the oven. Screw one leg into each insert.

LEVELING

Once the oven is in its permanent position, place a carpenter’s level on the oven

rack. Turn the adjustable feet in or out to level oven front-to-back and side-to-side.

ELECTRICAL CONNECTIONS

⚠ WARNING: Electrical and grounding connections must comply with the

applicable portions of the National Electrical Code and/or other

local electrical codes.

⚠ WARNING Disconnect the electrical power to the machine and follow lockout

/ tagout procedures.

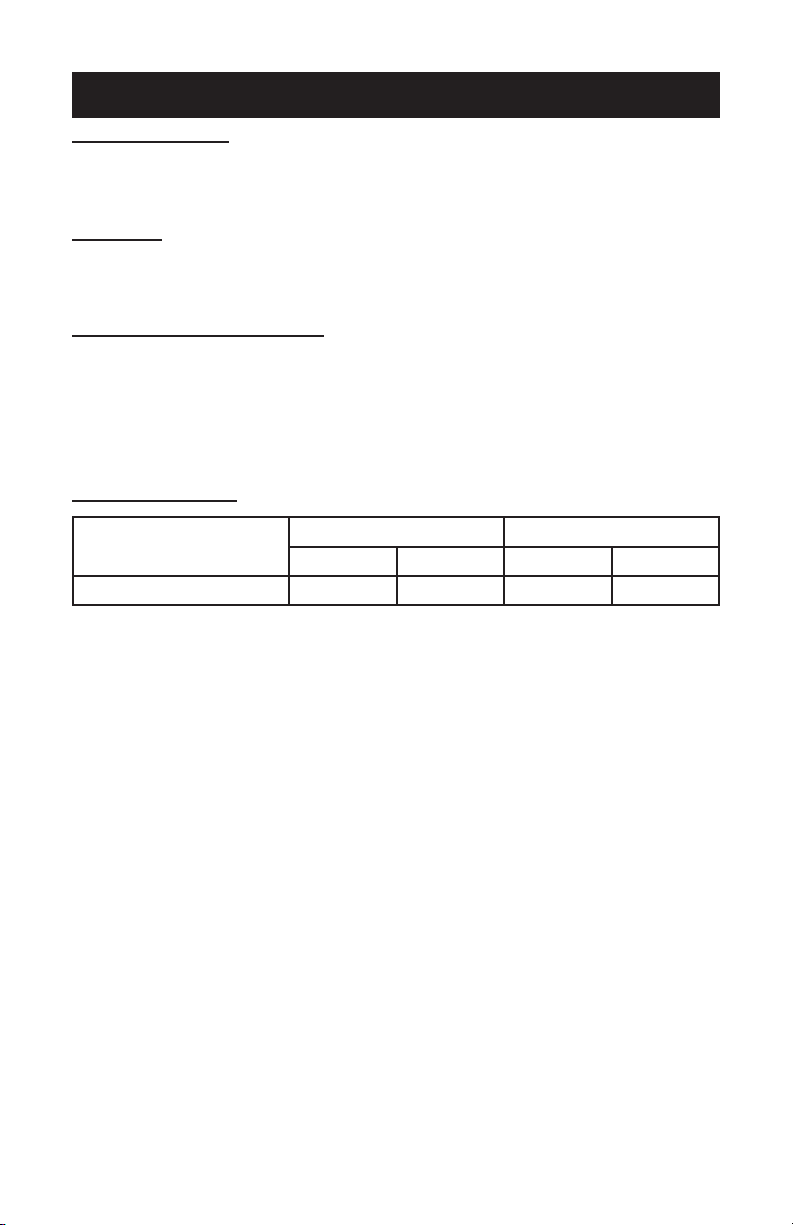

ELECTRICAL DATA

Total KW 3 Phase 1 Phase

208 V 240 V 208 V 240 V

8.0 (including blower motor) 23.0 A 19.0 A 38.0 A 33.0 A

Assure you have the proper receptacle installed before plugging to oven into power.

If the correct receptacle is not available for your oven’s power conguration, have a

licensed electrician install the proper receptacle to match that of your oven; NEMA

10-50P for single Phase or L15-30R for 3-Phase.

6

CONTROL PANEL

⚠ WARNING THE OVEN AND ITS PARTS ARE HOT. USE CARE WHEN

OPERATING, CLEANING OR SERVICING THE OVEN.

CONTROLS (Fig. 3)

FAN SPEED CONTROL —

Adjusts air velocity in the oven. Turn the

dial to adjust the fan speed and increase

or decrease the air circulation inside the

oven chamber. Begin with a setting of 8

and adjust accordingly to achieve your

desired production results.

ON LIGHT (Amber) —

Lit when Master Switch or Oven Cool

Switch is positioned at ON.

OVER HEAT —

Comes on when the oven temperature

reaches 480°F. Oven will automatically

shut down and go into a cool down phase.

Oven will come back on after it stabilizes

to normal operating temperatures.

THERMOSTAT —

Controls oven temperature during cooking

operation.

TIMER —

Use to set heating cycle time. Timer range

is 0 to 99 minutes 59 seconds. Alarm

sounds continuously when elapsed time

counts down to 0; oven does not turn off.

TIMER RESET —

To turn the timer off, press the timer reset

switch

POWER

BUTTON

FAN

SPEED

CONTROL

TEMP.

CONTROL

TIMER

START

TIMER

RESET

OVER

HEAT

COOLING

FAN

Fig. 3

7

PREPARATION

BEFORE FIRST USE

Before using the oven for the rst time, it must be “burned in” to release any odors

that might result from heating the new surfaces in the chamber.

1. Using a clean damp cloth, wipe the inside of the oven, including the racks.

2. Close the oven doors, turn the Master Switch to ON, set the Thermostat to

300°F (149°C) and allow the oven to cycle for 6 to 8 hours before turning the

Power Switch to OFF.

USING THE HIX SUBLIPRO-CT OVEN

Getting Started

Sublimation printing is an indirect process which requires a printer capable of running

sublimation ink, a computer with the appropriate printer drivers, and a heat source.

As a heat source for textile or at non-textile products, use almost any of our small

format presses (visit www.hixgraphics.com for details). Presses come in small sizes

starting at 9 x 12”, 15 x 15”, 16 x 20”, and in mid-size of 20 x 25”.

For sublimation on 3D-substrates, our Mug Wraps in combination with a SubliPro

sublimation oven are particularly well designed to do the job. Whether using a

press or a Sublimation oven with Mug wraps, three variables are particularly

important: adequate sublimation dwell time, equal and sufcient pressure, equal

heat distribution at the appropriate temperature. Trust only equipment that provide

all 3 parameters in a controllable and uniform way. HIX equipment is designed to

provide these parameters within very narrow tolerances, which is critical for success.

Controllable time and temperature, properly and evenly distributed pressure and

temperature are built in to all our product and are the reason for their generational

popularity.

If the oven reaches 475°F, the display will show “OVERHEAT” to indicate the

maximum temperature has been exceeded. If the temperature continues to climb

to 480°F, the oven will automatically shut down and go into a cool down phase to

protect the oven, its components, and the environment surrounding the oven. Once

the temperature of the oven has stabilized to normal operating conditions, the power

can be turned back on by resetting the Power Button to its “ON” state.

8

HOME SCREEN

1. Turn on the machine by pressing in the POWER BUTTON

Startup/Splash screen is displayed as the controller boots up.

Note: The current program number and the software revision of the control-

ler are displayed at startup. (The default settings are program number

P 19 software revision RV 1.0)

After boot up, the home screen is displayed showing the current heat platen

temperature and set cycle time. The heat indicating lamp is represented

by the snowake in the upper left corner of the display. The heat indicating

lamp will display anytime the heating element is heating and will cycle on

and off after the set temperature is reached to maintain set temperature.

Startup/Splash Screen

MACHINE PRESET

BUTTONS

ACCESS

SETTINGS MENU

TEMPERATURE

READOUT/SETTING

HEAT INDICATING

LAMP

TIME

READOUT/SETTING TIME SCALE

HOME MENU SCREEN

9

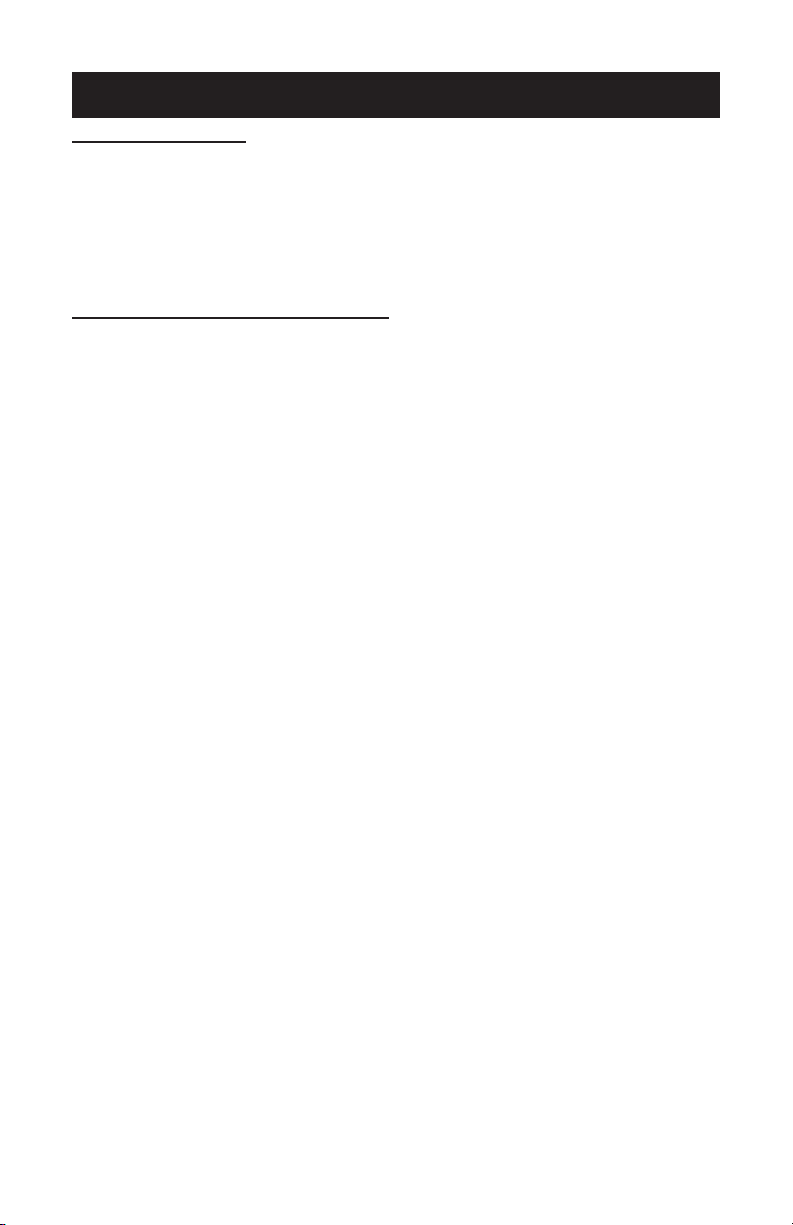

TIME & TEMP. ADJUSTMENT

ADJUST TEMPERATURE:

1. Touch the temperature readout on the display. “UP” ▲ and “DOWN” ▼

arrows will appear on the right side of the display and the temperature

value will start ashing and to indicate it is in set mode.

2. Press the “UP” ▲ or “DOWN” ▼ arrow to change the temperature value.

Holding down on an arrow will change the temperature in 1 degree incre-

ments for 10 values; then change to 10 degrees incremental changes.

3. Once the desired temperature value is set, either press the temperature

value to lock the set temperature or simply wait for 2 seconds and it

will lock in the new value automatically.

4. Once the machine reaches the temperature of the set value (between

0-9) the controller will “beep” signaling that the machine is ready to use.

ADJUST CYCLE TIME:

1. Touch the time readout on the display. “UP” ▲ and “DOWN” ▼ arrows

will appear on the right side of the display and the cycle time value will

start ashing and to indicate it is in set mode.

2. Press the “UP” ▲ or “DOWN” ▼ arrow to change the cycle time value.

Holding down on an arrow will change the time in 1 second increments

for 5 values; then change to 10 seconds incremental changes.

3. Once the desired cycle time value is set, either press the time readout

to lock the cycle time or simply wait for 2 seconds and it will lock in the

new value automatically.

TIME ADJUSTMENT SCREEN

UP ARROW

DOWN ARROW

TIME

READOUT/SETTING

TEMPERATURE ADJUSTMENT SCREEN

TEMPERATURE

READOUT/SETTING

UP ARROW

DOWN ARROW

10

SETTINGS

SETTINGS:

1. Press the “?” on the upper right corner of the display on the Home

Menu Screen to access the settings menu.

2. Press the settings sub menu title to be adjusted.

SHUTDOWN TIMEOUT

The shutdown feature shuts off the heat to the press after a period of in-

activity.

NOTE: The factory default is set at 3.0 hours.

1. From the settings menu press the “Shutdown Timeout” sub menu title.

2. Press the “UP” ▲ and/or “DOWN” ▼ arrows to set the desired shut-

down time.

NOTE: Shutdown time adjusts in 1/2 hour intervals. Press the “Down” ▼

button until “Disable” is displayed will deactivate this setting.

3. Press “Save” to save the setting.

4. Press “Back” to return to the previous screen.

NOTE: After the shutdown time has elapsed with the press idle, the heating

element will stop cycling to maintain the set temperature and the

home screen will display “SHUTDOWN.” Touching the display or

closing the press will take the machine out of shutdown mode.

SETTINGS MENU SCREEN

RETURN TO

PREVIOUS

SCREEN

ADJUST SHUTDOWN TIMEOUT

SETTING

SET QUANTITY OF PRESETS

DISPLAYED

VIEW/RESET CYCLE COUNT

SET TIME SCALE PREFERENCE

SHUTDOWN TIMEOUT ADJUSTMENT SCREEN

UP ARROW

DOWN ARROW

SHUTDOWN TIMEOUT

SETTING

SAVE SETTINGS RETURN TO PREVIOUS SCREEN

11

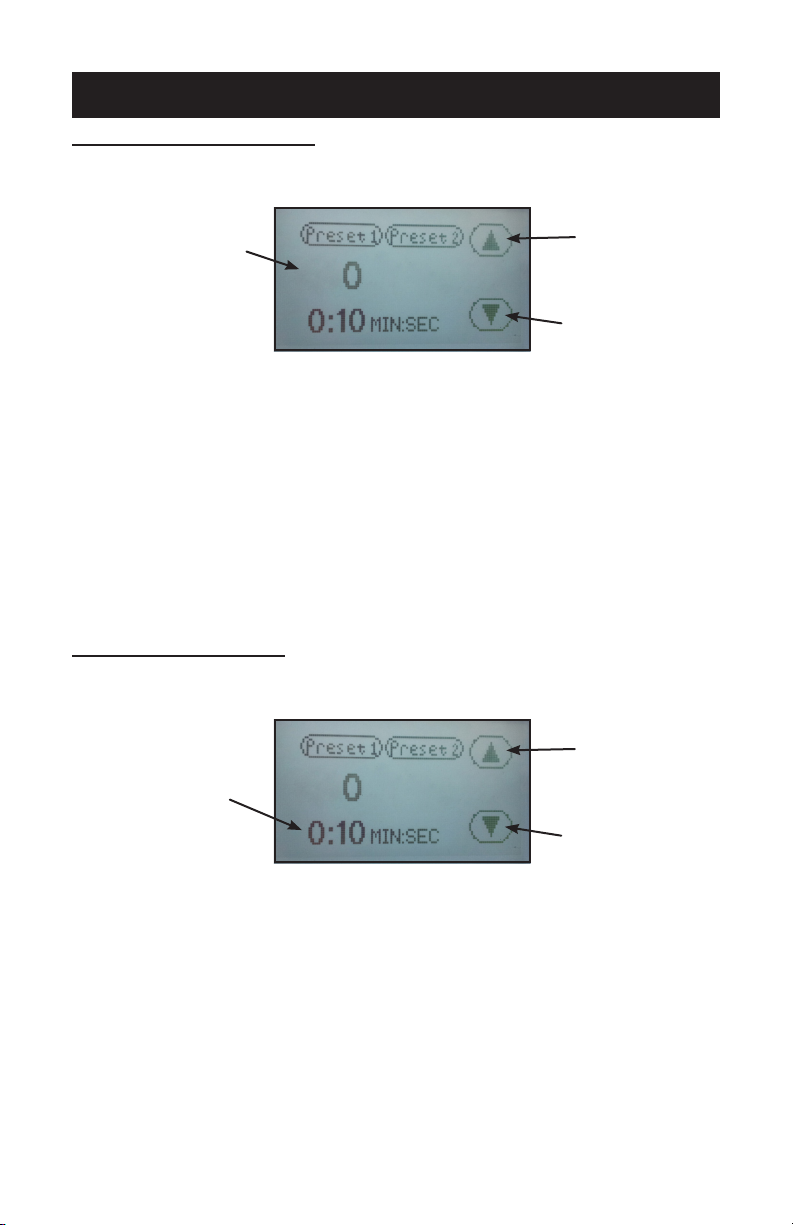

PRESET SETTINGS

PRESET QUANTITY

Temperature presets can be stored in the memory for different trans-

fer settings. By default two presets are displayed. This setting can be

adjusted to display four presets.

1. From the settings menu press the “Preset Quantity” sub menu title.

2. Press the number of presets to be displayed on the home screen, either

“Two Presets” or “Four Presets.”

3. Press “Save” to save the setting.

4. Press “Back” to return to the previous screen.

TWO PRESETS

DISPLAYED

FOUR PRESETS

DISPLAYED

SAVE SETTINGS RETURN TO PREVIOUS SCREEN

PRESET QUANTITY DISPLAYED PREFERENCE SCREEN

TWO PRESET DISPLAY

ON HOME MENU SCREEN

FOUR PRESET DISPLAY

ON HOME MENU SCREEN

12

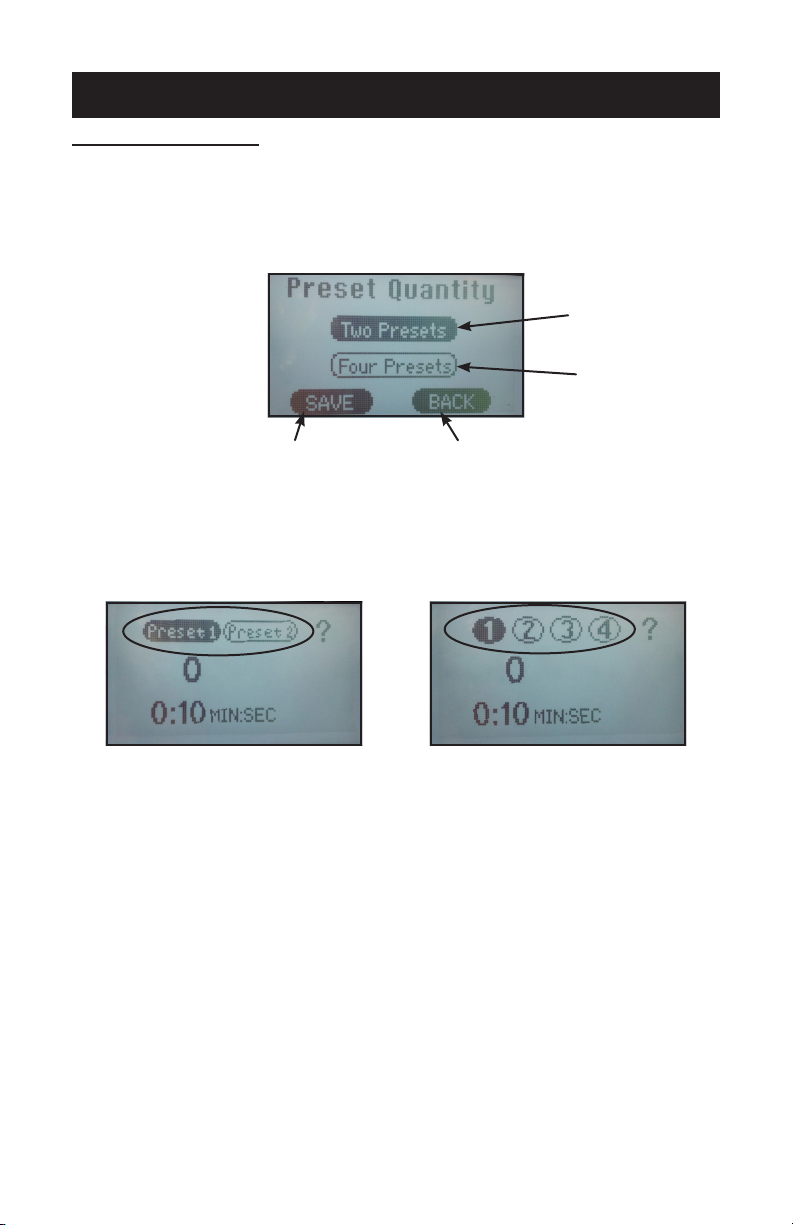

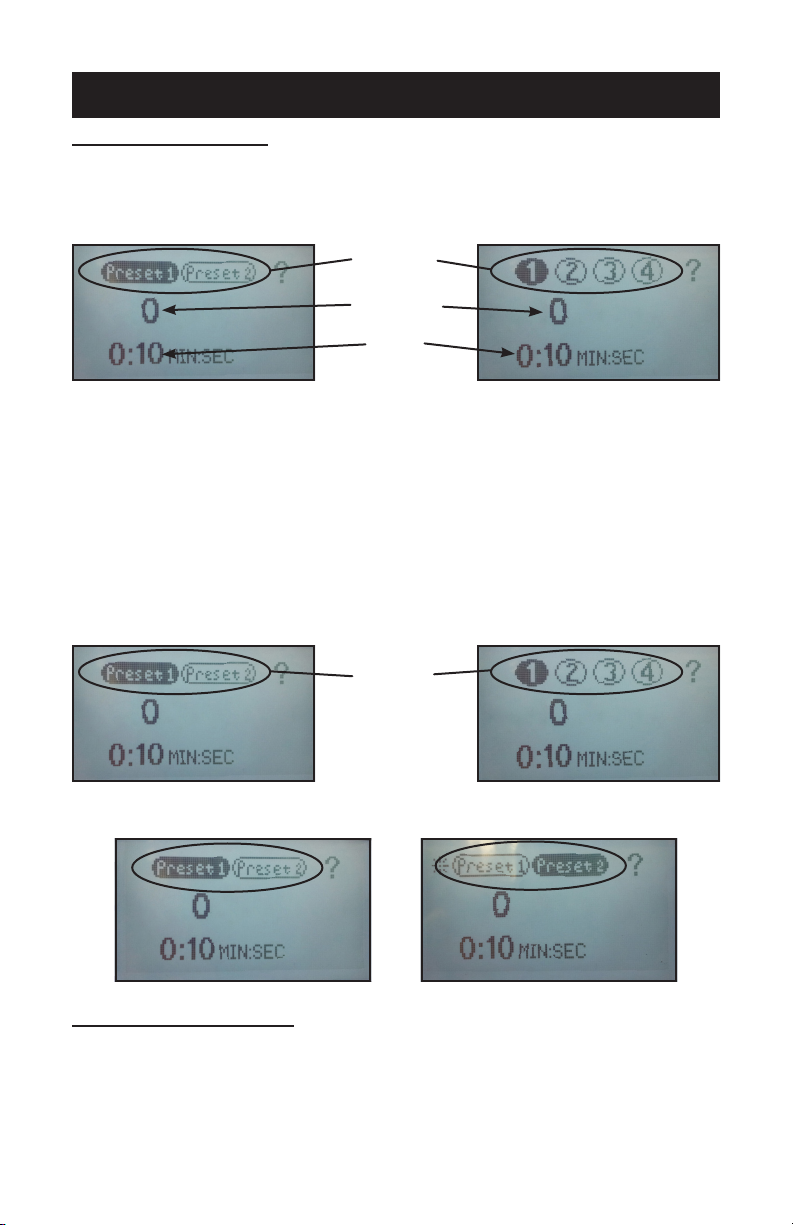

PRESET STORAGE

STORING PRESETS:

NOTE: The factory default settings for all presets is set to 200°F and 10

seconds.

1. Set the desired temperature and/or cycle time using the temperature

and time adjustment instructions in this document.

2. Immediately upon changing the time or temperature with the up and

down buttons, press the new temperature or time readout again until

the controller beeps once. Then press and hold the desired preset

location for two seconds. The controller will beep twice and the preset

button will display in reverse indicating the preset is stored in memory.

NOTE: Always refer to specic transfer recommendations for temperature,

time and pressure as instructed by the transfer manufacturer.

RECALLING PRESETS:

1. Press and release for approximately 1/2 second the preset button to

recall. The controller will beep and the preset location button will display

in reverse indicating the preset has been changed.

NOTE: The new set values will display for 1 second before the controller

starts adjusting the temperature or time to match the new setpoint.

PRESET

LOCATIONS

TEMPERATURE

SETTING

TIME

SETTING

HOME MENU SCREEN

PRESET 1 SELECTED

(two preset setting shown)

PRESET 2 SELECTED

(two preset setting shown)

PRESET

LOCATIONS

(press 1/2 second

to recall)

13

CYCLE COUNT

CYCLE COUNT

The cycle count feature counts the number of cycles that the machine

has undergone. A cycle is counted every time the countdown timer is

activated by closing the press.

NOTE: The cycle count will maintain the total count even if the power has

been turned off.

TO RESET THE COUNTER:

1. From the settings menu press the “Cycle Count” sub menu title.

2. Press “Reset.”

3. Press “Back” to return to the previous screen.

CYCLE COUNT/CYCLE COUNT RESET SCREEN

CYCLE COUNT

RESET TO ZERO RETURN TO PREVIOUS SCREEN

14

PREFERENCES

TIME SCALE

The time scale setting adjusts how the time is displayed on the home

screen. There are three Time Scale display options available in the

Time Scale menu:

• MIN:SEC (Factory Default)

• SEC (Seconds)

• 1/10 SEC (1/10 Second Resolution)

TO CHANGE THE SCALE:

1. From the settings menu press the “Time Scale” sub menu title.

2. Press the “UP” ▲ and/or “DOWN” ▼ arrows to select the preferred

time scale.

3. Press “Save” to save the setting.

4. Press “Back” to return to the previous screen.

TIME MODE PREFERENCE SCREEN

TIME SCALE

PREFERENCE

SAVE SETTINGS RETURN TO PREVIOUS SCREEN

UP ARROW

DOWN ARROW

15

OPERATION

Preheating

1. Turn Master Switch to ON. Amber ON light will come on, indicating that power

to the oven is on. The oven will need approximately 15 minutes to reach a

sufcient sublimating temperature.

2. Set Thermostat as desired. Refer to SUGGESTED SUBLIMATION GUIDELINES

for temperatures and times for various substrates. As a general guideline, HIX’s

in-house testing on standard 11/15 oz white ceramic mugs use a setting of:

• TIME: 13 - 15 minutes

• TEMP: 395ºF

• AIR CIRCULATION: High fan setting

NOTE: These settings are based upon in-house testing and are a starting point.

These settings may vary depending on a number of factors.

There are many variables involved in sublimation such as the size, shape

and type of coating of the substrate which affects the sublimation process.

Other variables such as different brands of sublimation printers, inks and

paper all require a certain amount of trial and error.

3. Prepare the substrates with transfers and wraps. When white HEAT light goes

off, oven has reached desired preheat temperature.

Sublimating

1. Open doors and load the substrates into the oven. Place on racks with the open

side of the substrate facing down. Close doors.

2. Set the Timer. After the preset time lapses, turn timer to OFF position to stop

alarm.

3. When sublimation is done, open doors and carefully remove sublimated product

from the oven.

End of Day

1. Turn OFF the oven power and open the door for approximately ve minutes to

allow the oven chamber to vent heat.

2. Turn Oven Cool switch to ON. Leave door ajar while the fan is on to cool the

oven.

3. When the oven has cooled sufciently, push the Master Switch and Oven Cool

Switch to the OFF position and clean the oven.

OPERATING HINTS

When using the SubliPro-Ct oven for the rst time with a new substrate, check

the sublimation quality before sublimating a batch of products to make sure the

sublimation results meet your quality standards.

Record your temperature and time settings for various products. The SubliPro-Ct

oven can provide consistent, repeatable results.

16

CLEANING & MAINTENANCE

CLEANING

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

Clean outside of the oven daily by wiping with a clean damp cloth.

Clean oven interior daily with soap or detergent and water. Rinse thoroughly and

wipe dry with a soft clean cloth.

For “heat tint” (slightly darkened areas caused by oxidation) which resist simple soap

and water cleaning, an abrasive cleanser (scouring powder) mixed into a paste may

be used. Apply with stainless steel wool or sponge, always rubbing with the “grain.”

MAINTENANCE

The oven and its parts are hot. Use care when operating, cleaning or servicing the

oven.

Disconnect the electrical power to the machine and follow lockout / tagout procedures.

LUBRICATION

The fan motor comes with sealed bearings and requires no lubrication.

The door hinges and mechanism require occasional lubrication with mineral oil.

SERVICE AND PARTS INFORMATION

To obtain service and parts information concerning this model, contact the HIX

Customer Service Department.

When calling for service, the following information must be available: model number,

serial number, manufacture date (MD) and voltage

17

HIX MUG WRAPS

Why use HIX 2-Step Mug Wraps?

Sublimating is a “Snap” with HIX 2-Step Wraps!

For sublimation to occur, a dye needs to be heated in order to sublimate into a gas.

Pressure is needed to create a proper contact with the substrate and to ensure a

detailed denition of the nal image.

Traditional mug presses combine both compression and heating in one device.

The advantage of the HIX Mug Wrap is that it separates these two actions: the

wrap provides the pressure, while your Countertop SubliPro Oven provides the

heat. This provides greater reliability than traditional mug presses and reduced

maintenance costs.

Our wraps provide a quick snap-on solution. Simply position and tape your artwork

to virtually any type of drinking vessel. Then, wrap the substrate and artwork with

the tting HIX Wrap. That’s it! You are ready to sublimate!!

The advantage of the HIX Wrap is its patented tool-less 2-step clasping technology.

No other mug wrap on the market is as easy to apply or remove. There’s no fumbling

with awkward closing mechanism or wrenches, and no need for extra hands when

you’re trying to juggle endless adjustments while closing a clamp with screwdrivers

or other tools.HIX Wraps open and close with a simple “snap.”

The HIX Wrap has two settings: a rst for substrates with handle, a second for

substrates without. The rst setting is used for traditional 11oz and 15oz mugs and

provide a near 360 degree enclosure of the mug. The second setting is used for

substrates without handle and provides a complete 360 degree wrapping.

The 2-step clasp can be closed to the rst “snap” for the substrates with handle,

and to the second “snap” for substrates without handle.

Substrates, artwork and wraps are now ready to be sublimated in your Countertop

SubliPro oven!

Wrap Styles

HIX 2-stepWraps can come in as many sizes and shapes as there are substrates in

the market. For the standard straight 11oz and 15oz white mugs, HIX has a standard

wrap which is readily available as part of its standard product stock. Similarly,

standard dog bowl wraps are also available from regular stock. Any standard Mug

Wrap may be purchased in bundles of a minimum of 10 units.

Custom HIX Mug Wraps

An ever-growing variety of containers, vessels, mugs, cups, bottles and glasses

are creating a rise in demand for Wraps to match.

HIX custom designs unique custom Mug Wraps for each shape and size substrate,

whether straight or slanted. Check us at www.hixgraphics.com or your local HIX

distributor for details.

18

USING HIX MUG WRAPS

⚠ CAUTION: MUG(S) and MUG WRAP(S) ARE HOT AFTER HEATING. AL-

WAYS WEAR PROTECTIVE GLOVE OR OVEN MITTS. KEEPS

CHILDREN AWAY FROM HOT/SHARP MATERIALS.

1. TRIM TRANSFER: Before applying, trim the transfer so that there is no excess

paper above or below the mug.

TIP: Trim the top of the transfer with a

straight edge; this will assist you in

lining the transfer up with the top of

the mug to help eliminate crooked

transfers.

2. APPLY TRANSFER: Secure the ends of your transfer to the mug using heat tape.

3. WRAP MUG: Lay mug wrap at on the table, position mug in the center of wrap.

With one hand, hold the handle against the “loop end” of the wrap at the point where

the silicone rubber wraps around the round bar. With your other hand, grasp the

“hook end” of the mug wrap, and wrap the silicone rubber around the mug. Insert

the bent up portion of the “hook end” into the rectangular opening on the “loop

end.” With both hands, squeeze the two halves of the mug wrap together until it

locks together. You will hear a ‘snap’ sound when the “hook end” is fully inserted

into the “loop end”.

4. PLACE IN OVEN: Make sure oven is set per transfer/ink manufactures specied

temperature usually 375° – 400°F for sublimation. Place your wrapped mugs in the

oven top down, this will allow heat to be trapped inside of the mug, improving transfer

quality. Space each mug at least 2 inches apart; 2” spacing allows for maximum

airow between mugs and more even heating of the entire mug.

19

USING HIX MUG WRAPS

5. REMOVE AND COOL:

NOTE: If you are not using a HIX Mug Oven with a Cooler then you will need to

wear heat protective gloves to handle the nished wraps and mugs.

Tip: Position any excess wrap forwards the

bottom of the mug. This will allow the

mug to sit more securely in the oven.

Remove mug from oven with heat protective gloves. Place thumbs against the

bottom lip of the “loop end” while placing index ngers against the top edge of the

“hook end.” With one motion, press thumbs up and index ngers down. This will

release the mug from the wrap. Pull the heat tape from the tabbed end and imme-

diately remove transfer with one continuous motion. If not using an in line cooler,

place mug in room temperature water to cool mug and stop sublimation process.

⚠ CAUTION: Wrap will be hot. Use care when applying wrap to another mug. Do

not re-use wrap when hot, let cool.

20

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

Web site: www.hixcorp.com • Phone: (800) 835-0606 • Fax: 620-231-1598

©2020 HIX Corp.

Design and Manufacturers of Graphic Imaging, Commercial Food, Industrial and Custom Drying Equipment

WARRANTY

(Effective 3/1/2020)

HIX will automatically register the equipment on the date it was shipped to you or your distributor. If the

equipment was not purchased directly from HIX, but through a distributor (either domestic or foreign), please

keep a copy of their sales invoice showing the serial number and date it was sold/shipped to you with this war-

ranty. In this case, we will use the distributor’s invoice date as the beginning warranty date. STAPLE A COPY

OF YOUR PROOF OF PURCHASE TO THIS WARRANTY and keep in a safe place to provide verication of

your warranty should a problem occur. Thank you.

Please ll in the following information and attach a copy of your receipt for your records.

Date Purchased: From:

Model #: Serial #:

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pittsburg, Kansas, U.S.A.

HIX warrants to the original purchaser, its Ovens and Dryers, Heat Transfer Machines, Textile Printers, Spot

Heaters, and Exposure Units against defects in workmanship and material, except for wear and tear for a

period of “One Year” from the date of purchase. HIX warrants Accessories for a period of 90 days from the

date of purchase. doughXpress products are covered under separate warranty.

In the event of a defect, HIX, at its option, will repair, replace or substitute the defective item at no cost

during this warranty period subject to the limitations of insurance and shipping costs stated below (excludes

labor).

In the case of heat transfer presses (except the Hobby Lite and Large Format presses), HIX warrants the

heat casting for the “Life” of the machine for the original purchaser. If a part becomes obsolete at the time

for repair, and/or cannot be reasonably substituted for, HIX will credit, at half the then current list price or last

recorded price, only that part toward a new machine or any product HIX offers. This credit offer shall be the

sole responsibility of the HIX Corporation in the event of an obsolete part.

This warranty does not cover belts, rail tape, pads, mug wraps, canvas, rubber blankets, bulbs, glass.

Warranty does not cover damages due to accident, misuse/abuse, alterations or damage due to neglect, ship-

ping or lack of proper lubrication or maintenance. HIX shall not be responsible for repairs or alterations made

by any person without the prior written authorization by HIX. This warranty is the sole and exclusive warranty

of HIX and no person, agent, distributor, or dealer of HIX is authorized to change, amend or modify the terms

set forth herein, in whole or in part.

In the case of a problem with the equipment identied herein, HIX Corporation should be contacted during

regular business hours to discuss the problem and verify an existing warranty. HIX personnel will assist the

customer to correct any problems which can be corrected through operation or maintenance instructions,

simple mechanical adjustments, or replacement of parts. In the event the problem cannot be corrected by

phone, and upon the issuance of a return authorization by HIX, the equipment shall be returned to HIX or an

authorized service representative. All insurance, packaging and shipment/freight costs are solely the respon-

sibility of the customer, and not that of HIX, and HIX shall not be responsible for improper packaging, handling

or damage in transit. Contact HIX customer service for complete return authorization information. Correct

shipping boxes are available from HIX.

This expressed warranty is given in lieu of any and all other warranties, whether expressed or implied,

including but not limited to those of merchantability and tness for a particular purpose, and constitutes the

only warranty made by HIX Corporation.

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to repair or replace the

nonconforming goods. HIX shall not be liable for any other damages, either incidental or consequential, or the

action as brought in contract, negligence or otherwise.

This warranty gives you specic legal rights and you may also have other rights which vary from state to

state.

Table of contents

Other Hix Oven manuals

Popular Oven manuals by other brands

Jenn-Air

Jenn-Air W132B Use & care guide

Whirlpool

Whirlpool AKZM 835 User and maintenance manual

GE

GE JKP35DPBB Dimensions and installation information

SEVERIN

SEVERIN TOASTOFEN MIT UMLUFT TO 2035 Instructions for use

Siemens

Siemens HB24D555W instruction manual

Samsung

Samsung NV70K1340BS/EF User & installation manual