Hix SubliPro User manual

Initial setup / installation ............................................................................2-7

Time & Temperature Control......................................................................... 8

Operation...................................................................................................... 9

Using Hix Sublimation Wraps................................................................ 10-11

Maintenance............................................................................................... 14

Notes for Substrates................................................................................... 15

Warranty ..................................................................................................... 16

SubliPro

Sublimation Mug Oven with Cooler

OWNER’S MANUAL

BEFORE warranty repair you MUST get Prior Authorization:

For Customer Service, Call 1-800-835-0606

or Visit www.hixcorp.com

70138 RV J_120220

SubliPro-4827

SubliPro-2414

CONTENTS

2

INITIAL SETUP / INSTALLATION

INSTALLATION AND SET UP INSTRUCTIONS

1. Leg Assembly

A) Remove four nuts on inside of dryer frame that secures the dryer

to crate bottom.

B) Raise dryer from crate bottom with forklift to allow access to four

corner posts.

C) Insert legs to paint line.

D) Secure each leg bolt, lower forklift to allow dryer to rest on legs.

2. Top Exhaust Blower Motor

A) Secure housing to dryer top using provided #14 x 1/2” HEX head

tap screws with #14 Star Washer.

B) Attachblackwirestoexconduittancoloredwiresusingorange

wire nuts. Polarity is not important.

3. Bottom Blower Motor

A) Secure to bottom of dryer using 4 Greer lock nuts. Align point of

arrow in motor plate to point of arrow on bottom of dryer.

B) Match wire numbers of blower motor to ex conduit tan colored

wires using orange wire nuts. Polarity is not important. Also attach

the two green ground wires together.

4. Duct Work

A) Run duct from the exhaust stack on the dryer to the outside of

building. Install a rain cap to prevent water damage to the dryer.

Maximum duct length 30 feet ( 9 meters) from dryer to where it ex-

ists the building. If longer duct runs are required a booster fan must

be installed.

5. Extensions

A) If the oven is shipped to you crated, remove the extension and

cooler section from the crate and mount to the oven body.

B) Plug the gear motor and encoder plugs into their respective recep-

tacles on the exit end of the oven.

6. Conveyor Belt

A) Refer to the separate instructions supplied with the wire belt to

show the proper installation and splicing of the wire belt ends back

together.

3

INITIAL SETUP / INSTALLATION

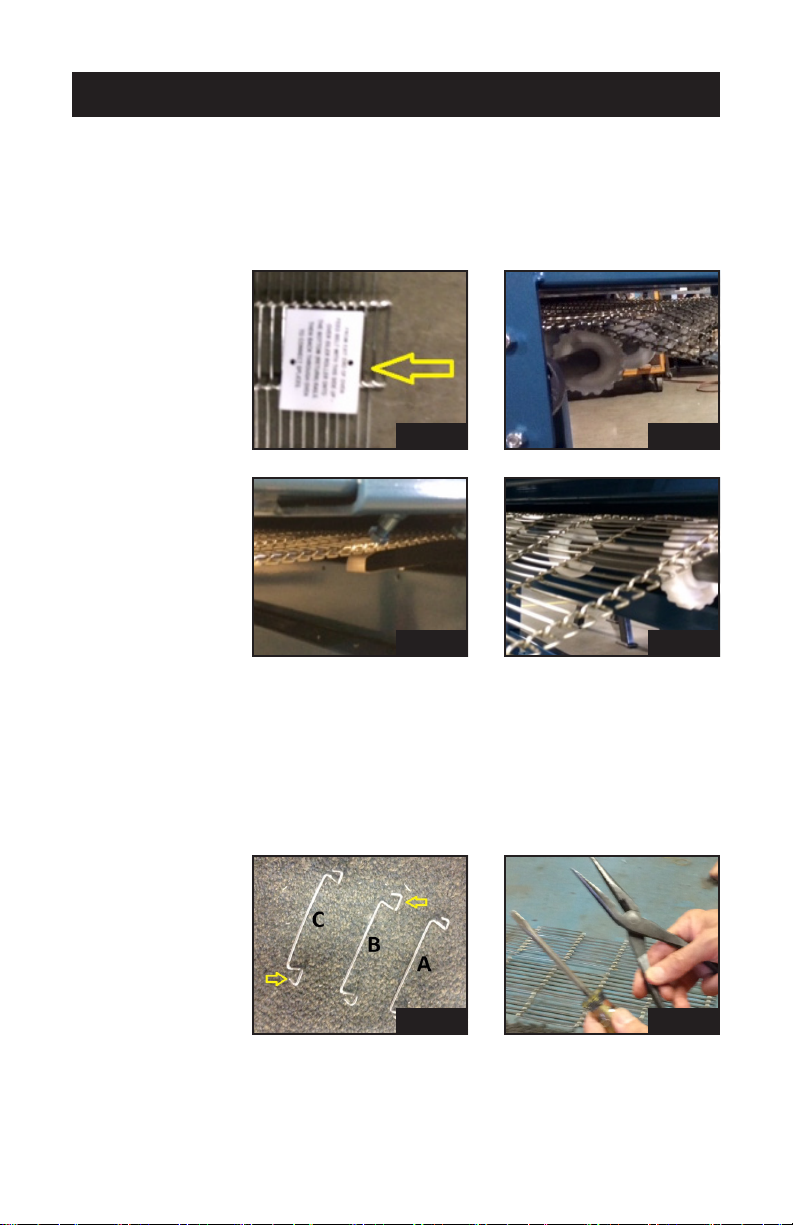

1. Both the oven and cooler crates have du-

plex nails (pic 1) on all four sides which

need to be removed. This allows the top

to be removed at one time (either with

four people or by using a fork lift).

2. The oven section has two 3/8-16 hex

nuts directly under the door openings

(pic 2), which need to be removed.

3. Next, position the forks of the forklift

completely under the side frame rail (pic

3) until they protrude at the other end, ca-

pable of picking up the entire main body

of the oven. Once positioned and well

centered, lift the oven body up and off

the crate base.

4. Remove the legs from the bottom of the

crate and bolt them in the frame holes

(pic 4).

5. The bottom blower motor attaches with

four 3/8” NC locknuts (pic 5a) located in

a packet inside the control box.

pic 1

pic 1

pic 1

pic 1

pic 1

4

INITIAL SETUP / INSTALLATION

Red/white arrow decals should point toward each other when the con-

gurationiscorrect(pic5b).Similarlynumberedwiresconnecttogeth-

er with the orange wire nuts (also in pack)(pic 5c).

6. The exhaust fan assembly attaches to the top with ten #14 x ½” hex

head tap screws. (pic 6a). The wires to the assembly are not num-

bered and can be fastened either way with the orange wire nuts.

7. The cooler section has four 3/8” headed

lag screws to be removed before lifting

the unit off the crate base.

8. The 2414 model has only one set of legs (pic 8a) with angle iron tabs

on the exit side only. The entry side has arm extensions only (pic 8b).

Fasten the two sections together with the 3/8-16 x 1” bolts already in

the tabs.

pic 1

pic 1

pic 1

pic 1

pic 1

pic 1

pic 1

5

INITIAL SETUP / INSTALLATION

9. The 3626 model has two sets of legs on the exit side, both self-sup-

porting once installed. The 4827 model has 3 sets of self-supporting

legs.

The telescope tubing (pic 9a) slides into the oven frame until it hits the

metal stops (pic 9b and c). Next, tighten the four 9/16” headed bolts to

secure them together (pic 9d).

10. Insert the gear box quick-connectors into

the handy box, located under the oven’s

fume hood at the exit side. One connects

with a twist lock, the other with a snap

lock (pic 10).

11. The cooler unit’s wires are numbered to

match up with the wires in the electrical

handy box. Remove handy box cover,

run the wires and ex conduit into the

90˚ Romex connector and tighten the

screws. Tie the similarly numbered wires

together with orange wire nuts (pic 11).

Then replace the handy box cover.

pic 1

pic 1

pic 1

pic 1

pic 1

pic 1

6

INITIAL SETUP / INSTALLATION

12. To install the belt, place the rolled up belt under the cooler section on

theoor.Thebelt’sfrontis marked(pic 12a).Startfeeding thebelt

throughtheovenbyguidingitrstovertheidlerpulley(s)attheexit

side, then over the bottom rails (pic 12b, c). When arrived at the front

end of the oven, loop the belt up and back through the oven, all the

way back to the exit end.

13. At the exit end, connect the two ends of the belt together with the pro-

vided belt splices. The splices are taped onto the belts edge. An extra

set is in the envelope with the belt.

Attention: there are 3 types of splices (pic 13a): one for the left end

(B), one for the right end (C) - both with one large and one small hook -

and one type for all center splices (A). The larger hook (yellow arrows)

is to be positioned on the outside edge of the belt.

pic 1

pic 1

pic 1

pic 1

pic 1

pic 1

7

INITIAL SETUP / INSTALLATION

Usingneedle-nosepliersandatheadscrewdriverworksbestwhen

weaving the link splices together (pic 13b, c and d).

14. When hooking up the electric connection to the main rotary switch,

be sure the wire connection is tight (pic 14a and b). Rotary switches

fail when this connection is no longer secure. Check periodically for

tightness.

pic 1

pic 1

pic 1

pic 1

8

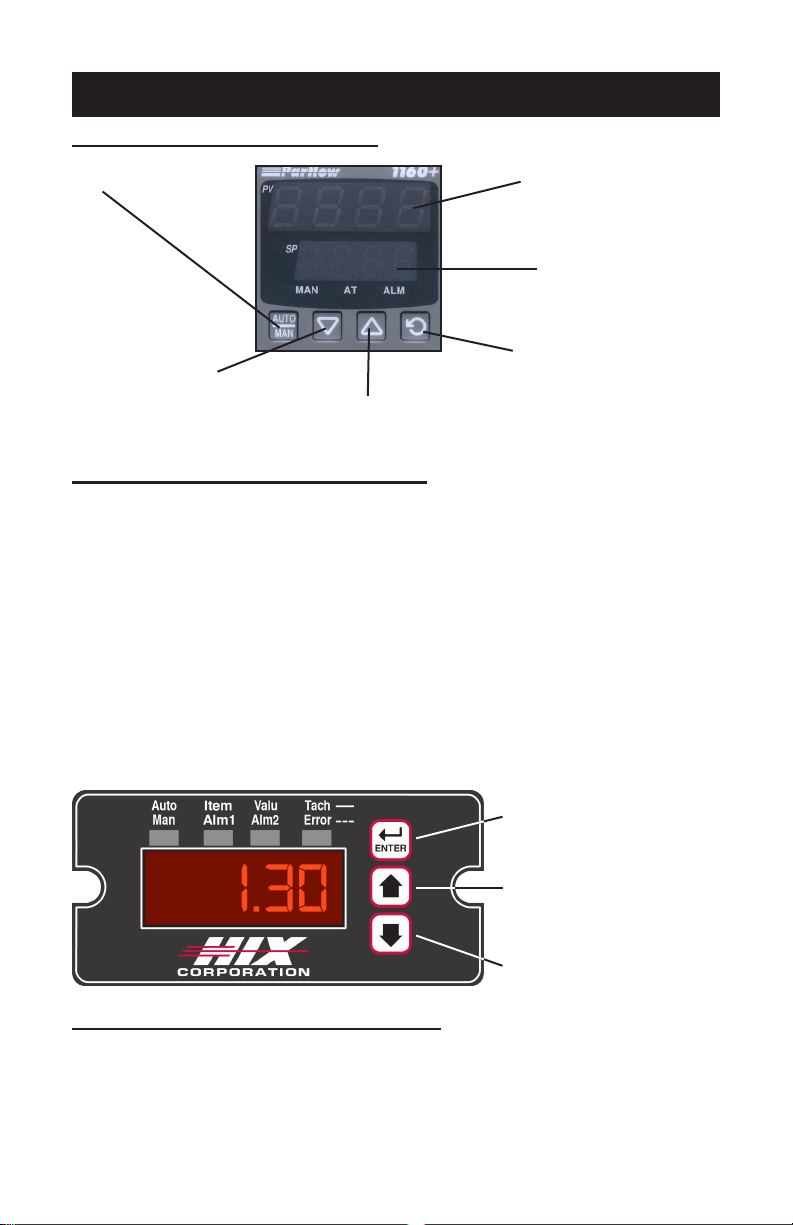

PROCESS TIME CONTROLLER

1. Controls belt speed and maintains a constant speed by monitor-

ing the motor RPM via a Hall-effect Sensor attached to the motor

shaft. Not effected by varying belt loads.

2. Displays process time in Minutes and Seconds.

Examples: 1.30 = 1 minute, 30 seconds

1.59 = 1 minute, 59 seconds

3. When the oven is turned off, the controller will remember the last

setting. Resetting the controller is not necessary each time the

dryer is turned on.

4. Function buttons detailed below:

RECIRCULATING AIR CONTROL

The dryer is equipped with a very effective top delivery/bottom recovery

variableowairrecirculatingsystem.Onezoneisprovidedonmodels

24”and36”beltmodels.Twozonesareprovidedon48”models.

TIME & TEMPERATURE CONTROL

TEMPERATURE CONTROL

Not functional.

Will decrease

setpoint (SP) when

“SP” is displayed.

Will increase setpoint (SP)

when “SP” is displayed.

Pressing this function button

once will allow “SP” to be

displayed enabling the opera-

tor to change the setpoint by

pressing the “up” and “down”

buttons located below. Press-

ing once again will return the

displays to their normal mode.

Lower display shows set-

point temperature.

Upper display shows cur-

rent value of process (oven)

temperature.

Nonfunctional

(factory only)

Decreases process time

(increases belt speed)

Increases process time

(slows belt speed)

9

OPERATION

OVEN OPERATION

General Oven operation for applying sublimation transfers to mugs, cups

and ceramic items. This information is for reference only and actual set-

tingswillvarydependingonimagequality,imagesize,thesizeofmugor

ceramic item, and quality of coating on item, ink and type of wrap being

used. It is very important that your dryer electric source is supplied with

the maximum voltage required; 240v ± 5v.

Your dryer may not operate to full potential if running below 235v. Electric

power does vary. Many power companies simply can not deliver consis-

tent power at ratings also power supply consumed in your grid by other

companies can cause intermittent and inconsistent power. Your power

company or electrician can assess your particular power supply.

TYPICAL TEMPERATURE SETTING:

370°-410°F

BELT SPEED.

Isdependentonimagesize,qualityofgraphicandsizetypeofink,paper

used and weight of object imaged. A general starting place is 11-13 min-

utes.

Typical Times with HIX Mug Wrap (Other wraps may take longer)

11ozMug………10-13minutes

15ozMug………11-18minutes

AIR SPEED

6-8 on dial.

OVEN SETUP AND SPACING;

Establishspacingbyrstusingscraporblankmugswithwrapandblank

paper (bond paper will work). If your oven does not maintain consistent

temperature (± 30°F) slow your oven down and/or increase spacing. Gen-

erally, running oven hotter will not help. In fact, items may get too hot and

scorch the image closest to the heater. Begin with items spaced at least

2” apart and 2” from side of dryer. Thicker/larger/heavier items will require

greater spacing.

APPLYING THE TRANSFER

With some wraps including the HIX tool-less “Snap” clasp wrap, you will

be able to image virtually top to bottom and handle to handle. While full top

to bottom and handle to handle imaging is possible it is not recommended

untilyouhavearmunderstandingandexperiencewithimagingmugs.

To achieve consistent results and reduce waste keep your transfer width

limited to 3/16” from the top rim and the bottom taper of the mug and at

10

USING HIX SUBLIMATION WRAPS

a) Hold the “loop end” of the mug wrap

in your hand.

b) Hold the mug with the handle

pressed against the “loop end” at

the point where the silicone rubber

wraps around the round bar.

c) With your other hand, grasp the

“hook end” of the mug wrap, and

wrap the silicone rubber around the

mug.

d) Insert the bent

up portion of

the “hook end”

into the rect-

angular open-

ing on the

“loop end.”

e) With both hands, squeeze the two

halves of the mug wrap together un-

til it locks together. You will hear a

‘snap’ sound

when the

“hook end”

is fully in-

serted into

the “loop

end”.

least a ¼” away from the handle you should see consistent quality. As you

become more experienced there are tips and tricks that will make full wrap

imaging more successful; not fool proof but more consistent results can be

achieved with proper preparation of the transfer. Also quality mugs must

be purchased, while a mug wrap helps to cover some imperfections in the

mug itself, nothing can help a poorly made, wavy or irregular surface and/

or coated mug.

TO USE YOUR WRAP

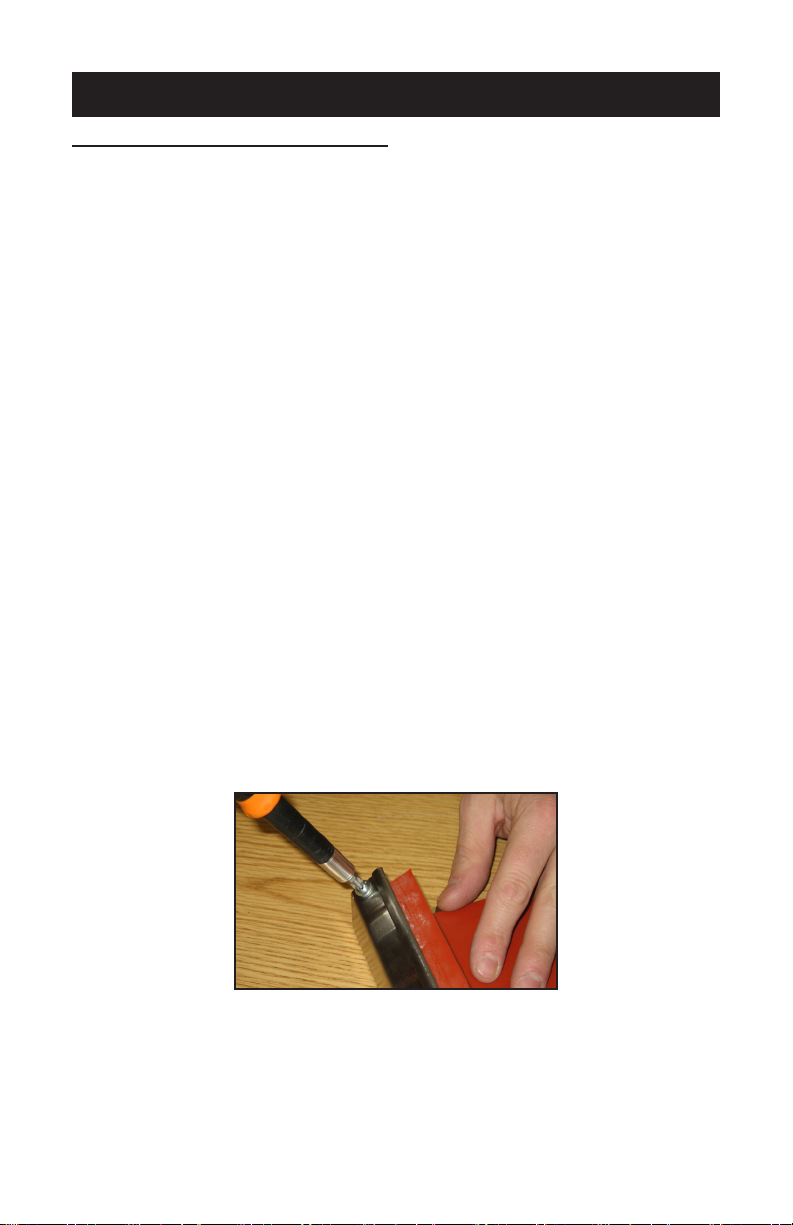

1. TRIM TRANSFER: Before applying the transfer trim the transfer so

there is no excess paper above or below the mug. TIP: Trimming the

transfer with a straight edge will assist in lining the transfer with the

top of the mug and help eliminate crooked transfers.

2. APPLY TRANSFER: Secure the ends of your transfer to the mug

using heat tape. TIP: Fold one end of the heat tape to make for quick

and easy removal of transfer.

3. WRAP MUG:

4. PLACE IN OVEN: Set oven to 400°F. Place your wrapped mugs

in the oven top down to allow heat to be trapped inside of the mug

improving transfer quality. Space each mug at least 2 inches apart

toallowformaximumairowbetweenmugsandmoreevenheating

of the entire mug.

11

USING HIX SUBLIMATION WRAPS

a) Remove mug from oven

b) Press thumbs against the bottom lip

of the “loop end.”

c) Pressindexngersagainst thetop

edge of the “hook end.”

d) With one motion, press thumbs up

andindexngersdown.Thiswillre-

lease the mug from the wrap.

e) Place mug in room temperature wa-

ter to cool mug and stop sublimation

process.

CAUTION: Wrap will be hot use care when applying wrap to another mug.

It is recommended to allow wrap to cool before using again.

INCREASING THE LIFE OF YOUR WRAP:

The following actions will increase the life of your wrap and help to prevent

premature failure.

- Space your mugs at least 2” apart in oven, this will allow for more

evenheatingandairowbetweenmugs.Alsothiswillpreventmugs

from banging together reducing the life of your wrap.

- Do not drop or bang mugs with wraps together. This can cause

small tears in your wrap leading to tearing of the wrap.

- Only use on items the wrap is rated for; the standard HMWIII is de-

signedforboth11ozand15ozmugs.Useofthesewrapsforanything

else may shorten the life of the wrap and could result in damage such

astearing.Forunusuallysizedorshapeditemspleaseutilizeawrap

custom made for your application.

- Sharpngernailsandringscansnare/tearawrap.

If the above procedures are followed and care is taken when handling these

wraps you should expect to get hundreds of cycles from your HMWIII.

5. REMOVE AND COOL:

CAUTION: Wearheatprotectiveglovestohandlethenishedwrapsand

mugs.

12

DIAGNOSTICS

HEATER AND RELAY LIGHTS

1. Heater LED’s: Cycle On When Heaters Are On

Small (1/8”) light-emitting diodes (LED’s) are driven by a current sensor

(one for each heater in the dryer). They can, in conjunction with relay

lights explained below, determine if heater(s) are burned out or if a relay

is at fault.

2. Relay Lights: Cycle Off When Heaters Are On

Large (1/4”) neon lights indicate proper opening and closing of each

heater relay. When relay lights are “on”, the relays are “open” and no

power is applied to the heaters (Heater LED’s Off). When relay lights

are “off”, the relays are “closed” and power is applied to the heaters

(Heater LED’s On). If one relay light stays “on” while the others are

off, then that pole is stuck “open” and should be replaced. The heater

LED’s will still function as normal as they are “double switched”.

NOTE: If all relay lights operated normally yet one of the heater LED’s will

not come on, check the suspected heater with an amp clamp. Normal

readingshouldbe9-12ampsdependingonelementsizeandvoltage

available.Ifreadingsindicatenocurrentowing,thentheheaterwill

require replacing.

ON

OFF

ON/OFF POWER BREAKER IN/OUT (I/O)

CIRCUIT BREAKERS

Turns all dryer power and

control circuits on and off.

Provides protection to con-

tactor coil only. Dryer MUST

be externally fused with ap-

propriatesizefuseorcircuit

breaker (FLA x 125% = fuse

size). See the following

sheet for fuse size to be

used for each dryer.

Provide protection

for control and

heater circuits only!

DO NOT use for

ON/OFF control! If

a breaker trips, de-

termine the cause

before resuming

operation.

OVEN OPENINGS

This oven is supplied with “Air Curtains” on

each end of the oven chamber.

They are designed to retain heat inside the

ovenchambertoimproveenergyefciency

and also eliminate air drafts from entering the

oven chamber resulting in better temperature

regulation.

Air Curtains

13

OPERATING PRECAUTIONS

GENERAL OPERATING PRECAUTIONS

While the below information will not cover every operating situation,

these guidelines should be understood and general common sense

applied when operating the equipment. Failure to do so could cause a

rehazard,explosionhazardandpossibleseriouspersonalinjuryor

death.

Intended Use:

HIX electric conveyor ovens may be used to cure or dry a number of

inks, substrates or products such as textiles, wood, plastic, glass or

any other similar substrates. The oven process temperature is to be

set within the safe temperature limitations of the ink or substrate. Re-

search of the temperature limitation of the particular ink or substrate is

solely the responsibility of the end user and not of HIX Corporation. HIX

Corporation will not be responsible for any damages to product, oven,

facilities or personnel caused by product being exposed to temperatures

exceeding their limitations or operating the oven in any manner in which

it was not intended.

Proper Venting:

Never block any of the air vents leading into or out of the control box.

Likewise never block any of the air vents located in the sheet metal

side covers along the lower frame rails. Blocking any of these vents

cancauseoverheatingoftheunitandcreatearehazard.Thetop

mounted exhaust on the oven shall be vented outside of the building.

See instructions in this manual for additional information on proper

venting of the exhaust.

Safe Operation:

Pay careful attention to the adjustable doors located on each end of the

oven. Ensure that the door on the exit end of the oven is raised higher

than that on the entrance end of the oven so there is no possibility that

product may get accumulated or lodged inside the oven chamber and

createarehazard.

Keep aerosol spray cans away from the oven. If they accidently fall on

the belt and enter the oven chamber they can overheat and explode

insidetheovenchambercausingarehazardandorpersonalinjury.

Neverintroduceanyammableliquidintotheoventoevaporate,such

as solvents, including, but not limited to alcohol, MEK, acetone, toluene,

etc.withoutconsultingthespecicapplicationwithHIXCorporationto

determine what amount can be safely introduced into the oven without

causingadangeroussituation.Failuretodosocancausere,personal

injury or death.

14

MAINTENANCE

MAINTENANCE SCHEDULE

Every month:

Removeandcleanorreplacelterslocatedoneachsideofcontrolbox.

Every 6 months:

1. Vacuum any lint/dust accumulation around air intake holes on both sides

of oven and on fume hoods.

2. Check tension on the wire conveyor belt and tighten if necessary.

Every Year: (Disconnect power at main panel)

1. Remove top chain guard cover and lightly lubricate the conveyor drive

chain; with SAE 20 weight oil. Replace after lubricating. DO NOT leave

off!

2. Haveaqualiedelectriciancheckallheaterelementstospecications

shown on wiring diagram.

3. Check brushes on conveyor drive motor.

4. Check/tighten all electrical connections on relays and contactor inside

control box.

6. Check thermocouples with ohm meter disconnected from temperature

control. Cold resistance should be between .5 to 2 ohms. Higher resis-

tance readings indicate possible problems with the thermocouple and

in this case it should be replaced.

TO ADJUST THE TENSION OF THE SILICONE RUBBER ON WRAPS:

When the mug wrap is closed around a mug, if the rubber is too loose

or too tight, loosen the two Phillips headed screws and adjust the rub-

ber length to achieve the desired tension. Re-tighten the screws to pro-

vide tension to hold the rubber in the wrap ends. Do not over tighten the

screws, as damage to the silicone rubber can result. (Pic 9)

TO REPLACE THE SILICONE RUBBER ON WRAPS:

If the rubber in the mug wrap has become damaged, or you are replacing

therubberforadifferentsizedmug,loosenthetwoPhillipsheadedscrews

and remove the rubber from the wrap ends. Thread the rubber between

the round bar and wrap itself. Re-tighten the screws to provide tension to

hold the rubber in the wrap ends. Do not over tighten the screws, as dam-

age to the silicone rubber can result.

15

NOTES FOR SUBSTRATES

16

(Effective 3/1/2020)

HIX will automatically register the equipment on the date it was shipped to you or your distributor. If the

equipment was not purchased directly from HIX, but through a distributor (either domestic or foreign), please

keep a copy of their sales invoice showing the serial number and date it was sold/shipped to you with this war-

ranty. In this case, we will use the distributor’s invoice date as the beginning warranty date. STAPLE A COPY

OFYOURPROOFOFPURCHASETOTHISWARRANTYandkeepinasafeplacetoprovidevericationof

your warranty should a problem occur. Thank you.

Pleasellinthefollowinginformationandattachacopyofyourreceiptforyourrecords.

Date Purchased: From:

Model #: Serial #:

This warranty applies to equipment manufactured by the HIX Corporation (HIX), Pittsburg, Kansas, U.S.A.

HIX warrants to the original purchaser, its Ovens and Dryers, Heat Transfer Machines, Textile Printers, Spot

Heaters, and Exposure Units against defects in workmanship and material, except for wear and tear for a

period of “One Year” from the date of purchase. HIX warrants Accessories for a period of 90 days from the

date of purchase. doughXpress products are covered under separate warranty.

In the event of a defect, HIX, at its option, will repair, replace or substitute the defective item at no cost

during this warranty period subject to the limitations of insurance and shipping costs stated below (excludes

labor).

In the case of heat transfer presses (except the Hobby Lite and Large Format presses), HIX warrants the

heat casting for the “Life” of the machine for the original purchaser. If a part becomes obsolete at the time

for repair, and/or cannot be reasonably substituted for, HIX will credit, at half the then current list price or last

recorded price, only that part toward a new machine or any product HIX offers. This credit offer shall be the

sole responsibility of the HIX Corporation in the event of an obsolete part.

This warranty does not cover belts, rail tape, pads, mug wraps, canvas, rubber blankets, bulbs, glass.

Warranty does not cover damages due to accident, misuse/abuse, alterations or damage due to neglect, ship-

ping or lack of proper lubrication or maintenance. HIX shall not be responsible for repairs or alterations made

byanypersonwithoutthepriorwrittenauthorizationbyHIX.Thiswarrantyisthesoleandexclusivewarranty

ofHIXandnoperson,agent,distributor,ordealerofHIXisauthorizedtochange,amendormodifytheterms

set forth herein, in whole or in part.

Inthecaseofaproblemwiththeequipmentidentiedherein,HIXCorporationshouldbecontactedduring

regular business hours to discuss the problem and verify an existing warranty. HIX personnel will assist the

customer to correct any problems which can be corrected through operation or maintenance instructions,

simple mechanical adjustments, or replacement of parts. In the event the problem cannot be corrected by

phone,andupontheissuanceofareturnauthorizationbyHIX,theequipmentshallbereturnedtoHIXoran

authorizedservicerepresentative.Allinsurance,packagingandshipment/freightcostsaresolelytherespon-

sibility of the customer, and not that of HIX, and HIX shall not be responsible for improper packaging, handling

ordamageintransit.ContactHIXcustomerserviceforcompletereturnauthorizationinformation.Correct

shipping boxes are available from HIX.

This expressed warranty is given in lieu of any and all other warranties, whether expressed or implied,

includingbutnotlimitedtothoseofmerchantabilityandtnessforaparticularpurpose,andconstitutesthe

only warranty made by HIX Corporation.

In no event shall HIX’s liability for breach of warranty extend beyond the obligation to repair or replace the

nonconforming goods. HIX shall not be liable for any other damages, either incidental or consequential, or the

action as brought in contract, negligence or otherwise.

Thiswarrantygivesyouspeciclegalrightsandyoumayalsohaveotherrightswhichvaryfromstateto

state.

WARRANTY

1201 E. 27th Terrace • Pittsburg, KS 66762 • U.S.A.

Web site: www.hixcorp.com • Phone: (800) 835-0606 • Fax: 620-231-1598

©2020 HIX Corp.

Design and Manufacturers of Graphic Imaging, Commercial Food, Industrial and Custom Drying Equipment

This manual suits for next models

3

Table of contents

Other Hix Oven manuals

Popular Oven manuals by other brands

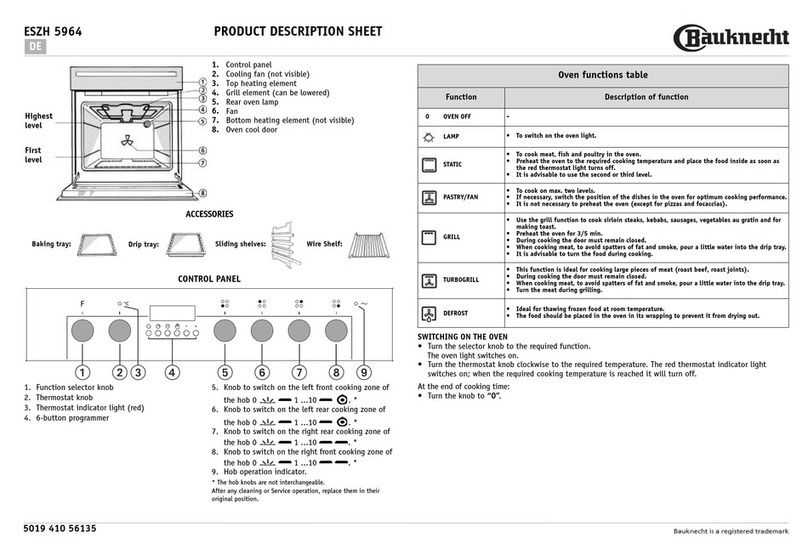

Bauknecht

Bauknecht ESZH 5964 Product description sheet

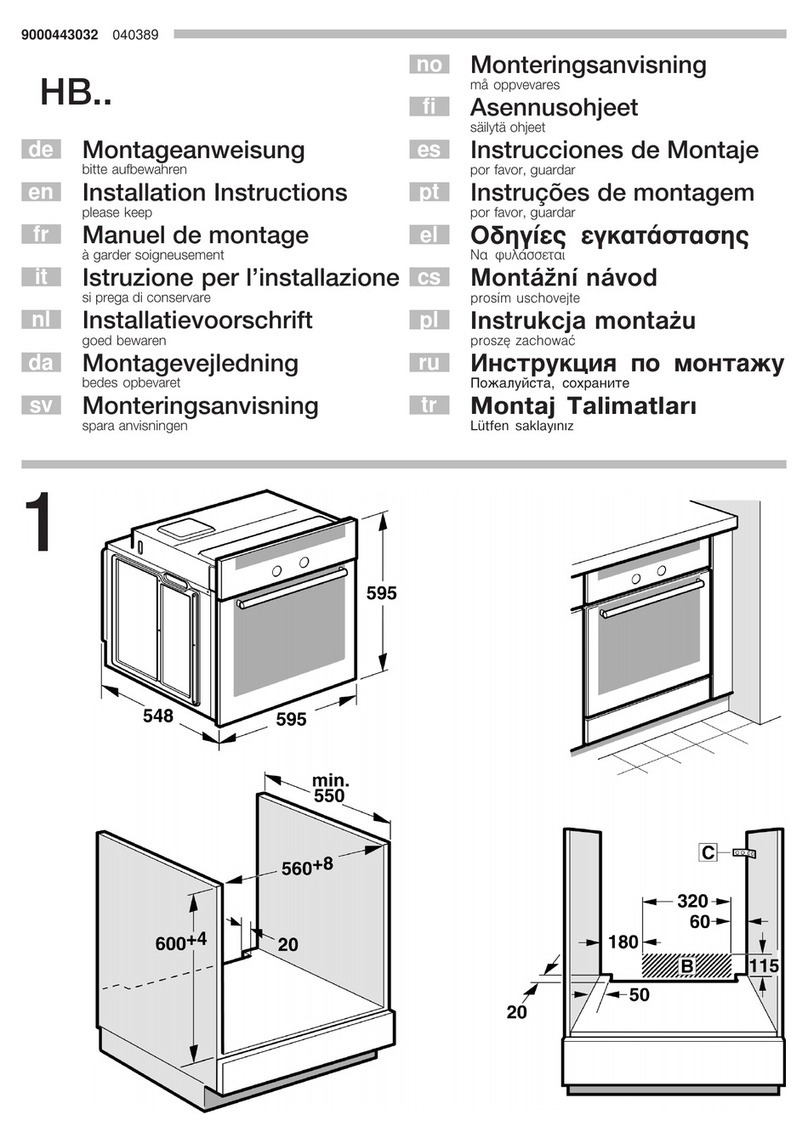

Bosch

Bosch HBG78R950B installation instructions

Aroma

Aroma ART-722SB instruction manual

Dacor

Dacor Renaissance MORD230 use and care manual

GIERRE

GIERRE BAKETEK Series Instructions for installation, use and maintenance

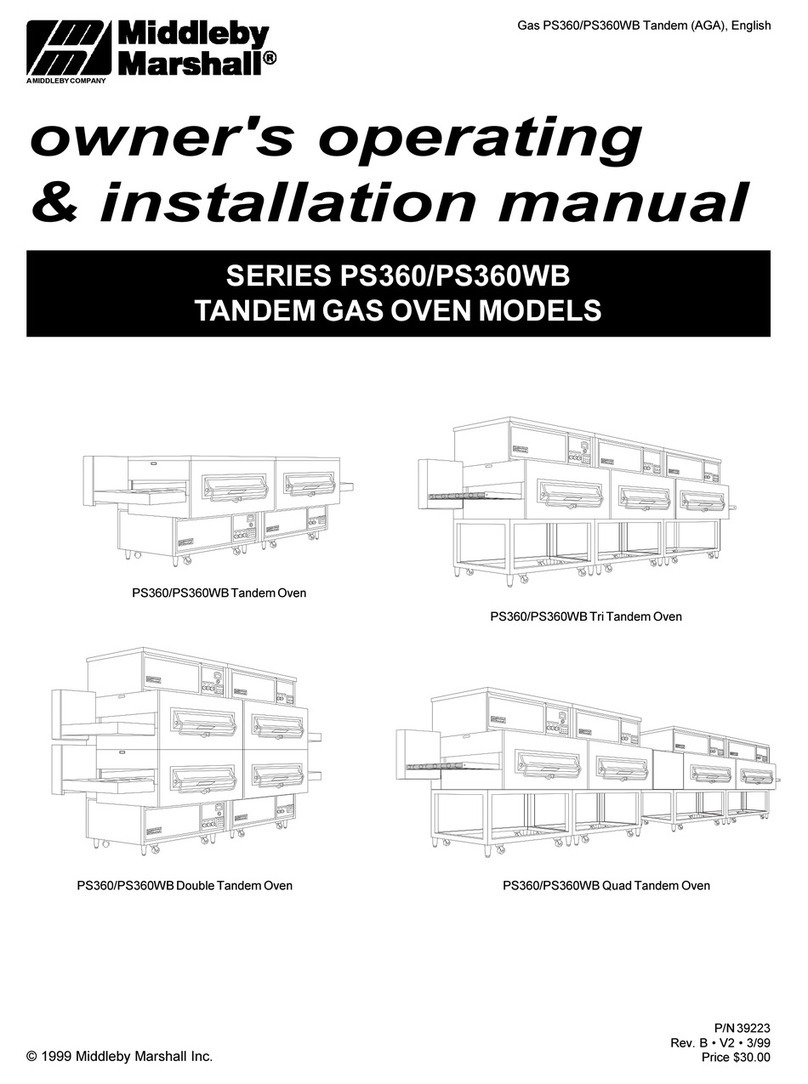

Middleby Marshall

Middleby Marshall PS360 SERIES Owner's operating & installation manual