then insert the connector into

the hole by hand, until it is

rmly gripped by the hole.

4. Using a rubber mallet, tap the

connector into place, taking

care to ensure that axis of con-

nector stays aligned with axis

of hole, until the face-ange

rests rmly against the face of

the concrete pipe/structure.

5. Chamfer and deburr the con-

necting PVC pipe end.

6. oroughly lubricate the end

of the PVC pipe and the inte-

rior of the connector with an

appropriate grade of Tylox™

pipe gasket lubricant. (For

connectors rated for “stan-

dard” usage, Hydrocarbon

-based lubricants must not

be used as these have a detri-

mental eect on the connec-

tor material and its water-

tightness)

7. Center the connecting PVC

pipe end within the connec-

tor, then gently push the pipe

home.

Note that for concrete pipe, the

PVC pipe should butt rmly up

against the internal stop in the

HKT-PP connector.

For concrete structures (HKT-

PMH), the connecting pipe must

be pushed home until the end of

the pipe is at least 3” beyond the

inner sealing n.

It is our recommendation that

all connecting pipe stubs be re-

strained from movement during

testing (vacuum or hydrostatic).

Pipe stub restraints should re-

main in place until future tie-in

of line is completed.

Available Sizes & Dimensions

PVC Pipe Size Cored/Formed

Hole Dia.

Main Pipe Dia.

Model mm in in

4* 100 4.960 to 5.010 12 to 30

6* 150 6.995 to 7.055 12 to 30

8 PP 200 8.955 to 9.045 12 to 30

8 PMH 200 9.955 to 10.045 ***

10 PP 250 10.955 to 11.045 15 to 30

10 PMH 250 12.040 to 12.130 ***

12 PP 300 13.480 to 13.570 18 to 36

12 PMH 300 14.025 to 14.115 ***

15 PMH** 375 17.975 to 18.070 ***

* 4” (100mm) and 6” (150mm) are available in both PP and PMH models.

** HKT not available in 15” (375mm) pipe-to-pipe (PP) model

*** For PMH models, as long as the sealing ns line up within the walls of the

manhole, they will work with any size of manhole structure.

Materials and Identication

Tylox™ HKT connectors are manufactured from syn-

thetic rubber compounds to meet the material require-

ments of ASTM C923.

Connectors are available for “Standard” or “Oil-resis-

tant” applications. Oil-resistant connectors will have

an orange dot on the rubber molding.

Other materials and specications may be available as

custom order. Please consult your Hamilton Kent rep-

resentative regarding your specic requirement.

Pressure Rating

Tylox® HKT connector are designed to provide wa-

tertight connections of at least 5 psig (34 KPa/11.5 ft

head).

Installation

1. Ensure that hole in concrete pipe/structure is free

from chips, cracks or other defects.

2. Remove all lose dirt and debris from the hole, and

from the exterior and interior of the connector.

3. Align the curvature of the face-ange of the con-

nector with the curvature of the pipe/structure and

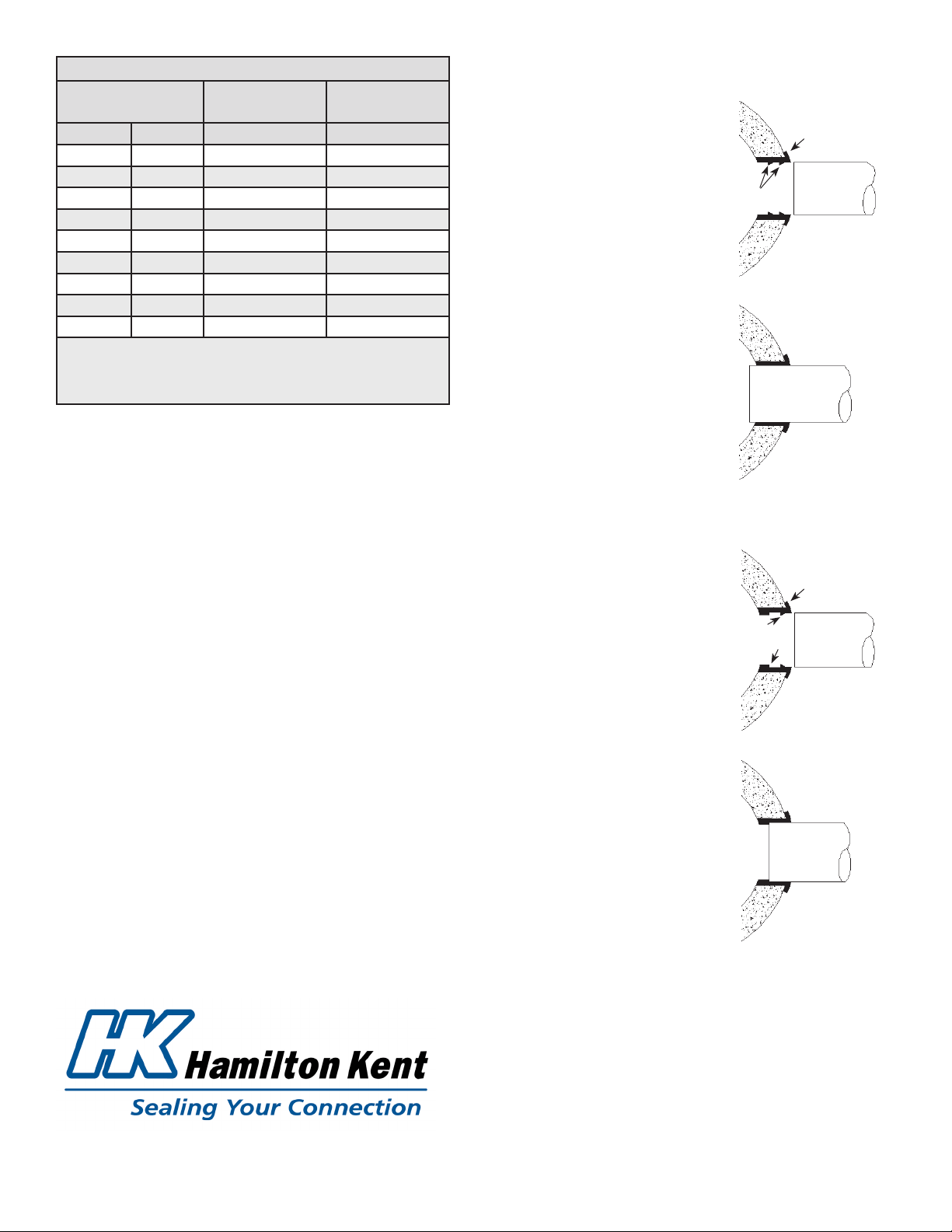

Sealing Fins

Sealing Fin

Internal Stop

HKT-PMH

HKT-PP

Face-Flange

Face-Flange

Lit_HKT_English_R8

TEL: (800) 268 8479

FAX: (888) 674 6960

WEB: www.hamiltonkent.com

Tylox® HKT connectors are manufactured by Hamilton Kent Inc. and/or Hamilton Kent LLC. ey are distributed worldwide by Hamilton Kent Inc, except for the U.S.A. where they are distributed by Hamilton Kent LLC.

Tylox® is a registered trademark of Hamilton Kent Inc.