HMI Wilkinson MST 22 MM User manual

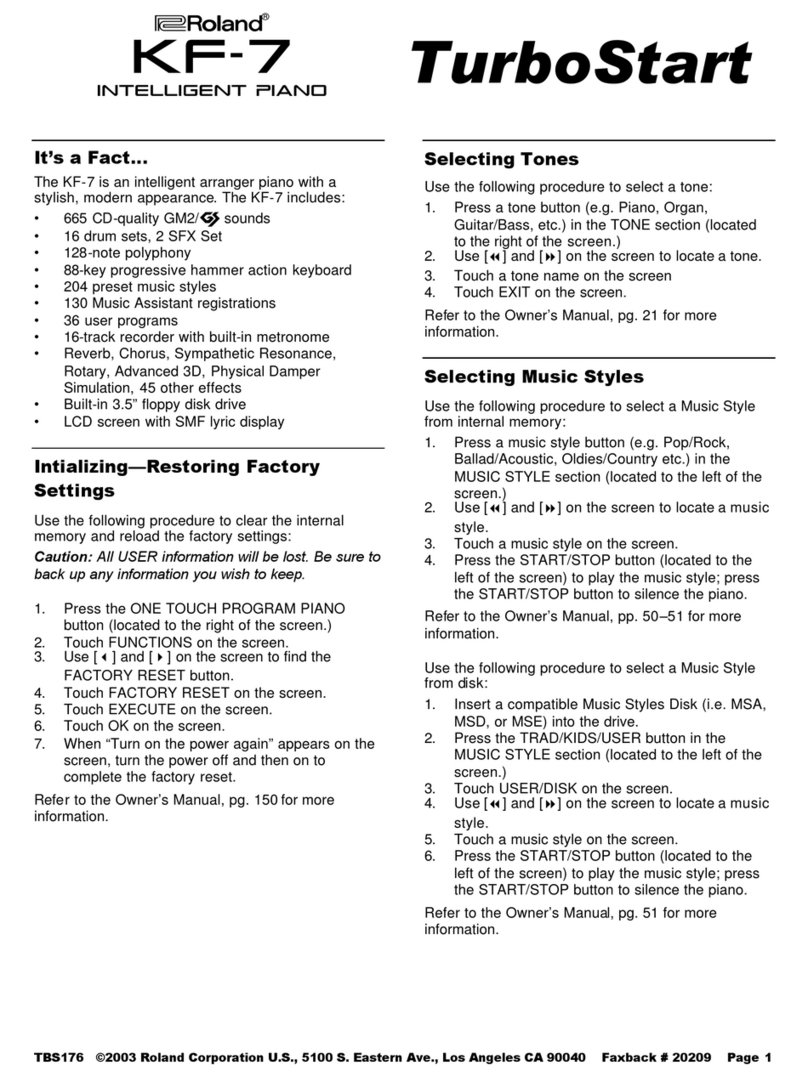

Set the action at the nut.

Set the action height and setting the intonation

Adjust the pickup height

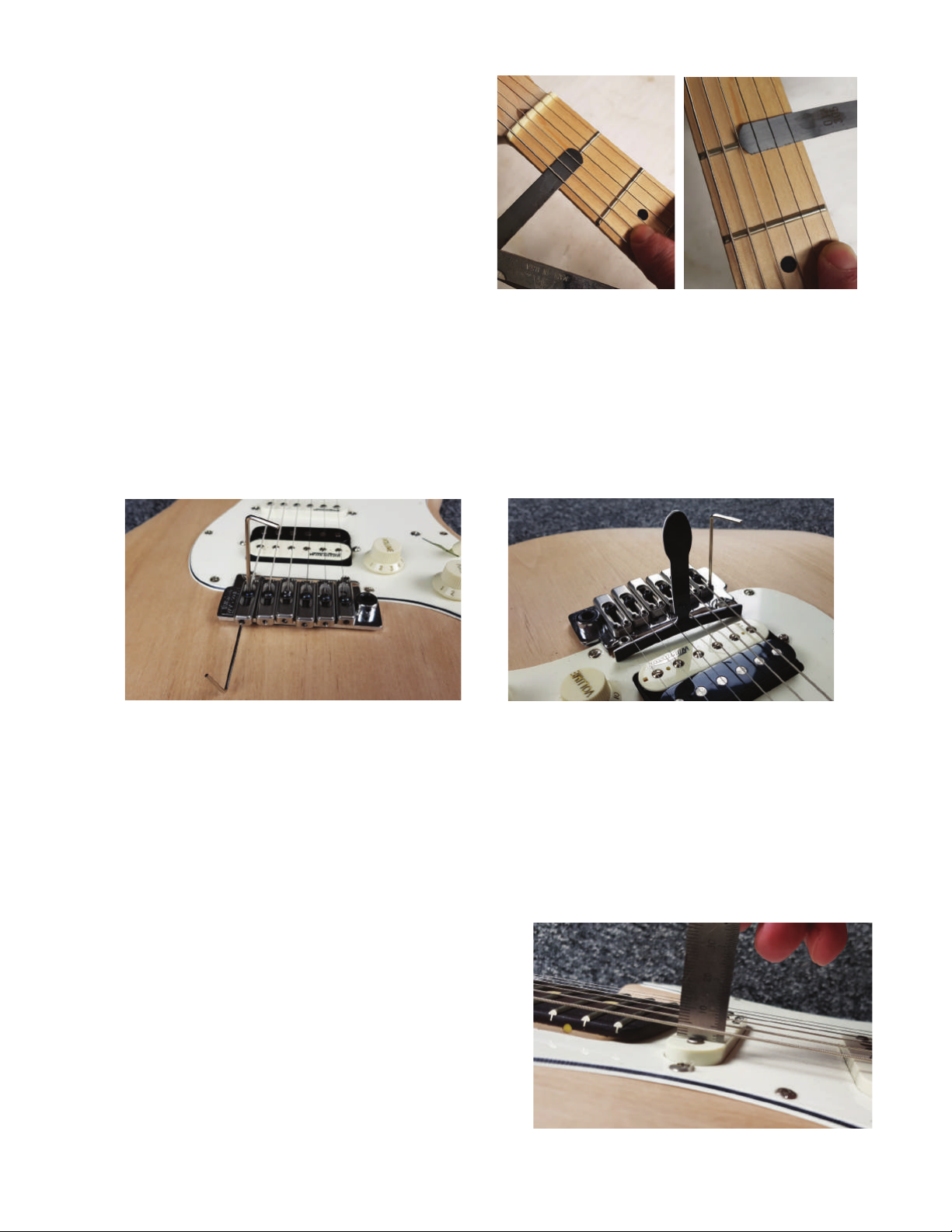

The next step is intonating the guitar by adjusting the string lengths at the bridge saddles so the guitar

plays in tune all the way up the neck.

ALWAYS remember to loosen the larger hold down screw on the

top of the saddle before attempting to adjust the intonation or saddle height of the saddles.

Using a strobe or other accurate tuner, first tune the strings to pitch. Then press the high E string

lightly at the 12th fret using just enough pressure to sound the note. Check it with your tuner.

If the note reads flat, the saddle needs to be adjusted forward towards the nut, shortening the length of

the string. If the note reads sharp, the saddle needs to be adjusted back away from the nut, increasing

the string length to set the intonation.

Holding down the low E and high E strings at the

22nd fret, adjust the bass side of the pickups to 5/64"

from the top of the pickup pole to the bottom of the

low E string. Adjust the treble side to 1/16".

Lower your string nut slots for better playability

using gauged nut files. Measure string height over

the 1st fret, between the bottom of the string and

the top of the fret. A comfortable medium action is:

Unwound strings (G, B, E): 0.012" at the 1st fret,

Wound strings (E,A,D): 0.020" at the 1st fret Use

feeler gauges to measure the gap, or use guitar

strings whose gauges match the measurement

you’re after. Stop when the string sits on your feeler

gauge. Go slow and check your work frequently

it’s easy to go too far in this step and ruin the nut.

Your guitar is now be ready to play and ENJOY !!

Now Re-tune your guitar and check the action .Sight

down the neck and check for any Over bow (bending

backwards causing string buzz on an open string or

Under bow on the neck causing a higher than neces-

sary action in the midle of the neck when playing.

Adjust the optimum action with the truss rod.

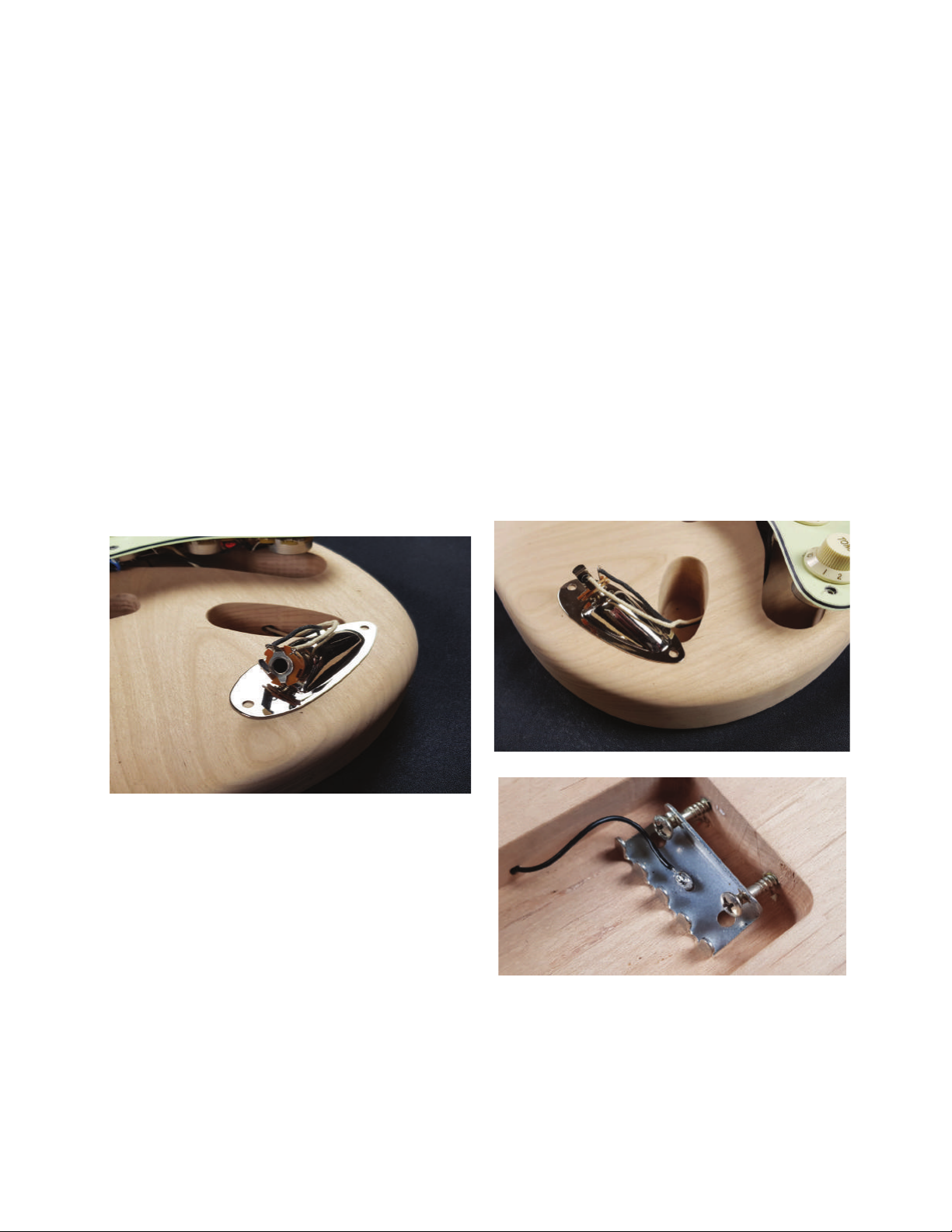

Your MST kit contains the Wilkinson VS50 II K vibrato bridge. This features saddles which lock to the

top plate thereby eliminating any saddle movement greatly enhancing the tuning stabilty when using

the vibrato. ALWAYS remember to loosen the larger hold down screw on the top of the saddle before

attempting to adjust the intonation or saddle hieght of the saddles. The design of thes saddles

allow you to keep the saddles low to the top plate (a big benefit for tuning stabilty).

The ultimate action can then be realised by using the pivot posts to adjust the height of the bridge

assembly. Measure string height over the 12th fret between the bottom of the string and the top of the

fret. A good starting point is: High (unwound) E string: 1/16" at the 12th fret Low (wound) E string:

5/64" at the 12th fret. You can always go lower or higher depending on your playing style.

After setting the two E strings, dial in the remaining strings to match the curve of the fretboard

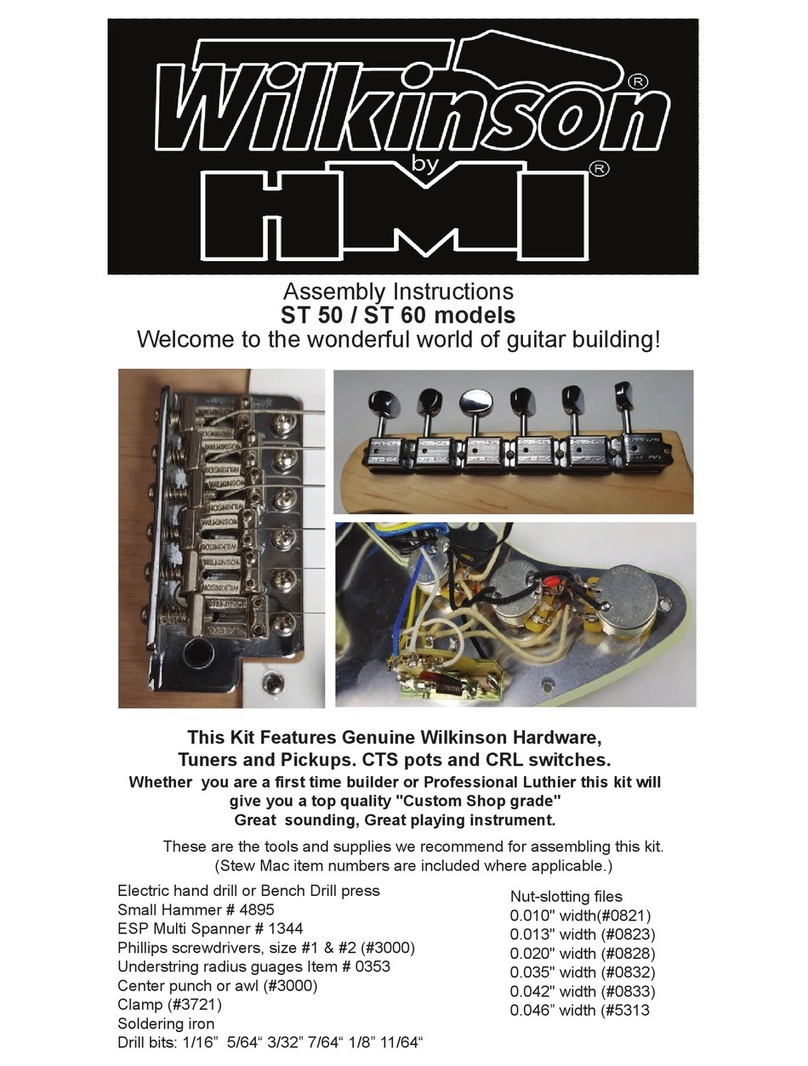

Assembly Instructions

MST 22 MM / MR models

Welcome to the wonderful world of guitar building!

These are the tools and supplies we recommend for assembling this kit.

(Stew Mac item numbers are included where applicable.)

Nut-slotting files

0.010" width(#0821)

0.013" width (#0823)

0.020" width (#0828)

0.035" width (#0832)

0.042" width (#0833)

0.046” width (#5313

Electric hand drill or Bench Drill press

Small Hammer # 4895

ESP Multi Spanner # 1344

Phillips screwdrivers, size #1 & #2 (#3000)

Understring radius guages Item # 0353

Center punch or awl (#3000)

Clamp (#3721)

Soldering iron

Drill bits: 1/16” 5/64“ 3/32” 7/64“ 1/8” 11/64“

Whether you are a first time builder or Professional Luthier this kit will

give you a top quality "Custom Shop grade"

Great sounding Great playing instrument.

This Kit Features Genuine Wilkinson Hardware,

Tuners and Pickups. CTS pots and CRL switches.

Using the correct amount of springs in relation to the feel and string tension is one of the most

mis-understood aspects of vibratos. Quite simply, no matter how many springs you install in

relation to string gauge the least springs you can use will give you the smoothest feeling and

best “return to zero” possible. This will result in superior tuning stability.

Neck relief refers to adjusting a neck so that it has a very slight upbow, rather than being perfectly

straight. This relief allows a little more room for string vibration, reducing the chance of hitting the

lower frets and causing fret buzz. Depending on your playing style, and how perfectly level your

fret tops are, a neck should be anywhere from perfectly straight to having 0.012" of relief. This

measurement refers to additional string height over the 12th fret, compared to a perfectly straight

neck. A straight neck tends to play and sound better but very few guitars end up with no relief at

all, and several thousandths of an inch or more is perfectly normal.

Install at least 2 springs (.009 to .042 ) or 3 springs (.010 to .046 or bigger). For a fully floating

vibrato unless you are using much heavier strings like (013 to .060), 3 springs should suffice.

Using the vibrato cavity backing plate as a spacer under the back of the bridge can help you

set up the vibrato very quickly.

Now screw the spring claw screws in to give more tension to the springs and tune your guitar

to pitch. If the backing plate becomes dislodged from under the bridge plate tighten the spring

claw screws even further until the backing plate is held firmly in place by the springs. Once you

have achieved your desired tuning, start to back off the spring claw screws until the backing

plate falls out from under the bridge plate. You will find now that the guitar is still tuned to pitch

and the bridge will be floating close to the ideal angle to give you both upward and downward

pitch changes. tightening or loosening the springs with the spring claw and re-tuning to pitch

will flaot the bridge in the ideal position for the full range of vibrato movement

Parts included in your KIT

Straight neck, or a little relief?

Adjusting the Truss rod

Truss rod

Headstock adjuster

Increase relief

Decrease relief

Modern Slim C profile with 12" Radius neck in 1 piece Maple

with Walnut "Skunk" stripe and Headstock adjust truss rod

Wilkinson WHS alnico"V" neck and

middle single coil pickups and High

Output WHHB Z bridge pickup

WVS 50 II K Vibrato

Modern Slim C profile with 12" Radius neck in Maple

with Rosewood fingerboard and Headstock adjust truss rod

Modern"Strat style" Unfinished fine sanded body

in 2 piece centre jointed American Alder

Wilkinson WJO5 PinLok tuners

with Locking posts

“S” style pickguard in

aged white loaded

and wired with with

CTSpotentiometers,

CRL lever switch and

cloth covered push

back hook up wire.

backing plate in

aged white

WVS 50 II K Vibrato

Install the strings and the remaining Vibrato springs.

Assembling your guitar

During assembly, use a padded surface to protect the finish from scratches and

dents.

Installing the tuners.

Mark out your mounting holes with a scribe or punch. Tuner mounting screws

are very delicate, and will break off if forced into hard maple. Use a 5/64" drill

bit to make pilot holes for the screws; if these holes are any smaller you risk

shearing off the screw heads.

Install the front collars and tighten into place keeping the tuners lined up with

each other

Lubricate the screw threads with a small amount the Wilkinson “Slipstick”

provided in the kit. With the tuners in place, install the screws in the pilot holes

with a #1 Phillips screwdriver.

Lay out the tuners, using a ruler to make sure they’re in line with one another

and square to the edge of the peghead.

Whenever you drill a hole be sure to

countersink slightly larger than the

screw diameter. this will reduce wood

tearout amd make for a clean assem-

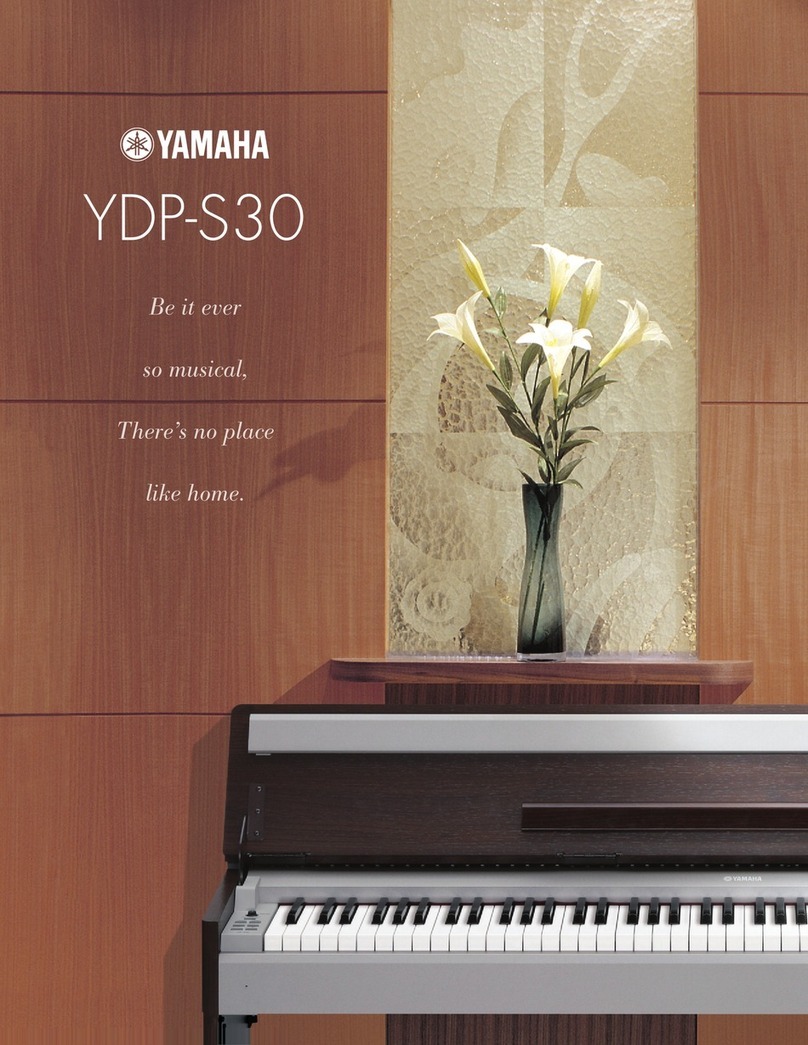

Install the Strap Buttons

Fitting the Pick-guard and Jack socket plate

Soldering the string ground

The two-strand hookup wire from the volume pot goes to the output jack. Thread the wire through

the hole from pickup cavity into the jack cavity. Solder the white insulated wire to the jack’s tip

lug (the rounded lug). Solder the bare ground wire to the jack’s sleeve lug (the square lug).

For more information, see our Stew Mac Trade Secrets video #186 “How to get a good clean

solder joint!” at stewmac.com

The remaining black lead wire is for the string

ground. Feed this wire through the hole from

the pickup cavity to the spring cavity. Solder this

ground wire to the spring claw. Now that you've

wired the output and ground, install the pick-

guard and the jack plate.

Lay out the pick-guard and jack plate using the neck and bridge for reference. Once positioned,

mark out the mounting screw holes with a scribe or punch. Drill pilot holes for the screws using

a 1/16" drill bit. Do not install the pick-guard yet. Mark the mounting holes for your jack plate,

then drill pilot holes for the screws using a 1/16" drill bit. Drill the jack plate mounting holes.

Always countersink drilled holes slightly to stop any grain lift when installing screws.

Do not install the jack plate yet.

Now you can fit the pickguard and Jack plate. Use the screws provided and don't forget

a little Wilkinson "Slipstick" on the threads to make the install even simpler.

Solder the output jack

Enlarge the 4 screw holes in the body with 11/64" drill bit. The body holes are drilled intentionally

small to allow the neck holes to be perfectly aligned. Before installing the neck it is essential that

these body holes have clearance for the neck bolt/screws to pass through the body un-hindered.

This is essential in order to facilitate a truly tight neck to body joint for maximum transfer of string

resonance from the neck to the body. I also find that countersinking these holes slightly

(under the neck plate) also helps provide the tightest neck to body joint as the countersunk

screw head can be deeper than the countersinks of the neck plate. Use a #2 Phillips screwdriver

to install the neck mounting screws through the neck mounting plate. Lubricate the 4 neck

mounting screws with "Slipstick" Dry Lube. Tighten the screws to hold the neck in place.

Install the neck

Your body has already been drilled for the correct locations of these buttons.

Use the screws provided with the kit. A little Wilkinson "Slipstick" on the screws

will make installing these a breeze.

Always countersink drilled holes slightly to stop any grain lift when installing screws.

The bridge post mounting holes

are drilled ready for the pivot

screw bushings. Press in the

brass bushings using The chuck

in a drill press or If you dont have

a drill press then you can hammer

the bushings in taking care not to

damage the brass inserts or their

threads. Using a dowel will help

with this and it will protect the

surface of the body when driving

them home flush with the surface.

The spring claw must be attached to the body

before the bridge can be installed. Center the

claw in the spring cavity so it sits 1/16" below

the surface of the body. The holes for the fixing

screws are already drilled. Attach the claw

using the 2 long screws provided, lubricate with

Wilkinson “Slipstick” and screw the claw in

place.Install one spring in the centre of the

spring block with enough tension on the claw to

hold the bridge in place. This will hold the

bridge in place whilst you line up the neck in

the body

Install the Bridge and Spring Claw.

Use a clamp to lightly hold the neck in place. Place a scrap of wood or soft faced clamp over the

frets so they don’t suffer any damage to their surface. Beware over tightening the clamp as this

could crush the frets and change/flatten the fret radius at this point of contact.

To align the neck and body I like to use a length of string/twine or thin hook up wire threaded

through the E string holes in the block and then run the wire/ string up the neck through the nut to

the E tuners to check alignment and make side-to-side adjustments to the neck as needed to make

sure the strings ride even along both edges of the fretboard. When you are happy with the align-

ment of the neck use the holes in the body to mark the hole locations in the heel of the neck. A

scribe, nail or transfer punch will make clean marks in the neck to show you where to drill. A 1/8”

brad-point drill bit turned by hand works perfectly for making these marks.

Drill the neck mounting holes

It’s important that these holes are drilled square to the neck, so a drill press works best for this job.

Use a 1/8" bit and drill the holes 11/16" deep. If you don’t have access to a drill press, use a drill

guide to keep your hand drill squared up.

The VS50 II K vibrato is designed to float above the body allowing subtle movement of the

bridge to create true vibrato shimmer. It will also “Dive Bomb” if required, making it one of the

most usuable bridges available. The bridge has excellent tuning stabilty and when set up it is

comparable to many double locking systems.

The saddles were designed to sit as close to the bridge plate as possible helping keep the

string angle over the intonation point shallow to stop the usual string “hang-up” most other

bridges have, but still having enough string pressure to transfer all the string energy and

resonance through to the body of the guitar. The saddles bolt directly to the plate thereby

eliminating all movement under the string adding even more sustain and tuning stabilty.

It is essential to remember to loosen the lock down screws before making any saddle height

or intonation adjustments. When you are happy with your action/string height etc.. tune and

stretch in your strings then Lock the saddles in place with the hold down screws.

Setting up the vibrato.

Lining up the neck and bridge

VS50IIK bridge floating

parrallel to body top

The bridge post mounting holes

are drilled ready for the pivot

screw bushings. Press in the

brass bushings using The chuck

in a drill press or If you dont have

a drill press then you can hammer

the bushings in taking care not to

damage the brass inserts or their

threads. Using a dowel will help

with this and it will protect the

surface of the body when driving

them home flush with the surface.

The spring claw must be attached to the body

before the bridge can be installed. Center the

claw in the spring cavity so it sits 1/16" below

the surface of the body. The holes for the fixing

screws are already drilled. Attach the claw

using the 2 long screws provided, lubricate with

Wilkinson “Slipstick” and screw the claw in

place.Install one spring in the centre of the

spring block with enough tension on the claw to

hold the bridge in place. This will hold the

bridge in place whilst you line up the neck in

the body

Install the Bridge and Spring Claw.

Use a clamp to lightly hold the neck in place. Place a scrap of wood or soft faced clamp over the

frets so they don’t suffer any damage to their surface. Beware over tightening the clamp as this

could crush the frets and change/flatten the fret radius at this point of contact.

To align the neck and body I like to use a length of string/twine or thin hook up wire threaded

through the E string holes in the block and then run the wire/ string up the neck through the nut to

the E tuners to check alignment and make side-to-side adjustments to the neck as needed to make

sure the strings ride even along both edges of the fretboard. When you are happy with the align-

ment of the neck use the holes in the body to mark the hole locations in the heel of the neck. A

scribe, nail or transfer punch will make clean marks in the neck to show you where to drill. A 1/8”

brad-point drill bit turned by hand works perfectly for making these marks.

Drill the neck mounting holes

It’s important that these holes are drilled square to the neck, so a drill press works best for this job.

Use a 1/8" bit and drill the holes 11/16" deep. If you don’t have access to a drill press, use a drill

guide to keep your hand drill squared up.

The VS50 II K vibrato is designed to float above the body allowing subtle movement of the

bridge to create true vibrato shimmer. It will also “Dive Bomb” if required, making it one of the

most usuable bridges available. The bridge has excellent tuning stabilty and when set up it is

comparable to many double locking systems.

The saddles were designed to sit as close to the bridge plate as possible helping keep the

string angle over the intonation point shallow to stop the usual string “hang-up” most other

bridges have, but still having enough string pressure to transfer all the string energy and

resonance through to the body of the guitar. The saddles bolt directly to the plate thereby

eliminating all movement under the string adding even more sustain and tuning stabilty.

It is essential to remember to loosen the lock down screws before making any saddle height

or intonation adjustments. When you are happy with your action/string height etc.. tune and

stretch in your strings then Lock the saddles in place with the hold down screws.

Setting up the vibrato.

Lining up the neck and bridge

VS50IIK bridge floating

parrallel to body top

The bridge post mounting holes

are drilled ready for the pivot

screw bushings. Press in the

brass bushings using The chuck

in a drill press or If you dont have

a drill press then you can hammer

the bushings in taking care not to

damage the brass inserts or their

threads. Using a dowel will help

with this and it will protect the

surface of the body when driving

them home flush with the surface.

The spring claw must be attached to the body

before the bridge can be installed. Center the

claw in the spring cavity so it sits 1/16" below

the surface of the body. The holes for the fixing

screws are already drilled. Attach the claw

using the 2 long screws provided, lubricate with

Wilkinson “Slipstick” and screw the claw in

place.Install one spring in the centre of the

spring block with enough tension on the claw to

hold the bridge in place. This will hold the

bridge in place whilst you line up the neck in

the body

Install the Bridge and Spring Claw.

Use a clamp to lightly hold the neck in place. Place a scrap of wood or soft faced clamp over the

frets so they don’t suffer any damage to their surface. Beware over tightening the clamp as this

could crush the frets and change/flatten the fret radius at this point of contact.

To align the neck and body I like to use a length of string/twine or thin hook up wire threaded

through the E string holes in the block and then run the wire/ string up the neck through the nut to

the E tuners to check alignment and make side-to-side adjustments to the neck as needed to make

sure the strings ride even along both edges of the fretboard. When you are happy with the align-

ment of the neck use the holes in the body to mark the hole locations in the heel of the neck. A

scribe, nail or transfer punch will make clean marks in the neck to show you where to drill. A 1/8”

brad-point drill bit turned by hand works perfectly for making these marks.

Drill the neck mounting holes

It’s important that these holes are drilled square to the neck, so a drill press works best for this job.

Use a 1/8" bit and drill the holes 11/16" deep. If you don’t have access to a drill press, use a drill

guide to keep your hand drill squared up.

The VS50 II K vibrato is designed to float above the body allowing subtle movement of the

bridge to create true vibrato shimmer. It will also “Dive Bomb” if required, making it one of the

most usuable bridges available. The bridge has excellent tuning stabilty and when set up it is

comparable to many double locking systems.

The saddles were designed to sit as close to the bridge plate as possible helping keep the

string angle over the intonation point shallow to stop the usual string “hang-up” most other

bridges have, but still having enough string pressure to transfer all the string energy and

resonance through to the body of the guitar. The saddles bolt directly to the plate thereby

eliminating all movement under the string adding even more sustain and tuning stabilty.

It is essential to remember to loosen the lock down screws before making any saddle height

or intonation adjustments. When you are happy with your action/string height etc.. tune and

stretch in your strings then Lock the saddles in place with the hold down screws.

Setting up the vibrato.

Lining up the neck and bridge

VS50IIK bridge floating

parrallel to body top

Assembling your guitar

During assembly, use a padded surface to protect the finish from scratches and

dents.

Installing the tuners.

Mark out your mounting holes with a scribe or punch. Tuner mounting screws

are very delicate, and will break off if forced into hard maple. Use a 5/64" drill

bit to make pilot holes for the screws; if these holes are any smaller you risk

shearing off the screw heads.

Install the front collars and tighten into place keeping the tuners lined up with

each other

Lubricate the screw threads with a small amount the Wilkinson “Slipstick”

provided in the kit. With the tuners in place, install the screws in the pilot holes

with a #1 Phillips screwdriver.

Lay out the tuners, using a ruler to make sure they’re in line with one another

and square to the edge of the peghead.

Whenever you drill a hole be sure to

countersink slightly larger than the

screw diameter. this will reduce wood

tearout amd make for a clean assem-

Install the Strap Buttons

Fitting the Pick-guard and Jack socket plate

Soldering the string ground

The two-strand hookup wire from the volume pot goes to the output jack. Thread the wire through

the hole from pickup cavity into the jack cavity. Solder the white insulated wire to the jack’s tip

lug (the rounded lug). Solder the bare ground wire to the jack’s sleeve lug (the square lug).

For more information, see our Stew Mac Trade Secrets video #186 “How to get a good clean

solder joint!” at stewmac.com

The remaining black lead wire is for the string

ground. Feed this wire through the hole from

the pickup cavity to the spring cavity. Solder this

ground wire to the spring claw. Now that you've

wired the output and ground, install the pick-

guard and the jack plate.

Lay out the pick-guard and jack plate using the neck and bridge for reference. Once positioned,

mark out the mounting screw holes with a scribe or punch. Drill pilot holes for the screws using

a 1/16" drill bit. Do not install the pick-guard yet. Mark the mounting holes for your jack plate,

then drill pilot holes for the screws using a 1/16" drill bit. Drill the jack plate mounting holes.

Always countersink drilled holes slightly to stop any grain lift when installing screws.

Do not install the jack plate yet.

Now you can fit the pickguard and Jack plate. Use the screws provided and don't forget

a little Wilkinson "Slipstick" on the threads to make the install even simpler.

Solder the output jack

Enlarge the 4 screw holes in the body with 11/64" drill bit. The body holes are drilled intentionally

small to allow the neck holes to be perfectly aligned. Before installing the neck it is essential that

these body holes have clearance for the neck bolt/screws to pass through the body un-hindered.

This is essential in order to facilitate a truly tight neck to body joint for maximum transfer of string

resonance from the neck to the body. I also find that countersinking these holes slightly

(under the neck plate) also helps provide the tightest neck to body joint as the countersunk

screw head can be deeper than the countersinks of the neck plate. Use a #2 Phillips screwdriver

to install the neck mounting screws through the neck mounting plate. Lubricate the 4 neck

mounting screws with "Slipstick" Dry Lube. Tighten the screws to hold the neck in place.

Install the neck

Your body has already been drilled for the correct locations of these buttons.

Use the screws provided with the kit. A little Wilkinson "Slipstick" on the screws

will make installing these a breeze.

Always countersink drilled holes slightly to stop any grain lift when installing screws.

Assembling your guitar

During assembly, use a padded surface to protect the finish from scratches and

dents.

Installing the tuners.

Mark out your mounting holes with a scribe or punch. Tuner mounting screws

are very delicate, and will break off if forced into hard maple. Use a 5/64" drill

bit to make pilot holes for the screws; if these holes are any smaller you risk

shearing off the screw heads.

Install the front collars and tighten into place keeping the tuners lined up with

each other

Lubricate the screw threads with a small amount the Wilkinson “Slipstick”

provided in the kit. With the tuners in place, install the screws in the pilot holes

with a #1 Phillips screwdriver.

Lay out the tuners, using a ruler to make sure they’re in line with one another

and square to the edge of the peghead.

Whenever you drill a hole be sure to

countersink slightly larger than the

screw diameter. this will reduce wood

tearout amd make for a clean assem-

Install the Strap Buttons

Fitting the Pick-guard and Jack socket plate

Soldering the string ground

The two-strand hookup wire from the volume pot goes to the output jack. Thread the wire through

the hole from pickup cavity into the jack cavity. Solder the white insulated wire to the jack’s tip

lug (the rounded lug). Solder the bare ground wire to the jack’s sleeve lug (the square lug).

For more information, see our Stew Mac Trade Secrets video #186 “How to get a good clean

solder joint!” at stewmac.com

The remaining black lead wire is for the string

ground. Feed this wire through the hole from

the pickup cavity to the spring cavity. Solder this

ground wire to the spring claw. Now that you've

wired the output and ground, install the pick-

guard and the jack plate.

Lay out the pick-guard and jack plate using the neck and bridge for reference. Once positioned,

mark out the mounting screw holes with a scribe or punch. Drill pilot holes for the screws using

a 1/16" drill bit. Do not install the pick-guard yet. Mark the mounting holes for your jack plate,

then drill pilot holes for the screws using a 1/16" drill bit. Drill the jack plate mounting holes.

Always countersink drilled holes slightly to stop any grain lift when installing screws.

Do not install the jack plate yet.

Now you can fit the pickguard and Jack plate. Use the screws provided and don't forget

a little Wilkinson "Slipstick" on the threads to make the install even simpler.

Solder the output jack

Enlarge the 4 screw holes in the body with 11/64" drill bit. The body holes are drilled intentionally

small to allow the neck holes to be perfectly aligned. Before installing the neck it is essential that

these body holes have clearance for the neck bolt/screws to pass through the body un-hindered.

This is essential in order to facilitate a truly tight neck to body joint for maximum transfer of string

resonance from the neck to the body. I also find that countersinking these holes slightly

(under the neck plate) also helps provide the tightest neck to body joint as the countersunk

screw head can be deeper than the countersinks of the neck plate. Use a #2 Phillips screwdriver

to install the neck mounting screws through the neck mounting plate. Lubricate the 4 neck

mounting screws with "Slipstick" Dry Lube. Tighten the screws to hold the neck in place.

Install the neck

Your body has already been drilled for the correct locations of these buttons.

Use the screws provided with the kit. A little Wilkinson "Slipstick" on the screws

will make installing these a breeze.

Always countersink drilled holes slightly to stop any grain lift when installing screws.

Using the correct amount of springs in relation to the feel and string tension is one of the most

mis-understood aspects of vibratos. Quite simply, no matter how many springs you install in

relation to string gauge the least springs you can use will give you the smoothest feeling and

best “return to zero” possible. This will result in superior tuning stability.

Neck relief refers to adjusting a neck so that it has a very slight upbow, rather than being perfectly

straight. This relief allows a little more room for string vibration, reducing the chance of hitting the

lower frets and causing fret buzz. Depending on your playing style, and how perfectly level your

fret tops are, a neck should be anywhere from perfectly straight to having 0.012" of relief. This

measurement refers to additional string height over the 12th fret, compared to a perfectly straight

neck. A straight neck tends to play and sound better but very few guitars end up with no relief at

all, and several thousandths of an inch or more is perfectly normal.

Install at least 2 springs (.009 to .042 ) or 3 springs (.010 to .046 or bigger). For a fully floating

vibrato unless you are using much heavier strings like (013 to .060), 3 springs should suffice.

Using the vibrato cavity backing plate as a spacer under the back of the bridge can help you

set up the vibrato very quickly.

Now screw the spring claw screws in to give more tension to the springs and tune your guitar

to pitch. If the backing plate becomes dislodged from under the bridge plate tighten the spring

claw screws even further until the backing plate is held firmly in place by the springs. Once you

have achieved your desired tuning, start to back off the spring claw screws until the backing

plate falls out from under the bridge plate. You will find now that the guitar is still tuned to pitch

and the bridge will be floating close to the ideal angle to give you both upward and downward

pitch changes. tightening or loosening the springs with the spring claw and re-tuning to pitch

will flaot the bridge in the ideal position for the full range of vibrato movement

Parts included in your KIT

Straight neck, or a little relief?

Adjusting the Truss rod

Truss rod

Headstock adjuster

Increase relief

Decrease relief

Modern Slim C profile with 12" Radius neck in 1 piece Maple

with Walnut "Skunk" stripe and Headstock adjust truss rod

Wilkinson WHS alnico"V" neck and

middle single coil pickups and High

Output WHHB Z bridge pickup

WVS 50 II K Vibrato

Modern Slim C profile with 12" Radius neck in Maple

with Rosewood fingerboard and Headstock adjust truss rod

Modern"Strat style" Unfinished fine sanded body

in 2 piece centre jointed American Alder

Wilkinson WJO5 PinLok tuners

with Locking posts

“S” style pickguard in

aged white loaded

and wired with with

CTSpotentiometers,

CRL lever switch and

cloth covered push

back hook up wire.

backing plate in

aged white

WVS 50 II K Vibrato

Install the strings and the remaining Vibrato springs.

Set the action at the nut.

Set the action height and setting the intonation

Adjust the pickup height

The next step is intonating the guitar by adjusting the string lengths at the bridge saddles so the guitar

plays in tune all the way up the neck.

ALWAYS remember to loosen the larger hold down screw on the

top of the saddle before attempting to adjust the intonation or saddle height of the saddles.

Using a strobe or other accurate tuner, first tune the strings to pitch. Then press the high E string

lightly at the 12th fret using just enough pressure to sound the note. Check it with your tuner.

If the note reads flat, the saddle needs to be adjusted forward towards the nut, shortening the length of

the string. If the note reads sharp, the saddle needs to be adjusted back away from the nut, increasing

the string length to set the intonation.

Holding down the low E and high E strings at the

22nd fret, adjust the bass side of the pickups to 5/64"

from the top of the pickup pole to the bottom of the

low E string. Adjust the treble side to 1/16".

Lower your string nut slots for better playability

using gauged nut files. Measure string height over

the 1st fret, between the bottom of the string and

the top of the fret. A comfortable medium action is:

Unwound strings (G, B, E): 0.012" at the 1st fret,

Wound strings (E,A,D): 0.020" at the 1st fret Use

feeler gauges to measure the gap, or use guitar

strings whose gauges match the measurement

you’re after. Stop when the string sits on your feeler

gauge. Go slow and check your work frequently

it’s easy to go too far in this step and ruin the nut.

Your guitar is now be ready to play and ENJOY !!

Now Re-tune your guitar and check the action .Sight

down the neck and check for any Over bow (bending

backwards causing string buzz on an open string or

Under bow on the neck causing a higher than neces-

sary action in the midle of the neck when playing.

Adjust the optimum action with the truss rod.

Your MST kit contains the Wilkinson VS50 II K vibrato bridge. This features saddles which lock to the

top plate thereby eliminating any saddle movement greatly enhancing the tuning stabilty when using

the vibrato. ALWAYS remember to loosen the larger hold down screw on the top of the saddle before

attempting to adjust the intonation or saddle hieght of the saddles. The design of thes saddles

allow you to keep the saddles low to the top plate (a big benefit for tuning stabilty).

The ultimate action can then be realised by using the pivot posts to adjust the height of the bridge

assembly. Measure string height over the 12th fret between the bottom of the string and the top of the

fret. A good starting point is: High (unwound) E string: 1/16" at the 12th fret Low (wound) E string:

5/64" at the 12th fret. You can always go lower or higher depending on your playing style.

After setting the two E strings, dial in the remaining strings to match the curve of the fretboard

Assembly Instructions

MST 22 MM / MR models

Welcome to the wonderful world of guitar building!

These are the tools and supplies we recommend for assembling this kit.

(Stew Mac item numbers are included where applicable.)

Nut-slotting files

0.010" width(#0821)

0.013" width (#0823)

0.020" width (#0828)

0.035" width (#0832)

0.042" width (#0833)

0.046” width (#5313

Electric hand drill or Bench Drill press

Small Hammer # 4895

ESP Multi Spanner # 1344

Phillips screwdrivers, size #1 & #2 (#3000)

Understring radius guages Item # 0353

Center punch or awl (#3000)

Clamp (#3721)

Soldering iron

Drill bits: 1/16” 5/64“ 3/32” 7/64“ 1/8” 11/64“

Whether you are a first time builder or Professional Luthier this kit will

give you a top quality "Custom Shop grade"

Great sounding Great playing instrument.

This Kit Features Genuine Wilkinson Hardware,

Tuners and Pickups. CTS pots and CRL switches.

This manual suits for next models

1

Other HMI Musical Instrument manuals