Power Supply

The measuring instrument HMP PDGpro is powered by a rechargeable

Lithium-ion polymer battery pack (abbreviated herein-after as Lithium

polymer battery pack) which is provided with overcharge protection and

deep discharge protection.

Safety

❙Do not dismantle, open or shred Lithium polymer battery

pack. Exposure to the ingredients contained within or their

ingredients products could be harmful.

❙Do not expose Lithium polymer battery pack to heat or fire.

Avoid storage of device/battery pack in direct sunlight.

❙Lithium polymer battery pack must not be short-circuited.

❙Do not subject Lithium polymer battery pack to mechanical

shock.

❙Observe local, state and federal laws and regulations for

disposal.

❙The supplied accessories must only be used for devices

supplied by HMP and according to this instruction manual.

Any other use may cause damages.

Switching-off automatically

The measuring instrument HMP PDGpro switches off automatically, in

case there is no action for about 90 s.

The device will not switch off automatically, as long as it is in

the measuring mode.

If the Lithium polymer battery pack of the measuring instrument drops

below the voltage required for operation, the device switches off

automatically, in order to prevent a deep discharging of the battery

pack. Before switching on the instrument again, please charge the

battery pack.

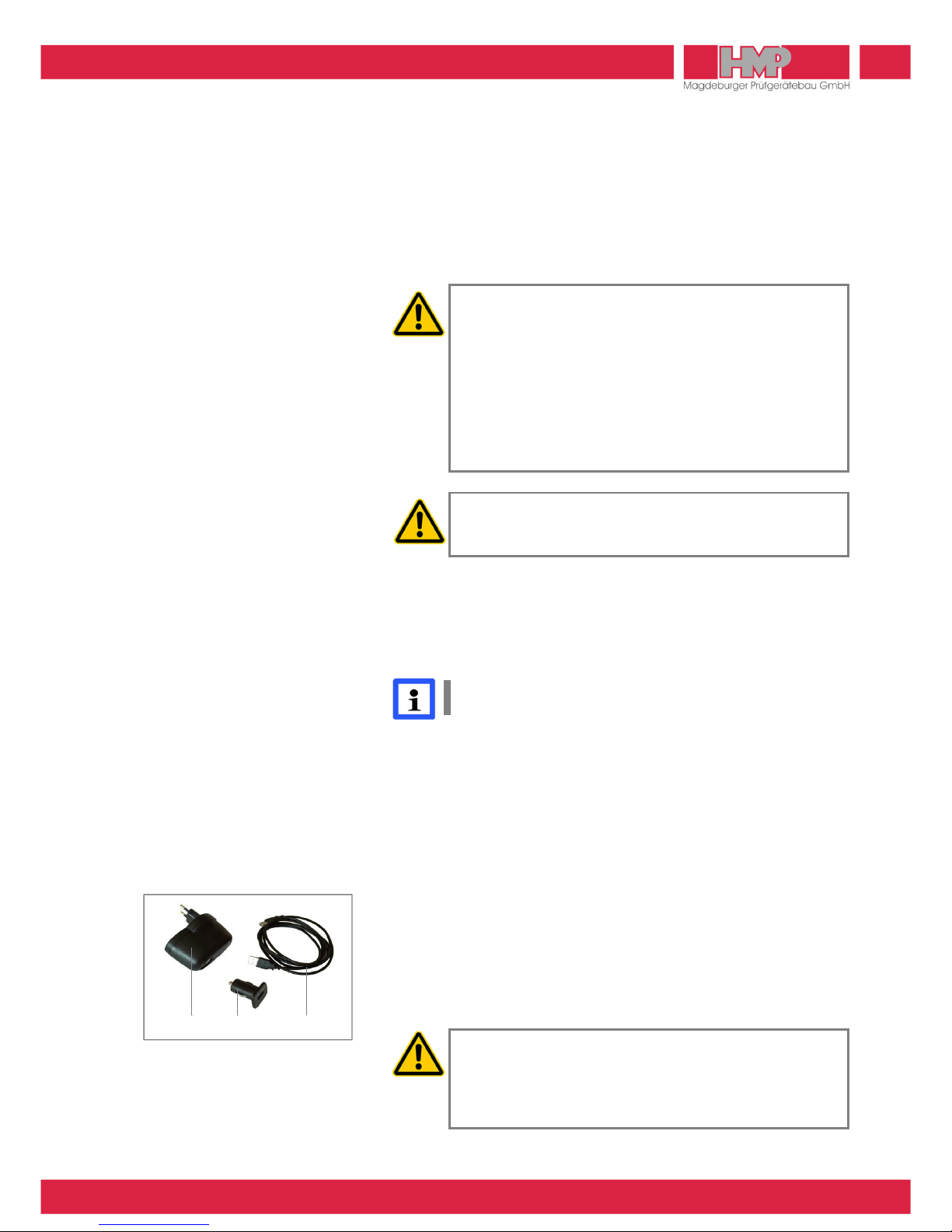

Charging of Lithium polymer battery pack

Lithium polymer battery pack should be charged only by means of the

supplied accessories (Figure 8). Accessories for charging the battery

pack – USB cable (1), USB car charger (2) and AC/ C adapter (3) – are

placed in the carrying case.

The USB car charger can be connected with a car-battery 12 V or by

means of AC/ C adapter to mains 230 V / 50 Hz.

❙For charging Lithium polymer battery pack only the supplied

chargers, which are provided for use with this device, should

be used.

❙Lithium polymer battery pack should not be charged over a

longer period if it is not needed.

2