3 of 45

Installation, operation, and maintenance manual-ABE Rev 1_2023

SUMMARY

Table des matières

1. CODE AND REGULATION ......................................................................................................................................... 4

2. GENERAL INFORMATION ......................................................................................................................................... 5

2.1. INTRODUCTION....................................................................................................................................................... 5

2.2. RESPONSIBILITIES ................................................................................................................................................... 5

2.3. RECEPTION AND STORAGE ..................................................................................................................................... 5

2.4. LIMITED GENERAL WARRANTY ............................................................................................................................... 6

2.5. PARTS, REPAIRS AND MAINTENANCE .................................................................................................................... 7

3. INSTALLATION INSTRUCTIONS ................................................................................................................................. 8

3.1. GENERAL ................................................................................................................................................................. 8

3.2. UNPACKING ............................................................................................................................................................ 8

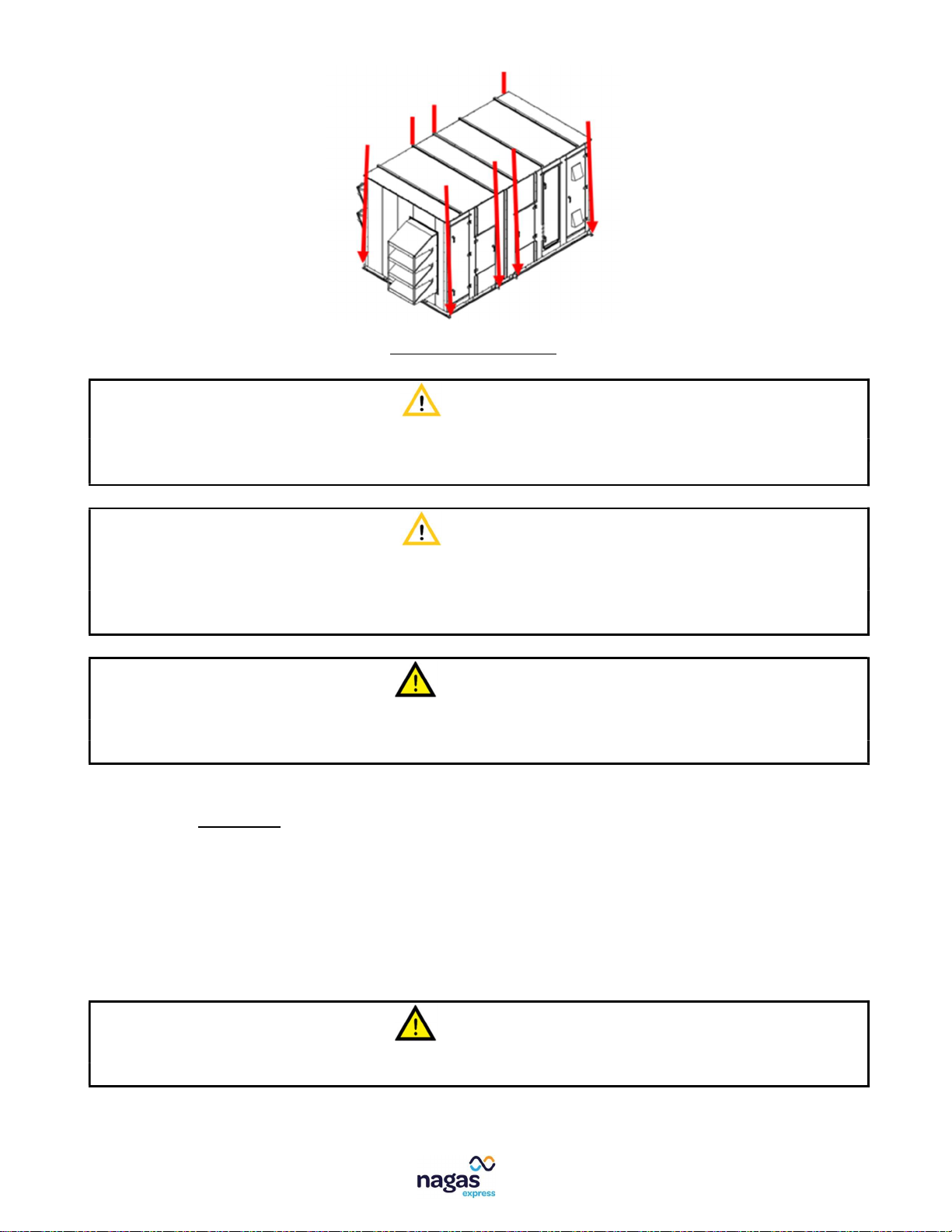

3.3. LIFTING .................................................................................................................................................................... 8

3.4. ASSEMBLY ............................................................................................................................................................... 9

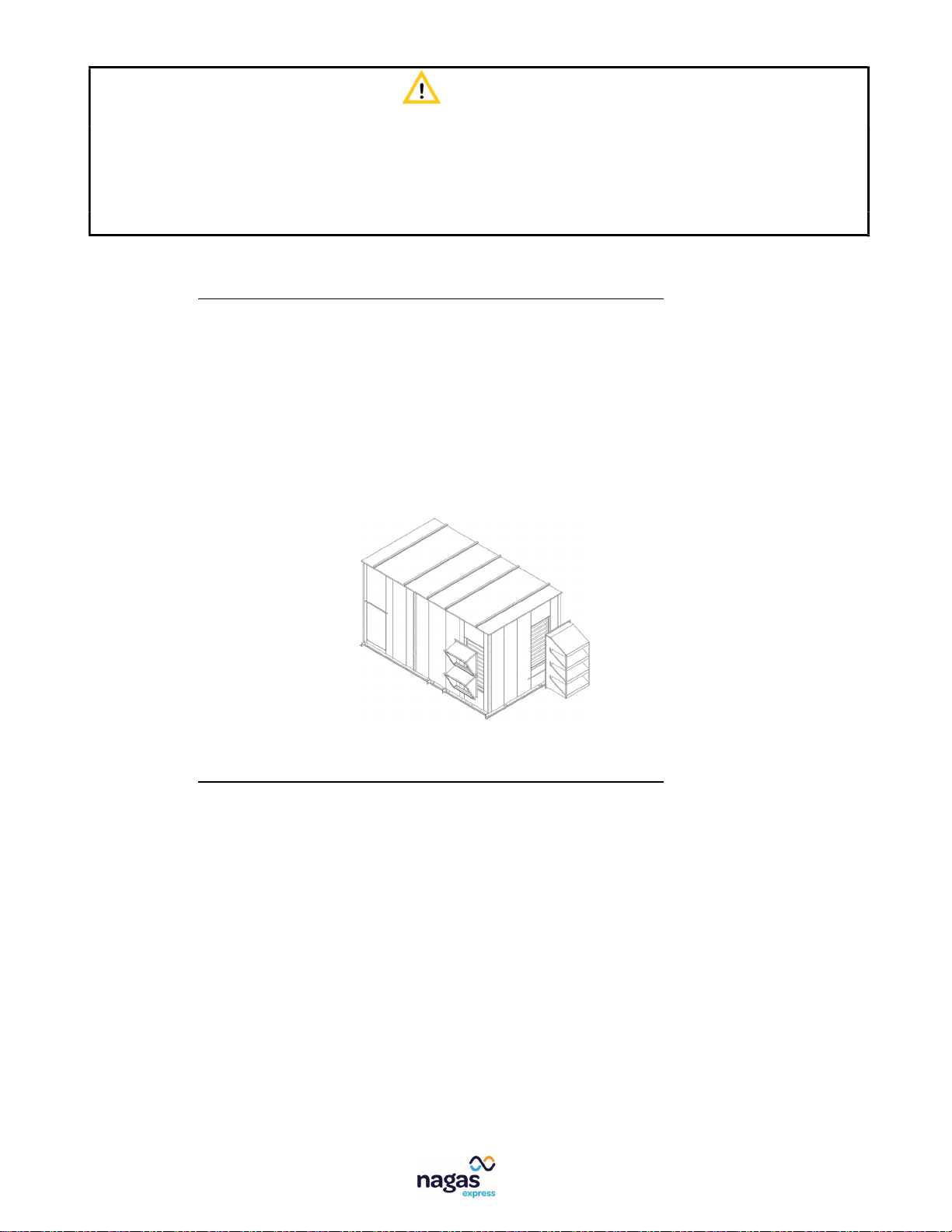

3.5. INSTALLATION OF AIR INLET/OUTLET COVERS (IF REQUIRED) ........................................................................... 10

3.6. INSTALLATION OF AIR INLET/OUTLET COVERS (IF REQUIRED) ........................................................................... 10

4. START-UP INSTRUCTIONS ...................................................................................................................................... 12

5. SHUTTING DOWN THE UNIT .................................................................................................................................. 13

5.1. EXTENDED SHUTDOWN ........................................................................................................................................ 13

5.2. EMERGENCY SHUTDOWN ..................................................................................................................................... 13

6. PRINCIPLE OF OPERATION OF THE RECUPERATOR ................................................................................................. 14

6.1. DESCRIPTION OF THE RECOVERY UNIT HOUSING ................................................................................................ 15

7. SEQUENCE CONTROL ............................................................................................................................................. 16

7.1. LOCAL CONTROL MODE ........................................................................................................................................ 16

7.2. REMOTE CONTROL MODE .................................................................................................................................... 16

7.3. BACNET CONTROL MODE ..................................................................................................................................... 17

7.4. CONTROL OF THE RECUPERATION ........................................................................................................................ 18

8. CONTROL INTERFACE HMI ..................................................................................................................................... 20

8.1. NAVIGATION IN THE HUMAN MACHINE INTERFACE (HMI) ................................................................................. 20

8.1.1. HMI STRUCTURE........................................................................................................................................... 21

8.1.2. BACNET LIST ................................................................................................................................................. 30

8.1.3. ALARMS LIST ................................................................................................................................................ 32

9. TYPICAL WIRING DIAGRAM ................................................................................................................................... 34

9.1. TYPICAL WIRING DIAGRAM .................................................................................................................................. 34

9.2. TYPICAL CONTROL PANEL ..................................................................................................................................... 40

10. UNIT MAINTENANCE ......................................................................................................................................... 41

11. BLOWERS BALANCING PROCEDURE .................................................................................................................. 43

12. STARTUP REPORT .............................................................................................................................................. 44

NOTICE: The specifications, illustrations and description in this document were, to the best of our knowledge,

accurate at the time they were approved for printing. Nagas Innovation Inc. has a policy of continuous

product improvement and reserves the right to change design and specifications, discontinue offering certain

features, or discontinue production of a given model size without notice. For more information, please

contact your local representative and your authorized distributor.