HMT MAX100T User manual

USER MANUAL

HMT MAX100T

Magnetic Drilling Machine

SERIAL NO.____________

DATE OF PURCHASE __________

PLACE MACHINE MOTOR STICKER HERE

HMT_MAX100T_V1

2

Congratulations on your purchase of the HMT MAX100T Portable Magnetic Drilling Machine.

Your model is designed to produce superior holes quickly and efficiently. Through years of

experience, constant innovation and development, HMT is committed to provide you with

cutting tool innovation to speed up metalworking.

Before operating your new magnetic drilling machine, please read all instructions first. These

include

the Operator’s Manual and Warning Label on the unit itself. With proper use, care and

maintenance, your model will provide you with years of effective hole drilling performance.

TO REDUCE THE RISK OF INJURY USER MUST READ AND UNDERSTAND ALL

INSTRUCTIONS

Holemaker Technology Ltd (HMT)

OSC, The Forge

Wheelers Lane, Linton

Kent, ME17 4BN

United Kingdom

0044 (0) 1622 740812

sales@holemaker-technology.com

www.holemaker-technology.com

HMT_MAX100T_V1

3

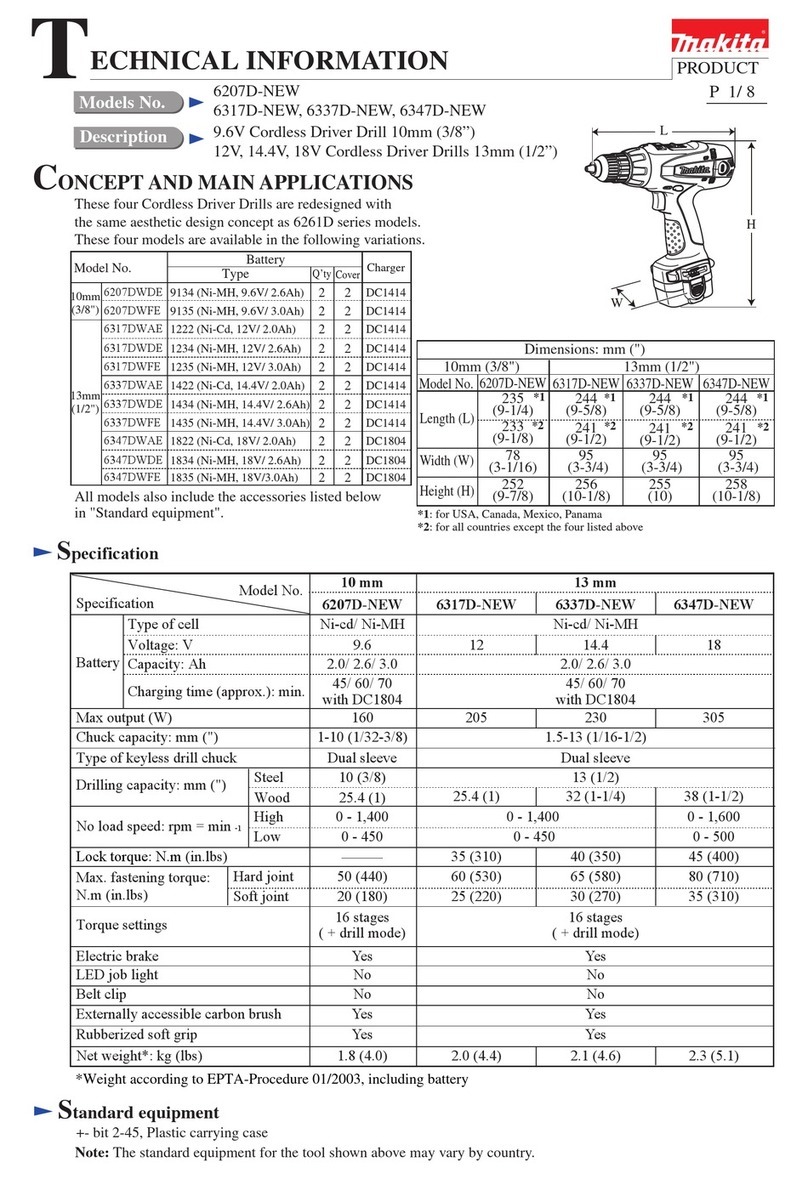

Fig. 1

HMT_MAX100T_V1

4

Explanation of terms used and Pictograms marked on tool

HMT_MAX100T_V1

5

GENERAL POWER TOOL SAFETY WARNINGS

Do not use this power tool before you have thoroughly read and completely understood this

Instruction Manual and the “General Safety Instructions”, including the figures, specifications,

safety regulations and the signs indicating DANGER, WARNING and CAUTION.

WARNING: When using electrical tools basic safety precautions should always be

followed to reduce the risk of fire, electrical shock and personal injury including

following.

Please also observe the relevant national industrial safety regulations. Non-observance of

the safety instructions in the said documentation can lead to an electric shock, burns and/or

severe injuries.

This Operator’s Manual and the “General Safety Instructions” should be kept for later use

and enclosed with the power tool, should it be passed on or sold.

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and dark areas invite

accidents.

2. Do not operate magnetic drilling machine in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Magnetic drilling machine may create

sparks which may ignite the dust or fumes.

3. Keep bystanders, children, and visitors away while operating a magnetic drilling

machine. Distractions can cause you to lose control.

ELECTRICAL SAFETY

1. Magnetic drilling machine plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs.

2. Avoid body contact with grounded surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

3. Do not expose magnetic drilling machines to rain or wet conditions. Water entering a

machine will increase the risk of electric shock.

4. Do not abuse the cord. Never use the cord to carry the magnetic drilling machine or

pull the plug from an outlet. Keep cord away from heat, oil, sharp edges or moving

parts. Replace damaged cords immediately. Damaged cords increase the risk of

electric shock.

5. When operating a magnetic drilling machine, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

6. If operating a magnetic drilling machine in a damp location is unavoidable, use a

residual current device (RCD) protected supply. Use of an RCD reduces the risk of

electric shock. Conform to local or site specific regulations.

PERSONAL SAFETY

1. Stay alert, watch what you are doing and use common sense when using a magnetic

drilling machine. Do not use machine while tired or under the influence of drugs,

alcohol, or medication. A moment of inattention while operating magnetic drilling

machines may result in serious personal injury.

HMT_MAX100T_V1

6

2. Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your

hair, clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

3. Avoid accidental starting. Be sure switches are off before plugging in.

4. Never place hands, fingers, gloves or clothing near cutting area or rotating machine

parts.

5. Remove adjusting keys or switches before turning the machine on. A wrench or a key

that is left attached to a rotating part of the machine may result in personal injury.

6. Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the magnetic drilling machine in unexpected

situations.

7. Use safety equipment. Always wear eye protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must be used for appropriate conditions.

8. Always use supplied safety chain during any work on non-horizontal components.

Mounting can release.

MACHINE USE AND CARE

1. When using the machine on non-horizontal surfaces, cutting paste or spray paste is

recommended. Do not use oil type liquids where oil can drip into the motor unit.

2. During machine operations, the annular cutter must be cooled and lubricated with

good quality cutting or lubrication oil. Remove the slug from the annular cutter after

each hole. Caution, the slug may be hot!

3. Use clamps or other practical way to secure and support the work piece to a stable

platform. Holding the work by hand or against your body is unstable and may lead to

loss of control.

4. Do not use machine if switch does not turn it on or off. Any tool that cannot be

controlled with the switch is dangerous and must be repaired.

5. Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool. Such preventive safety measures reduce the risk of

starting the tool accidentally.

6. When not in use, store Magnetic drilling machines out of reach of children and other

untrained persons. Tools are dangerous in the hands of untrained users.

7. Maintain machines with care. Keep cutting tools sharp and clean. Properly

maintained tools, with sharp cutting edges are less likely to bind and are easier to

control.

8. Check for misalignment or binding of moving parts, breakage of parts, and any other

condition that may affect the machine operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

9. Use only accessories that are recommended by HMT for your model. Accessories

that may be suitable for one machine, may become hazardous when used on another

machine.

SERVICE

1. Tool service must be performed only by qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

2. When servicing a tool, use only identical replacement parts. Follow instructions in the

Maintenance section of this manual. Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk of electric shock or injury.

3. When using this machine, you MUST wear ear and eye protection.

HMT_MAX100T_V1

7

ADDITIONAL SPECIFIC SAFETY RULES FOR MAGNETIC DRILLING MACHINES

•Keep your fingers well out of the drill area;

•Avoid touching the drilled core that is automatically ejected by the centering pin when

the working procedure is finished. Contact with the core when it is hot, or if it falls, can

cause personal injuries;

•Always use the drill guard. Before turning on machine ensure the guard is closed

securely;

•Always use the safety strap;

•The magnetic drilling machine is suitable for use on steel with a thickness starting

from 10 mm, with zero air gap between the magnet core surface and the mounting

surface. Curvature, coats of paint and surface irregularities will create an air gap.

Keep the air gap to a minimum;

•Always place the machine on a flat surface;

•Do not clamp the magnetic drilling machine on small or irregularly shaped objects;

•Always place the machine on a surface that is clear of shavings, chips, swarf and

surface dirt;

•Keep the magnet clean and free of debris and swarf;

•Do not turn on the machine until it has been mounted and installed according to these

instructions;

•Do not turn on the machine before having checked that the magnetic stand has been

tightened firmly to the mounting surface;

•Adjust the table so cutter does not extend into the work piece before drilling. Do not

perform any design, assembly or construction activities on the work piece while the

machine is turned on;

•Before turning on the machine, make sure the accessory has been mounted

correctly;

•Always use the recommended speed for the accessories and the material;

•Do not use the machine on the same work piece on which electric welders are being

used;

•Use only an appropriate cutting fluid. We offer a range of premium cutting oils and

lubricants which are specially developed and selected for optimum performance and

maximum tool life;

•Do not use liquid cutting fluids while drilling vertically or overhead. Dip the cutter in

cutting paste or apply an appropriate spray for these applications;

•Do not pour cutting fluid into the reservoir while it is mounted in the bracket. Do not

allow cutting fluid to enter the drill motor;

•Before use, ensure movable chuck guard operates properly; Use Guard to protect

user from flying chips and debris, and to protect from entry to moving spindle and

tool. Switch off motor to clear swarf build up during the cut.

•Ensure that metal chips or resinous residue cannot lead to blockage of the function;

•In case of jammed cutter disconnect the machine from the power supply, remove the

reason for the jam before turning on the machine again.

•Magnetic drills, pillar drills, and similar drill press equipment should have clear and

unambiguous emergency stop features in accordance with current CE Markings

and Directives

•Do not touch rotating tools, spindles, arbors or adaptors

•Do not place loose fitting gloves (especially Rigger Gloves), items of clothing, or

jewellery near rotating tools or machine spindles.

HMT_MAX100T_V1

8

•Safety chains or similar restraints should be used to prevent a magnet drill falling in

the event of a power cut to the electromagnetic base. Use extra caution with

generator power supply for this reason

•Wear approved Eye / Face guard, ear protection and hand protection at all times.

•Inspect cutting tools before use: Do not use the tool if cracks or damage is

observed on any part of the tool.

•Use cutting tools within the torque and RPM recommendations

•Inspect the cutting tool regularly for any signs of damage. Immediately replace the

tool if any damage is found.

•Before use, ensure the cutting tool is inserted securely into designated arbor,

adapter or socket.

•Be sure to disconnect power when handling cutting tools.

•Use Impact type cutting tools only with Impact rated sockets, extensions, adapters

& accessories.

•Risk assessment and method statements should be produced and followed by the

user at all times

•Metal swarf and chips produced should be assessed for potential cut hazards

•Excessive lubrication use should be assessed for potential slipping hazards,

especially on smooth or painted surfaces

•Position appropriate guarding to protect users and passers by from chips, debris

and entanglement hazards

•Slugs produced by annular cutters can become a hazard if they are allowed to fall

from height.

•Material, slugs, and swarf in recent contact with cutting tools can become very hot

RESIDUAL RISKS

In spite of the application of the relevant safety regulations and the implementation of safety

devices, certain residual risks cannot be avoided.

These are:

Impairment of hearing; Wear ear protection in areas with noise emissions > 80 db(A).

•Risk of personal injury from flying particles;

•Risk of burns due to accessories becoming hot during operation;

•Risk of personal injury due to prolonged use.

HMT_MAX100T_V1

9

POSITION Serial number

The Serial Number, which also includes the type of machine, the year and month of

manufacturing and identification number, is engraved on the frame, magnet and the motor

unit.

Example:

30 14 09 001

Model type

Year of Manufacture

Month of manufacture

Identification number

Package Contents

1 Magnetic drilling machine

1 Carrying case

1 Drill guard

3 Handles

1 Allen Key 2.5

1 Allen Key 3

1 Allen Key 4

1 Allen Key 5

1 Wrench

1 Lubrication system

1 Cutting oil

1 Safety chain

1 Operators manual

1 Exploded drawing

1 Safety Ear Protection

1 Safety Glasses

1 Safety Gloves

HMT_MAX100T_V1

10

TECHNICAL DATA HMT MAX100T

Emission values for sound and vibration

(Two-figure –specifications as per ISO 4871)

Sound emission

Measured A-weighted sound power level LwA (re 1 pW), in

decibels 100

Measuring uncertainty KwA, in decibels 3

A-weighted emission pressure power level measured at the

workplace LpA (re 20 μPa), in decibels 100

Measuring uncertainty KpA, in decibels 3

Vibration emission

Rated acceleration, in m/s² 0.5

Measuring uncertainty K, in m/s² 1.5

REMARK: The sum of the measured emission value and respective measuring inaccuracy

represents

the upper limit of the values that can occur during measuring.

Wear ear protection!

For measurement values obtained according to the respective product standard, see the last

page of this Instruction Manual.

HMT_MAX100T_V1

11

DESCRIPTION (fig. 1)

WARNING: Never modify the power tool or any part of it. Damage or personal injury

could result.

1. Safety Guard

2. Feed handle

3. Cooling system tank

4. Magnetic stand

5. Magnet switch

6. Motor switch

INTENDED USE

This magnetic drilling machine is intended for commercial use as a drilling machine for

drilling materials with a magnetizable surface using annular cutters and twist drill. Some

magnetic drills are also suitable for for tapping, countersinking and reaming in a weather-

protected environment using the application tools and accessories recommended by HMT

The magnetic drilling machine can be used horizontally, vertically or overhead.

INSTRUCTIONS FOR PUTTING INTO OPERATION

Please make sure that the contacting surface for the magnet is level, clean and rust-free.

Remove any varnish or primer. When working on materials that are not magnetizable,

suitable fixation devices, obtainable as accessories from HMT e. g. suction plate, vacuum

plate or pipe-drilling device must be used.

When working on steel materials with a material thickness of less than 12 mm, the workpiece

must be reinforced with an additional steel plate in order to guarantee the magnetic holding

power.

Check the machine for possible damage; Before using the machine, you must carefully

check protective devices or slightly damaged components to ensure they are operating

perfectly and as intended.

Check that moving are in perfect working order and do not jam and check whether parts are

damaged. All parts must be correctly installed and fulfill all conditions necessary to ensure

perfect operation of the machine.

Damaged protective devices and parts must be repaired or replaced according to

specifications by HMT of any authorized HMT dealer.

DO NOT use under wet conditions or in presence of flammable liquids or gases. This

magnetic drilling machine is a professional power tool.

DO NOT let children come into contact with the machine. Supervision is required when

inexperienced operators use this machine.

ELECTRICAL SAFETY

The electric motor has been designed for one voltage only. Always check that the power

supply

corresponds to the voltage on the rating plate.

Your HMT MAGNETIC DRILLING MACHINE is designed in class I (grounded) according to

EN 61029-1. Earth wire is required.

HMT_MAX100T_V1

12

If the supply cord is damaged, it must be replaced by a specially prepared cord available

through the HMT service organization.

EXTENSION CABLE

If an extension cable is required, use an approved 3-core extension cable suitable for the

power input of this tool (see technical data).The minimum conductor size is 1.5 mm²; the

maximum length is 30 meter. When using a cable reel, always unwind the cable completely.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or

changing set- ups or when making repairs. Be sure the switch is in the OFF position.

An accidental start-up can cause injury.

PREPARATION OF THE MACHINE (FIG. 1)

1. Assemble the feed handle.

2. Mount the drill guard.

3. Fit the lubrication system as necessary.

4. Place the machine on a clean, level and solid surface. Remove any particles that will

obstruct full contact between the magnetic stand and the mounting surface.

5. Fit the safety chain (in vertical or overhead drilling applications).

MOUNTING THE DRILL GUARD (FIG. 1)

The guard protecting against chippings and accidental contact must always be mounted

during operation.

1. Hold the guard in front of the magnet, aligning the slots in the guard with the holes in

the magnet.

2. Fit the screws into the hole located in the side of the magnet.

WARNING: Always use the safety guard.

FITTING THE LUBRICATION SYSTEM (FIG. 1)

The lubrication system can be used for horizontal drilling applications (the drill being used

vertically).

•Hold the cooling tank against the bracket on the slide and push it in its place.

•Connect the hose to the nipple on the spindle drive shaft.

In order to use the lubrication system, it must be filled with a sufficient amount of cutting fluid.

1. Make sure the flow regulator is closed;

2. Unscrew the cap;

3. Fill the container with cutting fluid;

4. Screw the cap back on.

WARNING: Do not use the lubrication system in vertical or overhead drilling

applications where a liquid oil can run down over the motor

FITTING THE SAFETY CHAIN/STRAP

1. Pass the safety chain through the opening near the grip;

2. Wrap the chain around the work piece;

3. Securely close the chain using the lock.

WARNING: Always use the safety chain/strap when using machine vertically and/or

upside-down..

HMT_MAX100T_V1

13

INSERTING AND REMOVING AN ACCESSORY

The tool holder accepts annular cutters with a 19,05 mm Weldon shank with one or more

flats.

WARNING: The teeth of a cutter are very sharp and can be dangerous.

1. In order to fit an annual cutter it is necessary to remove the guard (1);

2. Slide the pilot pin through the hole in the center of the cutter shank.

3. Insert the shank of the accessory as far into the tool holder as possible.

4. Tighten the two Allen screws with Allen key;

5. To remove the accessory, loosen the Allen screws and take out the cutter.

PRIOR TO OPERATION

Try a few simple projects using scrap material until you develop a “feel” for the machine.

OPERATION

Instructions for use

WARNING: Always observe the safety instructions and applicable regulations.

WARNING: To reduce the risk of serious personal injury, turn tool off and disconnect

tool from power source before making any adjustments or removing/installing

attachments or accessories.

MAGNETIC BASE

Material of minimum 10 mm thickness is required for the magnet to work the best.

The attachment force generated by the magnet depends on various factors.

•Thickness of the material the magnet is placed on;

•Paint or coating of the material the magnet is placed on;

•Metal chips, oil or other dirt under the magnet.

Make sure that the magnet attaches tightly to the work piece before turning on the motor unit

of the magnetic drilling machine. HMT magnets have 2 coils; make sure that both coils are in

contact with the material. Do not connect any other machines to the electrical outlet the

magnetic drilling machine is plugged into, as it may result in the loss of magnetic force.

Always use the safety chain included. Drilling above your head can be dangerous and is not

recommended. The use of magnetic drilling machines on pipes, not-flat or non-magnetic

materials is not recommended without specialist attachments

HMT_MAX100T_V1

14

THE CONTROL PANEL

1. The L/R Switch- This switch controls the direction of the motor unit. L is left

hand rotation, R is right hand rotation

2. The Motor Switch- This switch is used to switch the MOTOR unit ON and OFF

3. The Magnet LED indicator –this shows the generated magnetic force

4. The Fuse holder with Fuse- This fuse holder hold the fuse type 5x20, F2A

5. The Potentiometer –this controls the running speed of the motor unit. Note a

lower position will decrease the power as well as the speed of the motor unit

6. The Magnet switch –This is used to switch the main power and also the

magnet ON and OFF.

In order to operate properly, the machine has to be turned on following the

following procedure

Activating the magnet.

Connect the machine to the mains/work piece. To activate the magnet, press the red

button (FIG 2-6) above. The switch will be lit Red. The LED indicator will be lit GREEN if

the generated magnetic force is deemed sufficient hold. When LED indicator turns to

RED there is not enough magnet force to hold and it is not safe to proceed to drilling or

similar operations. To deactivate the magnet, press the same buttong (FIG 2-6) again

Turning the Motor ON and OFF

The motor unit can only be switched on when the magnet is activated. To turn the motor

on, press the green button with the marking “I”(fig 2-2) to switch the motor off, press the

red button with marking “0” figure

Torque

HMT_MAX100T_V1

15

The MAX100T is equipped with an all-time electronic torque protection. It will stop the

motor unit when it gets overloaded. In that case just push the OFF switch to reset and

ON switch to start drilling again

Temperature

The ECO50T is equipped with an all-time electronic temperature protection. If the

temperature of the motor unit runs up to 70 Degree Celsius the motor unit will stop. After

a few minutes it can be started again, and it is recommended to run the motor unloaded,

with speed dial ( see 5. Potentiometer) set on 100% in order to allow the motor to cool

down

The Electronic Controls

On the side of the motor unit are the

variable electronic control wheels. The

blue wheel regulates the rotation speed,

and the red wheel regulates the torque

power of the motor unit

When drilling with larger diameter cutters

or demanding applications, start drilling

with the torque wheel in a low position to

prevent cutter damage. Increase the

power setting slightly when the machine

stops before the task is achieved. When

the machine stops because of torque

overload, prese the O then the I button on

the on/off switch to start drilling again (Fig

2-2)

4- Speed manual Gearbox

The MAX100T is equipped with a 4 speed gearbox. The 2 gear switches makes it possible to

chose 4 manual speeds. Also the MAX100T has the electronic controls as detailed above so

the speed can be varied within each gear speed.

It is important that the closest mechanical gear is selected first with the blue wheel set to

fastest speed, and after that the speed decreased by dialing down the blue wheel electronic

adjustment. It is recommended the blue wheel electronic speed control is kept above 50% to

prevent the armature overheating.

600RPM –left switch up, right switch down

For twist drills 1-16mm, Hole cutters to

26mm

370RPM –left switch up, right switch up

For twist drills 16-24mm, Hole cutters up to

27- 50mm

175RPM –left switch down, right switch

down

For Hole cutters 50-80mm, for reamers

and taps <14mm

110RPM –left switch down, right switch up

For Hole cutters 80-100mm, for reamers,

countersinking, tapping

HMT_MAX100T_V1

16

The above RPM is guide advice only as all workpieces and tooling have different parameters

and should be used in accord with manufacturer’s instructions. The wear condition,

lubricant, hardness of material can all affect the optimum RPM required

To select the other gear, turn of motor unit and main power. Push the black switch on the

side of the gearbox, and slide to other position. A slight turn of the shaft by hand while sliding

the black switch to the other position, can be necessary, to line up the gears inside. If the

gears are not lined up correctly, the switch will be in a slightly raised position. When correctly

set, the switch will sit flush in the recess

DRILLING A HOLE

Now that you have read the explanatory information and safety recommendations above, you

are ready to actually start drilling. Follow these 10 steps for best drilling result:

1 Use the tip of the pilot pin to determine the center of the hole to be drilled.

2 Turn the magnet on and verify that the drill is in the right position and that the machine is

pushed tight against the work piece.

3 If your machine is equipped with a auto coolant system, put open the valve to release

the oil. If your machine does not have a auto coolant system, fill the holes of the spindle

with oil.

4 Turn the motor on at the highest setting and allow it to run at full speed.

5 Turn the arms to start drilling. Apply only a slight pressure when the Annular Cutter touch

the metal. Do not push the Annular Cutter with force into the metal.

6 Apply a regular pressure while drilling. The drilling performance does not improve by

putting more pressure on the tool. Too much pressure will overload the motor and your

Annular Cutter will be worn sooner. Let the cutter do the job and give it time to cut

the metal!!!

7 Adjust the oil supply when necessary, if your drill does not have a auto coolant system,

stop drilling regularly, refill the holes of the spindle and continue drilling.

8 Apply less pressure when the drill cuts through the material.

9 Turn the arms to put the motor in highest position and turn off the motor unit.

10 Remove the burr, metal chips and clean the cutter and surface without getting injuries.

Caution : The metal piece drilled out can be sharp and very hot!!

DRILLING WITH ANNULAR CUTTERS

Annular cutters only cut material at the periphery of the hole, rather than converting the entire

hole to shavings. As a result, the energy required to make a hole is lower than for a twist drill.

When drilling with an annular cutter, it is not necessary to drill a pilot hole.

WARNING: Do not touch the cutter or the parts close to the cutter immediately after

operation, as they may be extremely hot and cause burns to the skin. Ensure nobody

is in the work area where the metal core is ejected.

HMT_MAX100T_V1

17

DRILLING CONDITIONS

The ease with which material can be drilled depends on several factors including tensile

strength and

abrasion resistance. Whilst hardness and/or strength is the usual criterion, wide variations in

machineability can exist among material showing similar physical properties.

The drilling conditions are dependent on requirements for tool life and surface finish. These

conditions are further restricted by the rigidity of the tool and the work piece, lubrication and

machine power available. The harder the material, the lower the cutting speed.

Some materials of low hardness contain abrasive substances leading to rapid cutting edge

wear at high speeds. Feed rates are governed by rigidity of set-up, volume of material to be

removed, surface finish and available machine power.

THREADING –The machine is equipped with a reversible direction of rotation and can also

be used for cutting threads. Process as follows (for cutting a standard Right hand thread)

•Drill/create a pilot hole which is the correct size for the required tap thread

•Switch of the machine (Fig 2-2) to fit the tap

•If possible, keep the machine in the same position

•Select the lowest gear (Fig. 4 and lowest speed (Fig 2-5) and set the direction of

rotation to clockwise (right = R) at switch (Fig 2-1)

•Switch on (Fig 2-2) the machine and set the tap into the drilled hole

•Guide the tap into the hole using the handles, without exerting excess force. Let the

tap pull itself through the cut with a light pressure on the handle

•Switch of (Fig 2-2) the machine (just before the tap is completely through the hole.

Allow for the extra rotation as the tap slows to a stop.

•Set the direction of rotation to anti-clockwise (Left = L) at switch (Fig 2-1)

•Switch on the machine (Fig 2-2) and allow the tap to thread itself backwards out of

the threaded hole in the work piece. Guide with a light pressure on the handles. Do

not let the tap push up (withdraw) the motor unit by itself

Countersinking/ Reaming. Due to the wide range of operating speeds, the machine can be

used for reaming or countersinking

LUBRICATION

IN HORIZONTAL APPLICATIONS

•Adjust the fluid flow as required using the flow regulator;

•Add more cutting fluid if the shavings (metal chips) become blue.

VERTICAL AND OVERHEAD APPLICATIONS

Dip the cutter in cutting paste or apply an appropriate spray.

LUBRICATING THE FEED TRAVEL

The feed travel should be lubricated periodically with grease to ensure smooth operation.

•Raise the motor unit to the highest position possible;

•Lubricate the dove-tail guide way at both sides;

•Lubricate the gear rack.

After repeated use, the gear rack may become loose. If necessary, adjust the 5 self-locking

set screws at the left side. Tighten screws in series until the gear rack moves freely in the

dove-tail guide but does not allow the motor to wobble.

Cleaning

HMT_MAX100T_V1

18

WARNING: Blow dirt and dust out of the main housing with dry air as often as dirt is

seen collecting in and around the air vents. Wear approved eye protection and

approved dust mask when performing this procedure.

WARNING: Never use solvents or other harsh chemicals for cleaning the non-

metallic parts of the tool. These chemicals may weaken the materials used in these

parts. Use a cloth dampened only with water and mild soap. Never let any liquid get

inside the tool; never immerse any part of the tool into a liquid.

Optional Accessories and tooling

WARNING: Since accessories and tooling, other than those offered by HMT, have

not been tested with this product, use of such accessories with this tool could be

hazardous. To reduce the risk of injury, only HMT recommended accessories and

tooling should be used with this product.

Consult your dealer for further information on the appropriate accessories.

HMT_MAX100T_V1

19

MAINTENANCE

Your HMT power tool has been designed to operate over a long period of time with a

minimum of maintenance. Continuous satisfactory operation depends upon proper tool care

and regular cleaning.

CAUTION: To reduce the risk of injury, turn unit off and disconnect machine from

power source before installing and removing accessories, before adjusting or

changing set- ups or when making repairs. Be sure the switch is in the OFF position.

An accidental start-up can cause injury.

Just as every magnetic drilling machine with moving parts, your HMT magnetic drilling

machine also needs regular maintenance service. A few recommendations follow :

VISUALLY CHECK THE MACHINE FOR DAMAGE

Machine must be checked before operation for any signs of damage that will affect the

operation of the machine. Particular notice must be taken of the mains cable, if the machine

appears to be damaged it should not be used failure to do so may cause injury or death.

CAUTION: Clean all dirt, dust, metal chips and burrs of your magnetic drilling

machine

OPERATION OF THE MACHINE

The machines operation must be checked to ensure that all components are working

correctly. Replace any defective parts immediately. This prevents properly function parts

from being damaged.

CARBON BRUSHES

Brushes should be checked to make sure there is no abnormal wear present. This should be

checked at least once a week if used frequently. If the carbon brush has worn more than 2/3

the original length the brushes should be changed. Failure to do so may cause damage to

the machine.

CHECK MAGNETIC BASE

Before every operation the magnetic base should be checked to make sure that the base is

flat and there is no damage present. An uneven magnet base will cause the magnet not to

hold as efficiently and may cause injury to the operator.

CHECK MACHINES GREASE

The gearbox grease should be checked once a month to ensure all moving components are

covered to prevent wear. The grease should be changed at least once a year to ensure you

gain the best from the machine.

CHECK ARMATURE

This should be checked at least 1 per month to check that there are visual signs of damage

to the body or to the commutator. Some signs of wear will be seen on the commutator over a

period of time this is normal as this is the part that comes in contact with the brushes but any

signs of abnormal damage and the part should be replaced.

HMT_MAX100T_V1

20

ADJUSTMENT OF SLIDE

An essential requirement of the machine is that the slide can move in a smooth and

controlled manner, free of lateral movement and vibration.

This situation can be maintained by periodic adjustment of the slide and is accomplished in

the following manner:

1. Place the machine in an upright position and, by means of the capstan, raise the slide

to its highest position. Clean the brass rail strips and apply a small amount of light

machine oil to the wear surfaces.

2. Commencing with the top screw, loosen both setting nut (#4 on spare part drawing)

with included wrench 8 and the setting screw (#5 on spare part drawing) with included

Allen key 2.5. Then gently feed in setting screw until slight resistance is encountered.

Follow your way down adjusting all setting nuts and screws.

3. Operate the slide up and down a few times to test the movement and make any

further necessary adjustments. Try to ensure that all the screws are exerting a

uniform pressure on the slide from top to bottom. A perfectly adjusted slide will

operate freely up and down without any sideways movement.

REPAIR, MODIFICATION AND INSPECTION

Repair, modification and inspection of HMT Magnetic drilling machines must be done by

HMT or an HMT authorized dealer. The spare parts list will be helpful if presented with the

machine to the HMT dealer for service when requesting repair or other maintenance.

HMT machines are constantly being improved and modified to incorporate the latest

technological advancements. Accordingly, some parts (i.e. part numbers and/or design) may

be changed without prior notice. Also, due to HMT’s continuing program of research and

development, the specifications of machines are subject to change without prior notice.

Table of contents