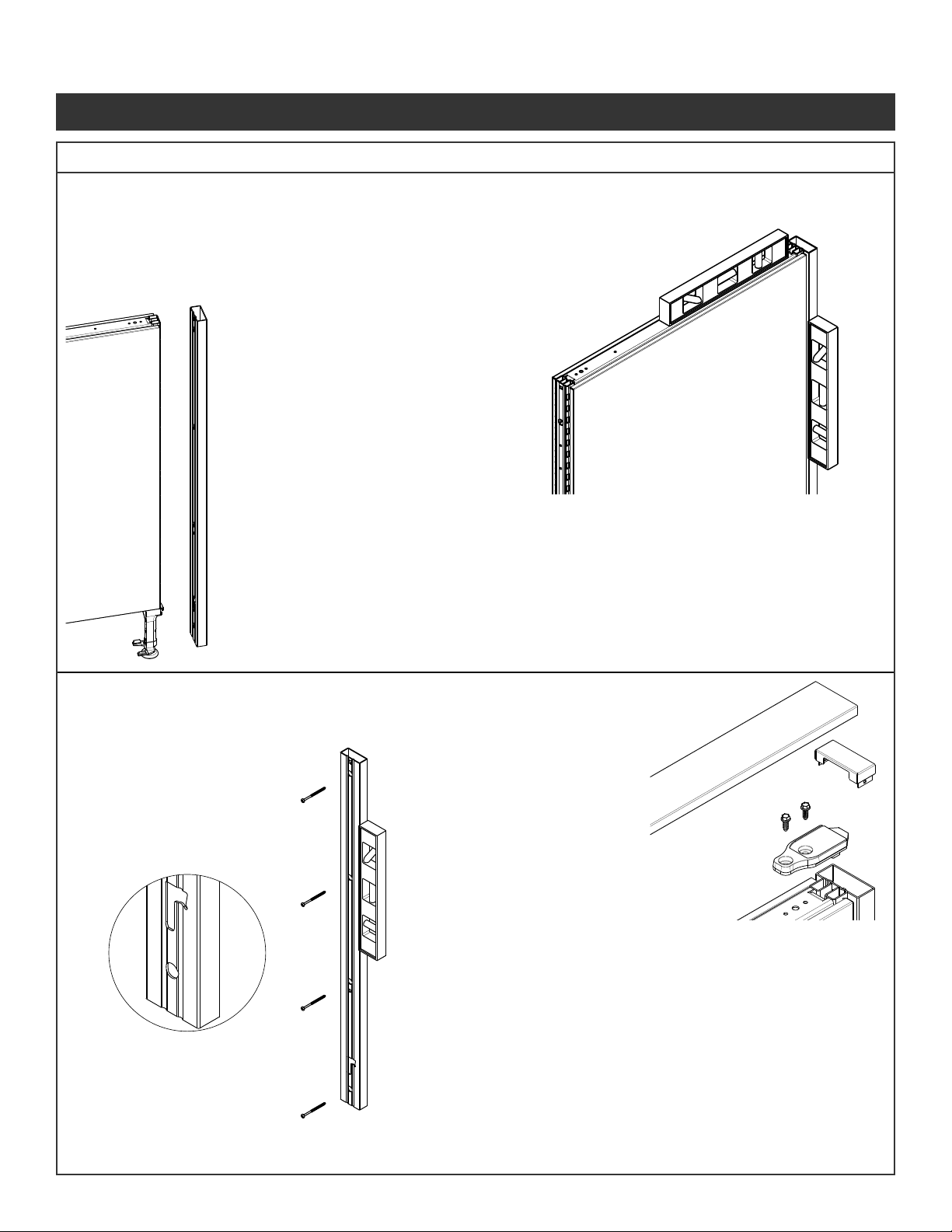

Current Style

Panel

Current Style

Panel

Previous

Style Panel

Previous

Style Panel

NOTE: Inline clip only required on one side of

panel connection.

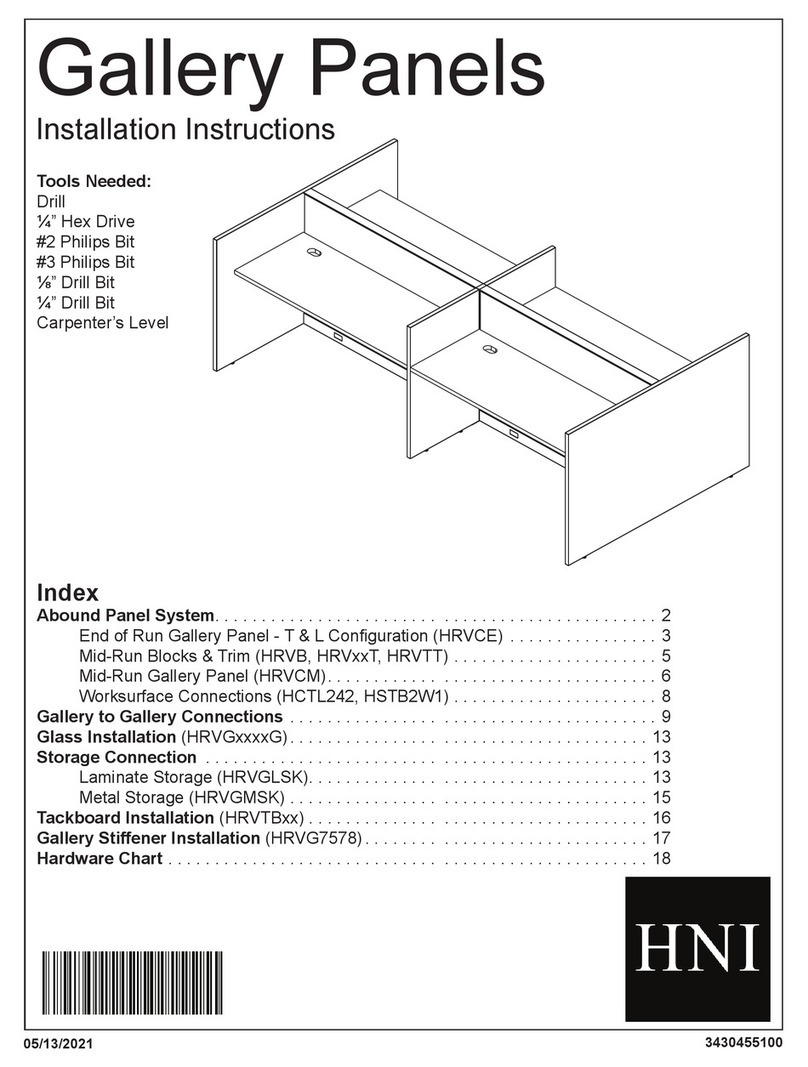

Step 1 - Remove the kickplate from one

side of each panel.

Step 2 - Position panels together with

the slotted vertical tubes in

alignment.

Step 3 - Secure the panels at the top by installing

the inline connector strap into slotted

steel tubes of both panels.

Step 4 - Attach the connector to the panels using

two screws (Fastener #1) provided.

Do not over torque.

Step 5 - Secure the panels at the bottom

by inserting a screw (Fastener #1)

through the slot in the glide tower into

the glide tower of the adjacent panel.

Step 6 - Reinstall kickplate.

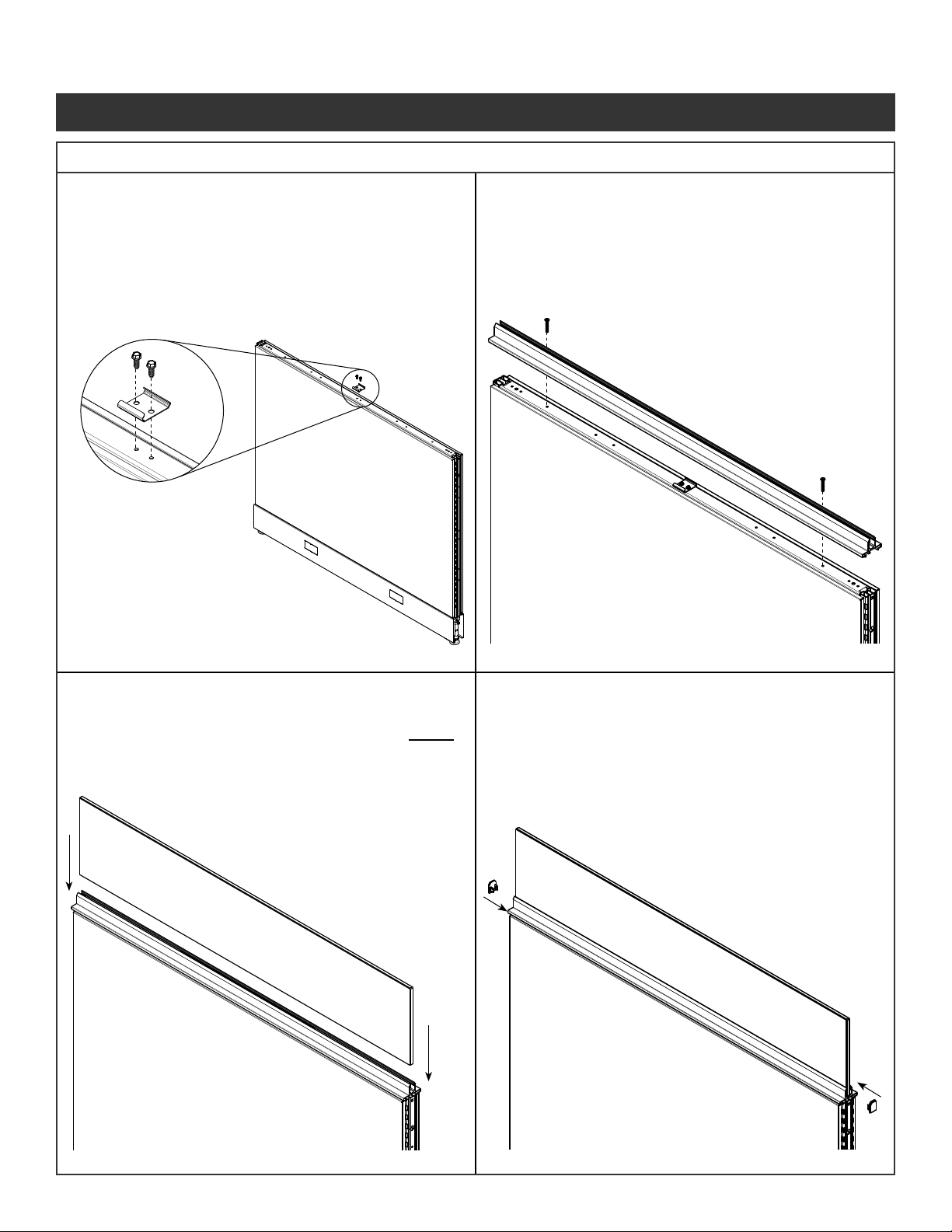

NOTE: Remove pins (Fastener #5) from

stackers for panel to panel connections.

Follow Steps 1 through 3 for current style connection.

Step 4 - Attach the connector to the current style panel

using one screw (Fastener #1) provided.

Do not over torque

Using the inline connector strap locate the hole

over the previous style panel. Using a 9/64 drill bit,

drill pilot hole into top horizontal tube.

Attach the connector to the previous style panel

using one screw (Fastener #1) provided.

Do not over torque.

Follow Steps 5 through 9 for current style connection

Step 7 - Locate position for inline clip.

Position determined by layout and worksurface

supports. Place closet to worksurface height as

possible without interfering with supports.

Step 8 - Use needle nose pliers to grab slots above or

below intended clip location.

Pull verticals together.

Step 9 - Insert bottom prongs of clip at a

slight angle into panel slots.

Rotate clip up so that the top

prongs enter the slot above.

Slide clip down to secure

connection.

Illustration 4. Previous Style Panel to Current

Illustration 3. Panel to Panel Connections

Panel System Installation Packet

343-3890A

(03/17)

Page 4 of 27