HNP Mikrosysteme mzr-7240 User manual

Operating manual for micro annular gear pump

mzr-7240

HNP Mikrosysteme GmbH

Bleicherufer 25

D-19053 Schwerin (Germany)

Telephone: +49 385/52190-301

Telefax: +49 385/52190-333

E-mail: info@hnp-mikrosysteme.de

http://www.hnp-mikrosysteme.de

Last update: March 2019

Impressum

Original instructions

Copyright

HNP Mikrosysteme GmbH

Bleicherufer 25

D-19053 Schwerin

All rights, including translation, reserved.

Without prior explicit written permission of HNP Mikrosysteme GmbH no part

of this manual may be, copied, reproduced or processed.

This manual has been prepared with care. HNP Mikrosysteme does assume no

liability for any errors in this manual and resulting consequences. Likewise, no

liability is assumed direct or subsequent damages arising from an incorrect use

of the devices.

While using micro annular gear pumps, the relevant standards regarding the

specifications of this manual have to be followed.

Subject to change without notice.

Contents Operating manual for micro annular gear pumps mzr-7240

Last update: March 2019 Technical data subject to change without prior notice! i

Contents

1General Information 1

1.1 Use 1

1.2 Pump Model Designation 2

1.3 Technical data of the micro annular gear pump mzr-

7240 3

1.4 Measurements and flow charts 4

2Safety instructions 5

2.1 Safety symbols in this operating manual 5

2.2 Staff qualification and training 5

2.3 Safety-conscious work 6

2.4 Safety instructions for the operator 6

2.5 Safety instructions for maintenance, check and

assembly of the pump 6

2.6 Unauthorized pump conversions and spare part

manufacture 7

2.7 Improper modes of operation 7

2.8 General safety instructions 7

3Transport and intermediate storage 8

3.1 Shipment of the pumps and protection measures 8

3.2 Transport 8

3.3 Intermediate storage 8

4Description 9

4.1 Principe of the micro annular gear pumps 9

4.2 Construction 10

4.3 Materials and media 11

4.4 Fluidic connectors of mzr-7240 12

5Modular system 13

5.1 Fluidic seal module 14

5.2 Axial bearing module 16

5.3 Gear box module 16

6Optional motor versions 17

6.1 Brushless DC-motor as mzr-7241 18

6.1.1 Operation with the S-KB-4 control unit 19

6.2 Brushed DC-motor without encoder as mzr-7242 23

6.3 Stepper motor without encoder as mzr-7243 24

6.4 Stepper motor with encoder as mzr-7243 25

6.5 Brushless DC-motor with integrated controller 26

6.5.1 Technical data of the drive 3564K024BCS 26

6.5.2 Connection of the micro annular gear pump to the

power supply 28

Contents Operating manual for micro annular gear pumps mzr-7240

ii Technical data subject to change without prior notice! Last update: March 2019

6.5.3 Connection of the micro annular gear pump with

terminal box S-G05 with screw clamp terminal 38

7System integration 40

7.1 Check before the first assembly 40

7.2 Mounting of the micro annular gear pump 40

7.3 General instructions for the assembly of the liquid

supply network 40

7.4 Mounting of the micro annular gear pump 41

7.5 Assembly instruction for tubing and accessories 41

7.6 Filter selection and use 44

8Startup/shutdown of a mzr-pump 45

8.1 Preparing for operation 45

8.2 Startup of the micro annular gear pump 45

8.3 Flushing procedure after use 45

8.4 Shutdown of the micro annular gear pump 47

8.5 Conservation 50

8.5.1 Dismantling of the system 51

8.6 Trouble shooting 51

8.7 Return of the micro annular gear pump to the

manufacturer 52

9Software »mzr-Pump controller« 53

10 Software »Motion Manager« (Option) 56

11 Accessories 58

12 Non-liability clause 58

13 EC Directive 59

13.1 Electromagnetic Compatibility (EMC) 60

13.1.1 EMC Directive and Standards 60

13.1.2 Information on use as intended 61

14 Declarations of conformity 62

15 Problems and their removal 67

16 Service, maintenance and warranty. 70

17 Contact persons 71

18 Legal information 72

19 Safety information for the return of already

employed micro annular gear pumps and

components 73

19.1 General information 73

Contents Operating manual for micro annular gear pumps mzr-7240

Last update: March 2019 Technical data subject to change without prior notice! iii

19.2 Declaration of liquids in contact with the micro

annular gear pump 73

19.3 Shipment 73

20 Declaration of media in contact with the micro

annular gear pump and its components 74

21 Supplement 75

1General Information Operating manual mzr-7240

Last update: March 2019 Technical data subject to change without prior notice! 1

1General Information

This operating manual contains basic instructions to be followed during

integration, operation and maintenance of a mzr®micro annular gear pump.

For this reason it is necessary to read it carefully before any handling of the

device. The present manual should always be kept at the operation site of the

micro annular gear pump.

In case assistance is needed, please indicate the pump type visible on the

housing.

1.1 Use

The micro annular gear pump mzr-7240 described in this manual are suitable

for continuous delivery and discrete dosage of water, watery solutions,

solvents, methanol, oils, lubricating liquids, paints and varnishes as well as

many other liquids.

!

If you intend to treat any aggressive, poisonous, or radioactive liquids, you

must conform to safety measures as according to the regulations in force. Any

project concerning handling of corrosive liquids should be previously discussed

with the pump manufacturer.

!

The micro annular gear pumps must not be used for invasive medical

applications, in which the liquid having had contact with the pump is re-

introduced to the body.

!

Micro annular gear pumps exclusively are provided for use in the industrial

area. A private use is excluded.

!

The micro annular gear pumps must not be used in aircrafts and spacecrafts or

other vehicles without prior consent of the manufacturer.

!

Data concerning resistance of the pumps to the manipulated liquids have been

elaborated according to the best of HNPM's knowledge. However, operating

parameters varying from one application case to another, no warranty for this

information can be given.

!

Information given in this manual does not release the customer from the

personal obligation to check the integrity, correct choice and suitability of the

pump for the intended use. The use of the micro annular gear pumps should

be conform with technical norms and regulations in force.

If you wish to receive more information than comprised in this manual please

contact directly HNP Mikrosysteme.

1General Information Operating manual mzr-7240

2Technical data subject to change without prior notice! Last update: March 2019

1.2 Pump Model Designation

This manual is valid for the micro annular gear pumps mzr-7241, mzr-7242,

mzr-7243 and mzr-7245 manufactured by HNP Mikrosysteme GmbH,

Bleicherufer 25, D-19053 Schwerin, Germany.

The bottom line of this manual shows issue and date of issue of the manual.

1General Information Operating manual mzr-7240

Last update: March 2019 Technical data subject to change without prior notice! 3

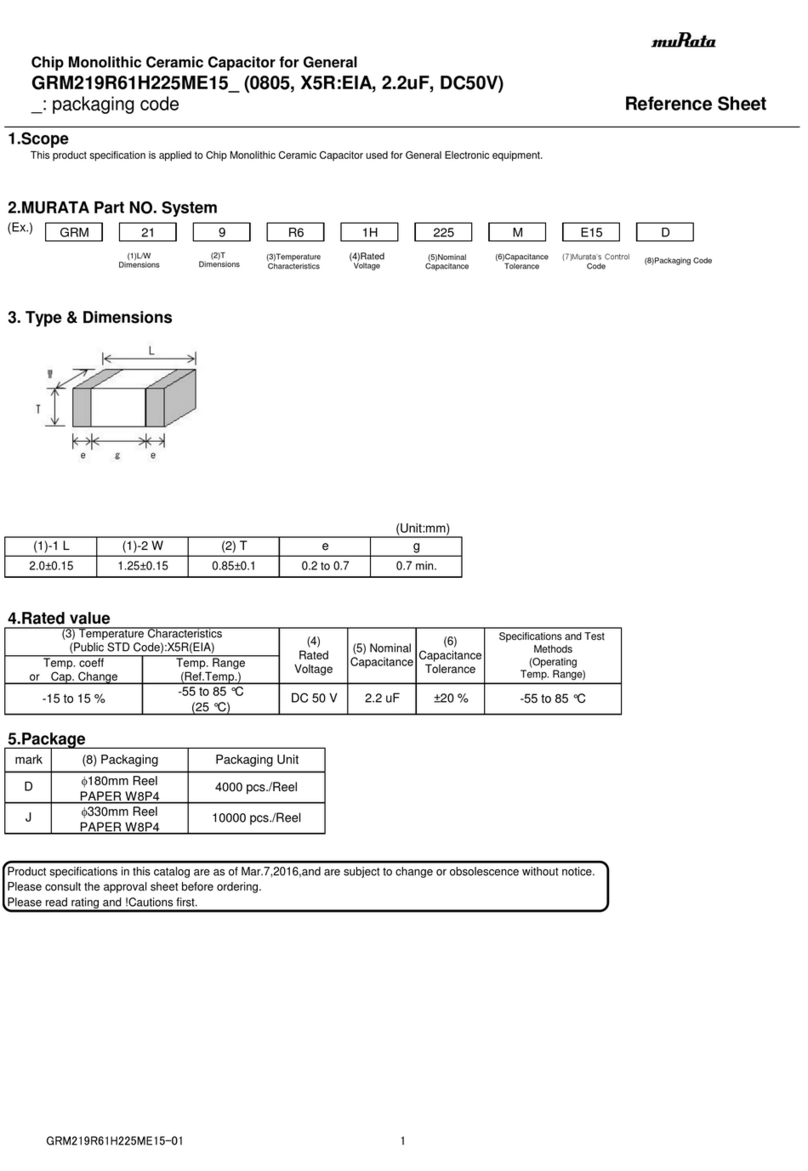

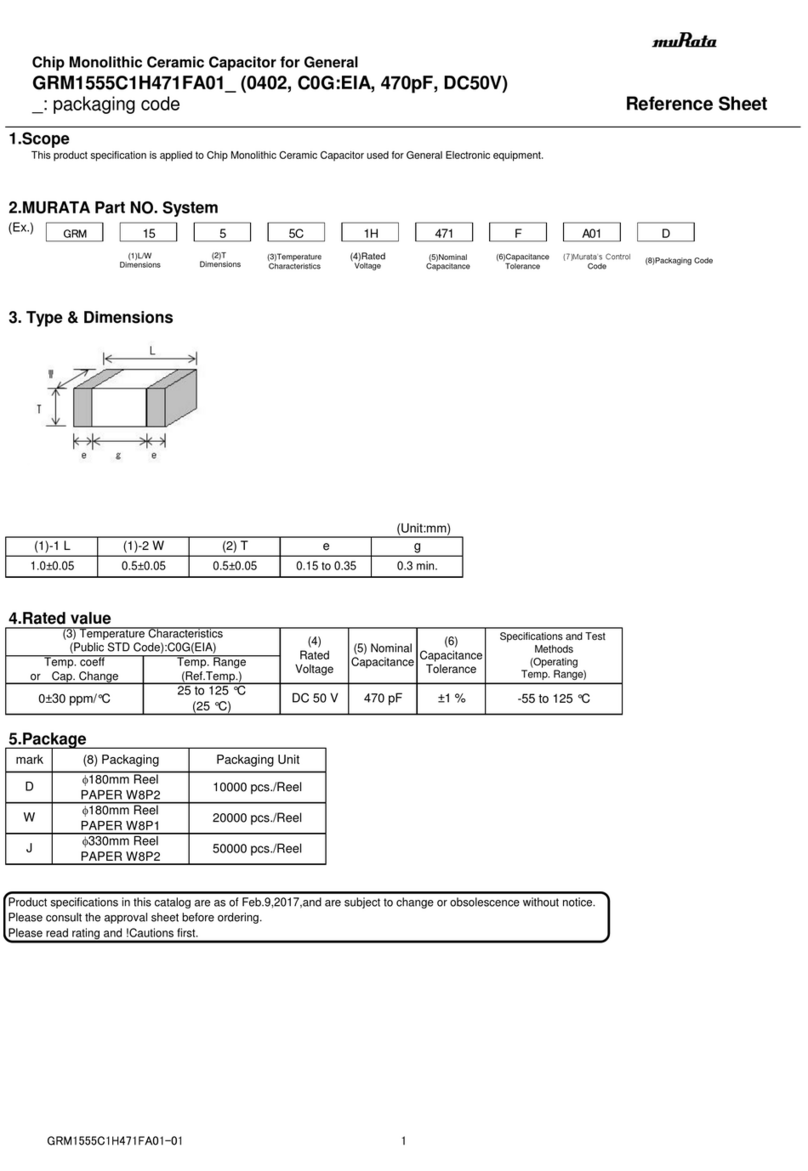

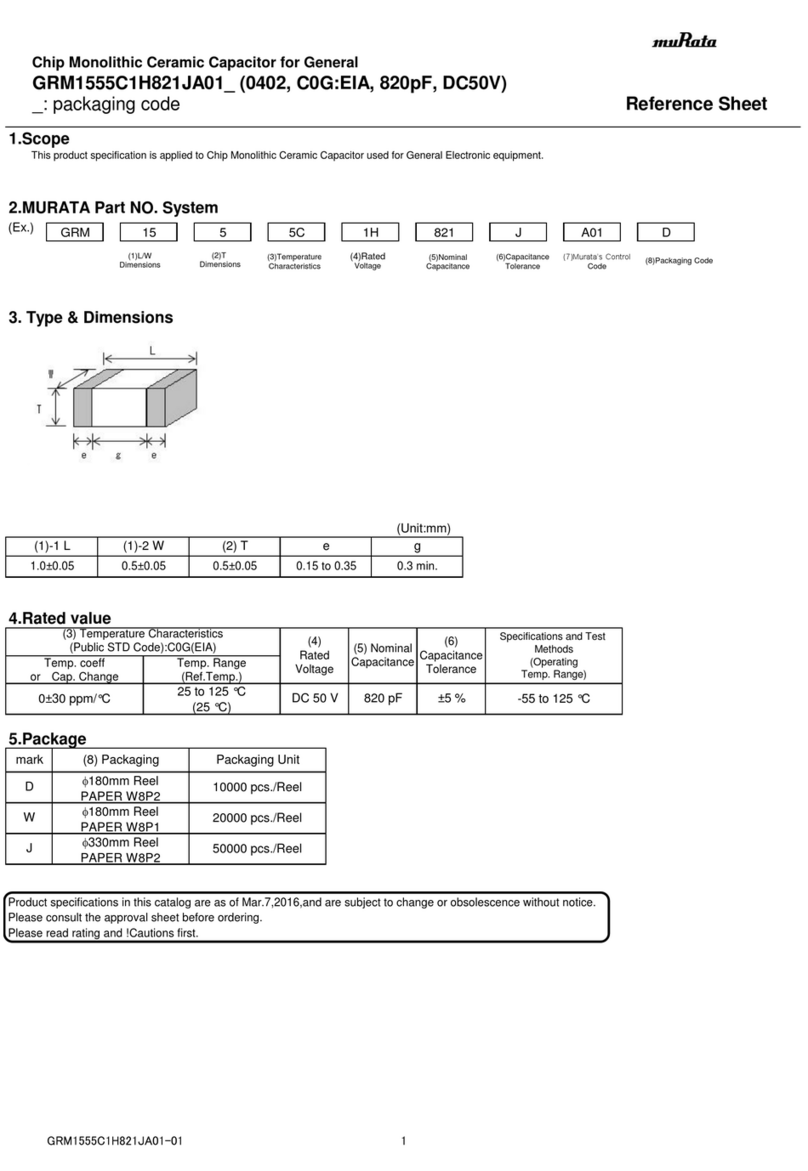

1.3 Technical data of the micro annular gear pump mzr-7240

The following table shows the technical data of the micro annular gear pump

heads mzr-7240.

mzr-7240

Technical data

Displacement volume [µl] 48

Measurements [mm] L x W x H 150 x 100 x 42 *

Weight [g]

550 *

Internal volume [µl] 110

Materials pump head see chapter 4.3

Threaded fluid supply

connections

see chapter 4.4

Coupling bellow coupling *

Performance parameters

Flow rate Q [ml/min] min. 0,048

[ml/min] max. 288

[l/h] max. 17,28

Smallest dosage volume [µl] 5

Differential pressure range [bar] 0 – 5 bar (290 psi)*

Max. inlet pressure [bar] 1 bar (14 psi)

viscosity range of pumpable

min.

0,3

liquids

η

[mPas]

max.

10.000*

Precision CV [%] 1

Pulsation [%] 6

Operating temperature [°C] min. -5

max. 60

Ambient temperature [°C] min. -5

50

Storage temperature [°C] min. -5

max. 40

Legende: true / available CV Coefficient of Variation

* depending on the motor / axial bearing

table 1 Technical data of the micro annular gear pump heads mzr-7240

Warning The material properties of a liquid (e.g. viscosity, lubricating property, particle

content, corrosiveness) impacts the technical data and the lifetime of pumps.

Under appropriate conditions the characteristic values may be increased or

decreased.

Warning If you intend to operate the pump out of the range of the above given

specification, please consult the manufacturer. Modifications may be necessary

to ensure successful operation. Otherwise the pump or the system may be

damaged seriously.

1General Information Operating manual mzr-7240

4Technical data subject to change without prior notice! Last update: March 2019

1.4 Measurements and flow charts

figure 1 Measures of the micro annular gear pump mzr-7245 (picture with a programmable servomotor)

Liquid water Liquid methanol

0

50

100

150

200

250

300

0 1 2 3 4 5

Differential pressure [bar]

Flow rate [ml/min]

6000

5000

4000

3000

2000

1000

Speed [rpm]

Viscosity 1 mPas

Liquid water

0

50

100

150

200

250

300

01 2 3 4 5

Differential pressure [bar]

Flow rate [ml/min]

6000

5000

4000

3000

2000

1000

Speed [rpm]

Viscosity 0,58 mPas

Liquid methanol

Liquid oil, 16 mPas Liquid oil, 100 mPas

0

50

100

150

200

250

300

010 20 30 40

Differential pressure [bar]

Flow rate [ml/min]

6000

5000

4000

3000

2000

1000

Speed [rpm]

Viscosity 16 mPas

Liquid oil

0

50

100

150

200

250

300

010 20 30 40

Differential pressure [bar]

Flow rate [ml/min]

6000

5000

4000

3000

2000

1000

Speed [rpm]

Viscosity 100 mPas

Liquid oil

figure 2 Flow charts mzr-7240

2Safety instructions Operating manual mzr-7240

Last update: March 2019 Technical data subject to change without prior notice! 5

2Safety instructions

Comply with the general safety instructions listed in the safety section as well

as with the special safety instructions listed under the other main sections. All

legal and corporate safety instructions have to be obeyed.

2.1 Safety symbols in this operating manual

Please comply not only with the general safety instructions listed below, but

also with specific safety instructions mentioned in the following chapters.

Non respect of the safety instructions marked with the following signs

represents danger to people:

Danger symbol High voltage symbol

!

Safety symbol according to

DIN 4844 – W9

Safety symbol according to

DIN 4844 – W8

Non compliance with the safety instructions marked with the following sign:

Warning

represents a risk of damage to the micro annular gear pump.

Operating instructions machined directly on the pump such as the indication of

liquid input and output should be followed and kept in a clearly readable

condition.

2.2 Staff qualification and training

The staff operating, servicing, inspecting and assembling the pumps must

evidence the appropriate qualification for these works. Areas of responsibility

and competence as well as monitoring of the staff must be precisely regulated

by the decision maker. If the personnel do not have the necessary knowledge,

they must be trained and instructed accordingly. If necessary, this can be

implemented by the supplier or the manufacturer on behalf of the operator.

Furthermore, the operator in charge must ensure that the content of the

present manual has been fully understood by the personnel.

2Safety instructions Operating manual mzr-7240

6Technical data subject to change without prior notice! Last update: March 2019

2.3 Safety-conscious work

The safety instructions listed in this operating manual, applicable national

regulations concerning accident prevention as well as internal work, operation

and safety regulations of the operator must be complied with.

2.4 Safety instructions for the operator

The surface temperature of the motor under full load may exceed 60°C. If

needed, this surface should be protected on site against contact in order to

avoid skin burns.

The drive should be protected against dust, water vapor condensation,

humidity, splash water, aggressive gases and liquids. Please provide for

adequate air ventilation and thus cooling of the motor.

The micro annular gear pumps mzr-7240 must not be used in areas exposed to

explosion risks or in the proximity of inflammable gases and vapors.

Possible leaks of dangerous liquids (for example from the shaft sealing) should

be guided away in a way not to represent any danger for the personnel and the

environment. The pump should be regularly checked for possible leakage. All

legal requirements in this matter should be followed.

The existing protections against contact for the moving parts of the pump (such

as for example the coupling) must not be removed during operation.

Take care that all risks resulting from the electric energy are excluded. (For

details please refer to the instructions provided by the authorities in charge or

your power supplier.)

Warning Please insure, that the totality of the liquid supply accessories such as tubes,

hoses, filters etc. are free from dust or dirt particles. Impurities such as metal,

plastic or glass particles may impair or damage the pump leading to its failure.

Warning Please, operate the pump with a filter featuring 10 µm or smaller pores. It will

protect the pump.

2.5 Safety instructions for maintenance, check and assembly of the pump

As a rule all maintenance work on the device should be performed when the

device is at a standstill. The shutdown procedure described in this manual must

be followed. Pumps delivering liquids hazardous to health must be

decontaminated. Immediately after the work had been completed all safety

equipment and protection measures should be applied.

Before starting the operation, please take into notice the instructions listed in

the chapter 8.

2Safety instructions Operating manual mzr-7240

Last update: March 2019 Technical data subject to change without prior notice! 7

Warning Should a malfunction of the pump occur, do not dismantle the pump on your

own but contact one of HNP Mikrosysteme's service staff for professional

assistance.

2.6 Unauthorized pump conversions and spare part manufacture

Conversions or modification to the device are only permitted with prior consent

of the manufacturer. Original spare parts and accessories authorized by the

manufacturer ensure safety. The use of other parts will annul the liability of the

pump manufacturer for any resulting consequences.

2.7 Improper modes of operation

The safety of operation of the delivered device can only be insured by correct

use, as described in chapter 1. The limit values given in this manual must not be

exceeded in any case.

2.8 General safety instructions

Please observe the following safety instructions

!

The pump may operate at high pressures. For this reason please use only the

delivered accessories and ensure that the employed fittings and tubing have

been prescribed and approved for these pressures.

!

In order to decrease the pressure, provide the system with a pressure control

valve directing the excess liquid to the storage tank or back to the suction side.

In the case of blockage of the pressure side the operating pressure can

multiply, this can lead to the damage of downstream components.

!

At a standstill, the liquid may flow through the pump in the direction of the

falling pressure. In order to avoid this unwanted movement, please integrate

non-return valves (see accessories).

!

Protect the micro annular gear pump and the electric drive against strokes and

shocks.

!

Under normal working conditions the shaft sealing rings integrated in the

pump prevent the liquid from leaking out of the device. The micro annular

gear pumps are "technically leak-proof" however not "hermetically sealed"

which means it may occur that gases or liquids enter to or escape from the

pump.

The allowed operating parameters of the drive should not be exceeded. In

particular an incorrect polarity setting of the supply voltage may lead to

damage of the control unit.

Warning Please insure, that the totality of the liquid supply accessories such as tubes,

hoses, filters etc. are free from dust or dirt particles. Impurities such as metal,

plastic or glass particles may impair or damage the pump leading to its failure.

Warning Please operate the pump with a filter featuring 10 µm or smaller pores. It will

protect the pump.

3Transport and intermediate storage Operating manual mzr-7240

8Technical data subject to change without prior notice! Last update: March 2019

3Transport and intermediate storage

3.1 Shipment of the pumps and protection measures

The pumps leaving the factory are secured against corrosion and shocks. The

inlets and outlets of the pumps are protected with plastic plugs in order to

prevent any foreign bodies from penetrating into the device.

3.2 Transport

In order to avoid any damage related to transport, the package must be

protected against shocks. HNP Mikrosysteme guarantees, that all goods leave

the factory in the best condition. Any noticed damage should be reported to

the concerned forwarding agent, authorized dealer or to HNP Mikrosysteme, as

manufacturer.

3.3 Intermediate storage

Following points concerning pump storage should be observed:

−Necessary conservation procedure (see also chapter 8.5)

−The protective plugs must be left screwed in

−The pump should not be stored in humid places

−For storage temperature - refer to chapter 1.3 of the present manual

4Description Operating manual mzr-7240

Last update: March 2019 Technical data subject to change without prior notice! 9

4Description

4.1 Principe of the micro annular gear pumps

Micro annular gear pumps are reciprocating and rotary pumps and are

provided with external toothed internal rotor and annular toothed external

rotor which are slightly eccentric bearing to each other (see figure 3). Both

rotors with their cycloid indenting are at any time interlocked and form a

system of several sealed pumping chamber during rotation. With rotation of

the rotors around their offset axis, the pumping chambers increase on the

induction side, while at the same time the delivery side of the pump decreases.

Between the kidney-like in- and outlet a homogeneous flow rate is generated.

internal

rotor

external

rotor

delivery sideinduction side

inlet outlet

figure 3 Assemble of the micro annular gear pump

figure 4 Function principle of the micro annular gear pump

Reciprocating and rotary pumps have a direct allocation to the fed amount of

the displacement volume Vg of the pump and its actuator’s number of

revolutions n. The displacement volume describes the volume, which is

theoretically fed with each revolution. The coherence of the flow rate referring

to the formula (= volumetric flow rate) Qof the pump is:

nVQ gVol ⋅⋅=

η

The volumetric efficiency

η

Vol describes the coherence of the actual flow rate

from the theoretical resulting value. Differences occur according to leaking, as

the sealing on the inside of the pump is done over a gap. The volumetric

efficiency is dependent on the media and the pressure against which it has to

be fed.

4Description Operating manual mzr-7240

10 Technical data subject to change without prior notice! Last update: March 2019

Example: The pump mzr-7240 feeds with its displacement volume of 48 µl with

3000 RPM and a volumetric efficiency of 100 % referring to the above-

mentioned formula the flow rate of 144 ml/min. The following table shows the

volumetric displacement in dependence to the number of revolutions (

η

Vol =

100 %).

Speed [rpm] Q [ml/min] Q [ml/h]

500 24 1440

1000 48 2880

2000 96 5760

3000

144

8640

4000 192 11520

5000 240 14400

6000

288

17280

table 2 Theoretical flow rate of the micro annular gear pump

The pressure, which the pump has to generate, is given by the construction of

the fluidic system and the results of the hydrostatic pressure and the hydraulic

resistants (given by tubes, contractions etc.).

The viscosity of the pumping medium has an important influence on the

volumetric efficiency. The volumetric efficiency increases with higher viscosity

according to the smaller disengagement through the gaps of the pump.

Cavitation is an effect, which can result in a specific ceiling speed. The reason

for this is the static pressure reaching the steam pressure of the liquid in the

inlet port of the pump. In this state an increase of speed does not result in an

increased flow rate. The formation of gas prevents a sufficient feeding of the

pump. With increasing viscosity of the liquid (e.g.> 10.000 mPas), the ceiling

speed is lower.

The specific feature of the mzr-pumps is their highly precise design, as well as

the guarantee of high accumulator pressure and high accuracy in flow rate and

dosage. Therefore, space width and transverse space width of the rotors as well

as the interspace to the adjacent case parts are in the range of just a few

micrometers. This precision is at the same time the criterion to achieve a

volumetric efficiency in the range of approx. 100 %.

4.2 Construction

The micro annular gear pump is composed of the pump head, the coupling

unit, the drive and the angle support (see figure 5).

4Description Operating manual mzr-7240

Last update: March 2019 Technical data subject to change without prior notice! 11

coupling unit

drive

angle support /

bearing bracket

micro annular gear pump head

liquid inlet /

suction side (S)

liquid outlet /

delivery side (D)

power

supply cable

figure 5 Construction of the micro annular gear pump mzr-7245-ha-v M5 +A

4.3 Materials and media

Wetted parts mzr-7240 pump head

Pump housing see table 4

Rotors, shaft, bearing see table 4

Shaft sealing graphite-reinforced PTFE,

316L spring

Static sealing see table 5

table 3 Construction materials of the wetted parts

Designation Material

Rotors, shaft, bearing

Material

Pump housing

-hs tungsten carbide Ni-based stainless steel 316 L (1.4404,

1.4435)

-ha tungsten carbide Ni-based Aluminum

table 4 Construction materials

Designation

Material static sealing

-v FPM (fluorelastomer)

-f FFPM (perfluoroelastomer)

-e

EPDM

table 5 Construction materials

4Description Operating manual mzr-7240

12 Technical data subject to change without prior notice! Last update: March 2019

The resistance of the construction materials to the delivered liquids should be

verified by the operator for each individual application. Pumps handling non-

lubricating liquids have shorter service lives.

4.4 Fluidic connectors of mzr-7240

Fluidic connectors Construction mzr-7241 Construction mzr-7245

S lateral 1/8" NPT internal

thread

M4 Tubes, square, screw

M5 Tubes, round, bearing bracket -

table 6 Fluidic connectors

The micro annular gear pump head has an inscription on the front side. The

liquid inlet connection is marked with the letter »S«, the liquid outlet

connection with the letter »D«. An arrow indicates the inherent turning

direction of the shaft.

In order to prevent foreign bodies from penetrating into the pump, the liquid

inlet and outlet are protected with plastic plugs or screws. Please remove them

before you assembly the pump.

5Modular system Operating manual mzr-7240

Last update: March 2019 Technical data subject to change without prior notice! 13

5Modular system

The spectrum of applications of the modular modular series may be expanded

by using different additional modules. The modules allow for special

applications, which could otherwise not be accomplished with a standard

pump version. The modules may be combined with each other and with almost

all available pump heads and motor versions.

−Fluidic seal module prevents possible chemical reactions between the

delivered liquid and the surrounding environment

−Axial bearing module enables the pump liquids with increased pressure

−Gear box module increases the torque of the drive allowing to deliver high

viscosity liquids and provides for a constant operation of the motor at low

speeds.

The configuration of a given pump version should in each case be discussed

with consideration to the specific requirements of the application. Additional

customized modules may be designed on demand.

5Modular system Operating manual mzr-7240

14 Technical data subject to change without prior notice! Last update: March 2019

5.1 Fluidic seal module

The module can be employed for liquids which tend to crystallize, when air

contact is given. The module prevents reactions by covering the outcoming

shaft by a fluidic ambience.

Fluidic seal module

liquid outlet

(delivery side)

sealing liquid

outlet

sealing liquid

inlet

liquid inlet

(suction side)

liquid supply tube

cartridge

Figure 6 Design of the micro annular gear pump with fluidic seal module (figure with mzr-7245 S +S)

(layout on the right: with the optional sealing liquid delivery set)

The module can be applied for liquids which tend to react or crystallize in

contact with gases such as oxygen or water. The use of a fluidic seal module

has to be confirmed with the pump manufacturer.

Functioning of fluidic seal module

Based on the pump design in the rotary shaft seal there is a liquid boundary

film where the liquid is in contact with the ambient. Here small amounts of

ambient humidity or oxygen can penetrate into the pump getting over the

sealing lip. To prevent penetrating molecules from outside into the pump but

also hazardous substances coming out of the pump the fluidic seal module was

designed.

For this reason a second rotary seal is added to the pump which is located in

the fluidic seal module. Between the two rotary seals a fluidic chamber (see

figure 7) is formed which is filled with a sealing liquid compatible to the

pumped liquid. The fluidic seal module has two ports opposite to each other

for filling and degassing. A pressure head can be applied to the sealing liquid to

assure a support of the sealing function. In certain cases the sealing can be

flushed.

The sealing liquid will dilute the pumping liquid during operation with a

dilution ratio of approx. 1:1,000,000. The sealing liquid has to be compatible

with the delivered liquid and has to be determined in interdependence. A

This manual suits for next models

4

Table of contents

Popular Industrial Electrical manuals by other brands

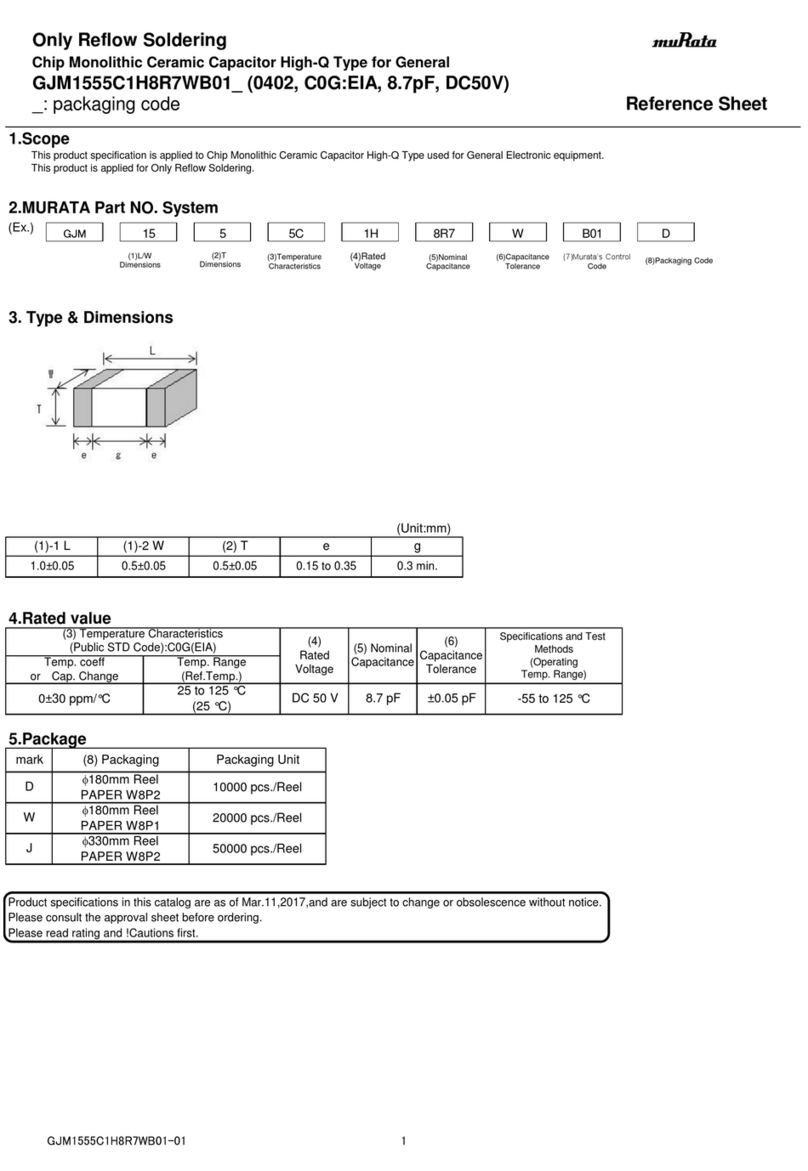

Murata

Murata GJM1555C1H8R7WB01 Series Reference sheet

Panasonic

Panasonic NM-EJW2A operating instructions

Murata

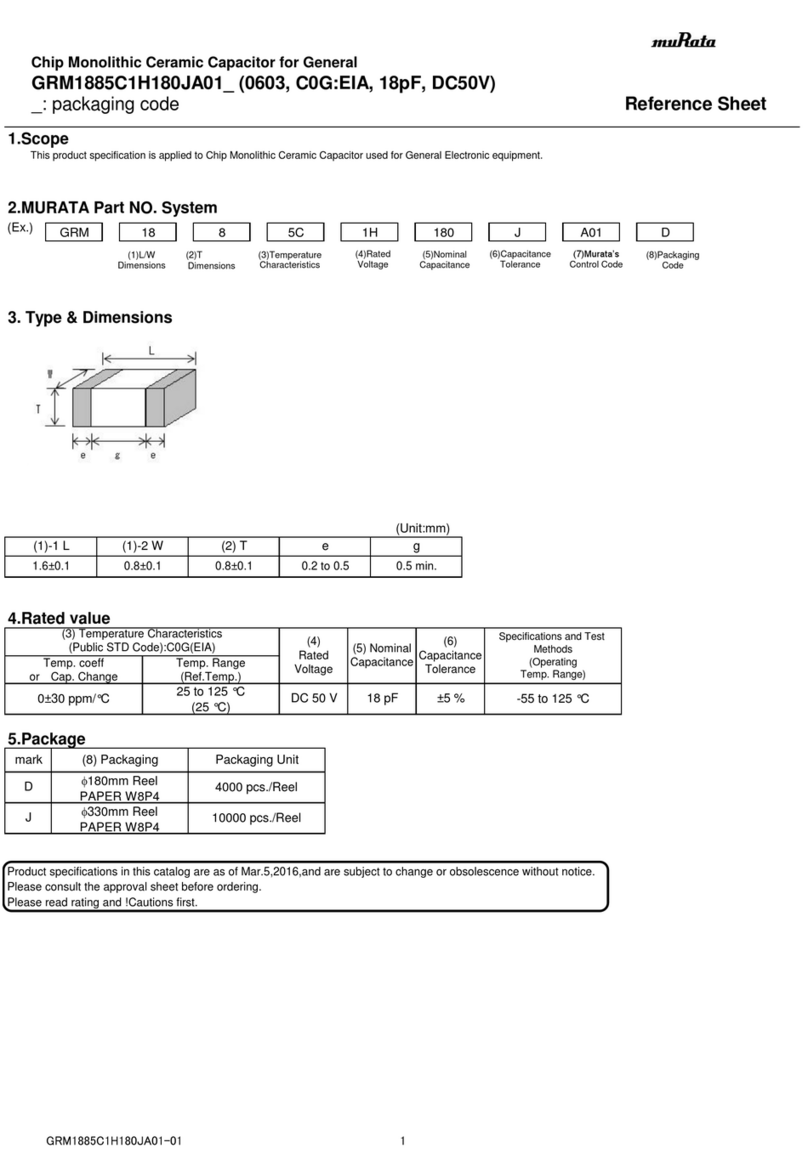

Murata GRM1885C1H180JA01 Series Reference sheet

Murata

Murata GRT21BR60J475ME13 Series Reference sheet

Murata

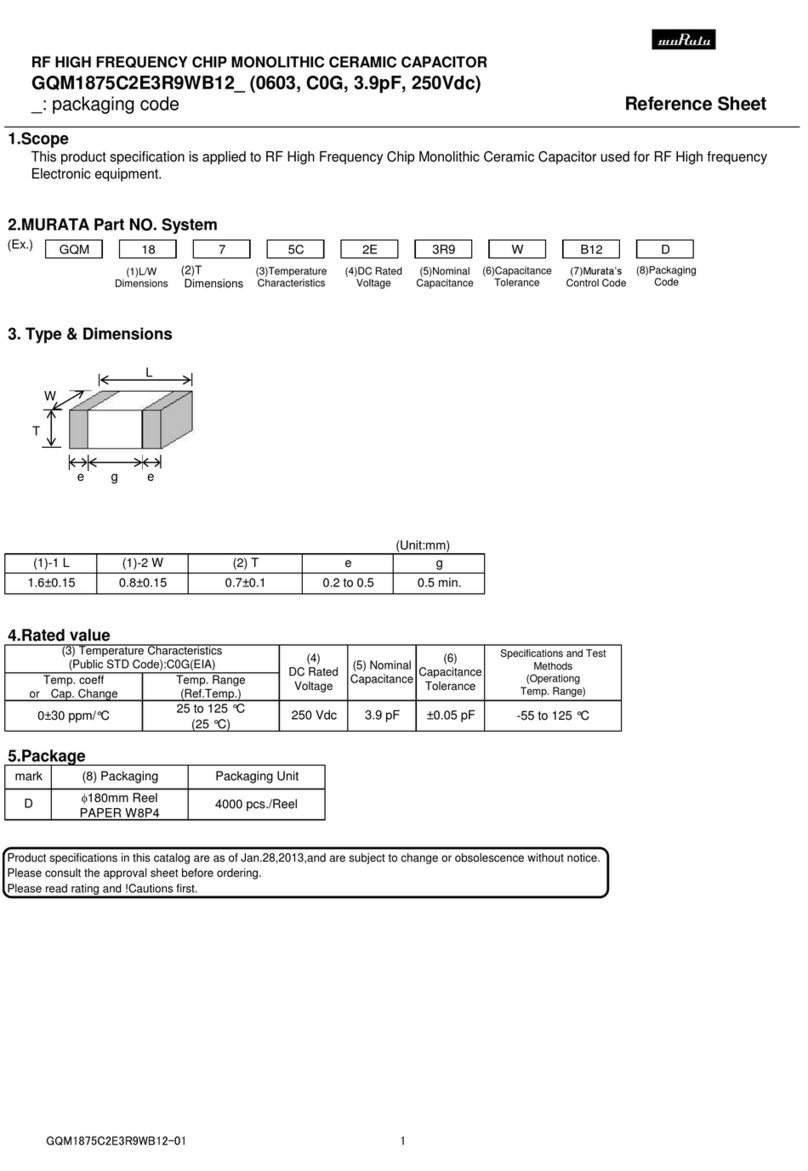

Murata GQM1875C2E3R9WB12 Series Reference sheet

Data I/O

Data I/O PSV5000 owner's manual

Murata

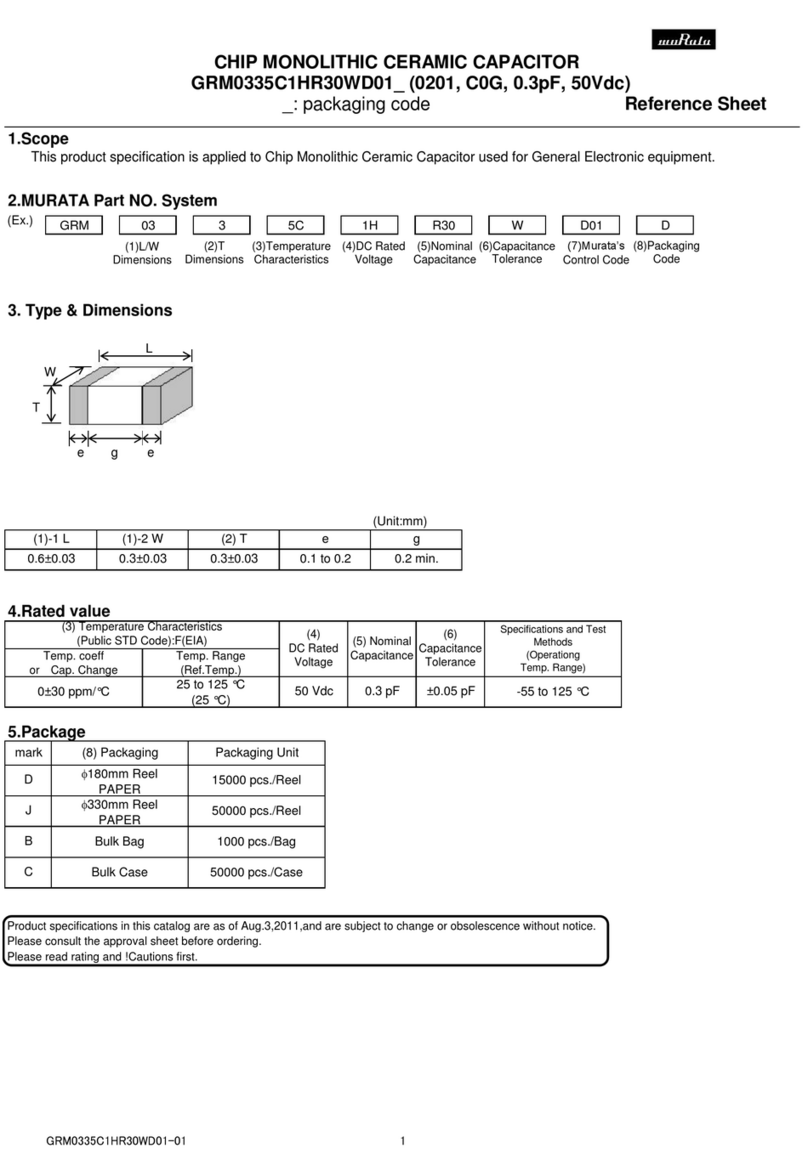

Murata GRM0335C1HR30WD01 Series Reference sheet

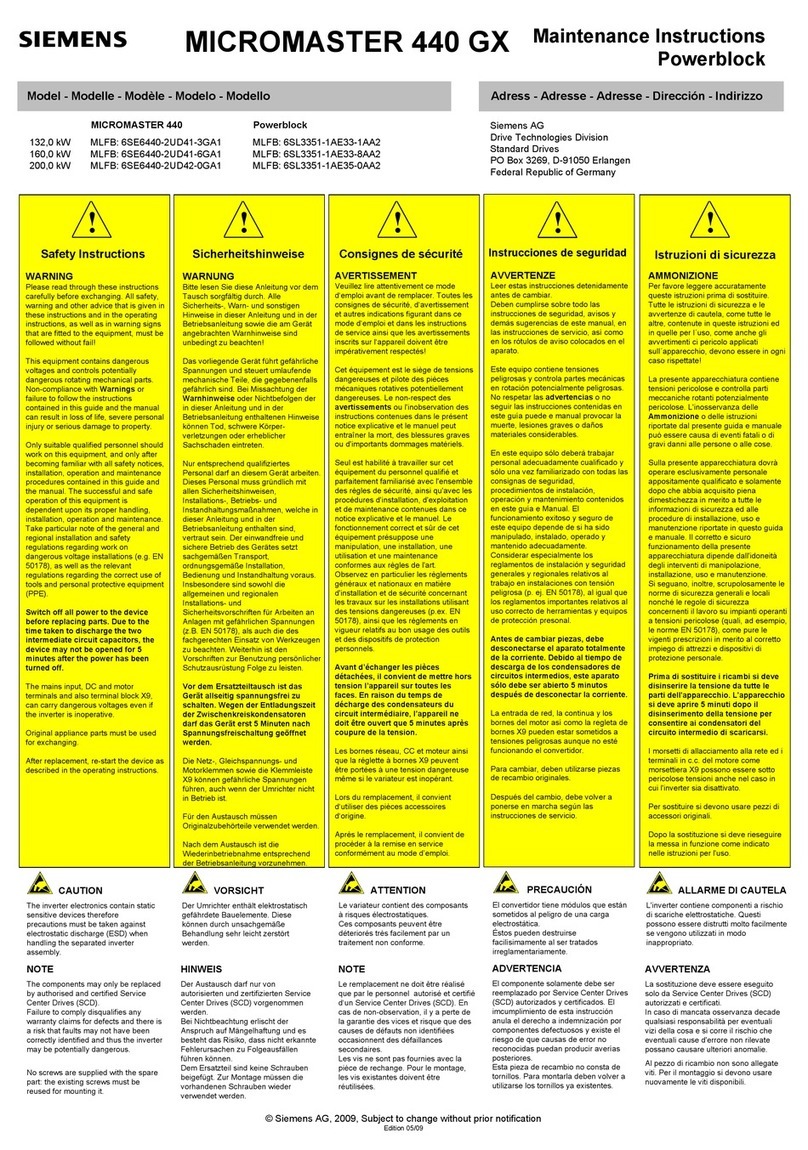

Siemens

Siemens MICROMASTER 440 Maintenance Instruction

Murata

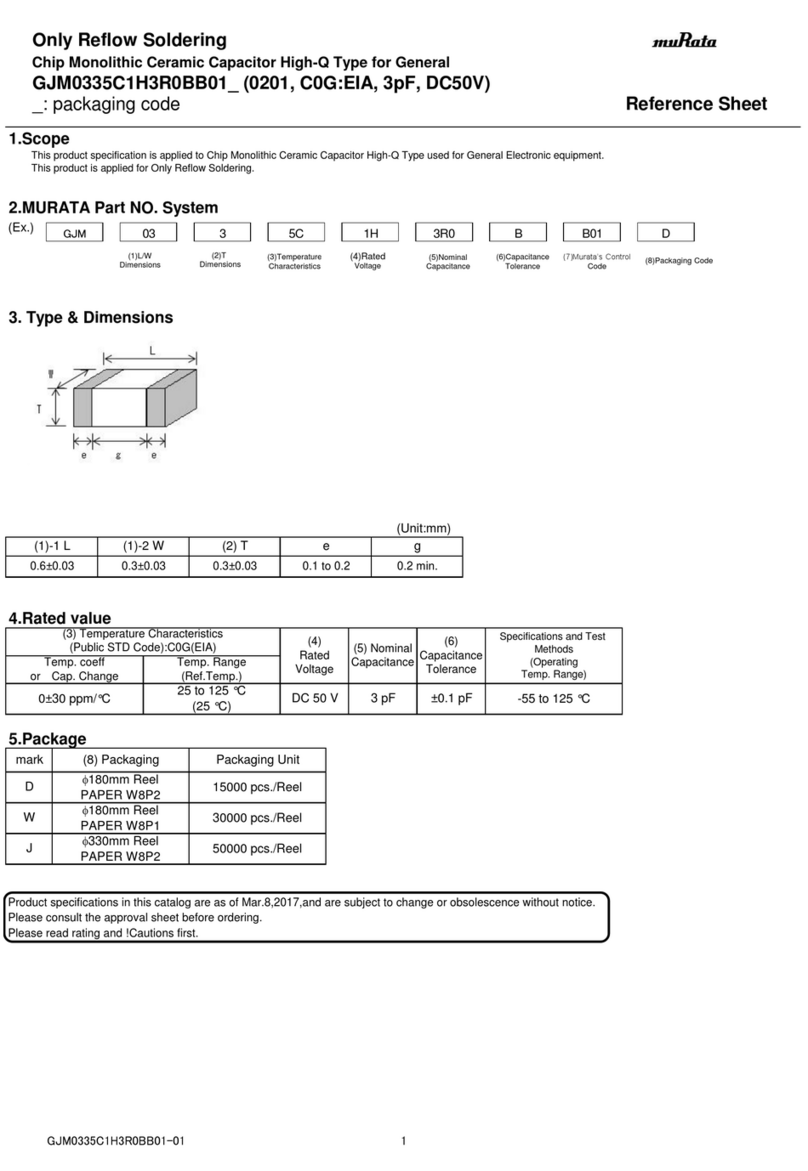

Murata GJM0335C1H3R0BB01 Series Reference sheet

GE

GE Entellisys Installation and maintenance instructions

Murata

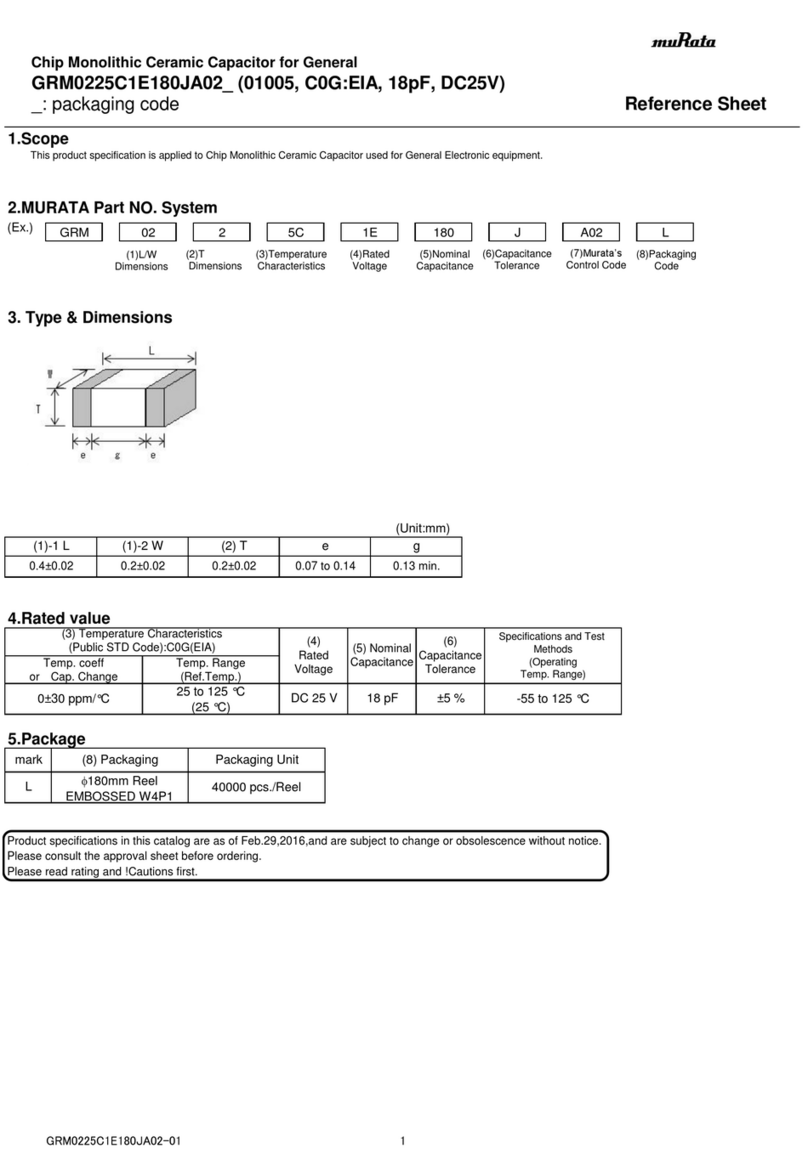

Murata GRM0225C1E180JA02 Series Reference sheet

Murata

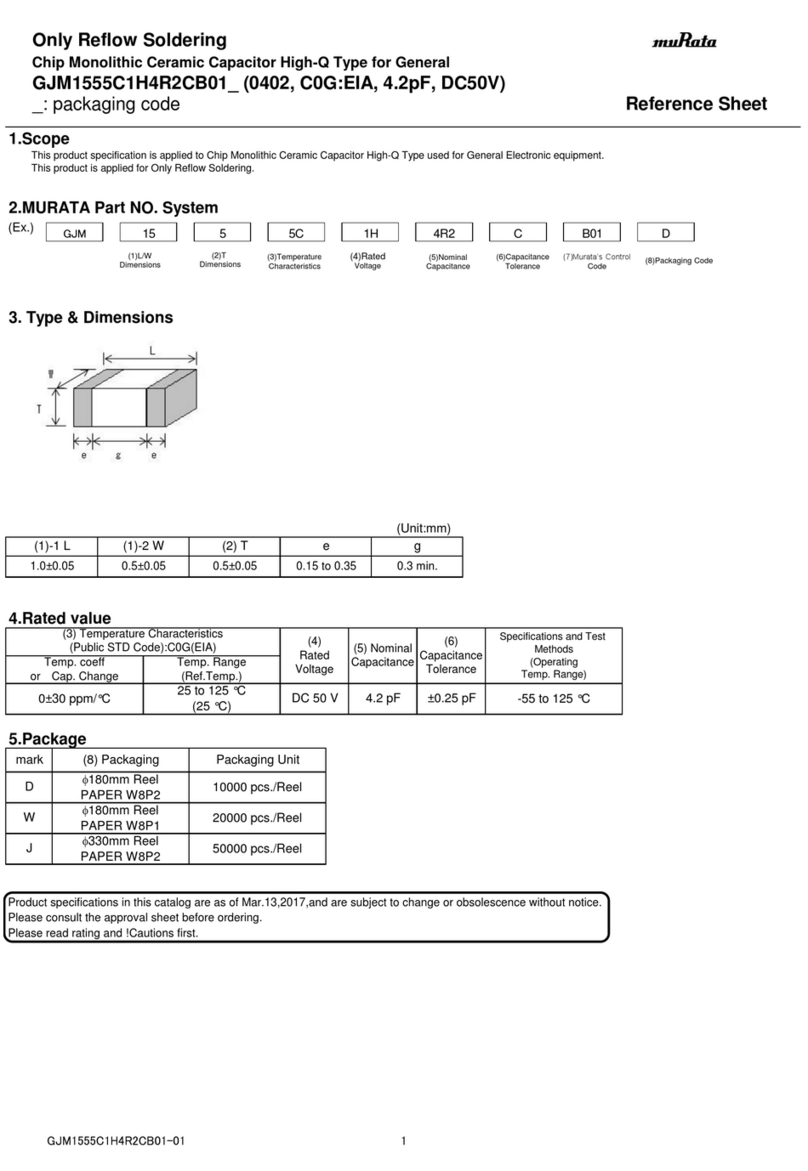

Murata GJM1555C1H4R2CB01 Series Reference sheet