Murata GRM0335C1HR60WD01 Series User manual

Other Murata Industrial Electrical manuals

Murata

Murata GRM188R71C273KA01 Series User manual

Murata

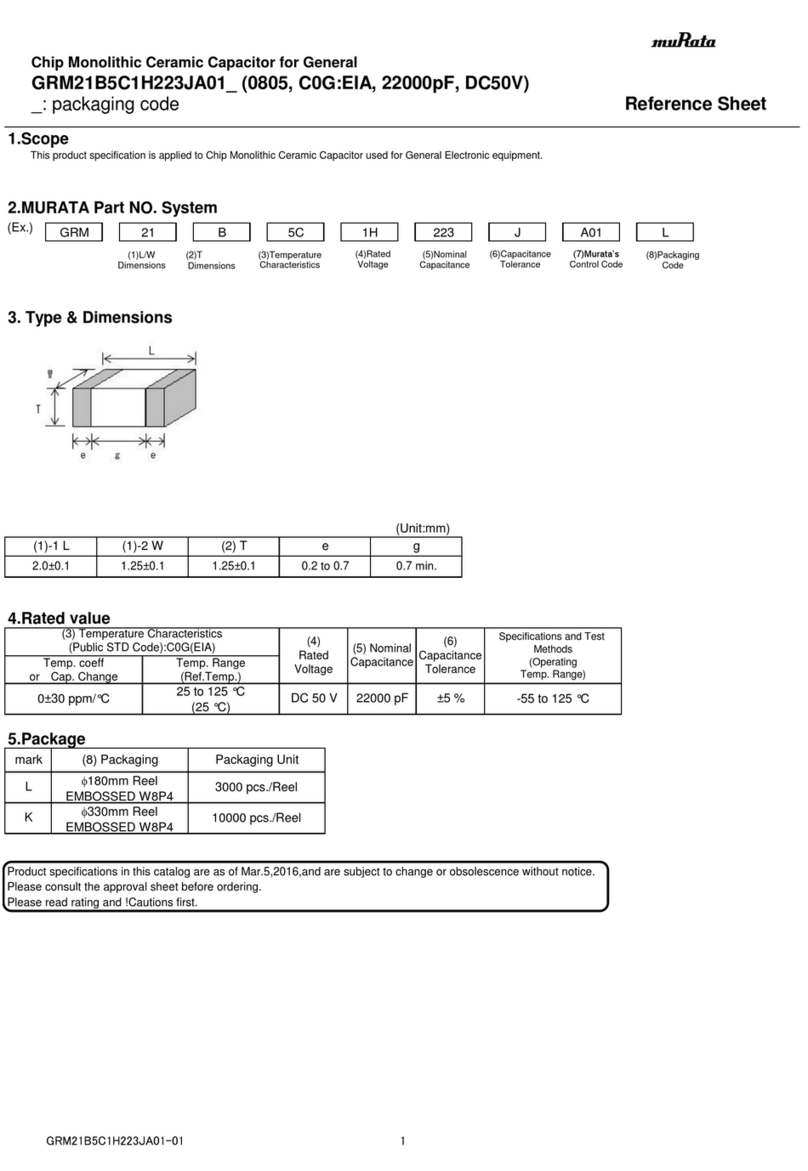

Murata GRM21B5C1H223JA01 Series User manual

Murata

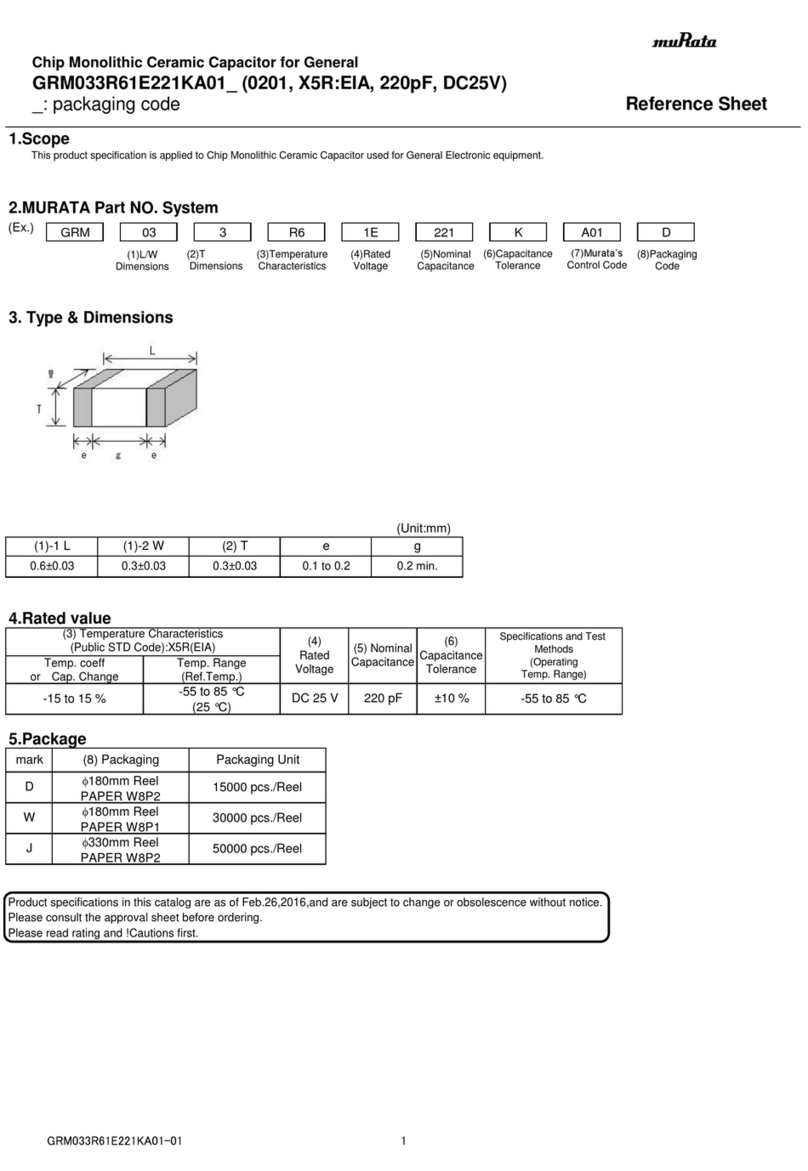

Murata GRM033R61E221KA01 Series User manual

Murata

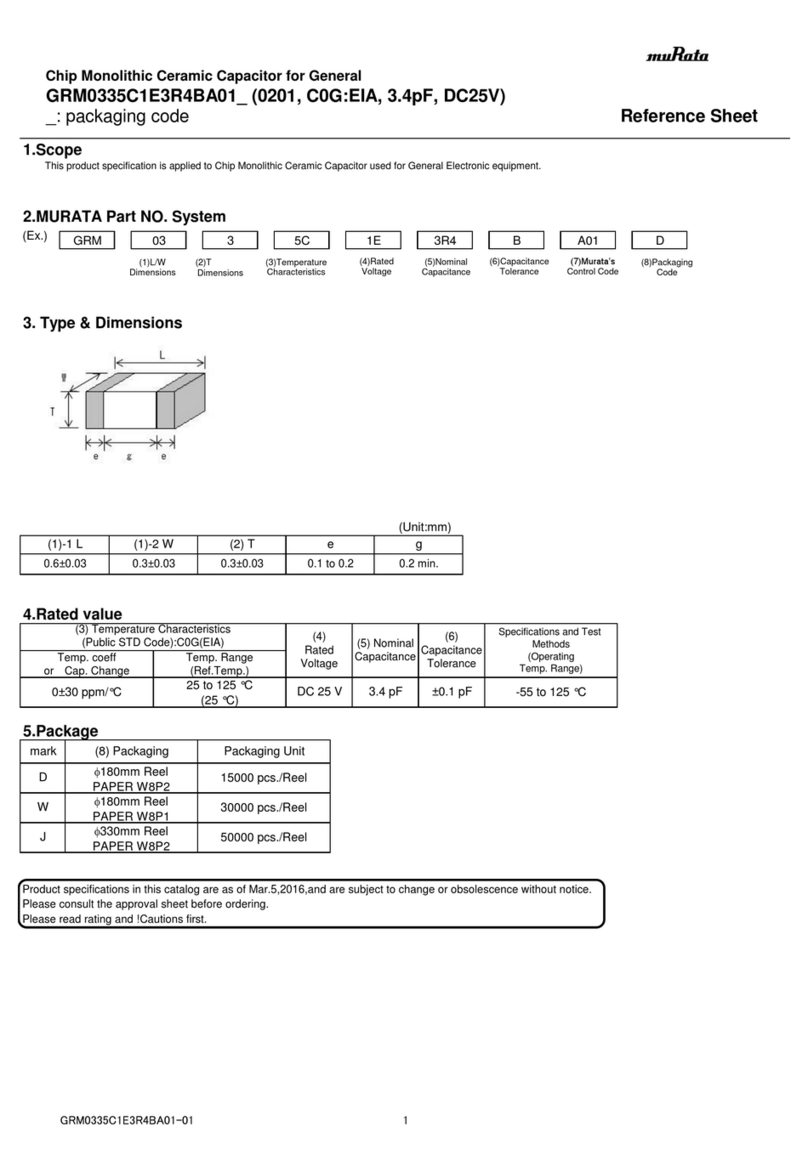

Murata GRM0335C1E3R4BA01 Series User manual

Murata

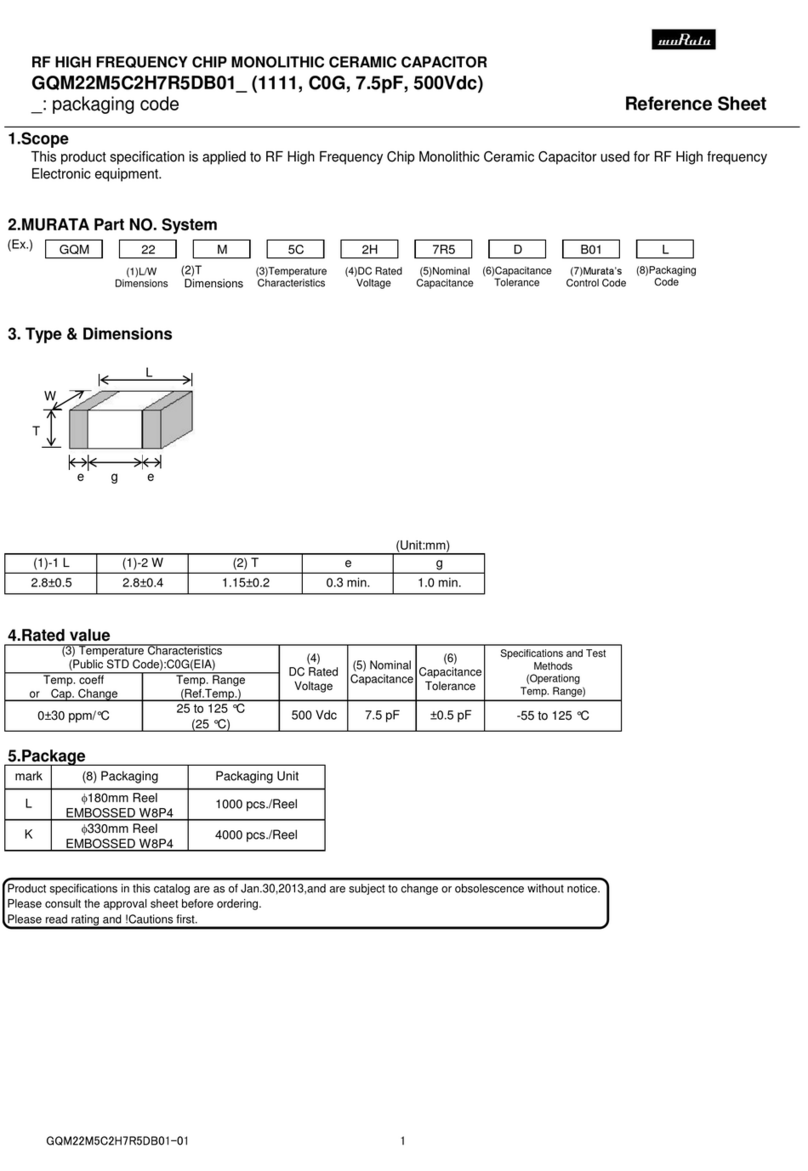

Murata GQM22M5C2H7R5DB01 Series User manual

Murata

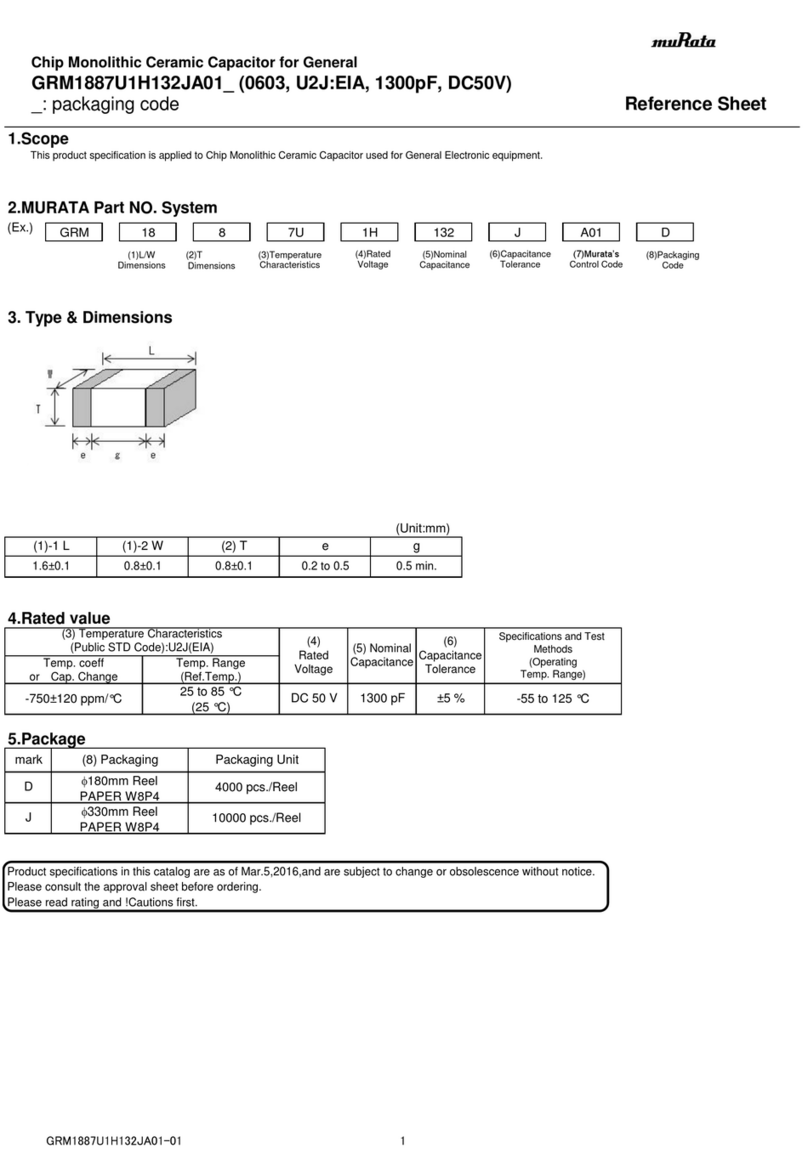

Murata GRM1887U1H132JA01 Series User manual

Murata

Murata GJM1555C1HR90BB01 Seies User manual

Murata

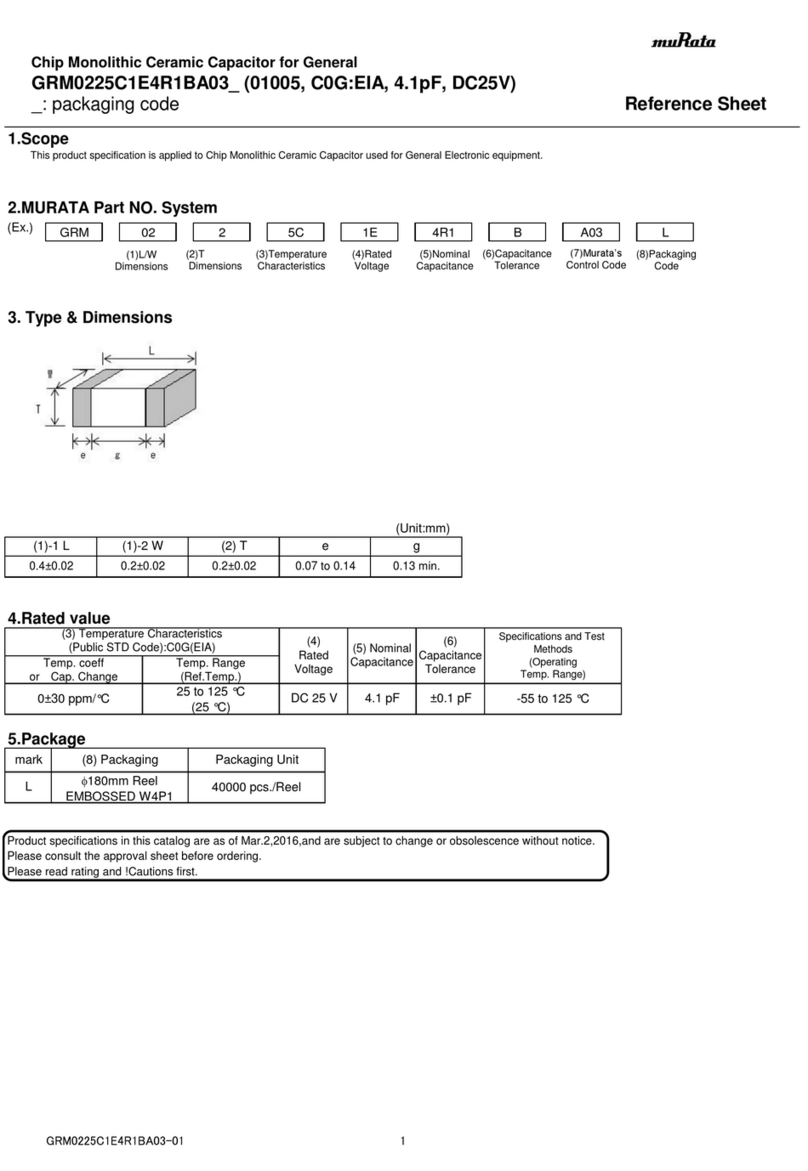

Murata GRM0225C1E4R1BA03 Series User manual

Murata

Murata GRM31CR61E106MA12 Series User manual

Murata

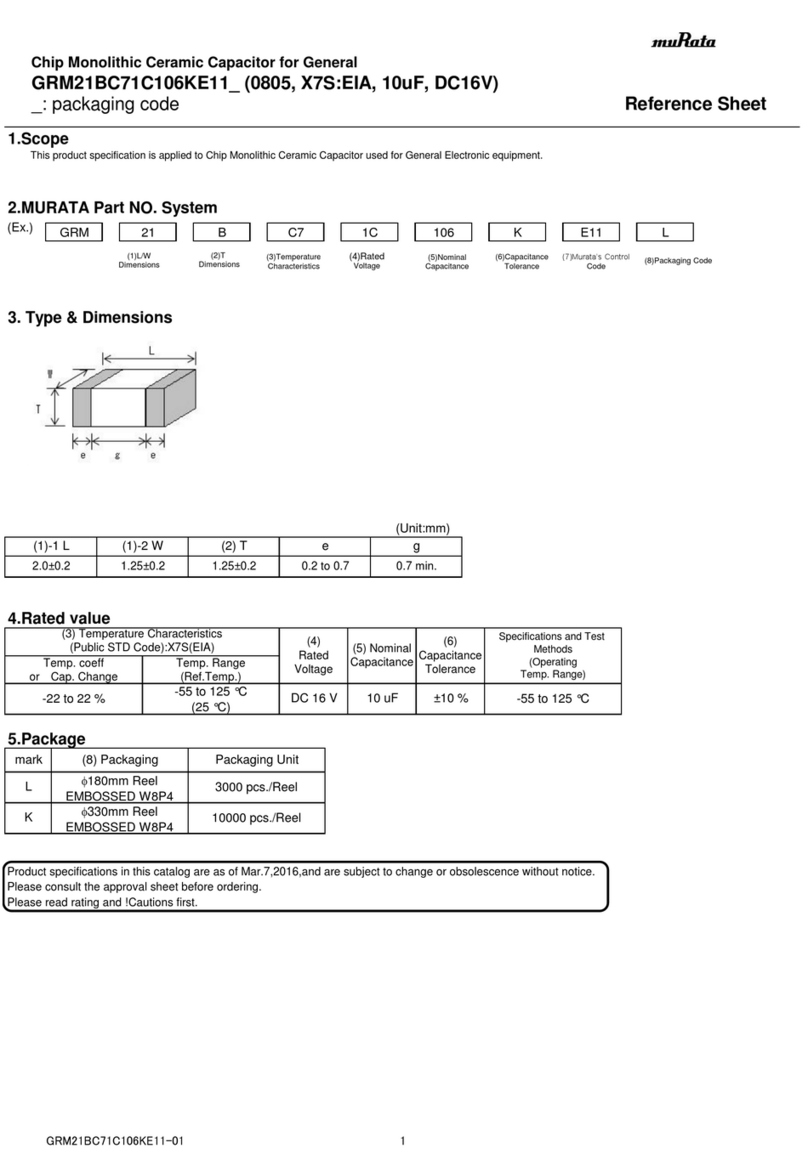

Murata GRM21BC71C106KE11 Series User manual

Murata

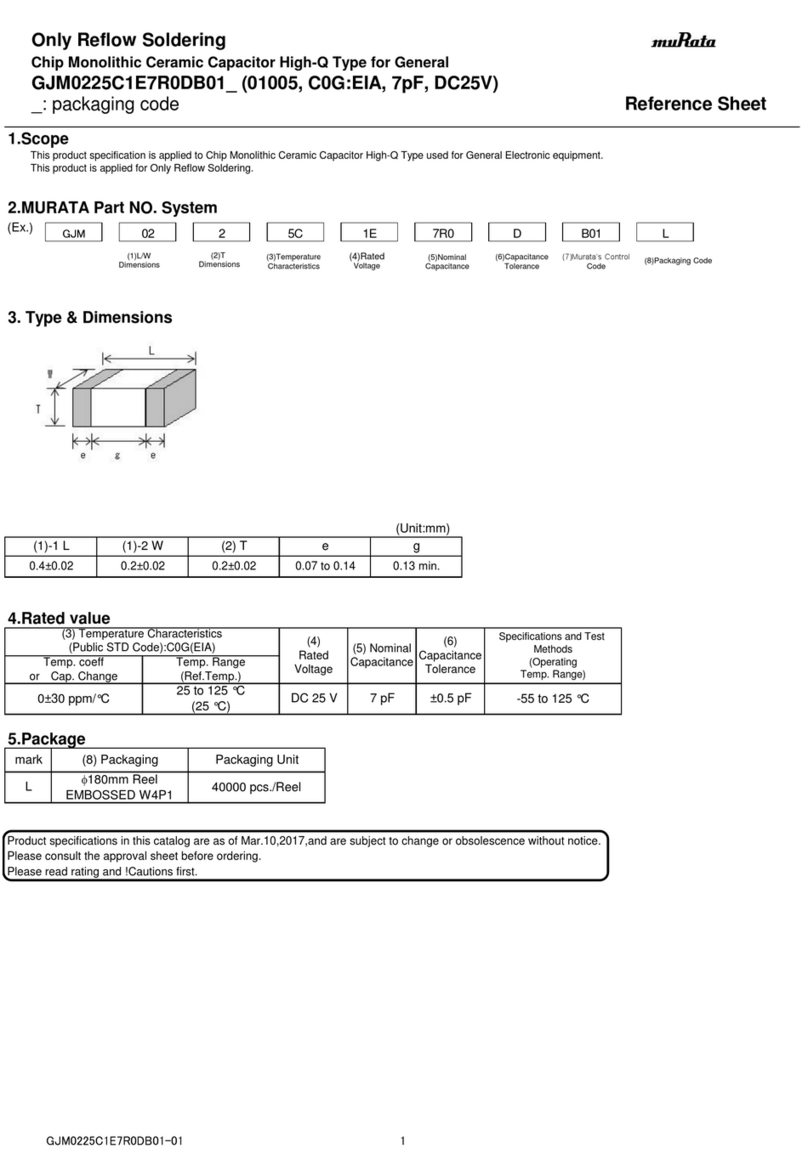

Murata GJM0225C1E7R0DB01 Series User manual

Murata

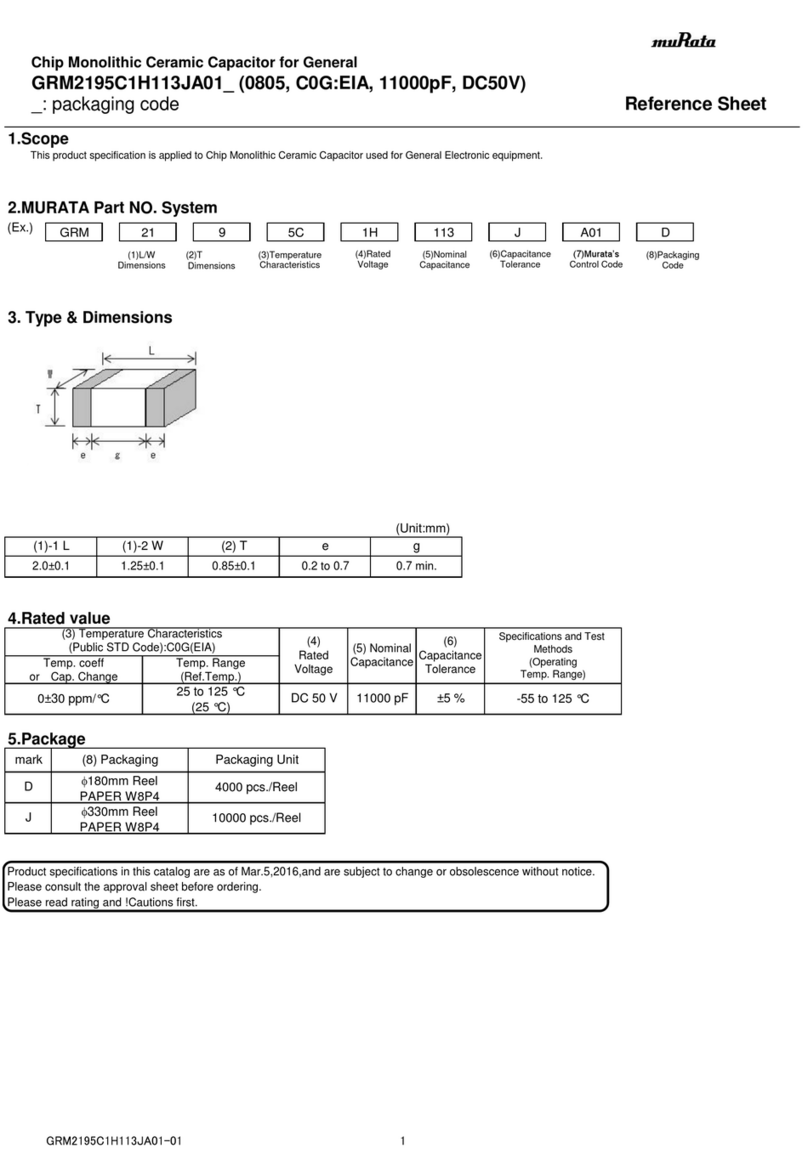

Murata GRM2195C1H113JA01 Series User manual

Murata

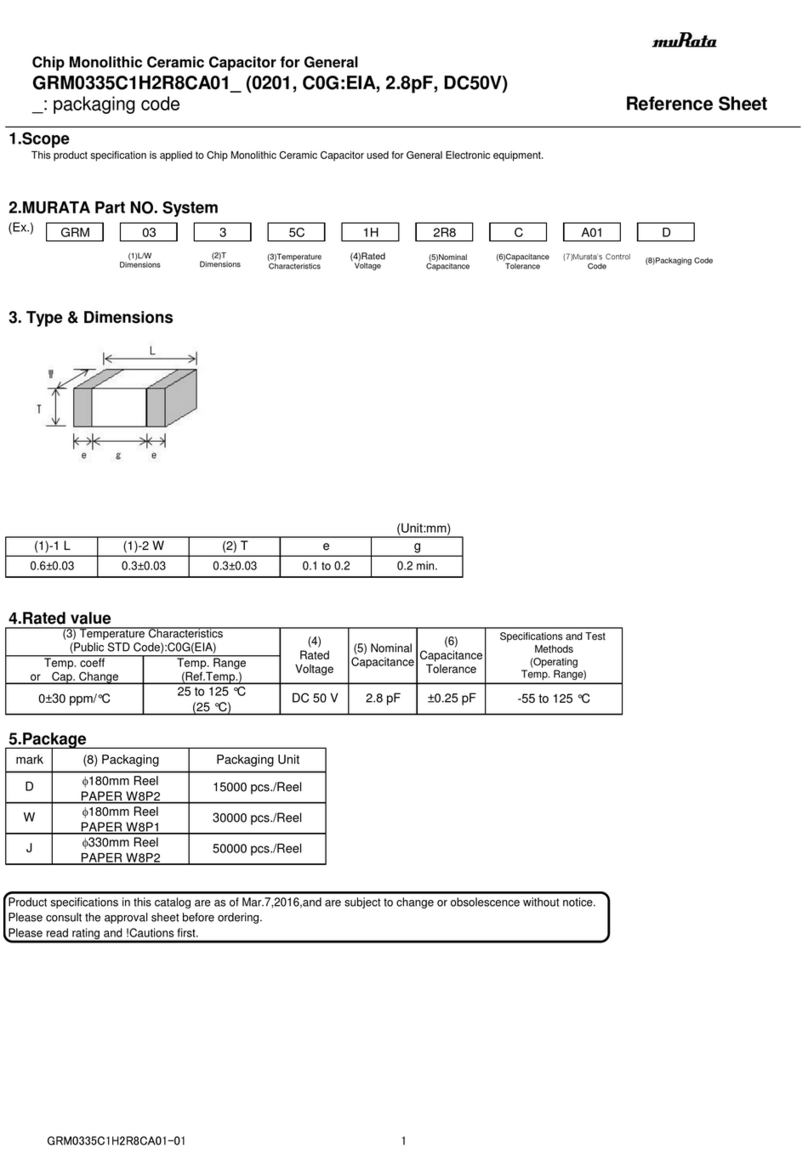

Murata GRM0335C1H2R8CA01 Series User manual

Murata

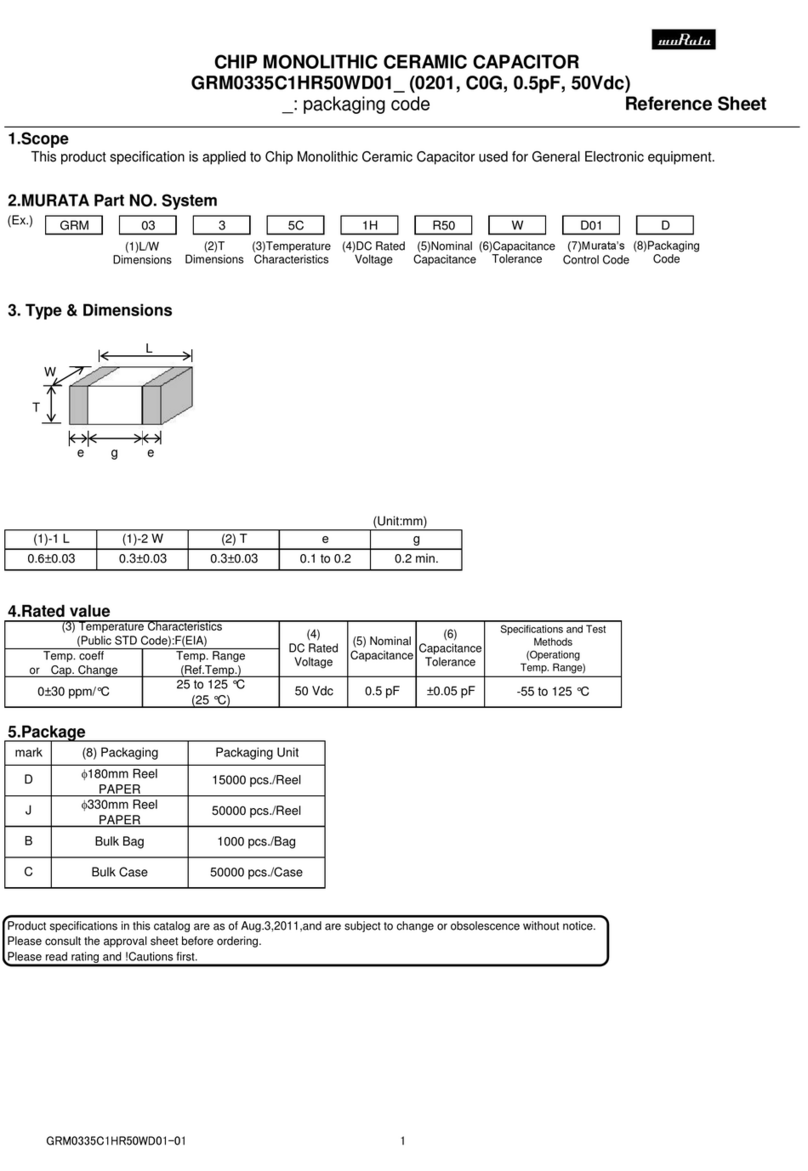

Murata GRM0335C1HR50WD01 Series User manual

Murata

Murata GRM155R71H122KA01 Series User manual

Murata

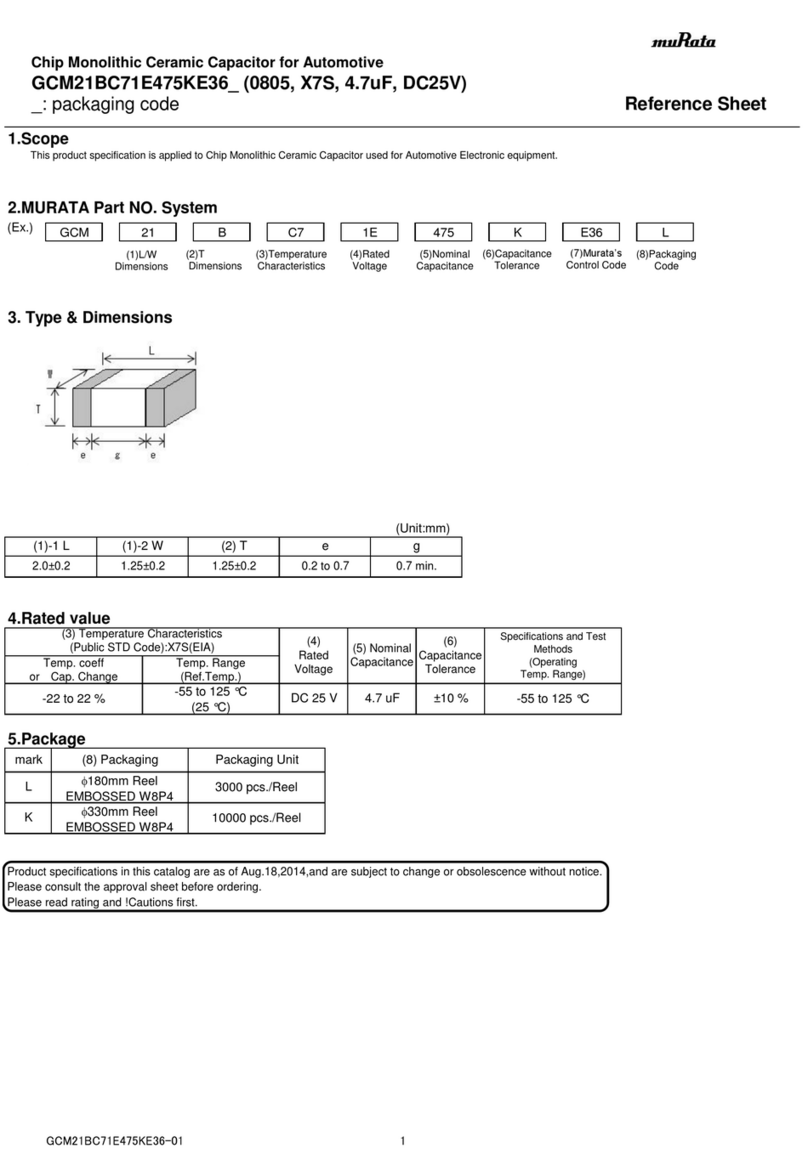

Murata GCM21BC71E475KE36 Series User manual

Murata

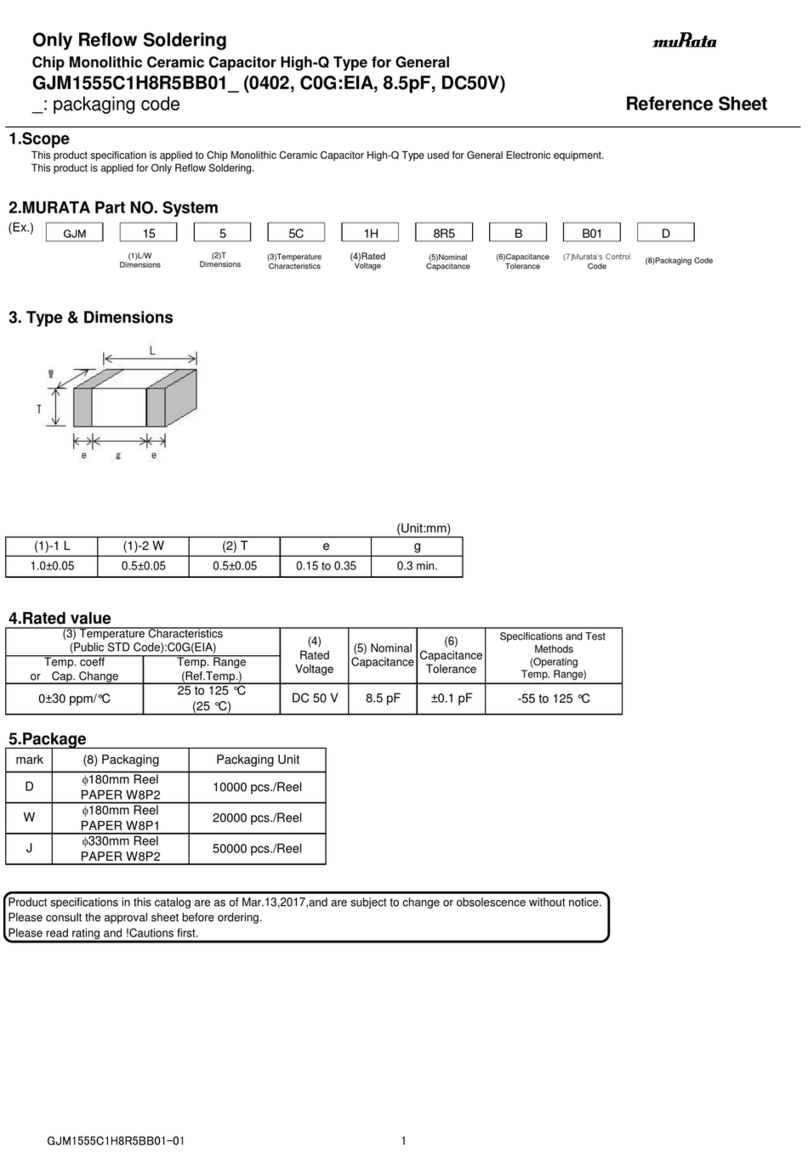

Murata GJM1555C1H8R5BB01 Series User manual

Murata

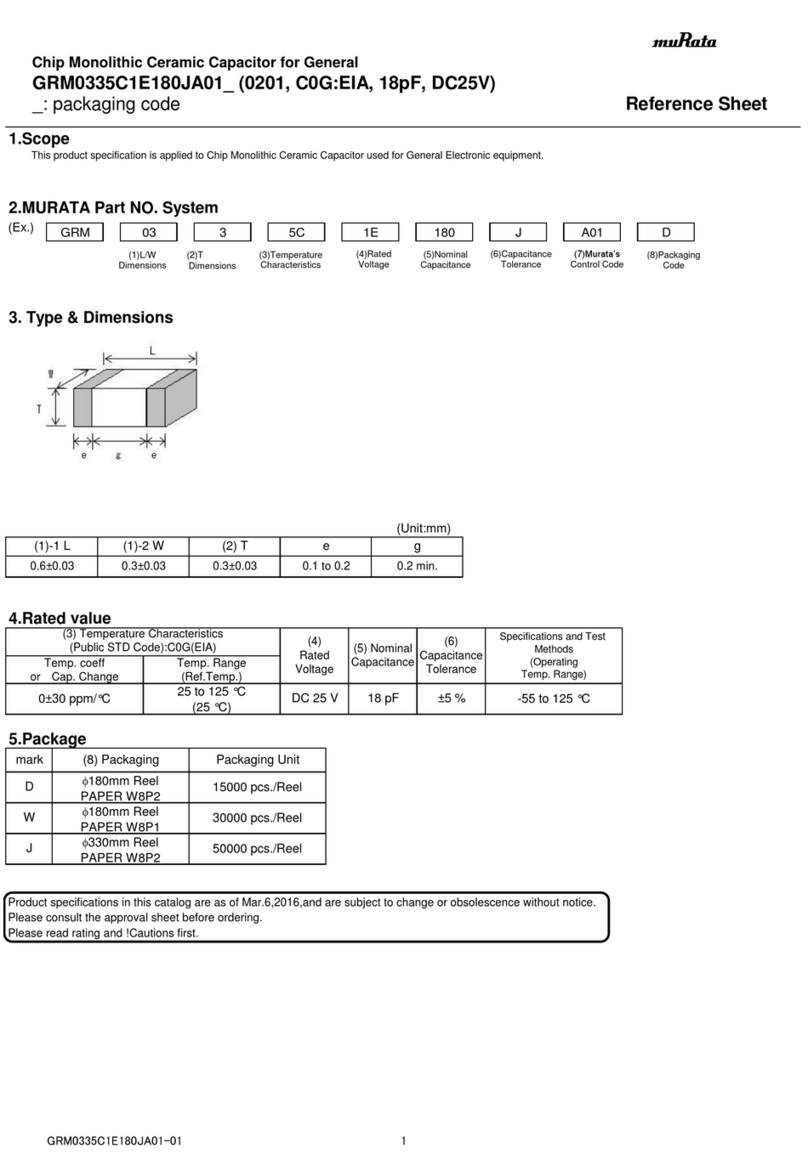

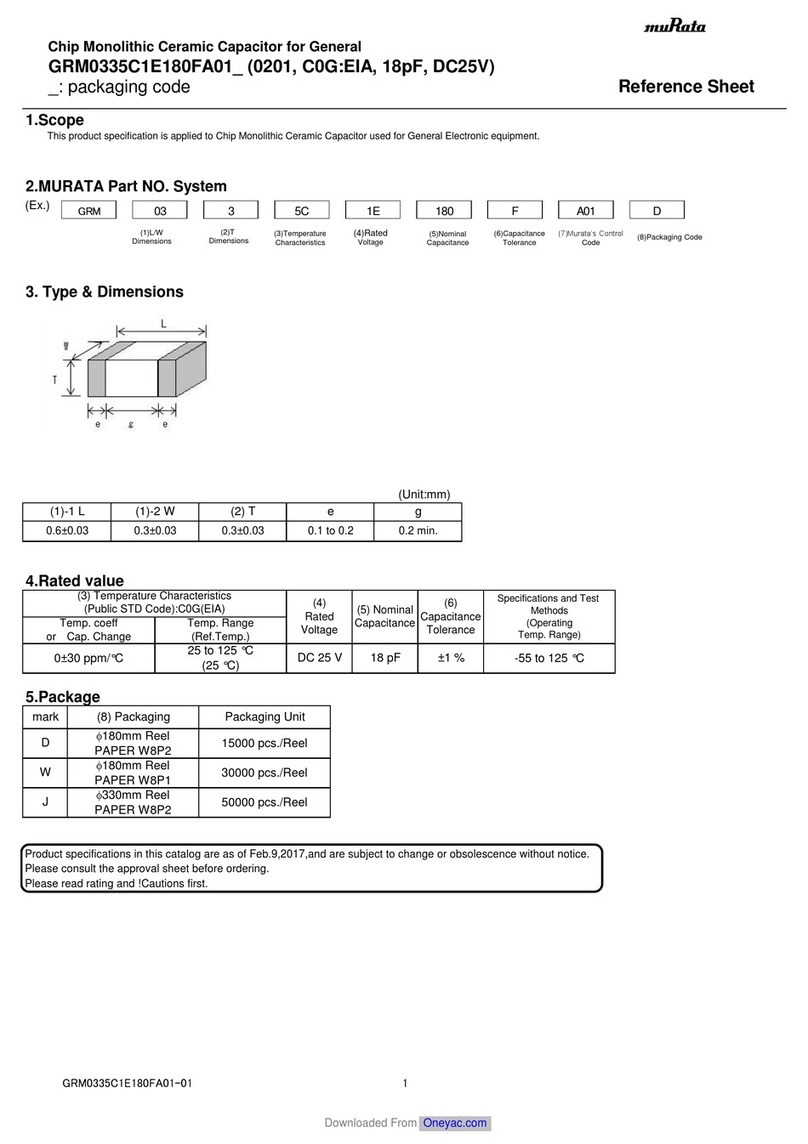

Murata GRM0335C1E180FA01 Series User manual

Murata

Murata GJM1555C1H2R4WB01 Series User manual

Murata

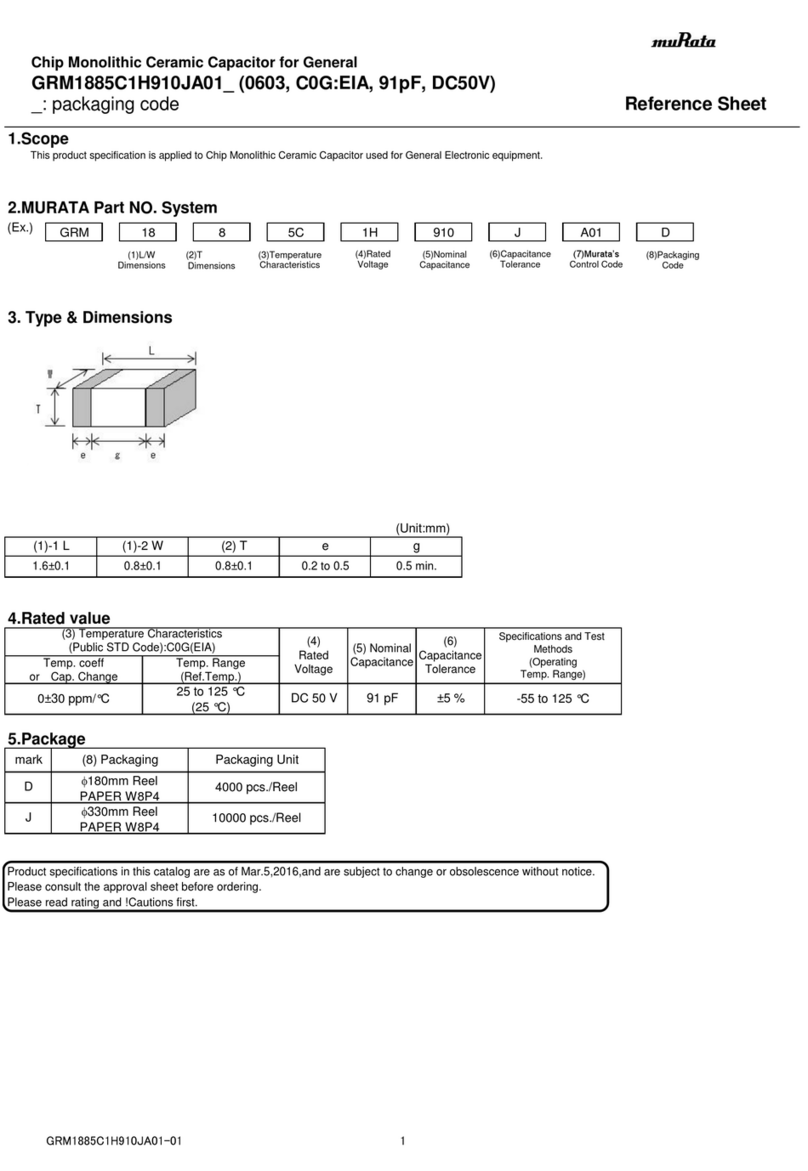

Murata GRM1885C1H910JA01D User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

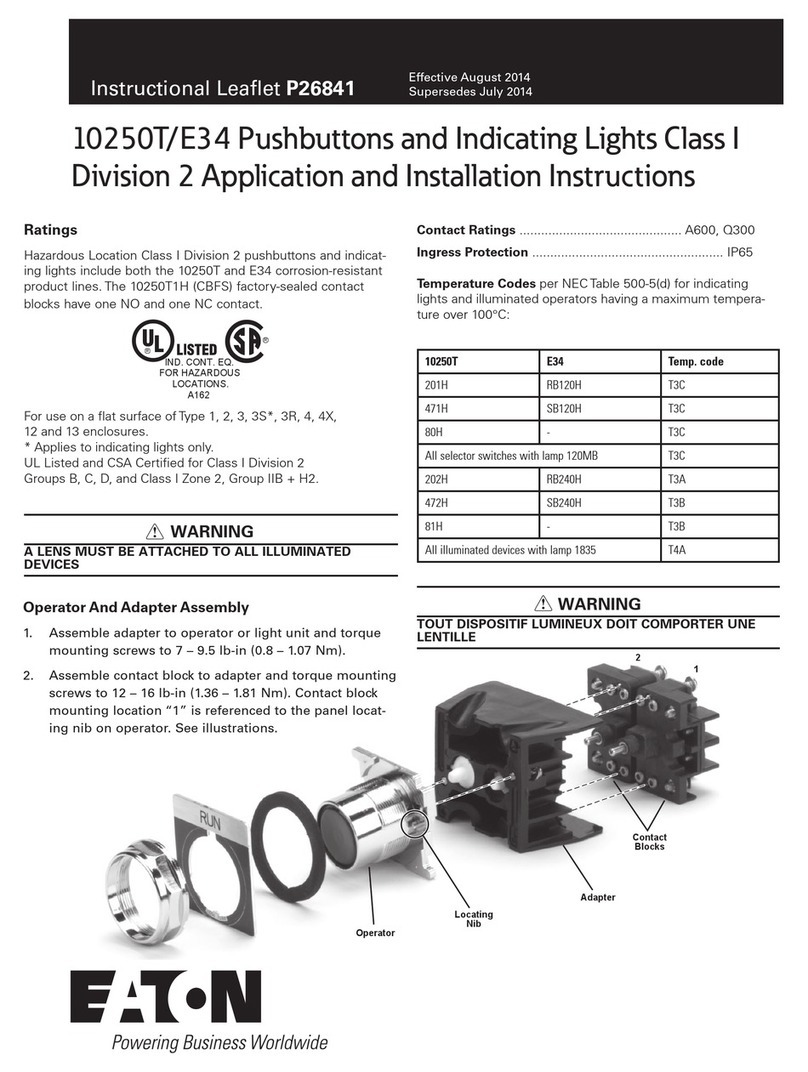

Eaton

Eaton Ulusoy HMH24-04 user manual

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

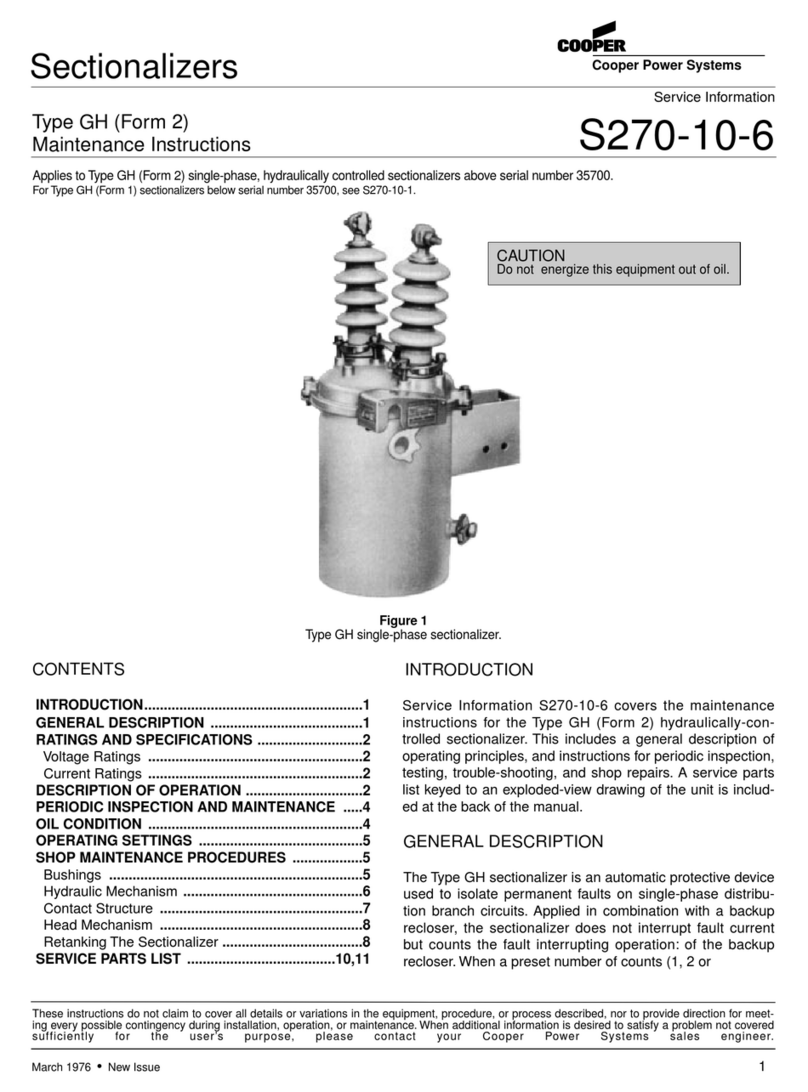

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions