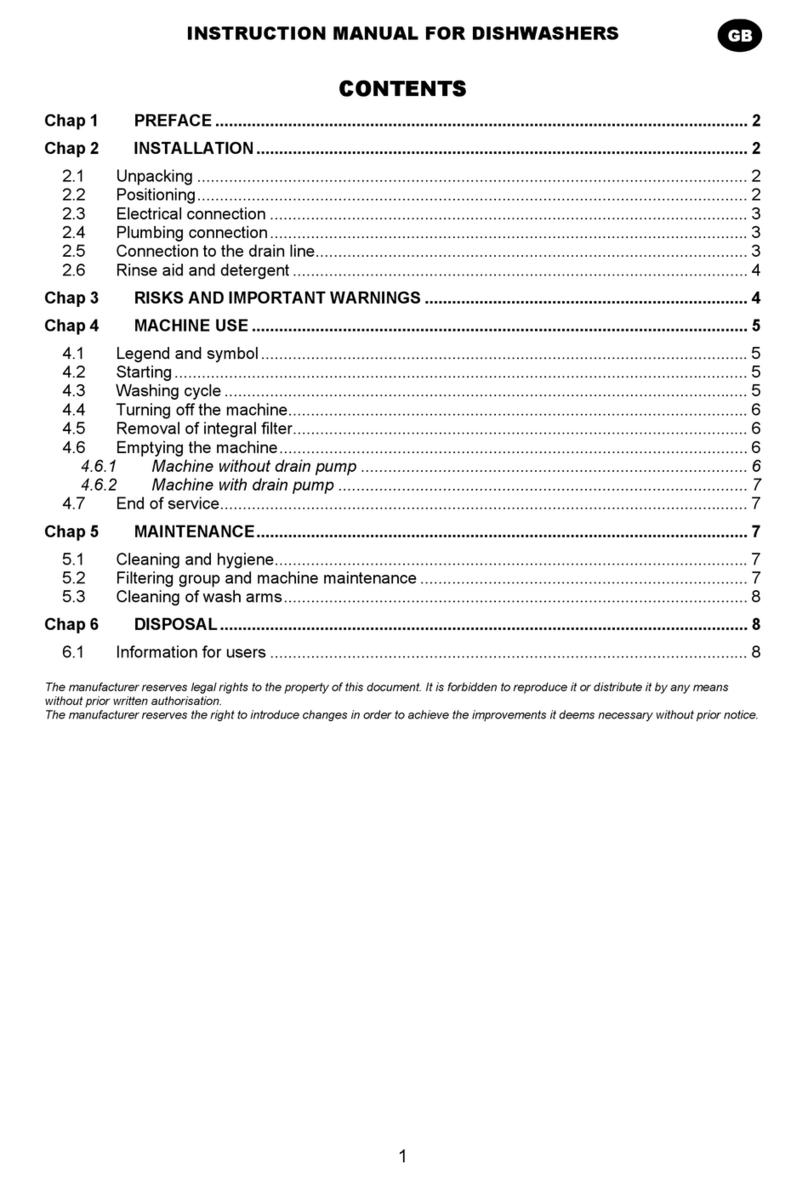

INSTALLATION

Page9

5. Dispenser settings

I Rinse-aid dispenser

Before starting the washing cycle, the dispenser and the delivery

pipe must be full.

Check that there is sufficient rinse-aid in the container and top up

if necessary.

The rinse-aid container must never be allowed to empty

completely and must not be topped up with corrosive or impure

products.

The warranty does not extend to any damage arising from incorrect use of the dispenser.

The dispenser is not factory-set; the dispenser must be calibrated by a qualified technician.

The dispenser is calibrated by adjusting a screw which is

accessed by removing the front panel under the wash chamber

door.

With the panel removed, without pulling the connection pipe, fill

the delivery pipe with rinse-aid, and then fully close the adjuster

screw, without forcing.

To determine the dosage for the preliminary setting, refer to the

information provided by the product manufacturer.

Once you have determined the required dosage, open the adjuster screw until this quantity is obtained.

A) Hydraulic dispenser.

One full turn of the adjuster screw is approximately equivalent to 0.4 grams of product per

operating cycle. The hydraulic dispenser can thus deliver from 0.4 grams/cycle (1 turn of the

screw) up to 3.2 grams/cycle (8 turns of the screw).

These values can only be guaranteed if the rinse-aid container is positioned approximately

40 cm below the level of the machine base. The quantity of rinse-aid dispensed will be increased

if the container is raised and decreased if the container is lowered relative to this position. If the

difference in height between the container and the base of the machine is greater than 80 cm, the

dispenser will not function correctly.

B) Electric dispenser (DB-2)

One full turn of the adjuster screw is approximately equivalent to 0.06 grams of product per

dispenser pulse, given that when fully open (16 turns of the screw), the dispenser delivers 1

gram/pulse. If the machine has 3 pulses per cycle, it can thus dispense from a maximum 3x1=3

grams/cycle (16 turns of the screw) down to a minimum of 0.06x3=0,18 grams/cycle (1 turn of

the screw).