Intended Use

ASA-Series | Version1.05 5

2.5 General safety rules

1. Keep order in the work area. Disarray in work areas

easily leads to injuries.

2. Pay attention to the environment of the work area. Use

the exhaust system indoors only, and do not use it in

damp or wet places. Ensure good lighting of the work

area. Do not use the extraction system in the pre-

sence of flammable liquids or gases.

3. Protection against electric shock. Avoid contact with

grounded surfaces.

4. Keep other people away. Make sure that other people,

especially children who are not involved in the work,

do not touch the machine and stay away from the

work area.

5. Check the power cord regularly and have it repaired

by an authorized specialist if damaged.

6. Keep the handles dry, clean and free from oil and

grease.

7. Wear appropriate clothing. Do not wear loose hanging

clothes or jewelry. You can get caught up in moving

machine parts. Non-slip footwear is recommended at

work. Remove rings, watches and bracelets before

starting work.

8. Before starting work, make sure the suction hose is

securely fastened. Make sure that the setting key has

been removed before putting the machine into opera-

tion.

9. Ground the suction hose to dissipate the electrostatic

charge on the connecting piece of the machine to be

vacuumed.

10. Stay alert. Observe your own work, follow the com-

mon sense and do not use the machine when a

process seems dangerous.

11. Follow the local regulations for electricity and safety,

as well as the valid European standards. Check

whether the power supply meets the requirements of

the device (see type plate).

12. The device may only be switched on when fully as-

sembled.

13. Never pull on the cable to remove it from the power

outlet. Keep the cable away from heat, oil and sharp

edges.

14. Maintenance work e.g. Bag, filter and hose change,

only with the power plug unplugged. There is a risk of

injury from touching the fan impeller.

15. Protect the device against moisture. If the machine is

operated outdoors, use only extension cords desi-

gned and labeled for outdoor use.

16. Do not operate in potentially explosive atmospheres.

17. Use only original accessories.

18. Check the device for perfect function before each

use.

19. Have defective switches replaced by an authorized

specialist.

20. Do not use the machine at temperatures below 0 ° C.

21. Observe accident prevention regulations and fire

protection regulations.

22. When changing the filter or chip bag, wear a dust

mask (filter mask with particle filter, filter class 2).

23. The use of accessories or accessories not recom-

mended in this manual may result in injury.

24. A guard or other item that is damaged should be pro-

perly repaired or replaced by an authorized service

center unless otherwise stated in this manual.

25. The machine complies with the relevant safety regu-

lations. Repairs may only be carried out by qualified

persons using original spare parts, otherwise signifi-

cant risks for the user may arise.

2.6 Residual risks

Dangers can arise from the extraction system if it is not

operated by trained persons and / or used improperly or

improperly.

Residual hazards are potential, non-obvious hazards,

such as:

- Injuries due to failure to observe the safety instructi-

ons, standards, guidelines or regulations

- Injuries caused by uncoordinated work,

- Danger from work on the electrical system, on the

cables and connections

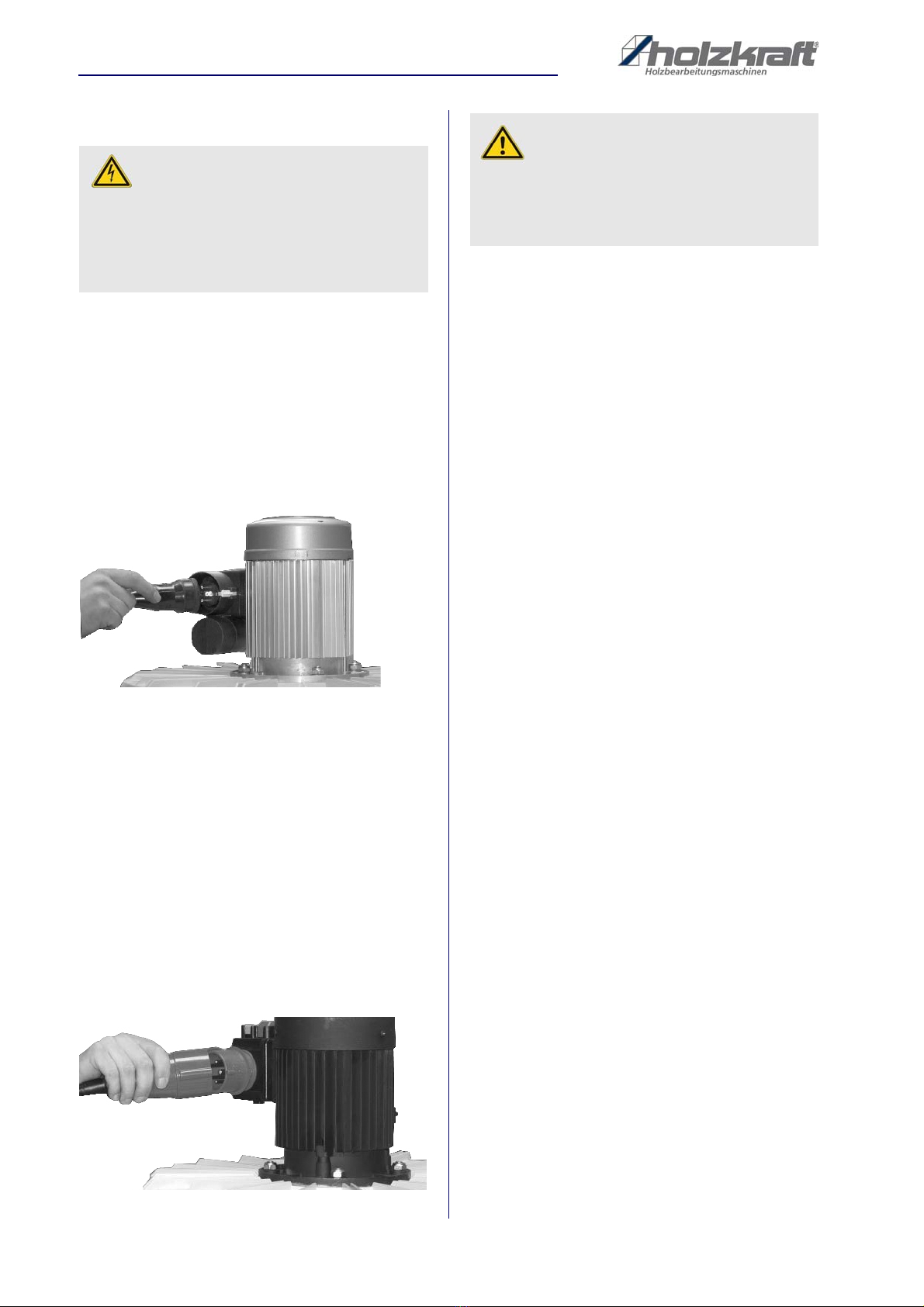

There is a risk of crushing by the clamping lever when in-

stalling the chip bag.

3 Intended Use

The extraction system was built exclusively for use in

combination with woodworking machines to extract mil-

ling, planing and sawdust (no dust). The extraction sy-

stem is used exclusively for extracting dry wood chips

from machine tools connected via a suction connection

or connected floor cleaning sets.

Solid bodies, e.g. Wood pieces (over an edge length of 1

cm) as well as metal parts and stones etc. must not be

vacuumed. Such bodies will damage the impeller (disc-

laimer of warranty).

WARNING!

When using a power tool, basic safety precautions

must always be taken to prevent the risk of fire,

electric shock and dangerous personal injury.

Read all of these instructions before working with the

machine and keep these instructions.