Table of contents

Page

1. Machine designation 5

2. Designated use 5

3. Technical data 5

3.1 Noise level .................................................................................................................................................6

4. Safety information 6

4.1 Residual risks...........................................................................................................................................7

5. Unpacking and installation 7

6. Scope of delivery and accessories 8

6.1 Scope of delivery ..........................................................................................................................................8

6.2 Special accessories ......................................................................................................................................8

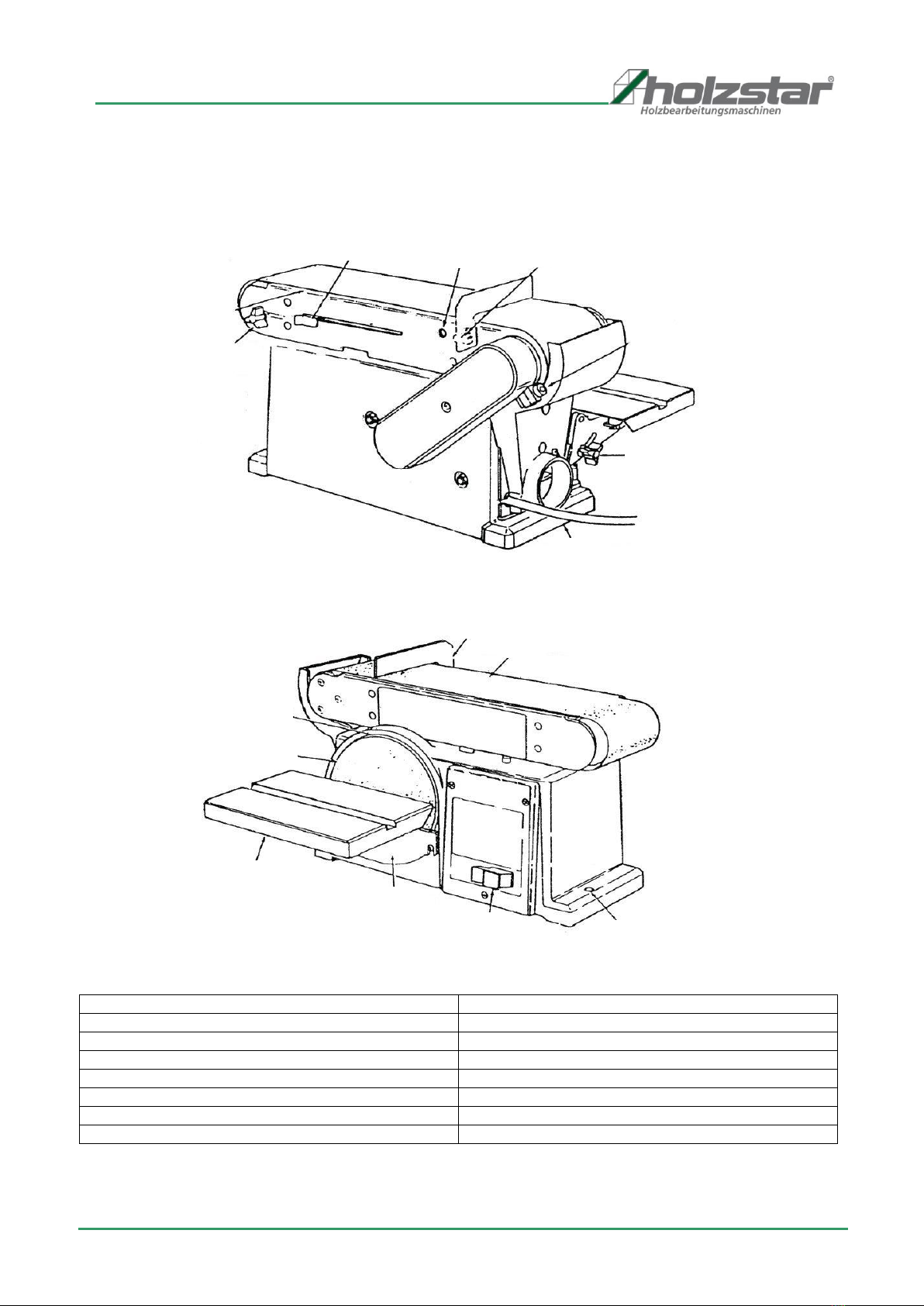

7. Control elements 9

8. Assembly 10

8.1 Safety stop...............................................................................................................................................10

8.2 Work table....................................................................................................................................................10

9. Settings 11

9.1 Pivoting the work table...............................................................................................................................11

9.2 Centring the work desk ..............................................................................................................................11

9.3 Vertical grinding..........................................................................................................................................11

9.4 Work table in vertical ..................................................................................................................................11

grinding position........................................................................................Fehler! Textmarke nicht definiert.

9.5 Replacing grinding disks ...........................................................................................................................12

9.6 Replacing grinding belts ............................................................................................................................12

9.7 Grinding belt run .........................................................................................................................................12

10. Machine control 13

10.1 General.........................................................................................................................................................13

10.2 On / off switch for BTS 250 ........................................................................................................................13

10.3 Surface grinding on the grinding belt .......................................................................................................14

10.4 Edge grinding in vertical grinding position..............................................................................................14

10.5 Grinding bent work pieces .........................................................................................................................14

10.6 Grinding round pieces on the grinding disk............................................................................................15

10.7 Grinding ends on the grinding disk ..........................................................................................................15

10.8 Connecting nozzle for extraction device ..................................................................................................15

11. Notes on the grinding process 15

12. Cleaning, maintenance and repairs 16

12.1 Cleaning .......................................................................................................................................................16

12.2 Maintenance ................................................................................................................................................16

12.3 Repairs .........................................................................................................................................................16

12.4 V-belt replacement ......................................................................................................................................17

13. Warranty information 17

14. Troubleshooting 17

15. EC declaration of conformity 18

16. Spare parts orders 19

17. Explosion drawing BTS 150 20

18. Explosion drawing BTS 250 21