9

or with the compressor’s air regulator. If the tool requires more force to

accomplish the task, verify that the tool receives sufficient, unobstructed

airflow (CFM). Then either:

a. Turn off and disconnect the tool, adjust the Regulator Knob, then resume

b. With the tool still turned on, increase the pressure (PSI) output of the

compressor regulator up to the maximum air pressure rating of this tool.

CAUTION! To prevent injury from tool or accessory failure: Do not exceed

the tool’s maximum air pressure rating of 90 PSI.

If the tool still does not have sufficient force at maximum pressure and

sufficient airflow from both regulators, then a larger tool may be required.

9. To prevent accidents, turn off the tool, detach the air supply, safely

discharge any residual air pressure in the tool, and release the throttle

after use. Clean external surfaces of the tool with a clean, dry cloth, a thin

coat of tool oil. Then store the tool indoors and out of children’s reach.

Your tool requires lubrication before every use.

Disconnect the air supply form the tool before lubricating.

Position the tool so that the inlet is facing up. Put in one to two drops of high

speed spindle oil or 3-in-l oil into the air inlet.

Operate the tool briefly to circulate oil after adding.

NEVER use detergent oil or additives.

If an in-line oiler is used,manual lubrication through the air inlet is not required

on a daily basis.

TROUBLE SHOOTING

Most air tool problems occur because humid and/or dirty air gets into the

line.Be sure to use an air filter to get rid of the moisture and minute particles.

Oil,either too much or too little,is another problem area.

Make sure the tool is oiled either manually through the air inlet,or

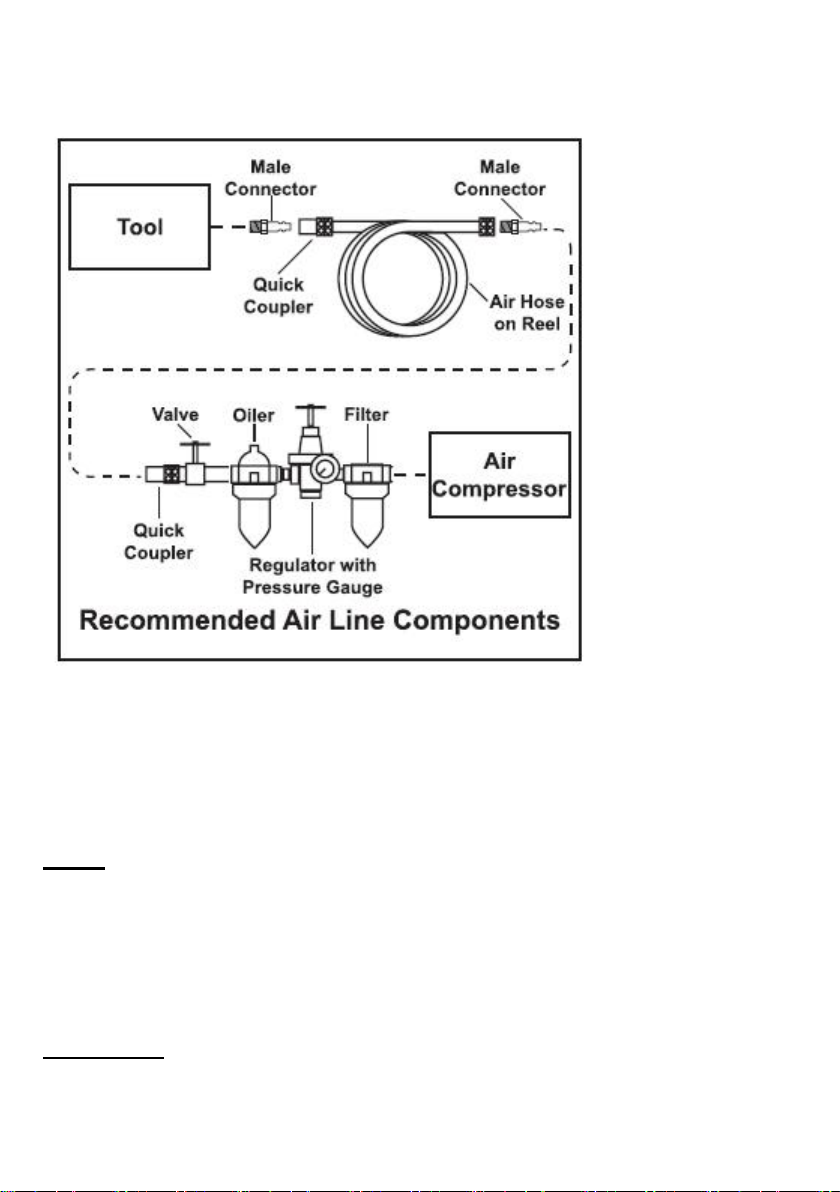

automatically with the in-line oiler as depicted.