RUNS, BUT TANK SHOWS NO BUILD UP

Cut off building air supply to eliminate possibility of

broken lines by closing supply valve on tank. If unit still

fails to build up, remove air intake filter. If still no

success, disconnect copper lines connected to intake

valves (3/4 HP and up). While the unit is running, no air

should be

coming

out of the copper line. If air is coming

out of the line, the unloader pilot is stuck or defective.

It should be removed, cleaned and inspected. The un-

loader pilot is at the other end of the copper line. See

Parts List for details of unloader and pilot.

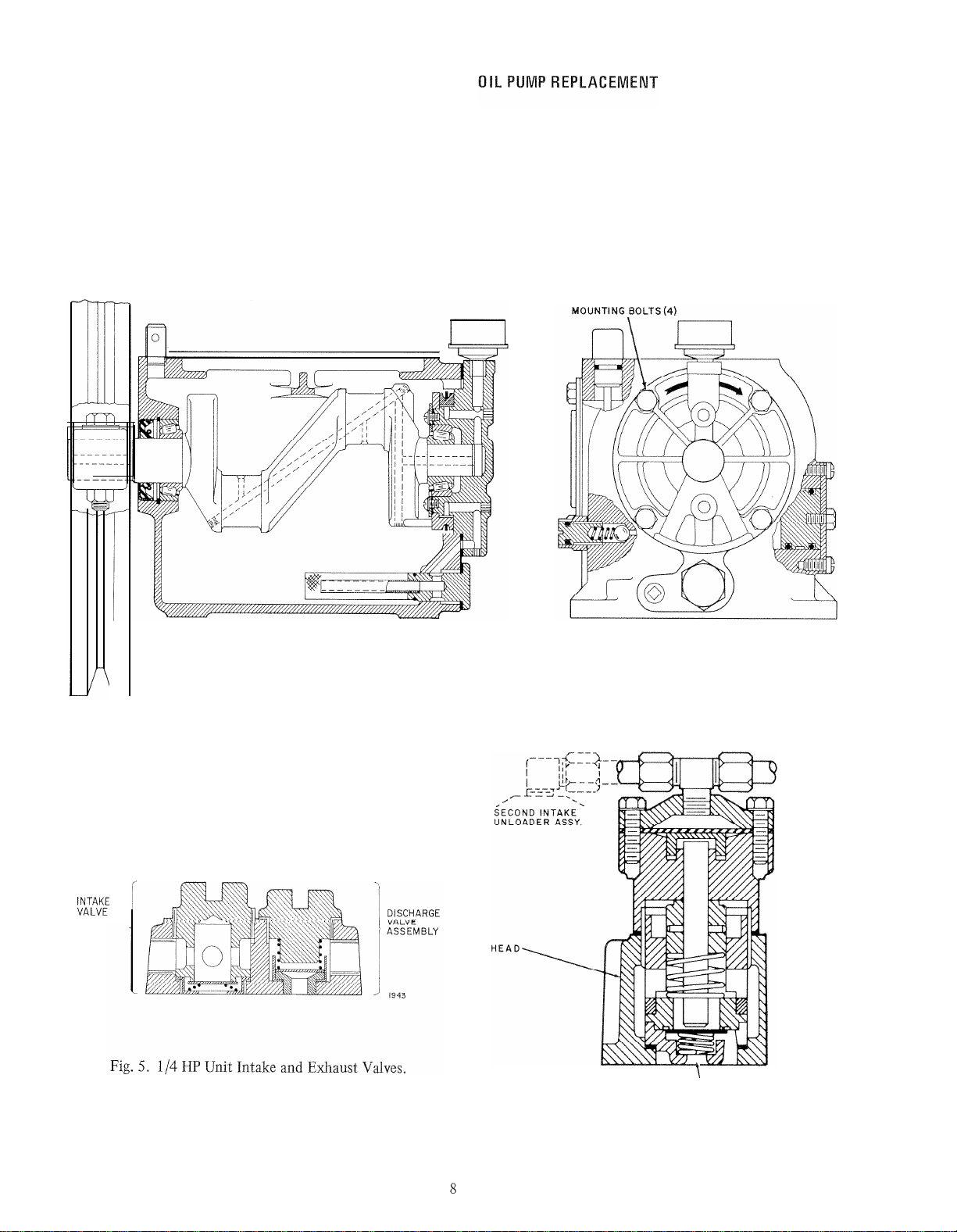

If unit is not equipped with unloading valves (1/4 to

1/2 HP are not), remove discharge tube and check for

air flow. Block with hand to check ability to build up.

If poor or no discharge air, disassemble and inspect valves.

If discharge is good, look for air leak between pump and

tank valve (cracked discharge tube, tank, etc).

BUILDS UP, BUT NOT COMPLETELY, OR TAKES

EXCESSIVE TIME

Cut off system by closing tank valve and check pump

up time (see Data Table II). Remove intake and recheck.

Disconnect copper line at intake valves(3/4 HP and up).

If air is coming out of line (while unit is running), dis-

assemble and clean unloader pilot located at other end

of line. See Parts List for details.

Another reason for poor delivery, in multicyclinder

units, could be

a

valve unloader sticking. The valve un-

loaders can be checked by disconnecting the copper line

leading to them and removing the cover bolts. Tapping

with a blunt instrument such as the handle of a large

screwdriver or small hammer, will loosen the cover so it

may be lifted off. Carefully remove the diaphragm; this

will expose the piston cup which operates the unloader.

With the unit running, manually depress the piston.

There should be a distinct change in the intake sound

indicating the valve is

being

held open. Slowly depressing

the piston, you should first feel the resistance of the

return spring, then the

piston

contacting the intake

valve, then the sound

change

is you move the valve off

the seat. Use fingernails to remove this piston cup for

cleaning beneath, if necessary.

If the source of the trouble has still not been located,

remove and inspect intake and exhaust valves for dirt or

warpage. (NOTE: The head must be removed on the 1/2

HP unit to service valves as they are not removable.) The

piston top and cylinder walls can be inspected at this

time.

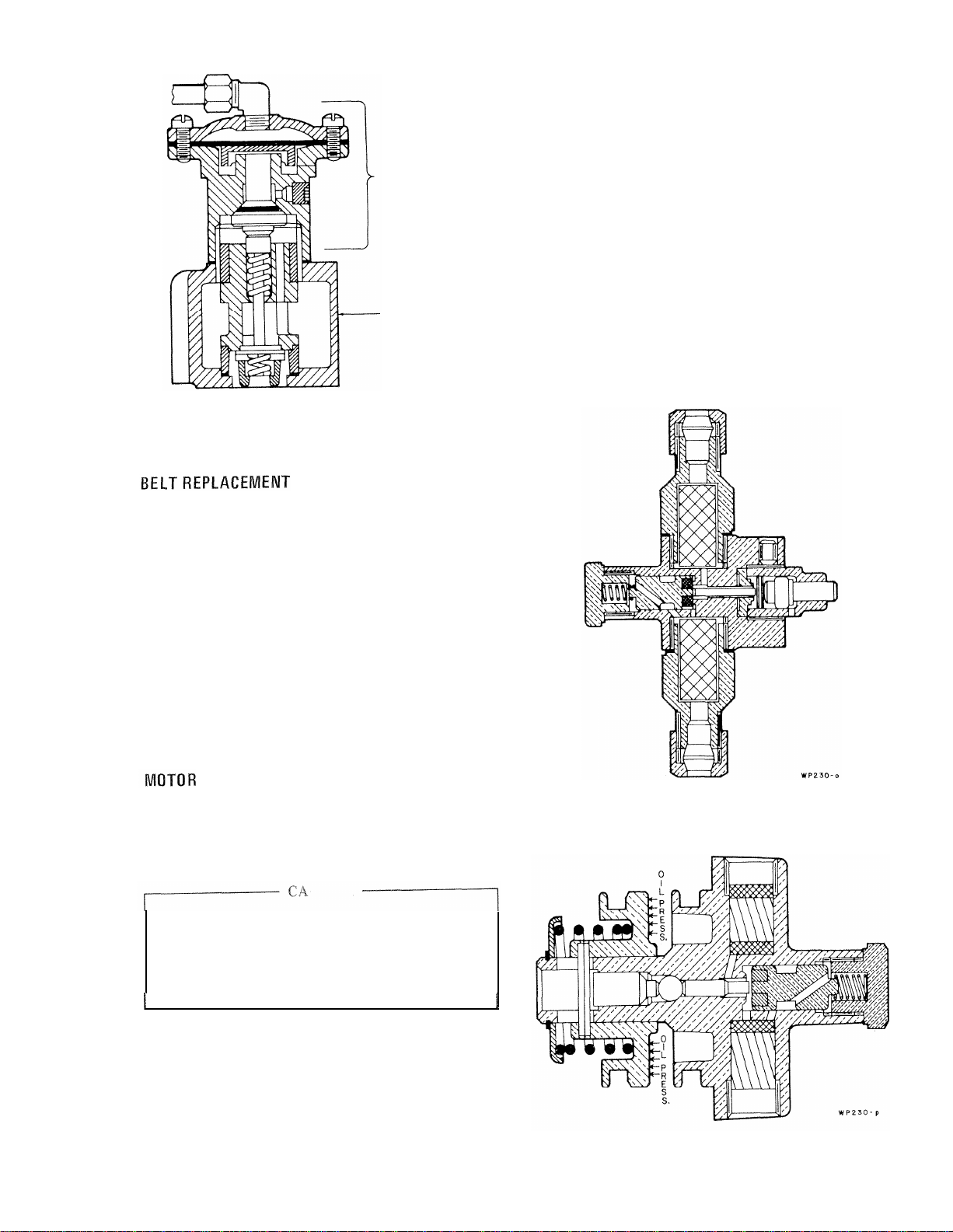

PUMP SLOWS, STALLS, OR GOES OUT ON OVER-

LOAD

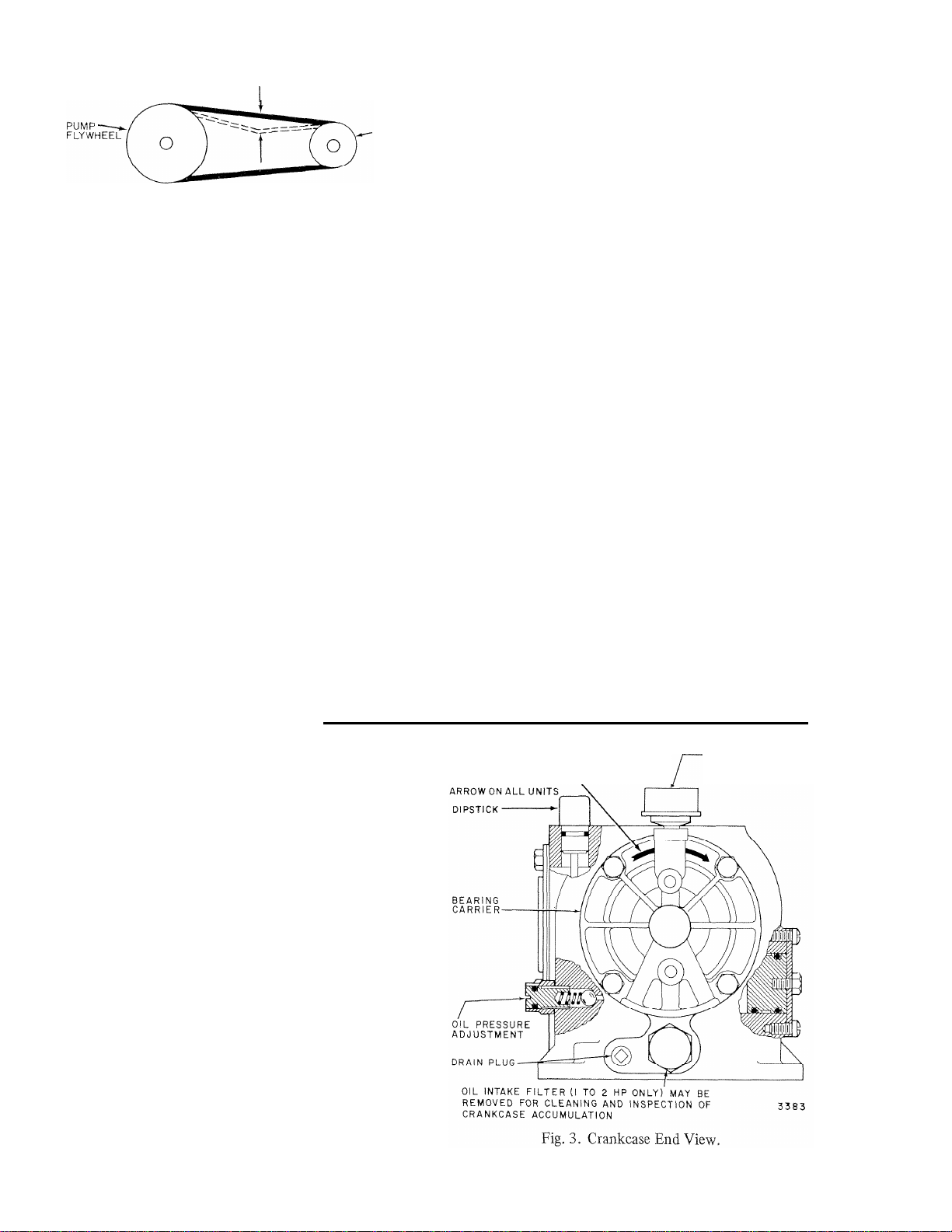

This is probably the result of the pump seizing. Check

oil level (and pressure in 1 HP and

up).

Check tank pres-

sure, should be 90 psi or lower. (On

WP240

units, turn

off power to both motor-pump units.)

Remove belt and bleed down tank. Turn pump by

hand, it should turn freely. If it does, motor may be

defective. If it does not, it may be the pump or a

plugged aftercooler tube. Disconnect discharge tube and

turn pump by hand again. If still hard turning, problem

is internal to the pump. If it now turns freely, check

piping to tank for obstructions.

EXCESSIVE VIBRATION

Usually due to omission of vibration pads or an

uneven weight distribution on the pads. Check this by

shutting off unit and applying your weight to the dif-

ferent corners of the unit. Excessive rocking should be

shimmed out. In very uneven floors, adjustable levelers

may be needed.

Belt guards often produce a vibrating noise even

under normal operating conditions. Readjusting will

usually eliminate this.

In some cases, the normal operation of the com-

pressor is considered excessive noise or vibration. In

these cases a remote air intake, adjustable pads, and air

line vibration isolators may be required, Isolators are

stocked in the commercial warehouse.

PUMP REMOVAL AND REPLACEMENT

Shut off power, drain oil, and bleed down tank.

Remove belt guard, loosen motor mounts and remove

belt(s).

Remove aftercooler tube at pump end. If tube is type

which wraps around crankshaft, then remove both ends

and any hold down straps.

If flywheel is accessible, then remove at this time;

otherwise it can be removed afterward if necessary. The

1/2 HP unit is held on with a keyed shaft and setscrew

and will probably need a puller. All others use a split

hub and key and can be removed by removing hub bolts

and nuts and driving a wedge into split.

Remove pump intake filter and the unloader air

supply line

(3/4

HP and up). Remove pump hold down

bolts and remove pump. (CAUTION: If flywheel has not

7

75-7131