Prodif 017SH Instruction Manual

OILLESS COMPRESSOR / AUTOLUBRICATED:

DIFAIR sas:Rue de l’embarcadère, Z.I de la Brande, 03600 Commentry.

WE DECLARE AT OUR RESPONSABILITY THAT THE FOLLOWING PRODUCT :

MODEL : 017SH COMPLIES WITH EUROPEAN GUIDELINES FOR SECURITY AND ENVIRONMENT ON

THE MACHINES:

2006/42/CE - Machinery - Replaces the 98/37/CE

2006/95/CE - LV - Low Voltage

2004/108/CE - EMC - Electromagnetic compatibility

2009/105/CE - Simple pressure vessels - Replaces the 87/404/CEE

97/23/CE - Pressure Equipment. (safety valve) Procedure: Module C1 - Notified Body 0036

Test Report No: P-PRC-03-10-C001763-01

2000/14/CE - Noise emission in the environment by equipment for use outdoors - According to Appendix VI -

Notified body 0071 - Sound power level guaranteed : 97 dBA - Sound power level measured : 94 dBA

2002/96/CE et 2002/95/CE - WEEE et RoHS.

STANDARDS USED :

EN 1012-1, EN ISO 12100-1 , EN ISO 12100-2, EN 13857, EN 286-1, EN953, EN ISO 13732-1,

EN50419, EN 55014-1, EN61000-3-2, EN61000-3-3, EN 60204-1, ISO3857-1/-2.

BUC: 30-05-2012 President: F. MURET

GUARANTEE

9 - GUARANTEE

The compressor is guaranteed for a period of

12 months starting from the date of purchase.

During this period, the manufacturer undertakes to

repair or to replace free of charge any defective

part, after an inspection has been completed at

the factory, in accordance solely with the

judgement of our technicians.

The guarantee is restricted to manufacturing

defects and applies to equipment used under

normal conditions. The guarantee will not apply

if the machine has been dismantled or modified

or if there are missing parts.

It excludes any responsibility for direct or indirect

damage to persons, animals or objects: if there

are missing parts, if the material or subset were

dismounted or modified.

Parts which are subject to normal wear, e.g

pressure switches, piston rings, belts, air filters,

gaskets and valves, etc., do not fall within the

scope of the guarantee.

No return is accepted without prior authorization.

The carriage costs incurred in returning all

part of a machine, even under guarantee,

will always be charged to the user.

The respect of the advice of use will preserve the

performances, the life expectancy as well as the

legal guarantee applicable to your compressor.

A compressor not maintained can be damaged

quickly.

If you do not use the compressor in accordance

with the contents of these instructions, we will

refuse any responsibility towards persons animals

or objects damaged.

The compressor presented in this note was

designed in the respect of the safety requirements

in agreement with the directives and texts in force

within the European Community. (See EC

Declaration).

This note was written in respect with Machine

Directive 2006/42/CE.

All uses advice necessary are indicated there.

Please keep this manual with the machine.

Please read entirely the safety requirements

and the instructions before using the

compressor.

To obtain the best results, respect all warnings

and instructions.

8 - GUARANTEE ADVICE

A-Notice 017SH.pmd 2012-05-30 DOCUMENT NON CONTRACTUEL Les données techniques sont indiquatives. Le constructeur se réserve le droit d'apporter toute modification sans préavis.

«CE» EUROPEAN COMPLIANCE

DECLARATION

41

7 - PICTOGRAMS LEGEND

3: Do not touch apparent hot surfaces (Cylinder head, pipe between tank and cylinder head, non-return valve).

4: Automatic restart of the compressor without warning.

5: Risk of electric discharge.

To undertake the maintenance of this machine before air pressure has completely fallen and electricity has

been disconnected.

Do not open the air valve before you have connected the air pipe and the tool to the compressor.

Do not breathe or project the compressed air of the compressor towards a person .

Use a sound protection in the event of prolonged use.

This equipment cannot be thrown as waste and is subject to a selective collection for its valorization or

recycling.

01: Read entirely the note before the startup or any operation of maintenance on the compressor.

02: To use a sound protection in the event of prolonged use.

WARNING SIGNALS:

OBLIGATION SIGNALS:

Acoustic power level

guaranteed.

SOME ADVICE:

1 3 2 4 5 017SH017SH

017SH017SH

017SH

017SH017SH

017SH017SH

017SH

MANUAL

INSTALLATION - USE

MAINTENANCE

For any communication with the distributor,

please indicate the identification sticker data of

the product. The sticker is applied on the side

of the compressor.

2

3 - FOR YOUR SECURITY

6 - COMMUNICATION- TRACKING PRODUCT

The air delivered by your compressor allows you

to use many tools, ensure conditions: advice, in

certain cases USE RESTRICTIONS of air tools

using air pressure.

Avoid any degradation of the electric cable and

move away from heat sources higher than 70°C.

After working, disconnect and roll up the cord in

the handle of transport of the compressor.

Do not use the machine with naked or wet feet.

Do not touch the compressor with wet hands.

Do not pull the cord to move the compressor or to

remove the plug.

Do not allow children to use the compressor.

Do not leave the compressor without monitoring

when it is connected; it can become source of

dangers.

The electric safety of this machine is assured only

when it is correctly connected with an efficient

grounding connection , as recommended in the

rules of electric safety requirements.

The responsibility for the manufacturer will not be

committed if grounding connection of the

installation is incorrect.

2 - INSTRUCTIONS, USES ADVICE

To obtain the best efficiency, please respect the

following indications:

- PLACE: Use the compressor indoors or under

shelter, do not expose it to the rain or near water

jets. Do not use the compressor in an explosive

atmosphere.

- VENTILATION: The compressor must be in a place

which allows ventilation, do not cover the

ventilation openings.

- TEMPERATURE: Use the compressor between

(+ 5°C and +35°C) (Otherwise, there are risks for

the electrical motor.)

- TENSION: Check that the sector tension and

tension indicated on the label are the same :

(Single phase:230 Volts - 50 Hz)

- HORIZONTAL SETTING: the compressor must be

installed on a horizontal plane, 10 ° angle is

allowable.

Check that the compressor has not been damaged

during the transport.

The switch must be in position «OFF».

Connect in a socket-outlet:

- Of 16 Amps under 230V.

- Connected to the ground.

- Connected to a differential protection.

- USING AN ELECTRIC EXTENSION:

- BEFORE USING:

Please only use an extension if absolutely

necessary.

We recommend the following dimensions: 5 meters

maximum length with section of wire of 2,5mm ².

Too small diameter wire sections and big lengths

would cause serious damage to the engine.

It is better to extend air pipe, which moreover will

give you stock of air.

- USE:

To start your compressor, it is necessary to:

Push the switch on position «ON».

NOTA: If you do not use the compressor, IT IS VERY

HIGHLYADVISED to switch it «OFF».

As your compressor has no reserve, the air escapes

by the safety valve and damages the parts of the

compressor.

4 - MAINTENANCE

Your compressor is auto-lubricated (oilless), and

therefore does not require any maintenance apart

from the following points.

The operating of motor compressor should be

intermittent, it means 60% of use for 40% of

downtime.

Beyond this limit, the motor may overheat.

When overheated, the internal thermal protection of

the engine will work automatically by cutting the

electric current.

The motor will restart as soon as normal conditions of

temperature will be restored.

If you want to change tools,you have to stop the

compresseur.

ATTENTION!

For painting:

Use only low pressure spray guns.

Use your compressor according the different

applications accepted (inflation, air tools, painting,

washing with only water-based detergents, etc..),

Implies knowledge and compliance with standards

set for each job.

INSTALLATIONAND SITE

INSTRUCTIONS

You have just bought your air compressor, it will give

you appreciable services.

Please ensure first that your compressor is powerful

enough, you may use it for:

- Inflating Tyres - Balloons - Swimming pools - Rafts

etc...... - Blowing / vacuum-cleaning / painting- Using

pneumatic tools :(ex. gun nailer, stapler, screw driver,

impact wrench, sand blasting, etc...)

Before use, it is imperative to read ENTIRELY the

present NOTE.

1 - INSTALLATION AND SITE

OPERATING INSTRUCTIONS

The compressor does not start:

- No electrical supply.

- The compressor is already pressurised,

disconnect the hose.

The compressor starts with difficulty:

- The electrical supply is insufficient.

- electrical supply cord is too long, or wire section

too small.

- Engine overload by cold weather.

- Electrical supply cord is cut or disconnected.

Abnormal noises, vibrations:

- loosened or worned parts.

- worned pump (mechanical noises).

- bad chocking of the compressor.

Low flow rate, pressure does not increase:

- suction filter is blocked.

- leaks in connection pieces.

- compression cylinder valves or inter-plate

gaskets broken.

- piston ring set worned.

5 - FAULTS / SOLUTIONS

3

How to choose the compressed air hose:

Use a rubber hose or a hose reinforced with safety

cable steel.

Do not use plastic hose,the temperature rises around

the cap connection, the plastic hose becomes soft

and exits from its setting.

In case of overheating

1 - Stop the compressor

2 - Before restart wait 5'

IDENTIFICATION STICKER OF THE PRODUCT

1 3 4 5 6

7

8

9

1

12

10

11 13

1 - Producer

3 - Power

4 - Tension- Phase Qty

and frequency.

5 - Maximum pressure

6 - Compressor weight

7 - Air delivery at 7 bar

8 - Revolutions per minute

9 - Measured noise level

10 - Serial number

11 - Code model

12 - Reference

13 - Year of manufacture

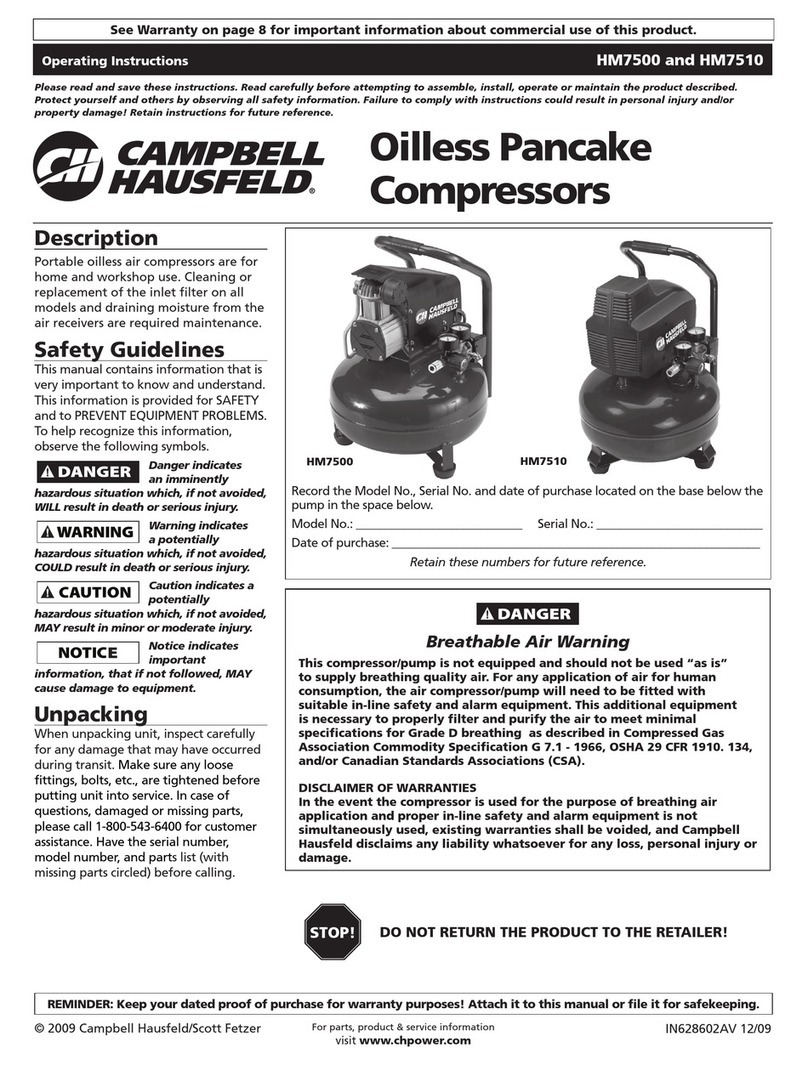

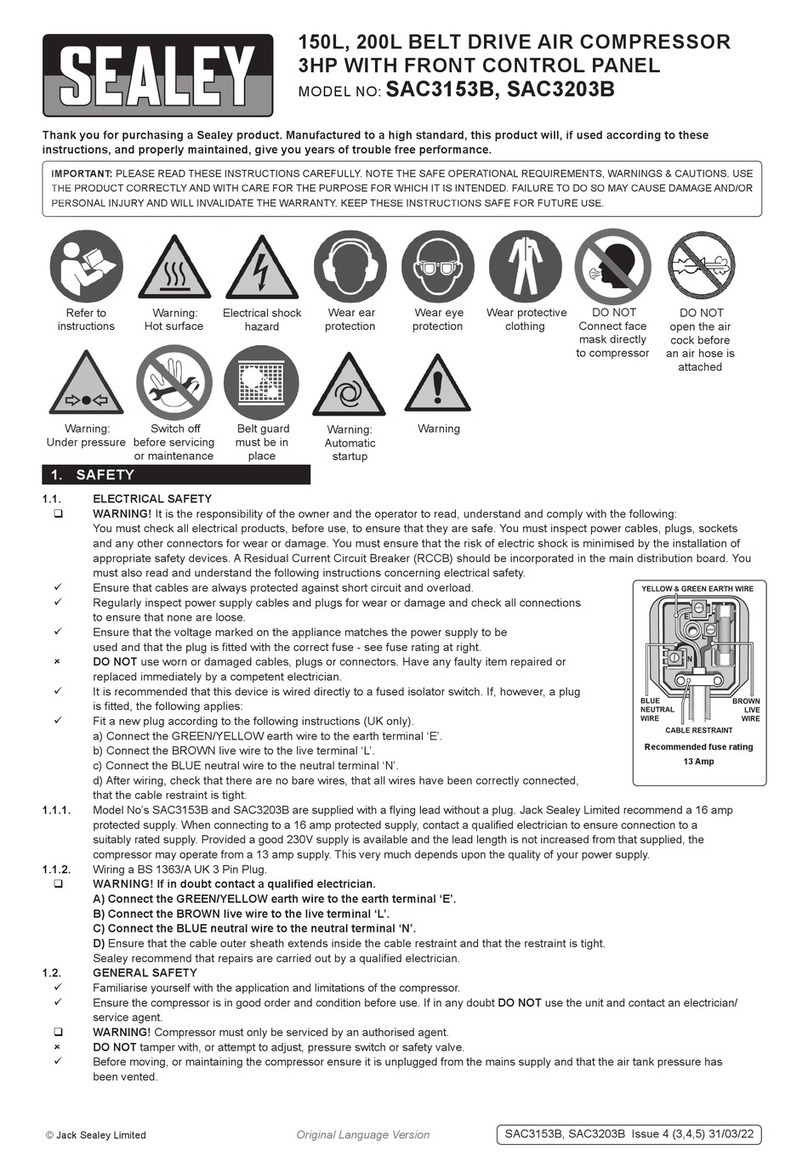

Other Prodif Air Compressor manuals

Popular Air Compressor manuals by other brands

EINHELL

EINHELL CE-CC 18 Li Original operating instructions

Ingersoll-Rand

Ingersoll-Rand GHH RAND SILU CS104 Mounting instructions

Fubag

Fubag OL 195/24 CM1,5 Operator's manual

MESTIC

MESTIC MCC-25 DC User instructions

Craftsman

Craftsman evolv 15206 Operator's manual

LUBCON

LUBCON Compguard FG 32 instructions

Senco

Senco PC 1010 operating instructions

Hitachi

Hitachi EC 10SB (SL) Instruction manual and safety instructions

Reflex

Reflex Reflexomat XS Original operating manual

Harbor Freight Tools

Harbor Freight Tools Central Pneumatic 38898 Assembly and operating instructions

DeWalt

DeWalt D55168 instruction manual

Craftsman

Craftsman 390.291558 owner's manual