GENERAL SAFETY !

The risk of serious injury or even death to yourself or others is a reality when tools and

machinery are not operated or maintained correctly.

All operators of this Angle Grinder must read this manual and fully familiarise themselves

with its operation before use.

Ensure the hydraulic power source is compatible for use with this Angle Grinder (e.g. flow

and pressure).

Ensure any abrasive wheel being fitted to this tool is compatible and is within the

maximum speed.

Only persons who have attended a recognised Abrasive Wheel Course (or equivalent)

and holds a valid certificate should fit abrasive wheels.

Do Not use non-reinforced cutting wheels with this Angle Grinder.

Do Not modify or fit non-approved parts without the manufacturers written consent. Any

warranty will become void and could result in injury or even death.

Do Not reverse the oil flow through the grinder as this will make the wheel rotate in

the wrong direction.

Never operate this tool when under the influence of drugs, alcohol, on medication,

tired or feeling unwell as your judgement becomes impaired and could lead to serious

injury or death, not just to yourself but others around you.

You have a duty, not just to protect yourself but also a duty of care to others.

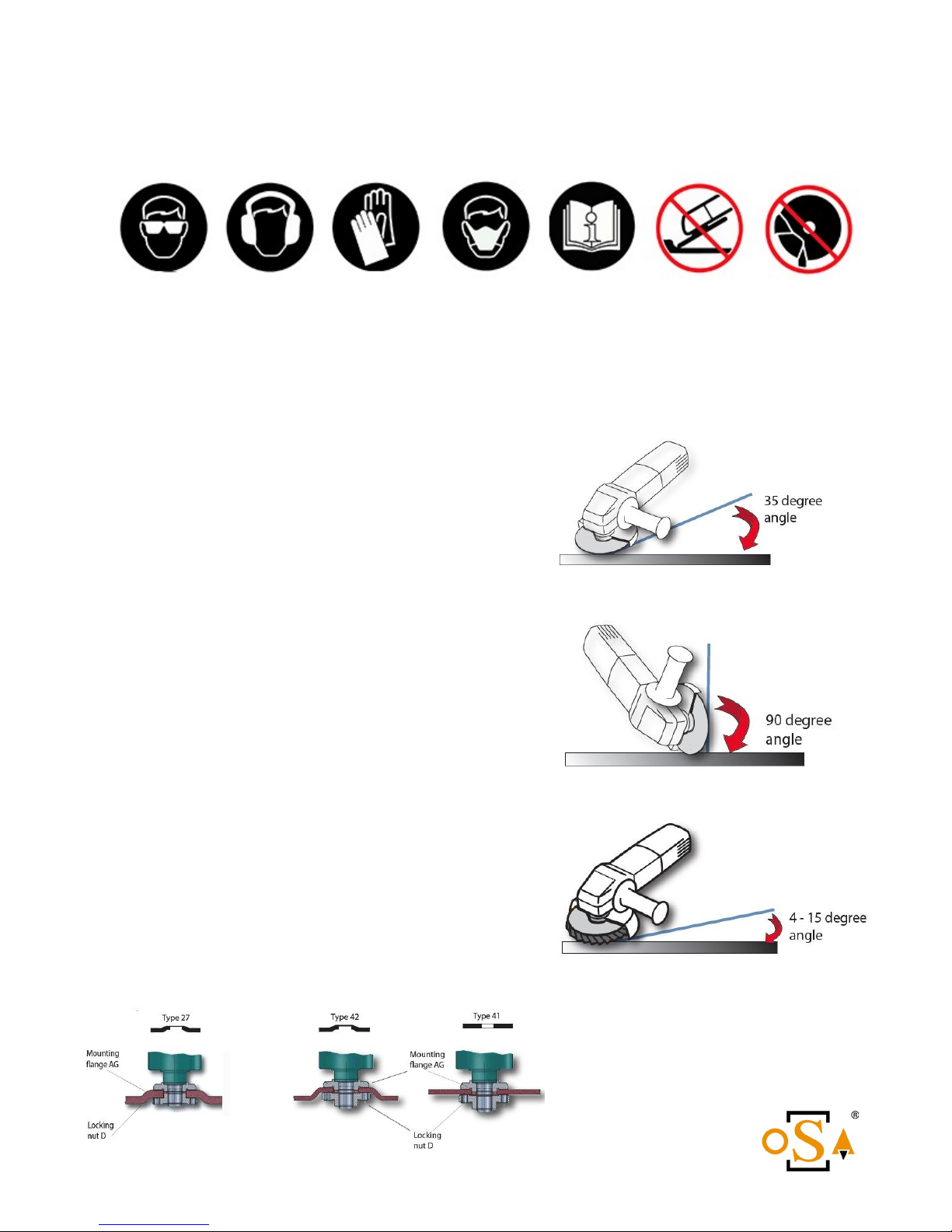

Safety Precautions

PPE (Personal Protective Equipment). Always wear approved fire retardant protective

garments covering arms and legs if appropriate, protective helmet, suitable eye

protection, ear defenders, suitable respiratory mask (in dusty conditions), safety boots,

protective gloves.

Do not operate this tool with loose clothing and tie back long hair. As any loose

items becoming entangled may cause serious injury.

Small jets of pressurized hydraulic oil can penetrate the skin. Never check for leaks

using your hands. Should oil penetrate the skin or be inadvertently swallowed seek

medical advice immediately. Do not induce vomiting.

Hydraulic oil along with other lubricants and greases can cause eczema. Should oils

etc. come into contact with bare skin wash off immediately with warm soapy water.

Inspect the abrasive wheel for damage, cracks, excessive or uneven wear. Discard

any wheel that has any defects or has been dropped.

4