trak®bloc batteries have low gas

emissions but are not completely free

from gas emissions.

It must be ensured that the charging gases

are drained off effectively during charging.

Covers on battery installation spaces must

be opened or removed.

The battery must be connected to the

charger with the correct polarity (positive to

positive and negative to negative) when the

charger is switched off. The charger must

then be switched on.

During charging, the temperature in the

battery increases by approx. 10 K.

Therefore, charging should only be started

when the temperature is below 35 °C. The

temperature prior to charging must be at

least 15 °C, as otherwise the battery will not

reach a sufficient level of charge during the

prescribed charge time.

If temperatures are consistently higher than

40 °C or lower than 15 °C, the charger will

need to undergo constant voltage regulation

dependent upon the temperature.

A correction factor of -0.003 V/Z per K

should be applied here.

2.3 Equalising charge

Equalisation charging is used to guarantee

the service life and to preserve the capacity.

Equalisation charging must be carried out

following normal charging.

This type of charging must be carried out

following deep discharge and repeated

insufficient charging. Only those chargers

that have been approved by the battery

manufacturer may be used for equalisati-

on charging. It is also recommended that

equalisation charging be carried out with

constant current once every quarter. The

charging current can be a maximum of 0.8 A

per 100 Ah C5rated capacity, and must be

deactivated after a maximum of 5 hours.

The charge voltage must not exceed 2,6 V

per cell. Observe the limit temperature!

Charging must be interrupted if the limit

temperature is exceeded.

2.4 Temperature

30 °C battery temperature is considered

the rated temperature. Higher temperatures

reduce the service life, while lower tempera-

tures reduce the available capacity.

45 °C is the upper limit temperature and

is not permissible as an operating tempe-

rature.

Therefore, trak®bloc batteries must not be

exposed to sunlight without protection.

2.5 Electrolyte

The electrolyte takes the form of suspended

sulphuric acid. The density of the electroly-

tes cannot be measured.

3. Maintenance

Do not top up with water!

Never open or remove the valves.

3.1 Daily

Charge the battery immediately after every

discharge.

3.2 Weekly

Carry out a visual inspection for contamina-

tion and mechanical damage.

3.3 Quarterly

The following must be measured and recor-

ded once the battery has been fully charged,

after a waiting time of at least 12 hours:

- Total voltage

- Individual voltage of the block batteries

If significant changes to previous measure-

ments or differences between the block bat-

teries are identified, then Customer Service

must be contacted for further testing or

repairs.

3.4 Yearly

(only for batteries in a steel trough)

In accordance with EN 62485-3, the insu-

lation resistance of the vehicle and the

battery must be checked by a specialised

electrician.

The battery insulation resistance check must

be performed in accordance with EN 1987-1.

The established battery insulation resistance

must not be below 50 Ohm per Volt of rated

voltage.

For batteries with a rated voltage of 20 V,

the minimum value would be 1000 Ohm.

4. Care

The battery must always be kept clean and

dry in order to prevent leakage currents.

Cleaning must be performed in accordance

with the ZVEI data sheet „Cleaning batteries“.

5. Storage

If batteries are taken out of operation for

extended periods, then they must be stored

fully charged in a dry and frost-free location.

In order to ensure that these batteries stay

ready for operation, the following charging

procedures must be applied:

Quarterly full charging as per Item 2.2.

If consumers such as measuring or control

equipment are connected, it may be neces-

sary to carry out a full charge every 14 days.

In general, self-discharge of 2 % per month

is to be expected.

The storage time should be taken into

account in any service life estimates.

6. Faults

If any faults are detected on the battery or

charger, contact Customer Service imme-

diately.

HOPPECKE Service:

+49 (0) 2963 61-591

Measured data as per Item 3.3 make trou-

bleshooting and fault rectification easier.

A service contract with HOPPECKE makes

it easier to detect faults in good time, to

prevent faults and to remedy any faults that

may occur.

7. REACH Statement Pb-Metal:

According to REACH regulation we inform

that, PzS- and PzB Batteries are containing

the SVHC substances Lead-metal (CAS.

Nr. 7439-92-1) with more than 0.1 weight %.

MSDS is available upon request from your

account manager.

For further information regarding REACH

please refer to https://echa.europa.eu.

Teil-Nr. 7240203030/04.21

HOPPECKE Batterien GmbH & Co. KG

P.O. Box 1140 · D-59914 Brilon

Bontkirchener Straße 1 · D-59929 Brilon-Hoppecke

Fax: + 49 (0) 29 63 61-735 Internet: www.hoppecke.de

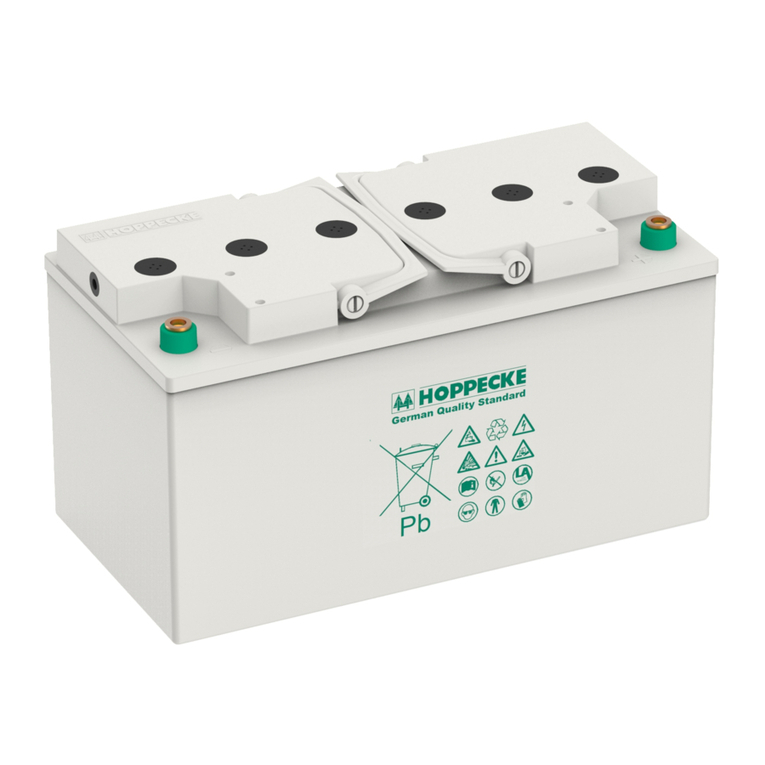

Pb

Used lead-acid batteries constitute waste for recycling that requires special monitoring. These batteries, which feature the

recycling logo and a crossed-out dustbin, must not be disposed of with household waste. The method of return and recycling must

be agreed upon with the manufacturer in accordance with Section 8 of the German Battery Ordinance (BattV).