7 of 15

Indesit Company

Service Manual UK English

INTRODUCTION & USE

These products are not specifically for cooling wine. They are as the name implies; Wine Cellars,

designed for storing wine in optimal conditions.

The temperature is factory set at 15°C, although this is adjustable and can be set according to

individual preferences.

Before the time comes to serve the wine, simply remove the chosen bottle/s from the cabinet and

prepare as necessary. This may be allowing it to stand for awhile where the temperature is suitable

or perhaps chilling in the fridge.

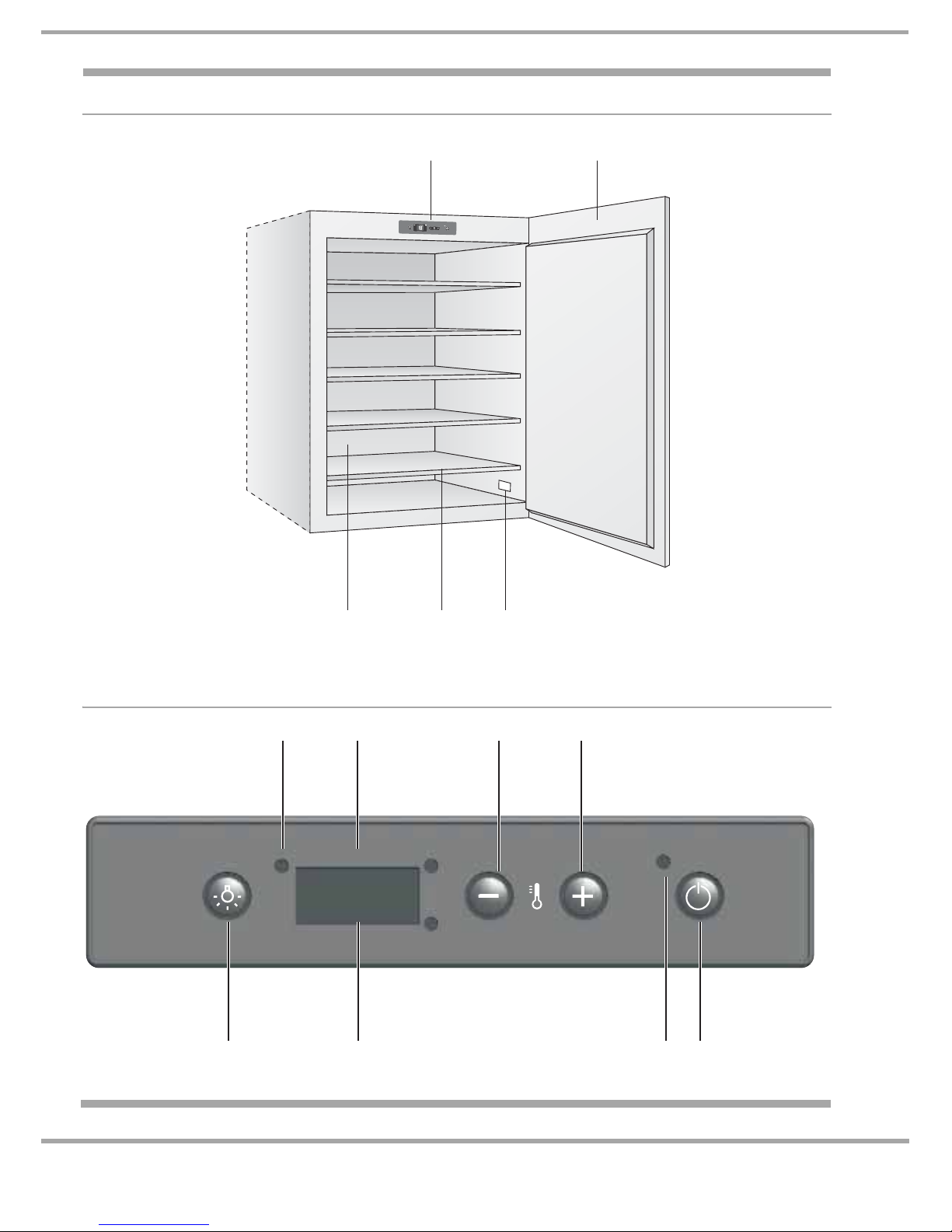

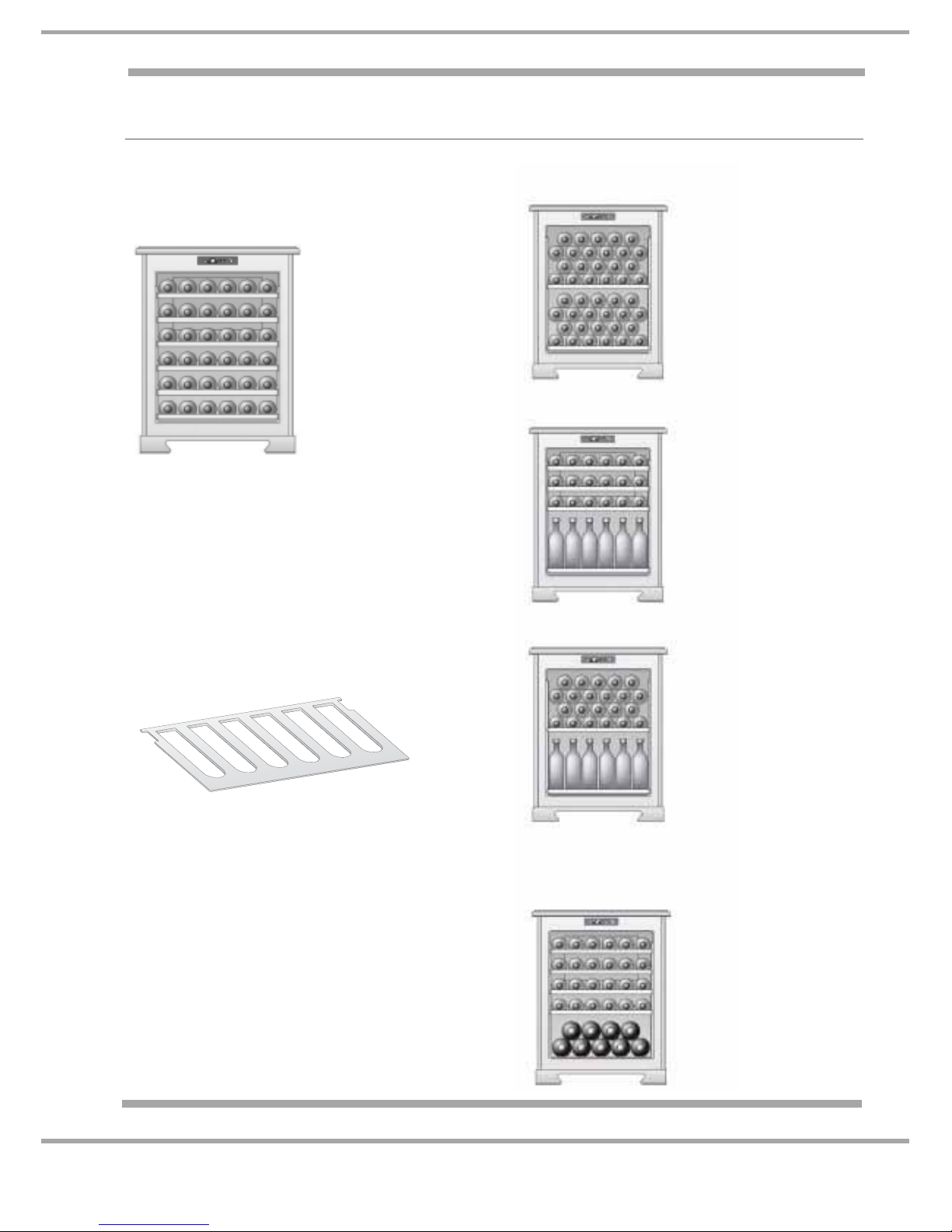

• Bottle storage WL24 of up to 46 bottles - WL36 up to 28 bottles.

• WL36, 5 wooden support shelves - WL24, 3 wooden support shelves.

• Digital Display - adjustable from +0°C to +18°C.

• Temperature sensing – replaceable thermistor.

• Internal fan to ensure more even temperatures throughout.

• Rear mounted air circulating fan to disperse heat from the condenser.

• Internal fluorescent light.

• Anti-condensation feature - Ventilation fan.

• Internal liner - black - to reduce light transmission / reflection, preserving the wine.

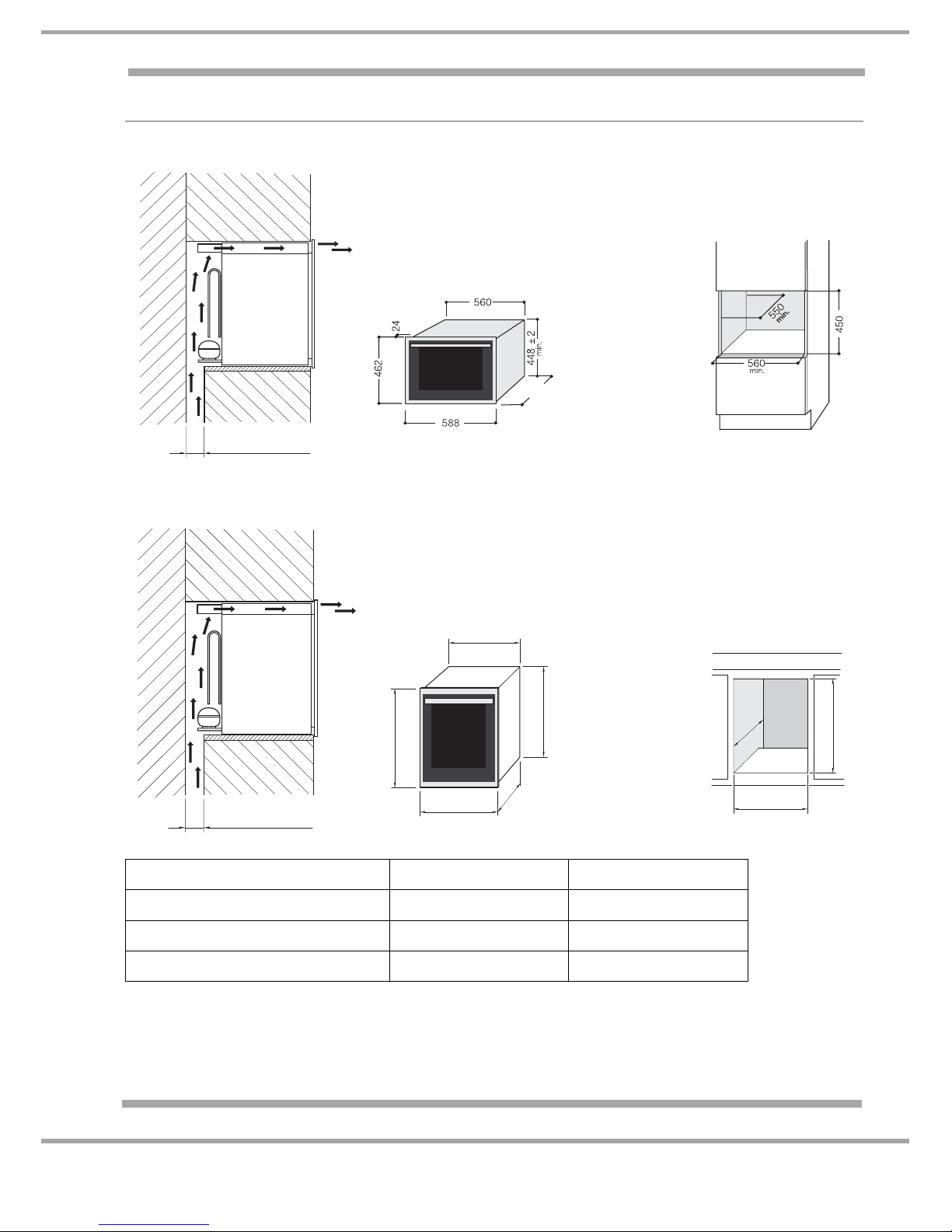

• Can be built-in or built-under a work top.

The main function of the wine cellar is to ensure that the wines are preserved in optimal condition.

When new, the selected temperature was factory pre-set at 15°C, a temperature that is considered

optimal for most wines.

Wine has a complex nature and good wine especially benefits from a long slow process to best

express its attributes, so very specific conditions are necessary.

Most wines being stored can be preserved at the same temperature, but, depending on their

different characteristics, should be served and tasted at very different temperatures.

Just as for wine producers, the actual storage temperature is not the primary concern, rather that the

temperature remains constant through time.

Temperature Display and Manual Adjustment

When the appliance is first plugged in and switched on, the display will indicate the set temperature

(15°C) momentarily. It will then show the internal temperature where there is a variance. This will

gradually change until the set temperature is reached.

• Press the + button on the Control Panel for one second; the display temperature will begin to

flash.

• Press the - or + buttons until the desired temperature is displayed.

• Wait 5 seconds for the display to stop flashing so that the temperature is set.

• Wait until the wine cellar display reaches the set temperature, and then place the bottles as

required.

• The displayed temperature can differ +/- 2°C from the set temperature. This is not critical it is

more important that the interior temperature is constant.

Thermometer Part No. C00149274 (8058) is available as a spare part to monitor temperatures over

time.

Note: User Handbook discrepancy

Models WL24 & WL36 do not have the Ageing Compartment described in some User Instruction

books.