Page 4 HQ Avanté User Manual

Safety Secon

This device complies with Part 15 of the FCC Rules.

Operaon is subject to the following two condions:

(1) This device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operaon.

Please note: Do not operate your HQ Avanté®

quilng machine unl you have completely read the

informaon contained in this manual. Please keep

all packaging and order informaon for warranty

purposes.

IMPORTANT SAFETY INSTRUCTIONS

Read all instrucons before using this machine.

When using this machine, basic safety precauons

should always be followed, including the following:

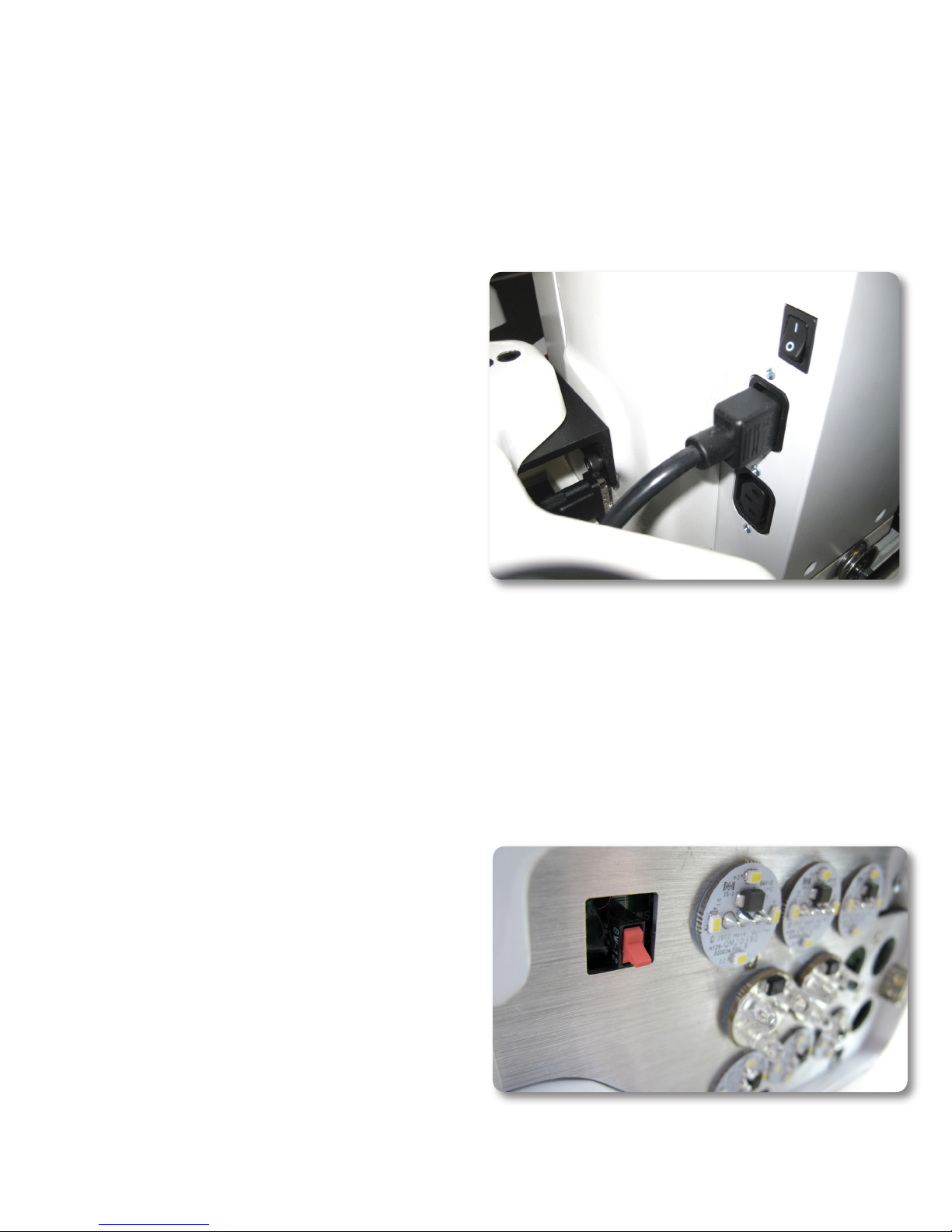

DANGER — To reduce the risk of electric

shock:

• A quilng machine should never be le

unaended when plugged in. Always unplug the

machine from the electrical outlet immediately

aer using and before cleaning.

WARNING — To reduce the risk of burns,

re, electric shock, or injury to persons:

• The HQ Avanté® is heavy. Never aempt to li it

alone. Always use two people when liing. Always

li from the throat of the machine, not from the

handlebars.

• Always unplug the HQ Avanté® from the electrical

outlet when performing any maintenance,

changing the needle, removing thread locks, or

when le unaended.

• Do not unplug by pulling on cord. To unplug, grasp

the plug, not the cord.

• Keep ngers away from all moving parts. Use

cauon around the needle or sharp external

components.

• Change the needle oen. Do not use bent or dull

needles. “Every quilt deserves a new needle”.

• Switch the machine to the symbol o, or

0, posion to turn it o when making any

adjustments in the needle area, such as threading

needle, changing needle, threading bobbin,

changing hopping foot, and so forth.

• Never drop or insert foreign objects into any

opening.

• The HQ Avanté® should only be used indoors away

from moisture.

• The HQ Avanté® should not be stored or used in

extreme temperatures.

• Use the HQ Avanté® only for its intended use as

described in this manual.

• To disconnect from the wall outlet, push the

switch to the o posion, then remove the plug

from outlet pulling from the plug, not the cord.

Never operate the HQ Avanté® if the cord is

damaged or not working correctly. If a mechanical

or electrical problem is encountered, return the

HQ Avanté® to the nearest authorized service

center or the manufacturer for examinaon,

repair, electrical, or mechanical adjustment.

• It is not recommended that the HQ Avanté®

quilng machine be used with any machine

quilng frame other than those recommended by

Handi Quilter.

• Use this quilng machine only for its intended use

as described in this manual. Use only aachments

recommended by the manufacturer as contained

in this manual.

• Never operate the machine with any air openings

blocked. Keep venlaon openings of the machine

free from the accumulaon of lint, dust, and loose

cloth.

• Do not operate where aerosol (spray) products

are being used or where oxygen is being

administered.

• Do not pull or push the machine across the fabric

excessively while stching. It may deect the

needle enough to cause it to break.

• Use only needles designed for free moon quilng

and recommended by Handi Quilter for this

machine. Other types of needles may be break

during normal quilng.

• Children shall not play with the machine. Close

aenon is necessary when this machine is used

by or near children.

• This sewing machine may be used by children

age 8 years and above and persons with reduced

physical, sensory, or mental capabilies or lack of