REVISION DATE: 13-Oct.-20

HIROSE ELECTRIC CO., LTD.

OBJECT

PRODUCT:

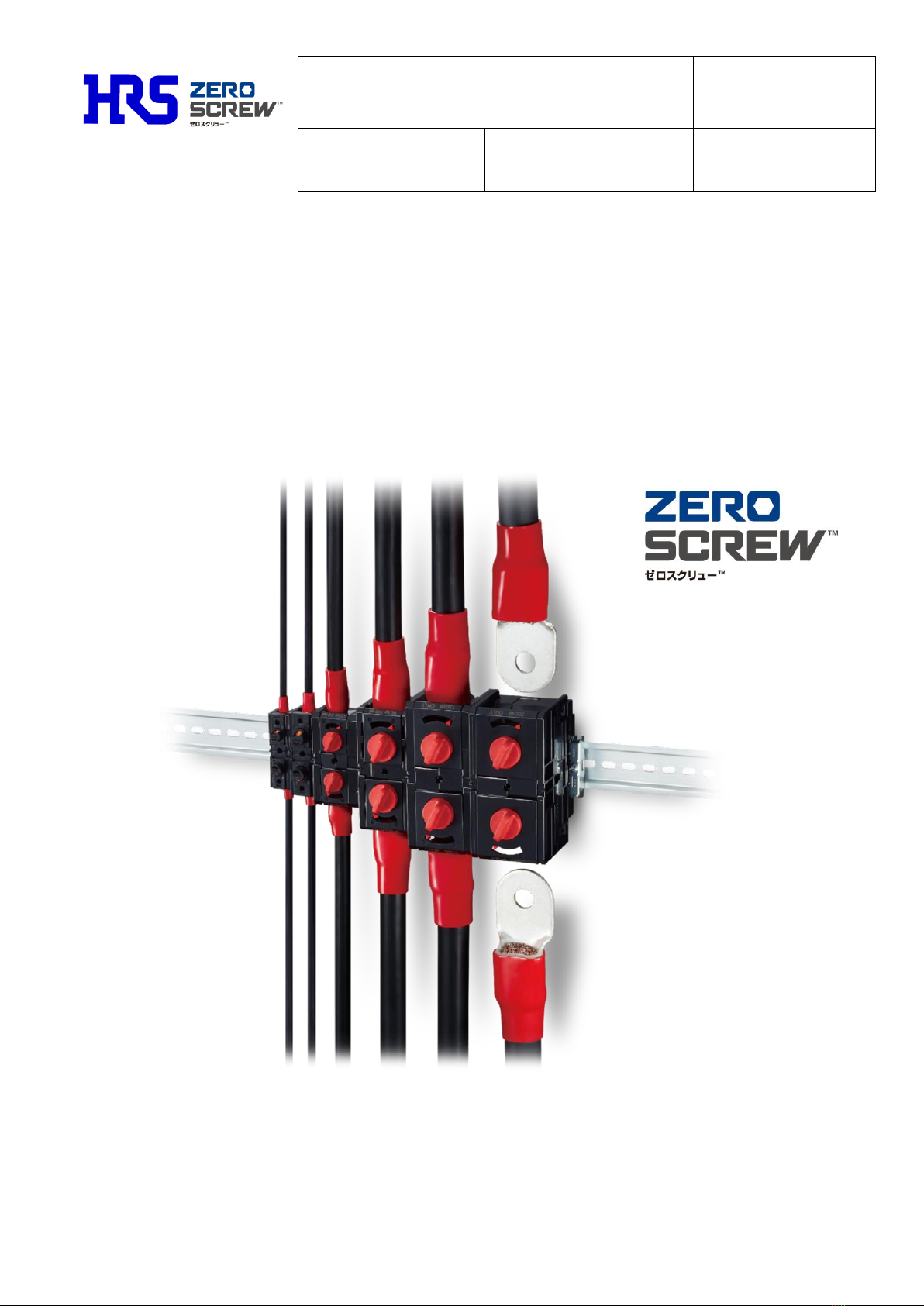

EF2 SERIES

Number Page

1. Introduction .............................................................................................................................. 3

1.1 Purpose of Hirose’s guideline................................................................................................... 3

2. Precautions ............................................................................................................................... 3

3. Product Number Structure and Outer Dimensions........................................................................... 5

3.1 Product Number Structure ...................................................................................................... 5

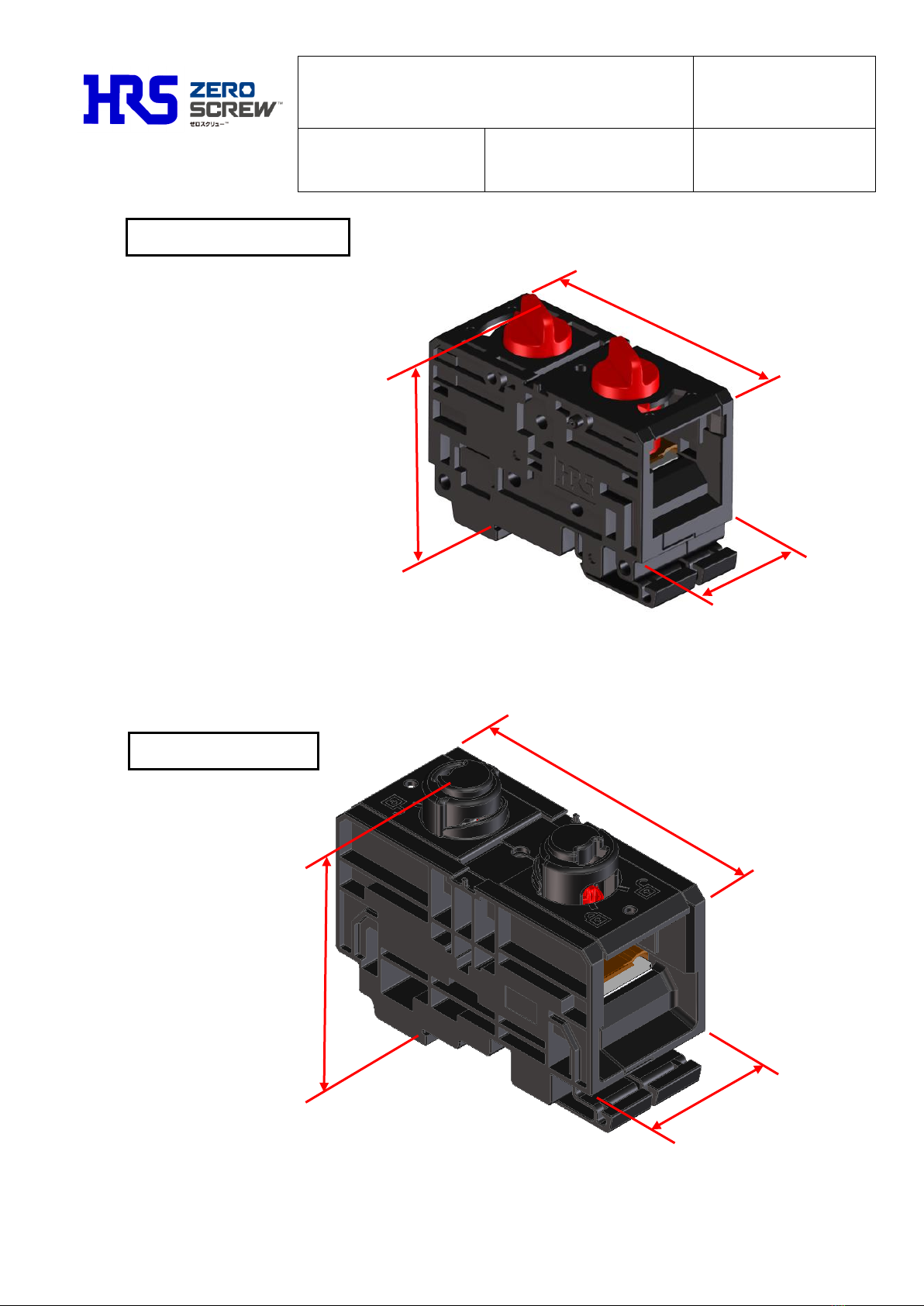

3.2 Outer dimensions .................................................................................................................. 6

4. Materials and Characteristics of Product ........................................................................................ 9

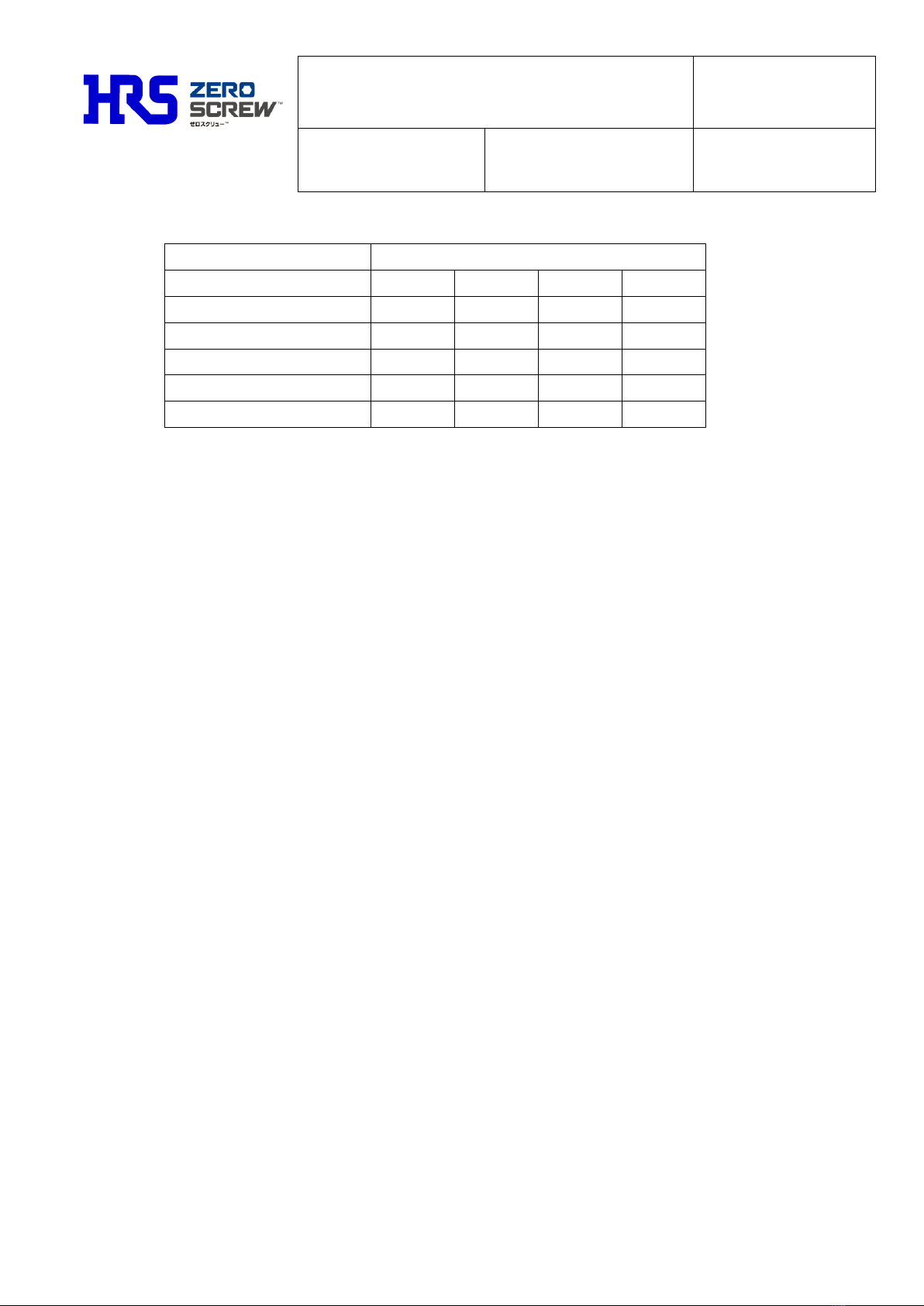

4.1 Series specification matrix ..................................................................................................... 9

4.2 Specifications of applicable cables..........................................................................................10

5. Usage and Precautions..............................................................................................................11

5.1 Applicable crimp contact (Contact with different thickness is not allowed) ....................................11

5.2 Crimp work procedure...........................................................................................................13

5.3 Product operation .................................................................................................................14

5.4 Support for linkage (Description of method for each product) .....................................................23

5.5 Mounting and removing to and from DIN rail............................................................................25

5.6 Bending radius for each cable (bending radius which allows routing) ...........................................29

5.7 Strength against prying of cable .............................................................................................30

5.8 Nameplate...........................................................................................................................35

5.9 Applicable probe and usage....................................................................................................35

6. Connecting Tools.......................................................................................................................36

6.1 Recommended crimping tools ................................................................................................36