Intended use

The device is intended solely for dehumidi-

fying air at atmospheric pressure in a com-

mercial environment.

Intended use also includes compliance with

the operating conditions (see Operating

conditions).

Any use other than the specified is deemed

improper. Improper use shall void all war-

ranty cover.

The air dehumidifier must not be operated

by children or by persons with limited phys-

ical, sensory or mental faculties.

Before operating the device, users must

have read and understood this operating

manual.

Reasonably foreseeable misuse

The device must not be used:

■In rooms/spaces that are not enclosed,

or outdoors

■In rooms with a potentially explosive or

aggressive atmosphere

■In rooms with air that has been treated

with ozone, or that contains a high con-

centration or solvents or dust.

■At locations where the prescribed min-

imum safety distances cannot be main-

tained

6 Safety

General safety instructions

■The device must only be operated by

persons who have been properly in-

structed in its operation.

■It is forbidden to make any modifica-

tions to device.

■Maintenance and troubleshooting tasks

must be performed by suitably qualified

persons only. Shut down the device and

disconnect the mains plug.

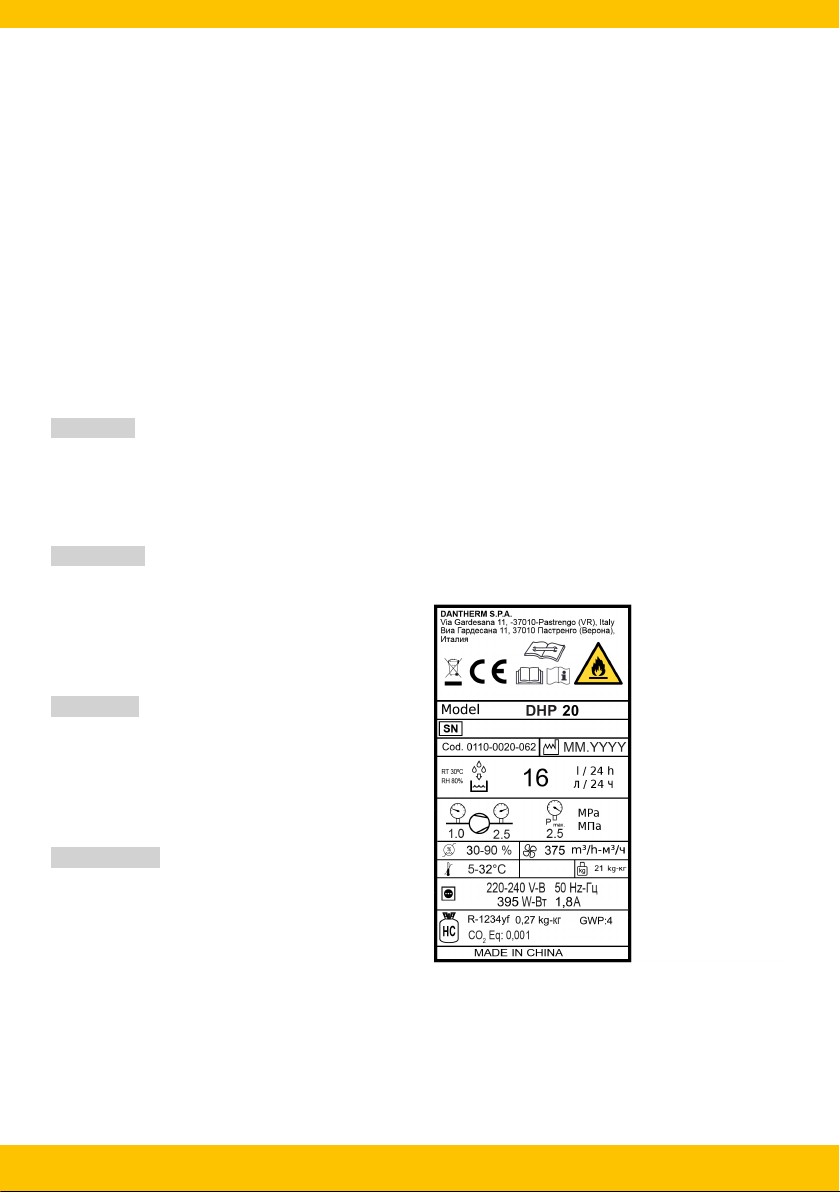

WARNING! Risk of explosion, injury from

burns or poisoning by refrigerant

The device is operated with an odourless

and flammable refrigerant. If the device is

operated incorrectly, there is a risk that the

refrigeration causes explosion, fire, poison-

ing or other injury. The refrigerant is pres-

surised.

ÜOnly operate the device in rooms larger

than 4m2.

ÜNever drill holes into the device, and do

not use welding equipment or cutting

torches in its vicinity.

ÜDo not attempt to speed up defrosting by

using implements.

ÜAll work on the refrigeration circuit must

be performed by staff of the manufac-

turer or an authorised technician.

ÜAvoid contact with the refrigerant.

ÜWhen handling the refrigerant, strictly

adhere to the applicable safety regula-

tions.

WARNING! Risk of electric shock

When carrying out work on electrically

powered components, or if such compon-

ents come into contact with water, there is a

risk of serious or even fatal injury from elec-

tric shock.

ÜAll work on the electrical equipment must

be carried out by qualified electricians.

ÜTake suitable measures to prevent elec-

trically powered components coming into

contact with water.

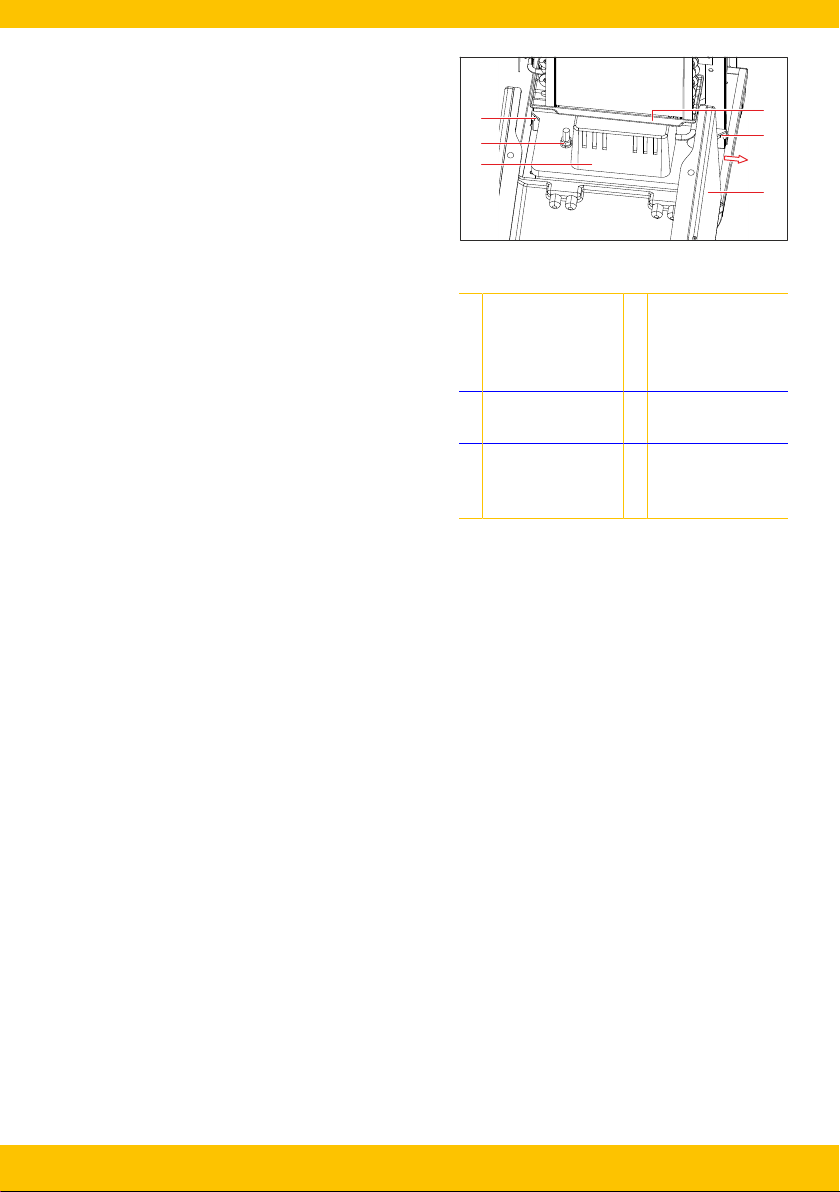

ÜBefore moving the device to a different

location, disconnect the mains plug and

empty the condensate tank.

6