Page 4

HUGO SACHS ELEKTRONIK - HARVARD APPARATUS GmbH D-79232 March-Hugstetten Germany

HSE PLUGSYS®TAM-A Type 705/1 and TAM-D Type 705/2

3 General description, application

The transducer amplifier module TAM is equipped, depending on the version, either with analogue

(TAM-A) or digital (TAM-D) display. Apart from a few exceptions, the amplifiers of the

two versions are identical. In the description below, the symbol TAM refers to both

module versions. The symbol TAM-A or TAM-D is used when referring to the different

properties of the two amplifier variants.

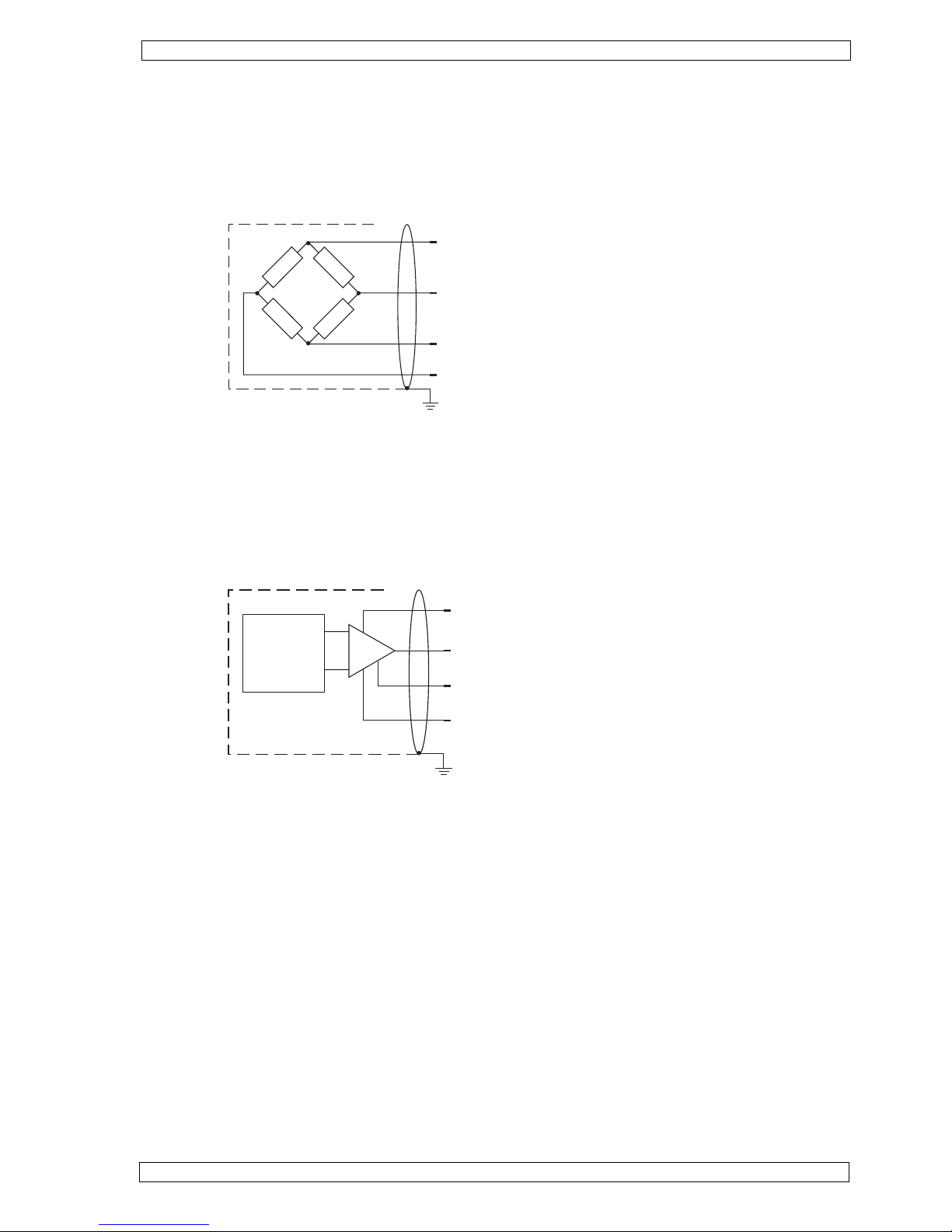

The amplifier module TAM is a univeral DC bridge amplifier. In conjunction with a suitable resistive transducer

it permits direct measurement of e.g. force, pressure or displacement. The amplifier is arranged as a plug-in

module of the PLUGSYS measuring system and is operated inside a PLUGSYS housing.

TAM-A (Type 705/1) is equipped with a LED line, a so-called bargraph. Visual analogue presentation of the

measured signal, is ideally suitable for monitoring dynamic signals.

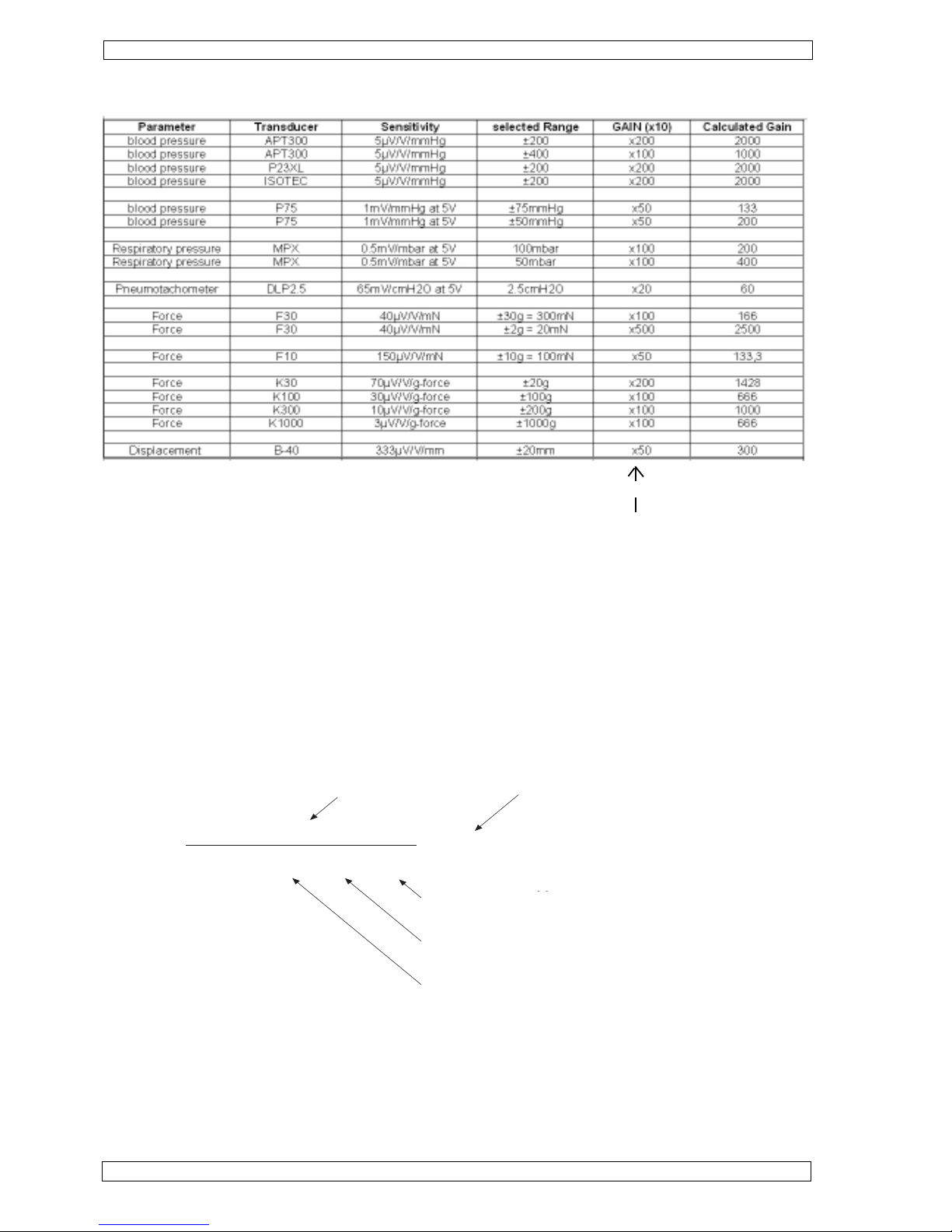

TAM-D (Type 705/2) carries a 3½-digit LED display. It is therefore particularly suitable for evaluating static

signals. The instantaneous measurement can be read directly on the numerical display of the TAM-D. By

calibrating the module to the transducer it is possible to adjust the sensitivity of the display so that the meas-

urement can be read off directly (e.g. force in ±100 mN, pressure in ±200 mm Hg, displacement in ±4 mm etc.).

The amplification (Gain) of the TAM can be adjusted over a very wide range (x2 to x10 000) to suit the require-

ments of the transducer. The DC supply (excitation voltage) for the transducer is fixed at 5 V, the value com-

monly employed today.

As a special feature, both amplifiers TAM-A and TAM-B are equipped with automatic zeroing in addition to

manual zero adjustment.

In order to have an easy calibration of a connected data acqusistion system a predefinded value eg. 10mN,

100mmHg or 5mm can be simulated on the output.

The output filter 30-100-300 Hz is used for smoothing the signal. It acts on both signal

outputs PULSE (internal) and BNC socket (front panel). The internal signal output MEAN is preceded by a low-

pass filter of 0.1 or 0.3 Hz. As an option the MEAN output can be connected to the BNC socket on the front panel

through an internal jumper on the circuit board.

4 Installing the module in a housing

The TAM module is designed as a PLUGSYS module and has a width of 8E corresponding to two slots. It can

be installed directly in any housing with a system bus. An exception is the PLUGSYS MiniCase Type 609; the

TAM can also be operated in this housing but installation requires some soldered connections and it is there-

fore only supplied completely installed from the factory.

If you bought your module installed in a housing these adjustments already have been made in the factory

prior to shipping.

Switch off the housing and pull out the mains plug.R

Remove the blank panel at the housing slot position intended for the TAM module.R

Make the internal adjustments according to Section 4.2.R

Insert the TAM module, note the guide rails.

R

Firmly push in the module, it must clearly engage with the bus connector.

R

Screw on the front panel, reconnect the mains cable to the housing, and plug in the transducer.

R

Before the module is installed in a housing it is necessary to make a number of internal adjustments. First it is

necessary to carry out the adjustments described in Section 4.2. Note the precautions described in Section

4.2.1 which are absolutely essential in order to avoid electrostatic discharges.

Brief procedure (for full details see the Operating Manual of the housing):

4.1 Installation procedure