For advice on the safety and suitability of this equipment

contact your local HSS Lift & Shift Depot.

There is a serious risk of personal injury if you do

not follow all instructions laid down in this guide.

This equipment is designed to be used by an able

bodied, competent adult who has read and

understood these instructions. Anyone with either a

temporary or permanent disability should seek expert

advice before using it.

Keep children, animals and bystanders away from

the work area. Cordon off a NO GO area using

cones and either barriers or tape, available for hire

from your local HSS Lift & Shift Depot.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Wear practical, protective clothing,

gloves and footwear. Avoid loose garments

and jewellery that could catch in moving parts, tie back

long hair.

Use this equipment for vertical lifts only and

use on a level area able to take the combined

weight of the load and the equipment.

May be used at any angle for lifting, dragging

or pulling. Anchor to a safe, secure point able

to take the load force applied. Allow for contact

friction if dragging.

This equipment is heavy (64kg), never attempt

to lift it on your own, always get help.

Make sure you know how to operate this

equipment safely and are aware of its limitations

before you use it.

It is both the hirer’s and the operator’s responsibility

to perform a risk assessment before using this

equipment. You are also responsible for the safety of any

person in the work area.

Make sure that anyone in the immediate work area

is warned of what you are doing.

Never exceed the equipment’s safe working load

of 500kg.

Always switch OFF the engine when not in use.

GENERAL SAFETY Ensure the work area is well lit and ventilated, if in

doubt, ask about site lighting and fume extraction

equipment at your local Lift & Shift Depot.

The capstan winch can cause serious injury.

Always keep feet and hands well away from the

capstan while the machine is running, taking special

care when starting.

Engines, especially the exhausts, get very hot so

switch OFF and allow too cool before touching them.

Do not work near flammable gases or liquids, petrol

or paint thinner fumes for example. Keep combustible

materials at a safe distance – at least 5m.

Make sure you know how to switch this machine OFF

before you switch it ON in case you get into difficulty.

Always stop the engine before making

adjustments to the equipment.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear, return it to

your local HSS Lift & Shift Depot.

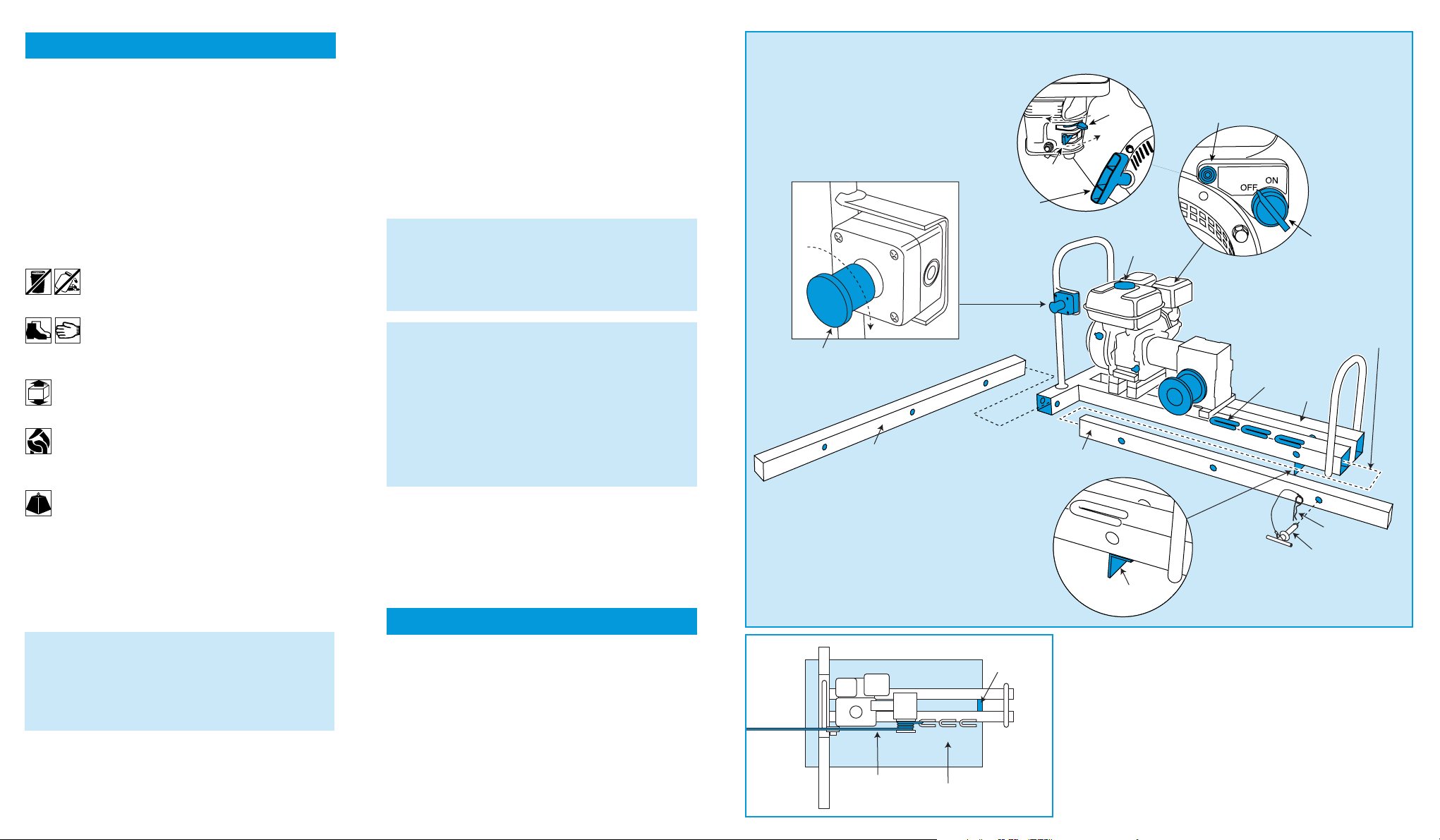

Place the unit next to the manhole then check the

engine’s oil and fuel levels.

Remove the cross bar from its transport stowage

position, to do this, remove the ‘R’ clip on the retaining

pin and slide the retaining pin out. Next remove the

cross bar and re-insert into the rear of the chassis.

Hold the cross bar in position by locating the retaining

pin into the central guide hole and lock in place with

the ‘R’ clip.

Where the unit’s position is to be at an offset angle over

the manhole, the cross bar can be set to the left or

right as necessary.

GETTING STARTED

Fuel Safety

NEVER refuel while the engine is hot or running.

NEVER smoke or allow naked lights into the

refuelling area.

ALWAYS mop up spilt fuel quickly and change

clothes if you get any on yourself.

ALWAYS store fuel in suitable sealed containers,

in a cool, safe place, well away from the

work area.

Exhaust Danger

Never operate petrol engines indoors or in a

confined space.

The exhaust contains gases that can kill.

Remove the manhole cover and place the unit over

the opening with the chassis’s front angle bar set

inside the lip of the manhole cover’s frame.

Centralise the unit over the manhole and place a

safety barrier around the area to safeguard against

pedestrian accidents.

The unit is fitted with a red emergency STOP

button, which stops the engine when pressed in.

To reset the button, turn it clockwise until it pops out

again.

Remember where the red emergency STOP button

is, so that it can be operated quickly in an emergency.