PAGE

03

PAGE

04

11. Random modification of the machine is not allowed. Only Pantheon accessories can be used for

maintenance and adjustment.

12. Do not operate the machine in rainy or foggy days.

13. Ensure no explosive flammable materials and steam nearby when operate machine. Do not operate

machine nearby the place with fuel, grain dust, solvents, dilution agent or other flammable items.

1. Operators should wear protective equipment when using the machine, such as dust masks, protective

gloves, overalls, helmets, insulated shoes and so on.

2. Make sure there is no oil leakage, electric leakage,water leakage on the machine before using. The machine

can be used normally.

3. Check the machine control switches and electric parts are in good conditions without moisture.

4. Make sure no obstacle or human being at working area.and make sure there is enough lighting device.

5. The anti-dust tape should be installed on the machine for safety. It is necessary to connect to industrial

vacuum cleaner when dry grinding.

6. The machine should be connected to appropriate electrical outlet. Only use the power cables that can

withstand high current.

7. Do not adjust the handle during machine operation. Only when the machine is stopped and the emergency

stop switch has been pressed,the worker can adjust the machine.

8. The handle has different functions when it is in different positions. Please read the manual for more

information.

9. Ensure the machine has stopped operating and the emergency stop button is pressed when changing

abrasives or accessories. If necessary, disconnect the power and the plug.

10. Keep the machine away from drains and furnace mouths or other dangerous goods, otherwise it may

cause personal injury or loss of machinery and property.

11.Tight-hold hand grip, clockwise rotate the emergency switch, then turn on the power button and start the

machine

12. Please note that the emergency stop switch can only be pressed or rotated. Prohibit upward pull.

13. Before operation,check the working surface and remove any protrusion to prevent machine plates and pads

from damage.

14 Double check before connecting to power, make sure the working Voltage, HZ is same with input

Voltage and HZ, no lack of phase of input power. (If the machine do not work normally , and it results in the

input power and working power is not the same, then manufacturers warranty is unavailable.)

15. Connecting with vacuum to achieve dust free working condition.

16. Install appropriate abrasive. Improper abrasive may cause personal injury and floor damage.

17. After installing the abrasive, keep the grinding plate touch with ground directly, adjust handle bar to the

"lifting position", so that the operator could operate the machine easily.

18. When machine inverter turns to overload protection, it means there is something wrong with the

machine(cable is too small or voltage is unstable) , if so please reference the following cable sizes which are

recommend. Or reduce the abrasive pressure(adjust the additional to suitable position) if users keep using

the machine when overload leads to damage, it would be not allowed to guarantee.

19. After few minutes of grinding ,stop to check how much the abrasive uses. This behavior could reduce the

economic loose when using wrong polishing pads.

20. Please do not upward the machine when machine is still running , otherwise the polishing pads may fly out

to threat the human safety.

2. Note: After the machine is stopped, the line is still energized. Disconnect all power before servicing the

machine.

3. The machine is equipped with an overload protection device and it will automatically jump off when the

machine is overloaded, to prohibit the machine from running; (re-adjust this overload in case of safety)

4. Continue to use the machine in the overloaded situation may cause some other losses even machine

can’t work normally,then manufacturers warranty is unavailable.

5. The purpose of installing an inverter in machine is to speed and protect the user and the machine. It is

forbidden to modify or adjust the inverter and modify the inverter parameters without the manufacturer's

consent. If the unit fails, it is only allowed to replace the defective parts with the accessories provided by

the manufacturer; (Other loss caused by changing, adjusting or modifying the inverter parameters

without the manufacturer's consent, and the machine is not working properly, the manufacturer does

not afford warranty)

6. Never modify the parts or lines inside the inverter by yourself.

7. Do not operate the machine when the distribution box is turned on.

8. If the machine current is overloaded, please pay special attention;

9. When the cables is energized or loaded, do not connect or disconnect the wires;

10. Using a damaged power cord may result in electric shock. Do not use a damaged power cord;

11. Cables should be kept away from hot surfaces;

12. The dryness of all electrical equipment should be maintained and the machine should be kept in a

dry place;

13. After the power is turned off, before the panel indicator is off, it indicates that there is still high voltage

inside the inverter, which is very dangerous. Do not touch the uninsulated electrical equipment;

14. The machine motor and the frequency conversion box are prohibited from entering twater; (the other

damage caused by the water inflow then the machine is not working properly, the manufacturer does

not afford the warranty);

15. The machine must be connected to the qualified wire and voltage, specifications is noted by the

manufacturer. (The machine label indicates the power supply specifications).

1. All circuit repairs can only be carried out by qualified personnel;

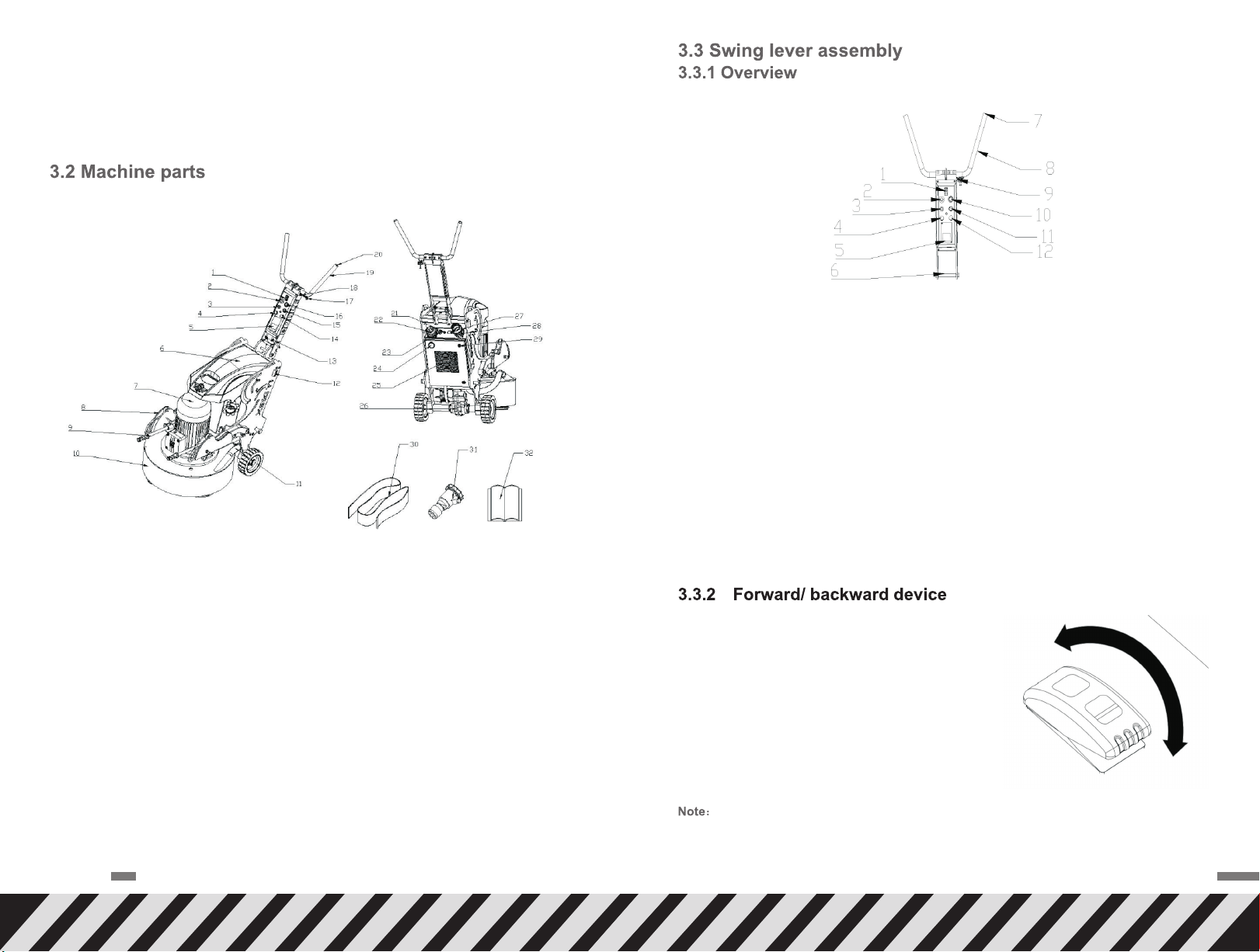

800LE is used to grind (rough grind, fine grind and polish) concrete, natural stone and terrazzo

floors or other materials specified in this manual or recommended by Pantheon .

The 800LE is a self propelled grinder. The forward/reverse switch can be used to control the forward and

backward movement of the driven wheel, so that the user can get rid of the action of manually pulling or

pushing the machine to forward/reverse, which greatly saves manpower and facilitates user operation.

The innovation of this equipment is that it equipped with a water tank and add additional weight iron. The

heat dissipation openings on both sides of the water tank make the heat dissipation of the frequency

conversion box faster and extend the service life of the internal electrical appliances. The design of the

water tank allows the equipment to be applied not only in dry grinding but also water grinding. The

benefits of water grinding are as follows: good flatness, small cutting amount, easy polishing, suitable for

later stone polishing.Increasing additional weight makes the lifting easier, and the grinding pressure can

be increased during grinding to make the ground smoother.

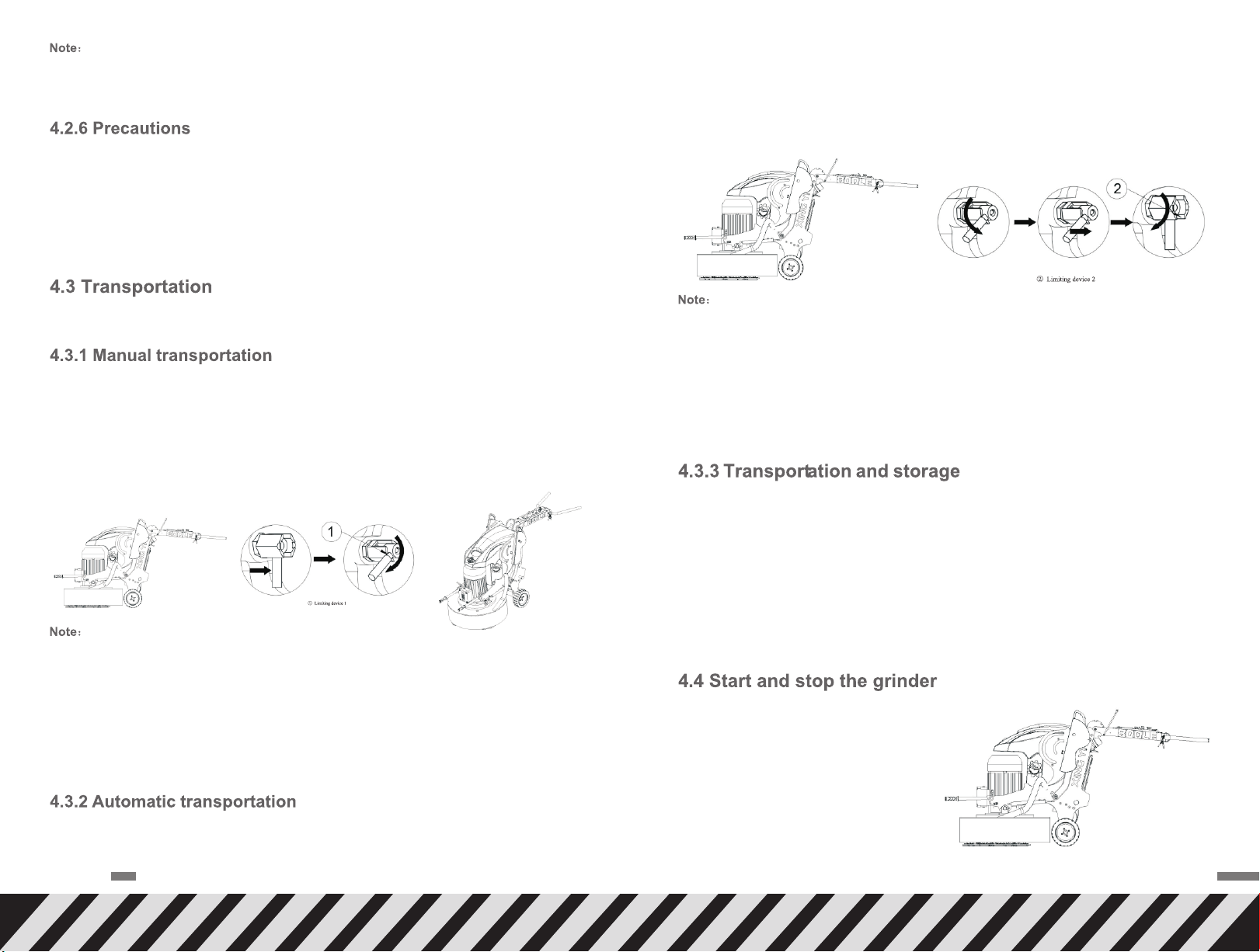

The swing lever and handle can be set in many different tilted positions. When the machine is manually

operated, you can choose the most suitable position. The grinding head of the machine can be used with

different grinding plate for operation. The dust belt covers the working area of grinding head. Because of

floating design, it always touch the floor, which not only ensures that the operator does not touch the