lp-701 Rev. 000 Rel. 003 Date 6.29.20

9

Return Water Temperature Sensor

This sensor monitors VWH return water temperature (System

Return).

Temperature and Pressure Gauge

Allows the user to monitor system temperature and pressure.

Electrical eld connections with terminal strips

The electrical cover allows easy access to the clearly marked line

voltage and low voltage terminal strips to facilitate wiring the VWH.

Supplied Condensate Collection System with Clean Out

This VWH is a high eciency appliance and will produce condensate.

The condensate collection system has a oat switch which monitors

condensate level and prevents condensate from backing up into

the combustion system. Inside the collection system is a built in trap

which seals the combustion system from the connected drain. This

condensate should be neutralized to avoid damage to the drainage

system or piping.

Flow Protection

The ow switch is designed to protect the VWH during low ow

conditions. The VWH control also monitors ow through the heat

exchanger by monitoring the return and supply sensors and will

shut down the burner before overheating occurs. The ow switch

activates at 4 GPM for 400 - 1000 Models; 9 GPM for 1500 - 2000

Models.

0-10 Volt Input

Allows the installer to connect a BMS (Building Management

System) to control the VWH.

0-10 Volt Output A (Congured through Control System)

0-10 Volt Output A is congured through the VWH control system.

0-10 Volt Output A is related to one of the following values: VWH

power, cascade power, fan speed, alarm status, temperature setting

based on outdoor reset curve, ame, or pump.

0-10 Volt Output B (Congured through Control System)

0-10 Volt Output B is congured through the VWH control system,

and is related to one of the following values: VWH power, cascade

power, fan speed, alarm status, temperature setting based on

outdoor reset curve, or ame.

UL 353 Internal Low Water Cuto (LWCO)

The supplied internal Low Water Cuto in conjunction with the 928

control meets UL 353 requirements to function as a safety, locking

out the VWH when water level is inadequate for safe operation. See

Service Mode, this manual, to test LWCO function.

Flue Temperature Modulation

As an additional safety feature, if the ue temperature exceeds

200oF, the control will modulate the VWH down based on the

vent temperature, rather than the supply temperature. If the ue

temperature exceeds 210oF the control will lock out the VWH.

HTP Link

HTP Link allows the installer to connect the VWH to WiFi, providing

the user / installer with tools to remotely monitor the system,

optimize eciency, and aid in troubleshooting.

System Sensor (Optional)

This sensor is designed to be used in a cascade system. The

system pipe sensor measures the temperature of return water and

communicates with the control system to modulate the ring rate of

the connected VWHs.

NOTE: When using a system sensor, pipe insulation must be

wrapped around it to improve temperature measurement accuracy

and increase overall system eciency.

C. Optional Equipment

Optional equipment available from HTP (and Part #):

• System Sensor (7250P-324)

• Indirect Tank Sensor (7250P-325)

• High and Low Gas Pressure Switch Kit with Manual Reset

(500 Model [7550P-999], 650 - 2000 Models [7550P-988])

• 4” Stainless Steel Vent Termination Kit (V2000)

• 6” Stainless Steel Outside Termination Vent Kit (V3000)

• 8” Stainless Steel Elbow (7550P-067)

• 8” Stainless Steel to PVC / CPVC Vent Pipe Adapter (7550P-064)

• Mechanical Manual Reset High Temperature Limit (6300P-998)

• Alarm System Kit (to monitor any failure) (7350P-602)

• 928 PC Connection Kit (7450P-330)

• Condensate Neutralizer (7350P-611)

• Condensate Removal Pump (554200)

• Glass-Lined Storage Tanks (GL-80, GL-119, GL-175)

• Stainless Steel Storage Tank (SSU-80CB, SSU-119CB)

NOTE: When using an optional system sensor, pipe insulation must be

wrapped around it to improve temperature measurement accuracy

and increase overall system eciency.

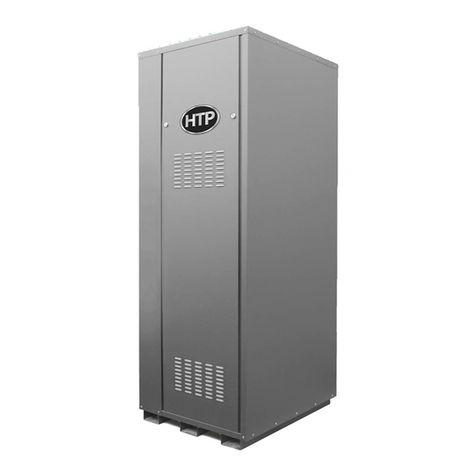

Part 3 - Prepare the VWH

Remove all sides of the shipping crate to allow the VWH to be moved

into its installation location. The VWH is heavy. At least two individuals

and special equipment (pallet jack, forklift, etc.) are needed to properly

handle the VWH. If surface ooring is rough, take care not to damage

the VWH when moving it into position.

COLD WEATHER HANDLING - If the VWH has been stored in a very

cold location (BELOW 0oF) before installation, handle with care until

the components come to room temperature. Failure to do so could

result in damage to the VWH.

Carefully consider installation when determining VWH location.

Please read the entire manual before attempting installation. Failure

to properly take factors such as VWH venting, piping, condensate

removal, and wiring into account before installation could result in

wasted time, money, and possible property damage and personal

injury.

Figure 1 - Moving the ELX - 1500 - 2000 Models Shown

This VWH is certied for indoor use only as shipped. DO NOT INSTALL

OUTDOORS without an optional Outdoor Installation Kit. Follow the

instructions included with the optional Outdoor Installation Kit when

installing the VWH outdoors. Installing the VWH outdoors without an

optional Outdoor Installation Kit WILL VOID the warranty, and could

result in property damage, severe personal injury, or death.

A. Locating the VWH

Incorrect ambient conditions can lead to damage to the heating

system and put safe operation at risk. Ensure that the installation

location adheres to the information included in this manual. Failure

to do so could result in property damage, serious personal injury, or

death. Failure of the VWH or components due to incorrect operating

conditions IS NOT covered by product warranty.