7

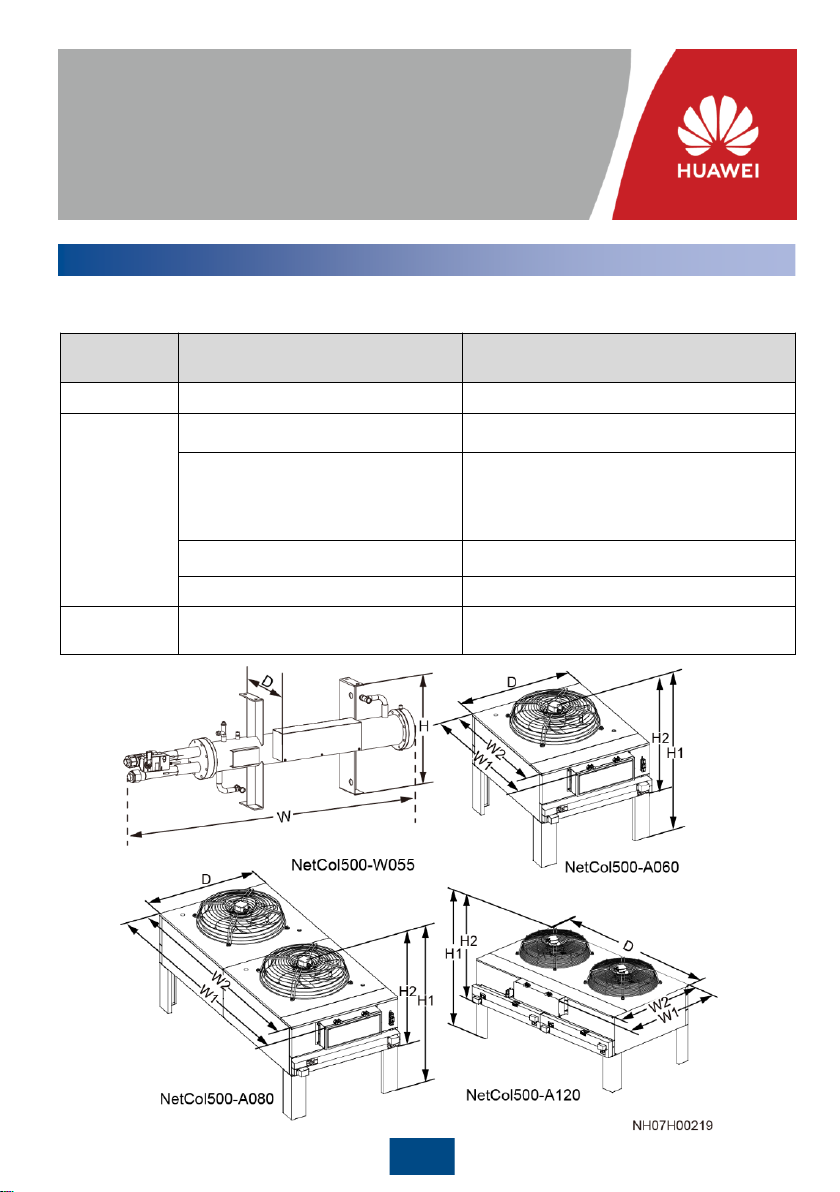

Vertical Installation

5.2

Unit: mm

6(Optional) Installing the Water Cooling Module

7Connecting the Refrigerant Pipe

Laying the Engineering Pipe

7.1

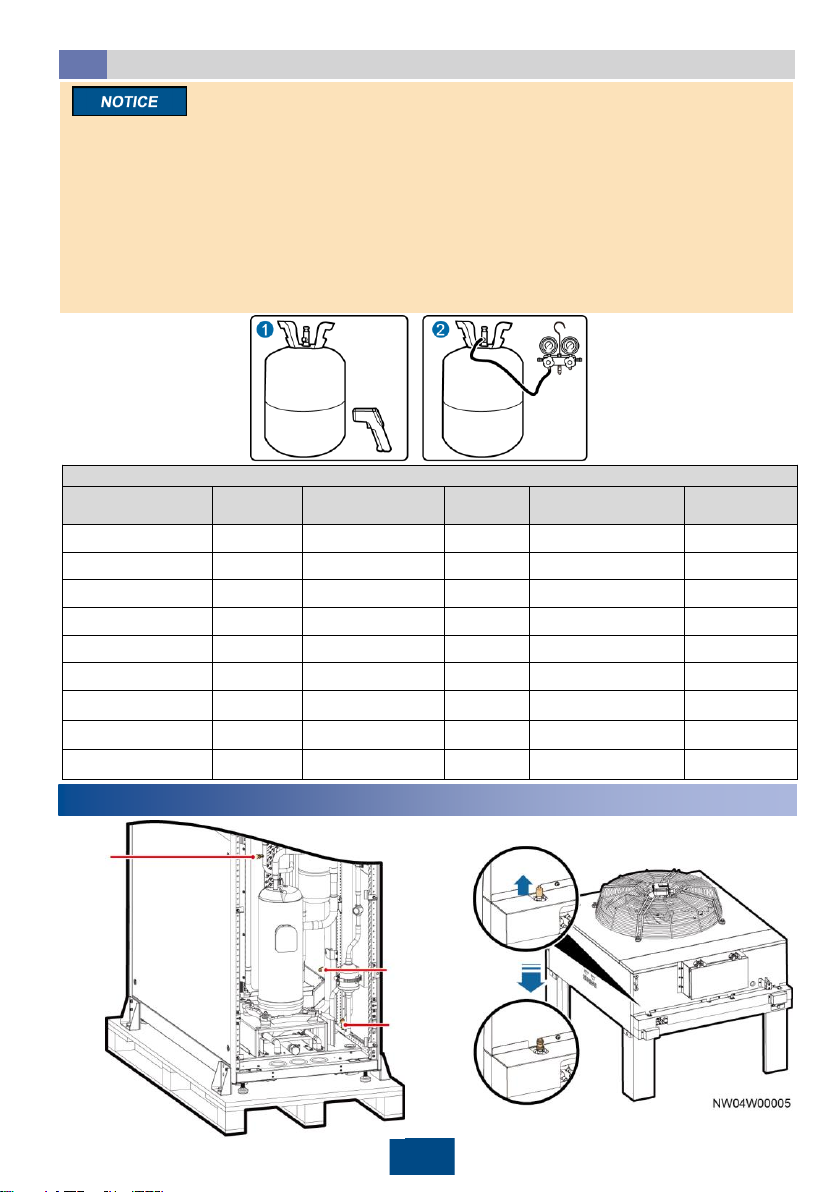

1. When outdoor unit is installed horizontally, the outdoor unit and the low-temperature component must be

at the same horizontal plane. When outdoor unit is installed vertically, the installing horizontal plane of

outdoor unit must not be lower than the installing horizontal plane of low-temperature component, and

the height difference cannot exceed 1.5 m.

2. Whencalculatingthe height difference, the compressor base is regarded as the baseline for the indoor

unit, and the condenser top is regardedas the baseline for the outdoor unit.

3. The inverted trap should be higherthan the top copper pipe of the condenser.

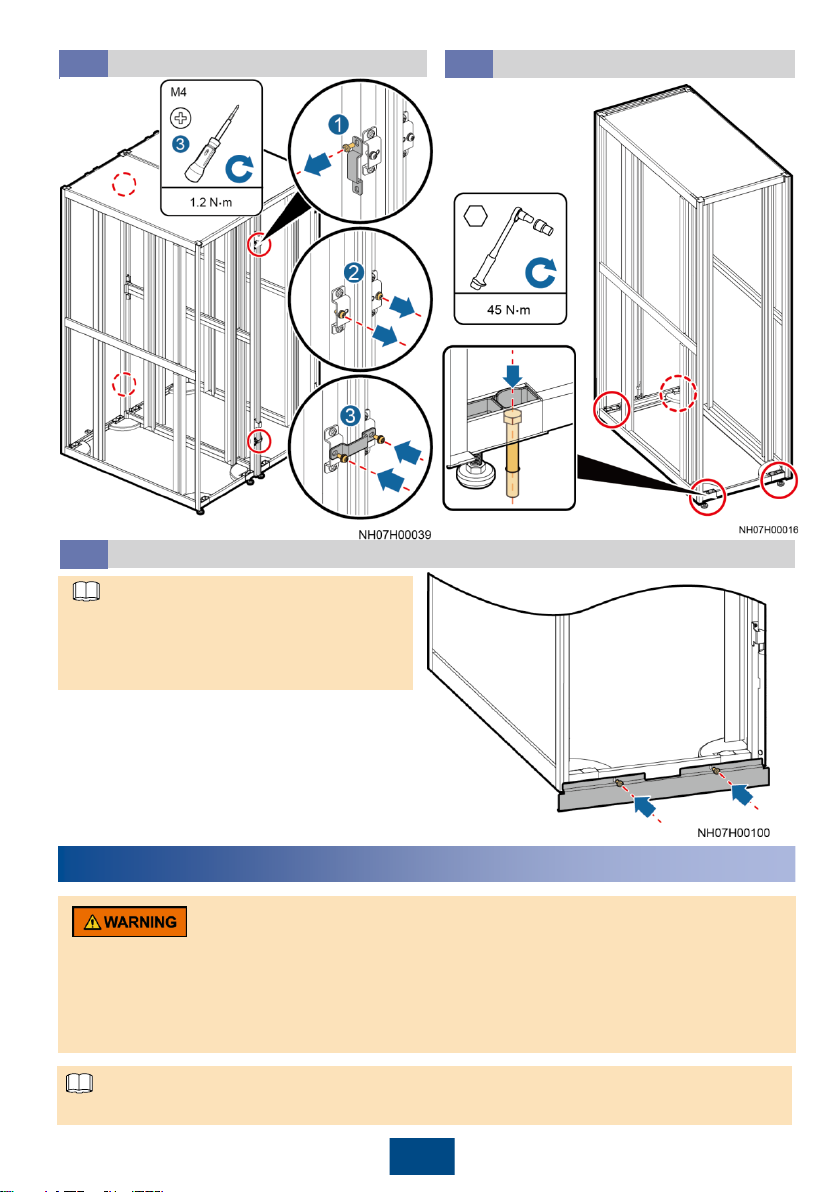

Scenario2: Horizontal concrete base installation

Scenario 3: Stack scenario

A maximum of four layers of water-cooling modules can be stacked. If four layers of water cooling

modules are stacked, the minimum floor height is 3 m.

Secure the water-cooling module using bolts in the fitting bag on four mounting holes.

Scenario 1: Horizontal

installation top view

Installation environment: enclosed indoor environment in which the temperature and humidity can be

controlled within the ranges of 4℃to 45℃and 5% RH to 90% RH respectively. If the indoor

installation position is ventilated, it should be more than 5 km away from the sea or pollution sources

(such as salt lakes, chemical plants, mineral plants, thermal power plants, and coal mines).

Unit: mm