8

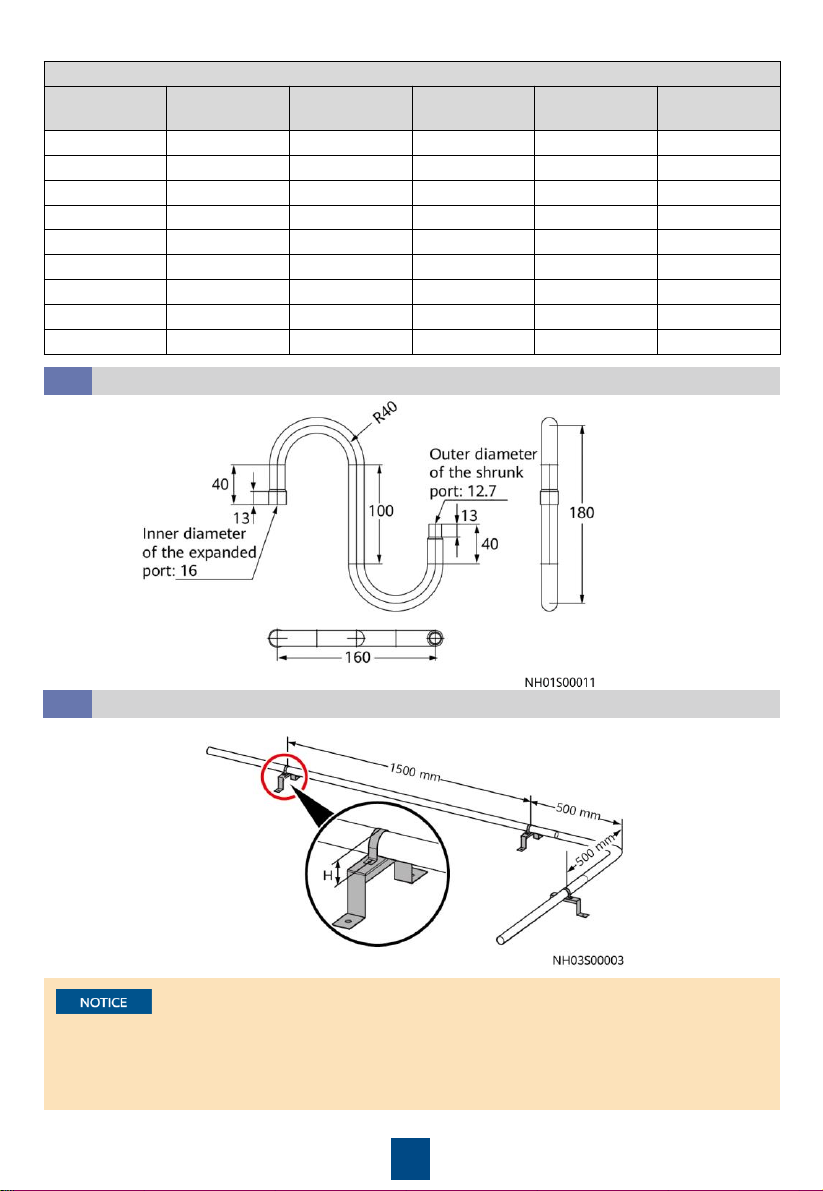

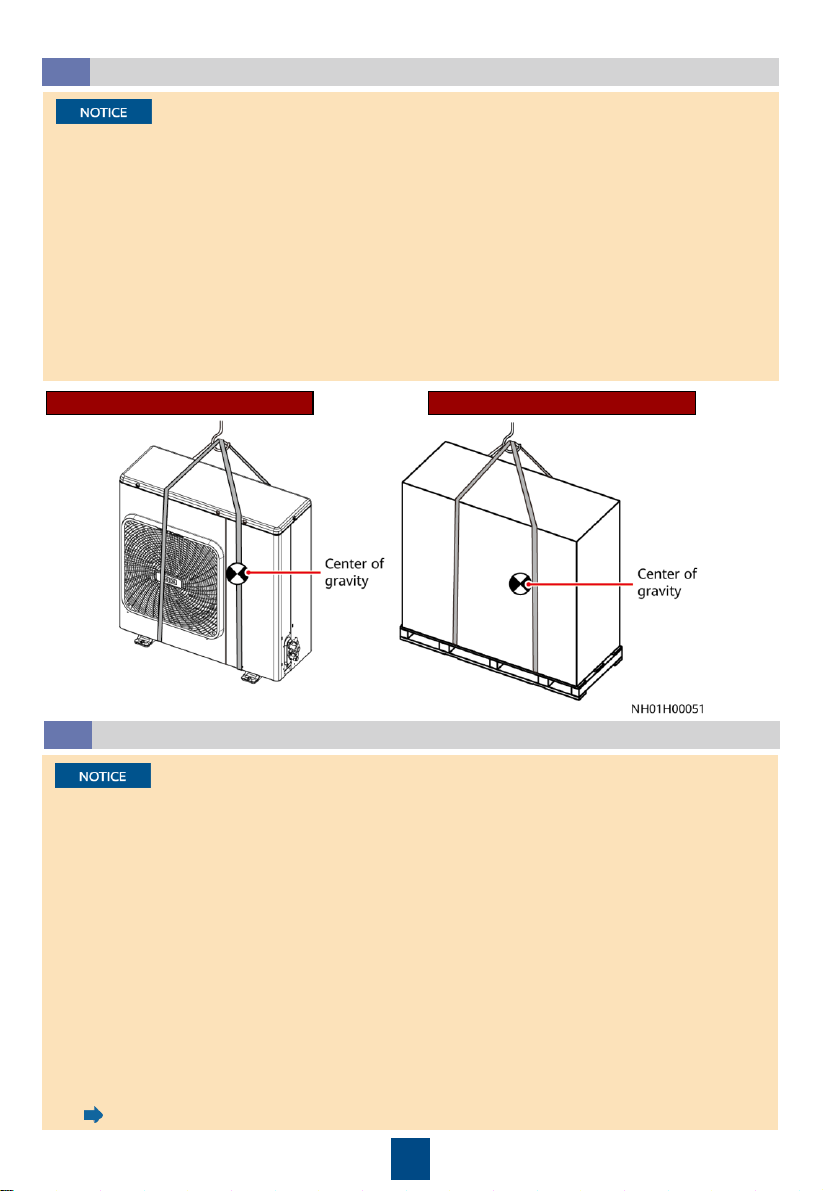

Hoisting the Outdoor Unit

4.1

•Select a hoisting mode based on site requirements. Hoist the packed outdoor unit using two

ropes that are at least 8 meters and raise it gently while keeping its balance. If the outdoor

unit has no package or the package is damaged, protect the outdoor unit using pads or

packing materials during the hoisting.

•When an outdoor unit is to be installed on an external wall, route the ropes through the

inner side of the two bottom feet. When an outdoor unit is to be installed on a rooftop, route

the rope through the inner side of the two wooden supports. This measure avoids the rope

from slipping during hoisting.

•When an outdoor unit is to be installed on a rooftop, you do not have to remove the

package during the hoisting. Otherwise, the outdoor unit appearance may be slashed.

•Keep the outdoor unit vertical and exercise caution when transporting and hoisting it.

•Do not hold the fan guard on the shell. Otherwise, it will be deformed.

•Do not touch the fan blades using hand or any other object.

•Secure the outdoor unit to prevent it from falling down in an earthquake or a strong wind.

Installed on an external wall Installed on a rooftop

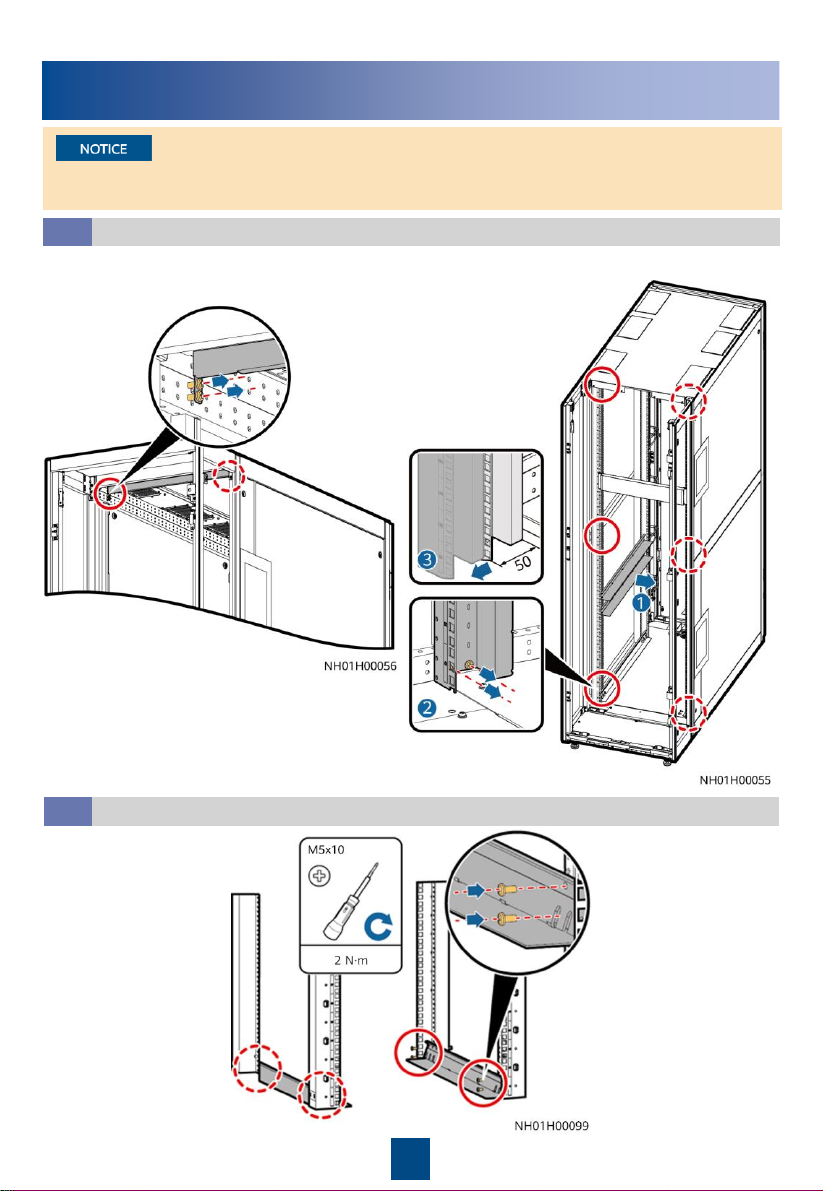

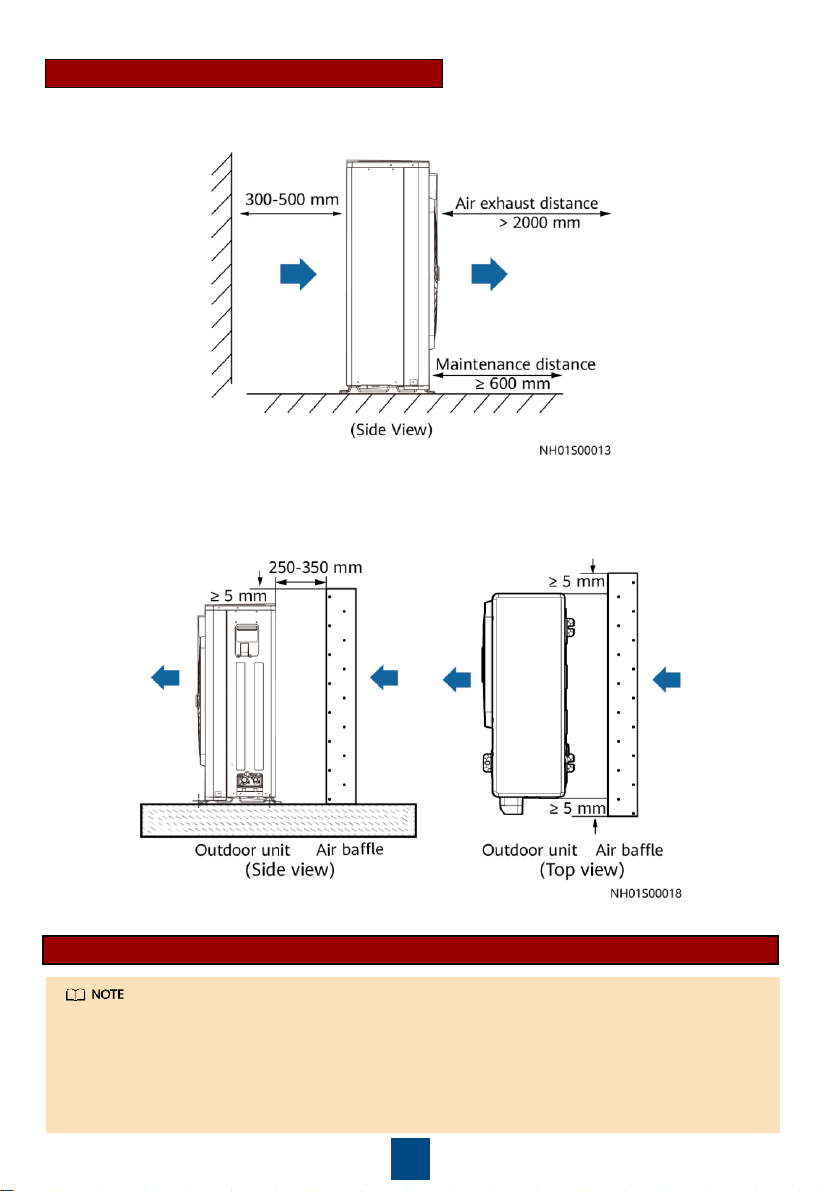

Space Requirements for Installing and Maintaining the Outdoor Unit

4.2

•To avoid fire disaster, install an outdoor unit in a dry and well-ventilated place without

flammable gas leakage.

•Select a place away from direct sunshine and radiation from other heat sources. If the sunshine

or heat radiation cannot be avoided, cover the outdoor unit.

•Do not install an outdoor unit in a place with much salt or corrosive gas.

•When installing the outdoor unit, ensure that the air intake vent and air exhaust vent of the

condenser are not dirty or blocked. Install an outdoor unit in clean areas that are away from

residential areas.

•At a high place with strong winds, install the outdoor unit against a wall to ensure the normal

operating of fans. Install baffle plates when necessary, take this measure to prevent wind from

blowing down the outdoor unit.

•Try to install an outdoor unit against a wall. If the site conditions cannot meet the requirements

and the local outdoor temperature may be below –10°C (NetCol500-A018) or 0°C(NetCol500-

A020), prepare and install an air baffle by referring to the figures on the following slide. The air

baffle height and width should be greater than or equal to the outdoor unit height and width,

respectively.

•If the site installation environment is complicated and the preceding conditions are not met,

contact Huawei technical support.

•indicates the wind direction.